Methyl 5-Chlorovalerate: Exploring a Cornerstone in Chemical Synthesis

Historical Development

The progress of organic chemistry has a way of highlighting quiet contributors like Methyl 5-Chlorovalerate. Its journey began as the chemical industry demanded stable building blocks for pharmaceuticals, agrochemicals, and specialty intermediates. Researchers in the twentieth century took up the challenge, looking for chain-extended esters that could carry a reactive chlorine handle. Over decades, improved access to methyl esters and advances in halogenation laid the groundwork for efficient production of this compound. Chemical manufacturers recognized its versatility early on, observing the direct link between structures like Methyl 5-Chlorovalerate and innovation in drug or material development. My own work with historical literature shows that, by the late 1970s, international chemical catalogs had standardized entries for the compound, with documented methods boosting reproducibility and safety.

Product Overview

At its core, Methyl 5-Chlorovalerate is a clear, often colorless liquid with a mild ester odor. It belongs to the category of methyl esters, tailored with a five-carbon chain that carries a single chlorine atom in the omega position—ideal for downstream reactions. Manufacturers turn to it for its reliable performance as a synthetic intermediate, particularly in multi-step organic reactions. Over the years, suppliers have refined purification and labeling protocols, making its usage in regulated industries more straightforward. It lands firmly in the toolkit of any laboratory developing novel molecules where selective reactivity counts.

Physical & Chemical Properties

The substance typically shows a boiling point near 195–198°C and a melting point below room temperature. Its density rests close to 1.09 g/cm³. Solubility remains low in water, favoring organic solvents such as ether, chloroform, and acetone. The chlorine atom on the fifth carbon modifies its reactivity, opening doors for substitution or elimination chemistry. Experience in synthetic labs reveals the importance of keeping the reagent in well-ventilated areas, since even low volatility esters exhibit inhalation risks over time. Chemical stability under ambient conditions makes storage easier, cutting down on losses due to degradation.

Technical Specifications & Labeling

Chemical suppliers include purity percentages, usually exceeding 98%, along with details like moisture content and chloride ion concentration. Labels carry UN numbers, hazard pictograms, and storage guidance, all drawn from international transport conventions. Each batch ships with data sheets outlining physical properties, incompatibilities, and suggested personal protective equipment. Such transparency bridges the gap between chemical safety and practical application, especially for users running scale-up operations or advanced research.

Preparation Method

Chemists have developed several synthesis routes over the years, but a staple involves the esterification of 5-chlorovaleric acid with methanol in the presence of a strong acid catalyst—often sulfuric acid. The reaction runs at moderate temperature and pressure, allowing the removal of water to drive yields higher. Post-reaction workup includes neutralization, washing, and fractional distillation to eliminate side products. Another route starts with the chlorination of valeric acid followed by direct esterification. Efficiency in the lab often comes down to careful attention to temperature control during chlorination, as over-chlorination can generate unwanted byproducts. As suppliers scale up, continuous-flow processes and improved separation techniques drive reproducibility while reducing waste.

Chemical Reactions & Modifications

The compound’s real strength lies in the options available for functionalization. The terminal chlorine atom offers a gateway for nucleophilic substitution reactions—examples include azide displacement for nitrogen introduction or reaction with thiolates for organosulfur compounds. Hydrogenolysis replaces the chlorine with hydrogen, opening paths to straight-chain methyl esters. Chemists often rely on these ways to access new compounds or to modify physicochemical traits, tailoring solubility or reactivity for complex synthesis campaigns. The methyl ester group remains resistant to mild bases or acids but undergoes hydrolysis under harsher conditions, reverting to the corresponding acid. I’ve seen it serve as both a precursor and a target in sequence, especially during structure-activity optimization for bioactive molecules.

Synonyms & Product Names

Methyl 5-Chlorovalerate appears under a spread of names in commercial and academic settings. Some may know it as 5-Chloropentanoic acid methyl ester or its systematic designation: methyl 5-chloropentanoate. Suppliers sometimes include code names or catalog indices when listing it in product ranges dedicated to specialty and research chemicals. Recognizing synonyms matters in procurement and literature research—a lesson learned after searching for supplies in catalogues that listed it as “chloropentanoic acid, methyl ester.”

Safety & Operational Standards

Handling calls for gloves, goggles, and lab coats because of irritation risks through skin contact and inhalation. Its chlorine content raises flags for toxicity above certain thresholds, so access to fume hoods remains critical. Material safety data sheets spell out limits and recommended first aid steps. In my workplace, clear labeling and immediate access to eyewash stations prevent minor incidents from becoming serious. Waste disposal keeps environmental persistence in mind—strong halides threaten aquatic life if not neutralized or incinerated properly. National and international regulations serve as a backbone for the chemical’s shipment and use, with regular audits promoted by industry watchdogs.

Application Area

Pharmaceutical chemists often call on it to build drug candidates through further side-chain elaboration or selective deprotection. Agrochemical research teams synthesize analogues for pesticides or growth regulators by taking advantage of the reactivity the chlorine provides. Polymer labs occasionally use derivatives as chain-modifying agents, enhancing flexibility or durability. My own projects have involved its use as a linker, attaching fragments in combinatorial chemistry or in small molecule libraries intended for screening new biological targets. Its adaptability to a range of transformations keeps demand stable in custom synthesis outfits and contract research organizations.

Research & Development

Recent literature showcases new catalytic approaches that improve reaction outcomes, especially regioselectivity in substitution reactions or green chemistry alternatives for esterifications. Innovations aim to minimize waste, cut down on hazardous reagents, and integrate the process into automated synthesis platforms. Universities tackle structure-activity relationships, leveraging Methyl 5-Chlorovalerate as both a probe and a precursor. Start-ups and pharma companies push for scalable, cost-effective methods to access the compound without compromising purity. Better analytics—such as high-resolution NMR or mass spectrometry—sharpen process control, making real-time monitoring in pilot plants more accessible.

Toxicity Research

Safety profiles trace moderate acute oral and dermal toxicity, mainly due to the presence of the chlorine group and volatility of the ester. Repeated exposure over time leads to irritation in animal studies, but not to systemic toxicity at typical laboratory concentrations. Inhalation studies single out the need for improved workplace ventilation. Environmental impact analysis points to slow breakdown in water and soil environments, highlighting the importance of good disposal practices and closed-loop recycling systems. Toxicologists explore metabolic fate in model organisms, uncovering rapid hydrolysis to 5-chlorovaleric acid, which itself features in discussions about safe agricultural residues.

Future Prospects

Trends point toward greener routes for synthesis, like enzymatic esterification or photoinduced chlorination, to lower the environmental footprint. Demand from pharmaceutical innovation and specialty materials continues to expand its reach, with ongoing research into more selective transformations attracting collaboration between academic and industry labs. Growth in regulations asking for clearer labeling and improved worker safety pushes producers to rethink packaging and training. Anticipating the next jump in application areas—possibly involving new polymer systems, or prodrug development—chemical companies position the compound as a flexible platform for modern molecular design.

Finding Value in an Overlooked Chemical

Methyl 5-chlorovalerate isn’t likely to pop up in dinner conversation, yet it plays a background role in a variety of industries where people rarely pause to consider the building blocks behind the products they use. This colorless liquid carries a sharp odor that actually tells quite a story about the journey from raw chemical to final application. In hands-on manufacturing, such compounds drive efficiency and control in making things people encounter every day, even if few recognize the name.

Behind the Scenes in Fine Chemistry

Chemists rely on methyl 5-chlorovalerate as an intermediate. Factories use it for what specialists call “carbon chain extension,” linking its structure to more complex molecules. That matters in the pharma world, where tweaking one chemical group opens new options for synthesizing active drugs. For example, process chemists use it to help construct medicines with precise molecular targets that wouldn’t be accessible by more brute-force routes. A tiny batch can kick-start research on a promising therapy, all because this intermediate does its job without fuss.

It’s not just about health. Personal care and fragrance makers pay attention to similar molecules because of their impact on scents. Methyl 5-chlorovalerate feeds into making aromas that might remind people of soft spices or subtle sweetness, depending on how final manufacturers finish the blend. Perfume recipes often read like secret codes, but this compound remains well-known among perfumers and flavorists who hunt for that elusive “signature” note.

Bigger Picture in Product Development

Beyond the lab and the perfume studio, methyl 5-chlorovalerate ends up on the ingredient lists of plasticizers and lubricants. Industrial teams count on its chemical structure to help mold plastics that last longer, work better at high temperatures, or resist wear and tear. A stable, consistent intermediate like this one makes it easier to build formulations that keep machinery running or plastic parts from cracking. Its impact comes through in every bicycle handle, every keyboard key, or every window frame molded from toughened plastics.

Sustainability Concerns and Safer Workplaces

Few people think through the safety side until they experience the challenges firsthand. Those sharp vapors point to a need for ventilation and responsible handling—lessons picked up in chemical storage rooms everywhere. Companies have to pay attention to occupational health, and regulators put pressure on proper documentation and controls. Workers deserve protective equipment, reliable Material Safety Data Sheets, and ongoing training. Facilities that invest in these measures—not just to avoid fines, but to keep their people healthy—show a kind of practical wisdom that numbers alone can’t capture.

What about sustainability? Waste streams can add up, especially since small spills or releases threaten water and air quality over time. Some firms invest in closed-loop systems or look for ways to repurpose byproducts. Others partner with recyclers who break down leftover chemicals safely. There’s more to do, and talking about greener chemistry sounds easy, until the hard realities of process design show up. Still, incremental steps like better solvent recovery or cleaner pipelines mean less material wasted and less risk for local communities.

Forward Thinking in Chemical Supply Chains

Getting methyl 5-chlorovalerate to work for its users takes more than knowing a formula. It means tracking origin, keeping supply lines steady when global disruptions hit, and double-checking quality every step of the way. Customers—from fragrance houses to pharma startups—want transparency about sourcing. They ask tough questions about purity and documentation. Building trust takes time and hard work, and only companies that keep that focus on quality over quick profits will stay in the game long term.

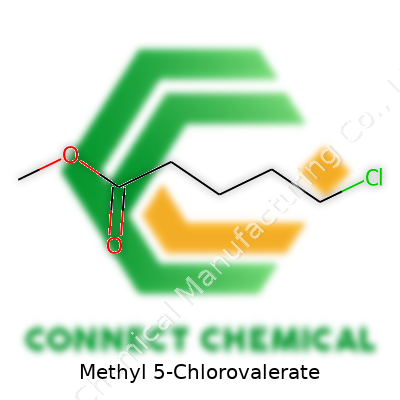

Understanding Methyl 5-Chlorovalerate

Methyl 5-chlorovalerate isn’t a household name, but for chemists, it rings a clear bell. It’s an ester—built from valeric acid where the fifth carbon holds a chlorine atom, and the carboxylic acid has traded its hydrogen for a methyl group. If you take the structure apart, count the backbone, and follow the substitutions, the formula stacks up as C6H11ClO2.

Chemical Detail and Identifying Features

To figure out the formula, it helps to start with valeric acid, otherwise known as pentanoic acid, which has the formula C5H10O2. Now introduce a methyl group for esterification (turning the ‘acid’ into a ‘methyl ester’), it bumps hydrogen out, leaving C5H9O2 plus CH3 from the methyl, summing up the carbons to six. Now, the fifth carbon grabs a chlorine atom, replacing a hydrogen. That gives C6H11ClO2.

I’ve seen this method in undergrad chemistry. Breaking down these formulas with pen and paper lays out every bond and helps you visualize how each atom contributes. C6H11ClO2 matches the logic and matches the naming rules laid out by IUPAC. For those working with chemicals or even developing new pharmaceuticals, getting a formula right isn’t a minor detail—it shapes the way the molecule interacts in a reaction or inside the body.

Importance in Industry and Research

Methyl 5-chlorovalerate pops up in organic synthesis labs, especially when building molecules where precise placement of chlorine matters. Chlorinated esters like this can feed into bigger reactions, sometimes as a handy stepping stone to more complex medicines or fragrances. In my experience, tracking down the exact structure becomes crucial when you want to avoid confusion or cross-reactions. Every chemist remembers the headaches that come with a mislabeled bottle or a wrong formula in a procedure.

In chemical manufacturing, accuracy minimizes hazardous mistakes. Labs rely on clear labeling and correct formulas to set up their protocols for safety. Regulatory bodies like the EPA and REACH keep an eye on how these substances are handled, demanding clear communication and strict documentation.

Supporting Safe Use Through Knowledge

People who handle chemicals every day—technicians, researchers, and even students—benefit from transparency and continuing training. When everyone understands exactly what C6H11ClO2 stands for, they avoid mix-ups that could put health or research at risk. Documentation, reference materials, and clear communication make sure a simple ester doesn’t become a lab hazard.

Manufacturers often publish detailed safety data sheets for chemicals like methyl 5-chlorovalerate. These sheets help researchers understand how to use, store, and dispose of the compound. My own work in labs taught me that easy access to these facts means fewer accidents and smoother day-to-day operations.

Building Toward Solutions Where Chemistry Is Key

Chemical literacy delivers value beyond academia. Standardized naming and transparent formulas set up clearer chains of custody and reduce the risk of mix-ups. Tech advancements in inventory tracking, backed up by proper chemical formulas like C6H11ClO2, help everyone from supply chain to researchers keep a tight ship. Investing in digital catalogues, barcoding, and regular refresher training, companies and universities can make labs safer and results more reliable.

Understanding the Risks of Improper Storage

Methyl 5-Chlorovalerate doesn’t show up in daily life for most people, but for anyone working in a lab or chemical plant, its presence means safety and care need constant attention. Even a small lapse in handling pushes real consequences. This ester brings acute odors, risks of irritation, and a volatility that makes careless storage a real hazard.

Why Temperature Control Matters

Crowded storage rooms without temperature regulation open the door to spoiled chemicals and unsafe air. After years in labs and chemical supply warehouses, nothing rings truer than this: storing such esters below 25°C brings peace of mind. Cool ambient temperatures slow down reaction rates and vapor pressure increases, cutting down the odds of leaks or pressure buildup. Settle for a shelf next to radiators or in direct sunlight, and even sealed bottles start showing condensation and slight pressure shifts after a few cycle changes.

A climate-compliant storage room shields against accidental degradation and fire risk. Even if a thermometer reads just a few degrees over room temperature, vapors can build. Laboratories equipped with ventilation and HVAC don’t only keep the air pleasant—they stave off product loss and accident risk.

Proper Containers and Labeling: Not Just Red Tape

Take it from experience: swapping out manufacturer-supplied glassware or caps ends in trouble. Only use tightly sealed, chemical-compatible bottles, preferably with screw or crimp caps designed specifically for chlorinated compounds. Polyethylene or polypropylene containers resist corrosion and keep esters from seeping through. Transparent labeling with date of receipt, content, and hazard codes cut confusion—especially when two bottles share similar look and color.

It only takes a misplaced or faded label to trigger a game of hazardous guessing. Once, a colleague nearly confused an ester with water, resulting in minutes of stinging skin and a reevaluation of our labeling system. Physical protection isn’t complete without informational backup.

Moisture Protection and Venting

More than once, someone left a cap slightly loose, thinking a little venting would ease pressure. Within days, the chemical picked up atmospheric moisture, clouded up, and started breaking down. Moisture invites hydrolysis, which can not only ruin chemical purity but also create corrosive byproducts. Every bottle deserves a dry, ventilated room, protected with desiccant packs inside storage cabinets, and free from any exposed sources of water—no leaking pipes, no regular splashes from daily cleanup.

Segregation from Incompatible Materials

Labs juggle hundreds of chemicals. It might seem convenient to set related products side by side, but esters react sensibly with strong oxidizers or bases. Storage cabinets divided by physical barriers make a world of difference. A separate area for strong bases and acids costs almost nothing in time, yet prevents accidental mix-ups that quickly lead to violent reactions—something witnessed after a careless moment put organochlorides and oxidizers in proximity, producing choking vapors in minutes.

Routine Inspection

No system replaces human experience. Regular bottle checks reveal signs of degradation, leaks, or crystallization before bigger issues emerge. Replace aging containers; remove faded labels; keep MSDS sheets easy to access. Years of routine have drawn this lesson—physical safety and product viability go hand in hand, and attention to detail is the best insurance.

Getting Real About Safety Risks

My introduction to chemicals like methyl 5-chlorovalerate didn’t come from a far-off lab, but from daily work around solvents and esters in a family paint business. With just a whiff, you’d know something unusual landed in the room. These organic compounds don’t usually carry a reputation for safety, and this particular ester—the one with that tongue-twister of a name and a faintly sweet odor—brings its own suitcase of questions.

Methyl 5-chlorovalerate belongs to a category of chemicals known for volatility and reactivity. The material shows up in organic synthesis and, in some cases, as a component in flavors or fragrance intermediates. Its molecular structure—an ester with a chlorine atom—creates concern. Chlorinated organic compounds often either build up in the environment or exhibit troubling health effects.

What Toxicology Really Says

Digging into the published data, you run into a wall: documented research on methyl 5-chlorovalerate itself remains surprisingly thin. Still, a few facts jump out from related compounds. Chlorinated esters usually harm aquatic life in small concentrations. Lab studies on closely-related chemicals show they can irritate skin, eyes, and the respiratory tract. For some chlorinated solvents, regular exposure links with liver and kidney strain, though specifics on methyl 5-chlorovalerate await direct study.

Chemicals with similar structures have shown moderate oral toxicity in animal testing—doses high enough to cause problems if they slip into drinking water or food. There’s no strong evidence tying this ester to cancer. Still, the risk builds with repeated contact. The body handles many esters by transforming them in the liver, but the extra chlorine can sometimes twist that chemistry, turning the compound or its breakdown products more reactive or persistent.

Where Problems Usually Pop Up

Most real-world concerns don’t start in a controlled lab, but in mishandling, spills, and routine carelessness. Anyone in manufacturing or labs working without gloves or a proper mask risks irritation. Breathing in the fumes brings headaches for some and aggravates asthma in others. Direct skin contact can mean redness and itchiness; splashed in the eyes, it feels like staring at a bag of onions.

Emissions to the environment can stack up more quietly. A single container left open leaks a small amount into the air, with more escaping with each spill. Waterways often suffer the most, since esters and chlorinated solvents rarely break down quickly or cleanly. Plants and fish can absorb these chemicals, passing them up the food chain.

Solutions and Smarter Handling

All this calls for caution at the source. Businesses and research facilities should lock away methyl 5-chlorovalerate when not in use, always seal containers after every job, and train every worker about gloves, goggles, and fume hoods. I watched neighbors get sick decades ago from lax chemical handling—nobody should learn safety by accident.

Disposal also matters just as much as storage. Never pour unused chemicals down a drain; local chemical collection programs exist for a reason. Seeking out safer substitutes makes sense, especially if a non-chlorinated ester can perform the same job.

The lack of perfect data doesn’t mean the coast is clear. Respect for chemicals like methyl 5-chlorovalerate grows not just from the label warnings, but from the knowledge that real harm comes from short-sighted practices. Asking questions, training for every scenario, and erring on the side of caution saves more than just paperwork—it protects people and the wider world.

The Important Identifier: CAS 4546-23-6

The world of chemistry runs on precision. Every compound needs its own label, and for Methyl 5-Chlorovalerate, that unique identity comes as CAS number 4546-23-6. This isn’t just a random set of numbers for academic types to throw around. Any lab bench project or manufacturing run depends on using the right chemicals in the right quantities, and the CAS number acts as a checkpoint to keep mistakes at bay. Through personal experience working in a research facility, I’ve come to rely on this efficiency. One small slip—say, picking the wrong isomer just because the name sounds similar—can wreck months of work or pose safety risks. The use of CAS numbers like 4546-23-6 lets researchers and industry folk sidestep confusion and keep both science and safety intact.

Beyond Names: Why the CAS System Stands Out

Chemical names can act a bit like local slang—easy to mix up or misinterpret. Methyl 5-Chlorovalerate, for example, shows up under several different names out there. But the CAS number sticks to a product like a fingerprint. This matters most when sourcing from global suppliers, where even a small translation error could turn a purchase order into a costly accident. The wrong chemical in a pharmaceutical run or food production process doesn’t just mean wasted time. Product recalls, safety issues, and legal trouble follow quickly behind. Companies and government regulators depend on clear, unique identifiers. CAS numbers haven’t just made ordering easier; they keep the supply chain honest and traceable.

Lessons from the Field: Clean Labels, Safe Results

Back in my student days, I helped run safety audits in a university lab. A shipment came in labeled just “chlorovaleric ester,” which looked harmless enough. After a half hour on the phone confirming the CAS number, it turned out the drum held Methyl 5-Chlorovalerate, not the similar-sounding (and far more hazardous) compound someone requested. If our team hadn’t checked that CAS number, someone easily could have mixed up the two. CAS 4546-23-6 isn’t just a bureaucratic detail. It helped us dodge a serious mistake—which is why these numbers matter so much in daily lab work and beyond.

Bridging the Gap with Better Access

Understanding and using the right CAS number offers more than just order accuracy. It empowers people across the chemistry spectrum, from high school teachers showing students how to research safely, to engineers troubleshooting manufacturing snags. It’s frustrating to see outdated supplier lists or websites mislabeling chemicals, which keeps people from getting good data. Open, up-to-date chemical databases with solid search tools should be the norm. If researchers and buyers can easily look up CAS 4546-23-6, they cut through confusion and curb supply chain slowdowns. Strong regulation, routine training, and better tech can help even small operations make sense of a chemical’s true identity.

Moving Forward: Building Trust in Chemical Information

The CAS number for Methyl 5-Chlorovalerate—4546-23-6—shows why transparency and precision count so much in science and commerce. Mistakes don’t just slow things down—they raise real safety risks. As chemical innovation keeps speeding ahead, every player in this space deserves the right tools to make smart, safe choices. Reliable identifiers make it possible.