Ethyl 5-Bromovalerate: A Commentary on History, Science, and Future Directions

Historical Development

Ethyl 5-bromovalerate didn’t just appear out of thin air. Early organic chemistry textbooks from the mid-20th century describe the broader esterification techniques and halogenation reactions that laid groundwork for producing compounds like this one. Before specialized chemicals like ethyl 5-bromovalerate earned a place in research and industry, experimenters relied on hit-or-miss approaches in stuffy labs with rudimentary glassware. Over several decades, improvements in distillation, advances in reaction control, and an eye for process safety brought reliable access to bromoalkanoate esters. For much of my time in college labs, I remember making derivatives much like this, with supervisors hovering closely, making sure nobody spilled volatile acids everywhere.

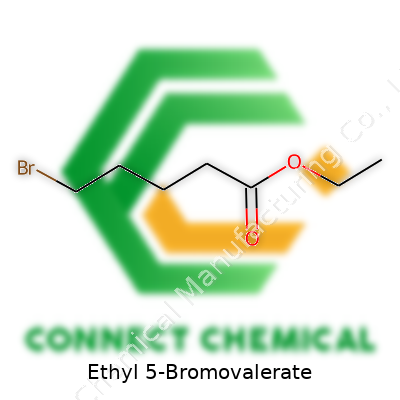

Product Overview

Ethyl 5-bromovalerate belongs to the family of haloalkanoic esters. Its systematic name paints a pretty clear picture: an ethyl group tucked onto the carboxy tail of a five-carbon chain, halogenated with a bromine sitting in the omega position. This chemical tends to show up in synthesis settings, where substitution-ready bromine plays a starring role in downstream transformations. Chemical suppliers list it under synonyms such as ethyl 5-bromopentanoate or ethyl pentanoic acid bromide ester, and its presence in research illustrates ongoing demand for specialty building blocks, both in small-scale labs and pilot production lines.

Physical & Chemical Properties

From hands-on experience, I know it comes as a clear to pale yellow liquid. With a boiling point usually around 115–120°C at reduced pressures, this stuff evaporates easily unless someone keeps it well-closed. Its characteristic ester odor wafts aggressively—one whiff in a poorly ventilated fume hood and you’re reminded of the importance of PPE. On paper, its molecular weight sits at 211.08 g/mol. The molecule’s bromine atom makes it denser than its parent ester, affecting both handling and storage expectations. In solution, the Br at the terminal carbon acts as a good leaving group, making the molecule valuable for nucleophilic displacement reactions.

Technical Specifications & Labeling

Quality and repeatability matter at every stage, right down to the label. Vials from trusted chemical suppliers usually spell out not just the compound name and structure, but also the purity—often 97% or higher—along with the batch number, CAS number (to avoid confusion with structural isomers), UN packaging codes, and proper precautionary pictograms. Safety data goes right onto the bottle or comes as a prominently attached sheet, keeping storage in tightly sealed amber glass a standard to hold up. Whenever uncertainty crops up over appearances (say, if the liquid turns brown), quality control teams use gas chromatography and NMR to check for breakdown products or contamination.

Preparation Method

From my own trials and what’s written in updated organic synthesis guides, making ethyl 5-bromovalerate begins with bromination of valeric acid or pentanol derivatives, then follows up with classical Fischer esterification. The bromination step uses reagents like phosphorus tribromide (PBr3) or N-bromosuccinimide, always requiring careful temperature control to manage heat release and avoid byproducts. Once the acid bromide forms, reaction with ethanol under acidic catalysis, typically using concentrated sulfuric acid, yields the desired ester. Industrial setups scale up this approach with improved distillation and solvent recovery, but on the bench the product sometimes needs further purification to clear away color impurities and overbromination.

Chemical Reactions & Modifications

Ethyl 5-bromovalerate serves as a versatile hub for synthesis. That weak C-Br bond proves handy for SN2 displacement; thick catalogs of chemical reactions highlight how amines, thiols, or alkoxides swap in at that fifth carbon, delivering a big range of new esters, amino acids, or peptide side-chains. Grignard reactions turn it into larger skeletons, especially when researchers want to add carbons or introduce new stereo centers. I’ve used related compounds for tuning the tail-group of active molecules in agrochemical programs, and results often changed dramatically just from small tweaks to these end groups. Any project in chemical biology that needs precise alkyl chain modification probably has turned to structures like this at least once.

Synonyms & Product Names

Catalogs and safety documents interchangeably use names like ethyl 5-bromopentanoate, 5-bromovaleric acid ethyl ester, or pentanoic acid, 5-bromo-, ethyl ester. Whenever a new researcher starts a project, sorting through these similar titles feels like half the battle. This redundancy sometimes throws off new students—missing a bromine or an ethyl on a structure search sends you barking up the wrong tree for days. It pays to memorize those alternative monikers and keep the CAS number within arm’s reach to cut the confusion.

Safety & Operational Standards

Safety earns its keep every day in the lab. Ethyl 5-bromovalerate, while not explosively hazardous like some acyl bromides, can irritate skin and eyes if handled recklessly. Its volatility means fume hoods aren’t a suggestion—they’re a necessity. Proper goggles, gloves, and long sleeves shield against splashes. Globally Harmonized System guidelines rate this material with hazard codes for acute toxicity and general irritancy, so Health and Safety officers everywhere, from German pharma giants to small startups in California, enforce similar strict protocols: labeled secondary containment, limited storage quantities, and chemical-absorbent spill kits ready for use. R&D teams who lose sight of these habits pay dearly if an exposure accident halts the workflow.

Application Area

Labs use ethyl 5-bromovalerate mostly as an intermediate. Medicinal chemists depend on these bromoalkanoate esters for creating libraries of candidate molecules, especially during those initial screens of enzyme inhibitors or small-molecule mimics. Polymer researchers have used similar haloesters to make controlled-release pharmaceutical coatings, adjusting drug delivery rates by tweaking side-chains. In flavor and fragrance development, specialists look for robust building blocks for analog synthesis, reaching for esters when novel volatiles are the goal. Personal experience in agricultural research showed that halogenated esters often bring improved insecticidal activity, likely because brominated tails fit better into protein targets than plain alkyl chains. Startups looking down the green chemistry path examine these brominated building blocks for bioconjugation with enzyme tags, sometimes spinning out completely new classes of bioactive molecules.

Research & Development

Conversations with colleagues often revolve around blocking or activating the carboxyl tail, or swapping out the bromine for something more reactive. A cluster of recent papers documents the use of ethyl 5-bromovalerate in “click” reactions—quick couplings for high-throughput discovery. Teams worldwide explore stereoselectivity, energetic efficiency, and renewable routes, driven by new regulations on solvent waste and halogen emissions. These transformations keep chemists awake at night, angling to solve selectivity puzzles or lower the process temperature. The hunt for new catalysts and greener solvents constantly pushes standard prep methods. Some labs even look at biotransformation, coaxing unique proteins to convert natural fatty esters into bromo derivatives, slashing the need for heavy-metal reagents entirely.

Toxicity Research

The precautionary approach reigns here—structural similarities with other alkyl bromides set off alarms for toxicologists. Standard animal model studies point toward low-to-moderate oral toxicity, with exposures at high concentrations causing CNS depression, respiratory distress, and liver stress. Like many esters, once inside the body, enzymatic hydrolysis transforms the molecule into bromopentanoic acid and ethanol. The brominated acid brings its own baggage, often flagged for potential neurotoxicity or environmental persistence. Dermal contact tests, sometimes cited in old EPA bulletins, showed some irritation and potential for mild mutagenicity in sensitive systems. While no mass poisonings have traced back here, ongoing regulation keeps a watchful eye, especially as chemical companies defend supply chain safety.

Future Prospects

Looking downstream, suppliers and academic labs seem poised to move away from older bromination methods, zeroing in on enzymatic or electrochemical substitutions with cleaner profiles. Formation of value-added pharmaceuticals often depends on quick access to bromoesters, which means innovations in flow chemistry and miniaturized reactors matter now more than ever. Strict environmental laws squeeze out routes that produce persistent organic pollutants. Customers in pharma and agriculture sectors push harder for cradle-to-grave traceability—data logging extends all the way from raw bromine sourcing to end-of-life product breakdown. Some see promise in automating custom synthesis, letting AI-driven robots generate new bromoester analogs overnight, shifting the game for both efficiency and safety. Future research faces the tough balance: preserve the utility of these halogenated compounds, but swap in sustainable production and disposal that doesn’t leave scientists or regulators holding their breath.

A Look Inside Chemical Building Blocks

Most people haven’t heard of ethyl 5-bromovalerate, but many chemists treat it like a staple. This compound, with its simple structure, plays a background role in pharmaceutical research, agricultural chemistry, fragrance creation, and even material science. Over the past decade, work in organic synthesis has made building blocks like this one both valuable and easier to source.

Pharmaceutical Research and Development

Scientists depend on ethyl 5-bromovalerate because its bromine atom makes it a great candidate for reacting with other molecules. Labs use it to build more complicated structures, trying to create new medicines or improve existing ones. The pharmaceutical industry in China, India, and parts of Europe rely on compounds in this category to shorten the distance from lab bench to factory floor. Brominated compounds like this help researchers work out better ways to target certain enzymes, making drug development a bit faster and less risky for their investors.

Pesticide and Agrochemical Formulation

Farmers know that pests eat into their yield and profits. Agrochemical makers often test new pesticide ideas by linking molecules, and ethyl 5-bromovalerate gives them a good handle for this kind of work. Its chemical structure allows for the attachment of custom tails, giving a route toward specialized pesticides or plant growth regulators. By supporting diverse chemical reactions, this single building block gives rise to a wide set of agrochemicals. Modern regulations ask for safer and more specific compounds, and chemists leverage flexible molecules like ethyl 5-bromovalerate to meet these standards.

Flavors and Fragrances

Take a walk through any grocery store—the smell of fruits, spices, and bakery goods often comes from carefully crafted aroma chemicals. Makers of flavors and scents have learned that small esters can blend well to create specific notes. Some of these companies use ethyl 5-bromovalerate as a starting material to build longer, more complex scent molecules. While few consumers know which chemicals build their favorite aromas, safety experts in this industry review these structures, making sure everything used meets food and fragrance guidelines. Scientists have also found ways to tweak this compound to help create new scents or stronger flavors that preserve the signature of natural products.

Material Science and Research

Materials research isn’t all plastics and metals. Some teams look for new polymers or special surface coatings, searching for ways to make materials repel water or stick better to certain surfaces. Ethyl 5-bromovalerate offers a clean spot to add variety, changing the way a polymer chain acts or letting the final product bond differently. Over the years, several university and startup groups used this compound to create proof-of-concept materials. Many of these experiments sit at the edge of commercial use, promising stronger, lighter, or more environmentally friendly products. The hope is that by starting with simple, trusted chemicals, researchers can control the final material’s behavior at every step.

Navigating Safety and Supply

This chemical doesn’t show up on any shopping list outside science, but sourcing it from a safe, reliable supplier matters for both researchers and companies. Local regulations and responsible handling practices keep labs safe—most university departments teach about the importance of tracking each step and maintaining records. The actual risk of exposure stays low with standard lab practice, but anyone working with ethyl 5-bromovalerate wears gloves and goggles, following procedures shaped by earlier experience and shared international data.

Solutions and Opportunities Going Forward

With pressure building to create cleaner, more sustainable chemicals, organizations rethink building blocks like ethyl 5-bromovalerate. Green chemistry movements promote using less hazardous reagents and better waste reduction—several manufacturers now look to bio-based routes or recycling steps to shrink the environmental footprint. Teams that test new processes or partner with universities often lead the field, but the best practices spread quickly through conferences and publications, benefiting everyone who works with these specialized chemicals.

Building Blocks of Ethyl 5-Bromovalerate

Ethyl 5-Bromovalerate comes from valeric acid, a compound that pops up often in organic chemistry classrooms. On top of that, a bromine atom gets involved at the fifth carbon position, and the acid group hooks up with an ethyl group—two extra carbons and five hydrogens. Its chemical formula rolls out as C7H13BrO2. That string packs more behind it than first meets the eye. Plug that molecule into research labs and it turns into a tool for building more complex chemicals, including fragrances, pharmaceuticals, and specialty polymers.

Where You Find It

Lab benches across the globe work with Ethyl 5-Bromovalerate. I remember grabbing a bottle in a college organic chem lab while prepping for a nucleophilic substitution reaction. That experience turned a dry lesson on esters and halogens into something I could touch and smell—though the odor wasn’t exactly pleasant. The compound made its mark in the synthesis, plugging into bigger, more intricate molecules.

Why Accuracy in Chemical Naming Matters

Mess up a formula, and the reaction tanks. I’ve seen firsthand what happens when a chemist grabs the wrong ester because they mixed up their numbers or missed a halogen. Suddenly, hours of work end in confusion and a foul-smelling mess in the fume hood. Respect for the formula C7H13BrO2 comes not from rote memorization, but from hours spent untangling mistakes. In chemical manufacturing, accuracy in formula writing keeps costs down, guarantees product quality, and protects people from mishaps.

Roots in Safety and Regulation

Ethyl 5-Bromovalerate isn’t just a benign lab curiosity. It sits under regulatory spotlights in some countries—brominated compounds get flagged for their persistence in the environment and potential health risks. The European Union leans on thorough documentation to limit exposure. In teaching labs, labeling and safety data sheets get checked twice before the bottle leaves storage. I ran into these precautions as a teaching assistant—tending to students who underestimated just how potent such organobromine chemicals can be.

Knowledge Builds Safer Chemistry

Mistaking a formula like C7H13BrO2 for a similar ester can open a can of worms, not just in the lab but in the environment, too. Safe handling starts with knowing the makeup of what you’re working with. After teaching students for years, I can count the number of times double-checking a formula avoided trouble. Personal responsibility for precise chemical knowledge has fueled a lot of improvements in academic and industrial safety culture.

Steps Toward Better Chemical Handling

One step scientists take includes double-verifying reagents at every stage. In research group meetings, I’ve watched teams quiz each other on chemical formulae and safe handling. Database systems and barcodes limit room for human error. Improving chemical education—emphasizing not just memorizing formulas, but understanding what they mean—trains new generations of researchers to stay sharp and keep the workplace safe.

To sum it up, Ethyl 5-Bromovalerate’s formula (C7H13BrO2) marks more than a molecular count. It’s a checkpoint for safety, a tool in synthesis, and a lesson in paying attention to scientific detail. Every bottle on the shelf is a small test of careful practice, and every time it’s used right, it shows respect for the work that has come before.

Understanding the Risks

Ethyl 5-Bromovalerate looks harmless at a glance, but this chemical can pack a real punch if taken lightly. In labs and workshops, the right approach separates routine research from dangerous accidents. If you've stood near a chemical bench, you know shortcuts backfire fast. This compound gives off a strong odor, dries out the skin, and irritates eyes and lungs. Spill some on an open cut and you’ll remember the sting. Breathe in the vapors, and your airways remind you not every liquid belongs in easy reach.

Personal Safety Steps

Gloves matter more than a simple precaution—nitrile protects best since ethyl 5-Bromovalerate soaks through weaker barriers. Safety glasses or chemical splash goggles make a difference. Even after years at the bench, nothing feels worse than a surprise splash. Face shields help if you’re pouring larger volumes or working in fume-heavy spaces.

Long sleeves and lab coats offer another layer when spills threaten. Street clothes leave arms exposed, so gear up the way professionals do. Shoes, not sandals, spare you from the pain of a dropped beaker or splash on bare skin.

Good Ventilation Means Safer Air

A chemical hood eliminates so many headaches—literally and figuratively. Ethyl 5-Bromovalerate’s vapors can sneak up fast. A fume hood pulls those vapors away before you inhale a lungful. If no hood is available, open windows wide and run strong fans, but this never matches a properly maintained exhaust. Repeated exposure in a closed space leads to headaches, nausea, or worse. That’s the reason old-school chemists used to end up with chronic coughs.

Storage Practices that Prevent Trouble

A proper chemical storage cabinet, made for organics and labeled with hazard signs, keeps people safe. Never leave this chemical near heat or open flames, because it’s flammable. Store the bottle tightly sealed, in a cool and dry place, away from direct sunlight or big temperature swings. Too many accidents happen with unlabeled or poorly stored reagents. If you’ve ever spent a Saturday cleaning out an old lab fridge, you know how old, leaking bottles turn into a science experiment no one wants.

Spill Cleanup and Waste Disposal

Even in careful hands, spills happen. Keep absorbent pads or vermiculite close, so you can contain liquid and stop it from spreading. Scoop material into labeled hazardous waste containers, not regular trash. Wipe surfaces with mild detergent and water only after soaking up the chemical, since strong bases or acids trigger reactions.

Used gloves, wipes, and empty bottles all count as hazardous waste. Pouring leftovers down the drain causes problems for water tables and the wider environment. If uncertain, local safety offices and hazardous waste teams provide exact instructions. Responsible disposal avoids fines, closed labs, or, worse, contamination.

Why Training and Experience Matter

Reading safety data only goes so far. Watching a seasoned technician handle volatile liquids teaches more. Training sessions and regular safety drills make responses automatic, not just theoretical. Newcomers sometimes rush through safety briefings, eager to dive into research. Everyone who’s spent time in a chemical lab has stories of small mistakes causing outsized messes.

Respect for chemicals, not fear, grows with experience. Lab culture—honest risk assessment, labeling, double-checking PPE—keeps everyone healthy. In my work, the difference between good habits and guesswork became clear the moment an accident happened.

Solutions for a Safer Work Environment

Regular audits by safety officers spot issues before someone gets hurt. Updated training based on real incidents reminds staff of potential risks. Establishing a clear protocol for storing, handling, and disposing of ethyl 5-Bromovalerate makes safety second nature. People protect each other best by speaking up when shortcuts appear, keeping communication open, and insisting on good habits over false speed.

Understanding Chemical Purity and Its Real-world Impact

People in labs keep a close eye on chemical purity for a reason. It’s about trust—no chemist wants to see a reaction fail over a smudge of contamination. Ethyl 5-Bromovalerate usually comes with a purity of 97% or higher, and this puts it in good standing for research and manufacturing. Suppliers who take their business seriously give a certificate of analysis showing the latest batch tested above 97%. Anything less sketches up all sorts of questions, from limits in reaction yield to the presence of byproducts that create side problems downstream. Out in small research groups and busy flavor labs, settling for less than this grade rarely goes well. People learn to value that number for the peace of mind and consistency it brings.

Typical Appearance: What to Expect on Your Bench

Every chemist recognizes the value of a quick glance at a bottle before measuring out a compound. For Ethyl 5-Bromovalerate, the liquid sits as a colorless or nearly colorless oil. Most bottles, fresh from a trusted supplier, promise a clear, transparent substance. Sometimes an off-yellow tint sneaks in, but seasoned researchers know that off-color might point to age or minor degradation. The faint sweet, fruity smell stands out if you’re working close to the bench; it’s not as sharp as chloroform or as harsh as acetic acid. Texture tells another story—this isn’t a dry, volatile solvent that vanishes in seconds. The oil pours with enough body to remind you it’s a heavier ester.

People who work with organobromides expect a certain heft and slipperiness, and Ethyl 5-Bromovalerate delivers. Pouring a sample, anyone familiar with standard esters can spot the difference between a healthy, unadulterated liquid and one that signals issues. Sediment, cloudiness, or darker shades often nudge chemists toward questions—do you need to purify before use, or scrap the entire batch? More experience means spotting these clues early and taking action before time and material vanish into thin air.

Why Purity and Appearance Matter

Chemistry doesn’t forgive shortcuts. Poor purity or unexpected appearance spells trouble in lab notebooks and production. The presence of unlisted impurities risks side products, lowering yield or even putting an entire process on hold. Pharma researchers working with esters like this one can’t tolerate inconsistency, not just because of performance but also regulation. Flavors and fragrance creators rely on clear liquids to avoid tainting delicate formulations. Having worked in academic and industrial labs, I’ve stood on both sides—chasing better yields, minimizing surprises. Everyone breathes easier knowing their solvent or reactant passes both the eye and the instrument test.

Solutions: Sourcing and Verification

Reliable sourcing solves problems before they start. Choosing established suppliers, checking batch paperwork, and verifying with in-house instruments (like GC or NMR) saves frustration and lost funds. In some places, repurification stands as a last resort, but it costs time. Clear records and careful visual checks bridge gaps between paperwork and reality. Chemists who document every sample, photograph batches that look “odd,” and compare results with colleagues build a safety net against mistakes. Labs that teach careful handling from the first year up give people a fighting chance at noticing the unexpected—and fixing it.

Takeaway

Ethyl 5-Bromovalerate serves its purpose well when sold above 97% purity and appears as a clear, colorless, oily liquid. When bottled clean, verified by eye and instrument, it keeps laboratory and production spaces running smooth. In hands-on chemistry, details like these make the difference between winning a result and rewriting the plan. Attention to both purity and appearance avoids the headaches no researcher wants on their desk.

Understanding the Risks and Responsibilities

Ethyl 5-Bromovalerate isn’t something most folks have in their garage or kitchen. It’s a specialty chemical with a purpose, often used in the pharmaceutical and research industries. Despite its important uses, careless handling brings real and serious risk. I’ve seen firsthand how fast a minor slip-up with such chemicals can escalate—corrosive fumes, spoiled inventory, even close calls with personal safety.

Simple Steps: Keeping Stability in Check

Anyone dealing with Ethyl 5-Bromovalerate knows quick temperature swings spell trouble. This compound breaks down if exposed to heat, light, or moisture. A tight-sealed glass container, stored away from sunlight and humidity, works far better than any jar tossed on an open shelf. Cooling plays a crucial role. Room temperature often won’t cut it for long-term stability. On my team, we always used a chemical refrigerator set just above freezing for single-use portions.

Shop storage supplies won’t offer enough peace of mind. Purpose-built chemical storage cabinets with solid ventilation stand as the best insurance. A spill on a porous wooden shelf turns into a safety hazard or worse, a potential fire source. Investing once in proper shelving paid back tenfold for my workplace—no ruined batches, no worried calls about accidental contamination.

Ventilation and Labels: Two Points Few Discuss

Plenty of accidents and close calls could have been avoided by simply labeling every container, every time. Clear, bold labels listing not just the chemical name, but also concentration and hazard warnings, help everyone in the lab or warehouse stay on the same page. A mistake with toxic chemicals happens in seconds. Even seasoned chemists can misidentify an unlabeled bottle in a busy moment.

Poor ventilation forces fumes and vapors to linger, irritating eyes, skin, and lungs. A tight, airless closet or storage room with no air exchange puts workers and anyone nearby at risk. Chemical fume hoods, even small benchtop models, make a big difference. During one summer stretch, our basic portable hood saved us from a major headache—literally—by pulling the vapors out of the room.

Transport: No Place for Corners Cut

Many hazards show up during transport. I’ve seen containers bounce loose in trucks, even without rough roads. One cracked cap can leak fumes or liquid, ruining cargo and risking injury. Rigid, shock-absorbing boxes and outer drums saved us more than once. Road regulations in most countries don’t treat chemicals lightly or offer second chances after an accident.

Every shipment travels with its own detailed paperwork. Not just for border agents or police—a clear manifest lets first responders react fast in a crisis. Personally, I urge anyone sending out a shipment to double-check that safety data sheets ride along with every box. This small step stops a small problem from turning into a disaster, especially if an accident catches people off guard.

Looking Ahead: Safer Practices Serve Everyone

Handling Ethyl 5-Bromovalerate—and any specialty chemical—asks for discipline, the right gear, and a clear head. Skipping a small step one day can lead to wasted product, workplace injuries, or worse. Investment in solid container choices, reliable cooling, and open communication across the workforce builds a routine that stands up to pressure. In my experience, making storage and transport a team effort within the lab or supply chain pays lifelong dividends in both safety and peace of mind.