Ethyl 6-Bromohexanoate: An Exploration of Its Development, Properties, and Prospects

Historical Development

The story of Ethyl 6-Bromohexanoate stretches back to the continued evolution of synthetic organic chemistry through the twentieth century. Chemists searching for more effective intermediates in pharmaceuticals and materials science emphasized halogenated aliphatic compounds. Laboratories focused on modifying fatty acids and simple esters, seeing clear potential in brominated derivates for their controlled reactivity and robust shelf-life. The emergence of Ethyl 6-Bromohexanoate became a milestone, drawing interest not just for what it could do in the lab, but for how the addition of a bromo group on a straightforward ester backbone uniquely shaped subsequent syntheses in both academic and industrial research spaces.

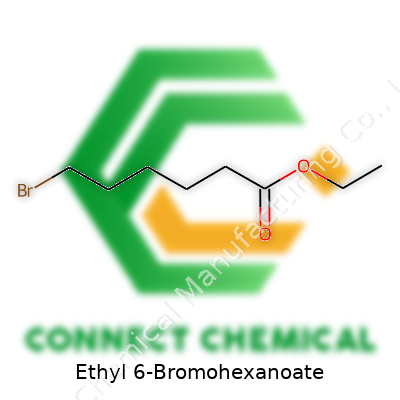

Product Overview

Ethyl 6-Bromohexanoate stands out as a versatile ester. With a structure built from a six-carbon chain, bromine on the terminal position, and an ethyl ester group, it bridges functional flexibility and chemical simplicity. Reliable sources provide this compound at purities tailored to meet exacting research requirements. As a practical intermediate, it fits comfortably in the toolkit of both large-scale manufacturers and small research outfits aiming to build more complex molecules starting from relatively simple feedstocks.

Physical & Chemical Properties

This compound usually appears as a clear to pale yellow liquid, carrying an unmistakable organic odor. Its molecular formula, C8H15BrO2, lists up a density that falls around 1.2 g/cm³ and a boiling point in the realm of 131–133°C at 20 mmHg. It dissolves conveniently in many organic solvents—think ether, chloroform, or dichloromethane—but resists water. The bromo group, set at the terminal position, delivers a reactive handle that supports further elaboration without making the molecule overly volatile or unstable. The compound's moderate polarity (due to the ester and bromo groups) influences how one handles and stores it, keeping it from evaporating too quickly during standard lab operations.

Technical Specifications & Labeling

Suppliers label their Ethyl 6-Bromohexanoate according to industry best practices. Purity often stretches above 97%. Accompanying certificates of analysis flag up important factors—refractive index, boiling point range, and moisture content through Karl Fischer titration among others. Containers use amber glass or robust plastics, sealed under nitrogen to minimize degradation. Shipping labels warn of potential hazards, including irritancy and environmental considerations. Clear batch numbers and manufacturing dates further support traceability through the supply chain.

Preparation Method

One of the dependable methods for synthesizing Ethyl 6-Bromohexanoate involves the esterification of 6-bromohexanoic acid with ethanol and a catalytic amount of sulfuric acid under reflux. Chemists who favor an acid bromination approach begin with hexanoic acid, converting it into the 6-bromo compound before introducing the ethanol. The main challenge lies in controlling water removal to drive the reaction to completion. After refluxing, the reaction mixture requires precise washing with sodium bicarbonate and water to neutralize residual acids and remove unreacted starting material. Fractional distillation typically completes the purification, isolating the target ester in good yield.

Chemical Reactions & Modifications

Ethyl 6-Bromohexanoate arrives at the bench ready for transformation. Its terminal bromo group acts as a launching pad for nucleophilic substitutions, making it practical for the introduction of amines, thiols, or other nucleophiles. It's possible to swap that bromine for a range of functional groups using classic SN2 conditions. Base-catalyzed hydrolysis reverts it to the corresponding carboxylic acid, opening further modifications through amidation or coupling strategies. In my own experience, using strong nucleophiles such as alkoxides or cyanide, it's simple to forge useful intermediates for agricultural chemical synthesis or polymer research. The elegance comes from a reliable reactivity that doesn't fuss over mild inconsistencies in solvent or temperature, which helps reduce waste and save time in practical workflows.

Synonyms & Product Names

This compound turns up in literature and catalogs under names like 6-Bromohexanoic acid ethyl ester or Ethyl 6-bromohexanoate. Others recognize it as Hexanoic acid, 6-bromo-, ethyl ester. The CAS number 5445-17-0 often secures positive identification amid a sea of similar derivatives. With this kind of clarity, confusion drops—essential when ordering or cross-referencing among different international sources.

Safety & Operational Standards

Ethyl 6-Bromohexanoate deserves respect in the lab, as it can irritate the skin, eyes, and respiratory tract. Appropriate PPE—gloves, goggles, and lab coats—reduce exposure risks. Engineering controls matter too: fume hoods prevent inhalation of vapors and minimize risk of splash injuries. Labs rely on solvent-resistant containers, clear labeling, and locked storage protocols to keep both the compound and surrounding personnel out of harm’s way. Emergency protocols cover spills with suitable absorbents and safe disposal practices, in line with environmental safety norms.

Application Area

Ethyl 6-Bromohexanoate opens doors across diverse fields—pharmaceuticals claim a large share, using it as an effectual intermediate in the synthesis of active compounds, particularly for molecules that benefit from bromo-functionalized chain extensions. Agrochemical developers count on its reactivity for building herbicide and pesticide candidates. In the world of material science, chemists leverage its ability to introduce controlled branching or anchor functional groups onto polymer backbones. The accessibility of the ester group makes it practical when research groups need quick access to a broad suite of analogs for lead exploration, straightforward scale-up, or isotope labeling.

Research & Development

Current R&D efforts chase both deeper understanding and broader potential for Ethyl 6-Bromohexanoate. Labs on the front lines of medicinal chemistry push for structure-activity relationship data, aiming to build safer, more targeted therapeutics by using bromoalkyl esters as modular fragments. Academia often takes the compound into areas like supramolecular assembly or new polymeric material synthesis, seeking lightweight, flexible, and responsive scaffolds. As someone who’s run short exploratory programs with this molecule, I’ve watched new transformation methods bring down costs and speed up access to advanced derivatives. Industrial partners often prioritize more robust and safer manufacturing approaches, ensuring sustainability isn’t left behind in the rush for new intellectual property.

Toxicity Research

Toxicological studies suggest Ethyl 6-Bromohexanoate requires careful handling. Animal data point toward low-to-moderate acute toxicity with principal concerns around repeated exposure rather than single doses. The bromo group itself presents potential organohalide toxicity if the compound bioaccumulates. Skin and eye irritation top the list of practical concerns in a working lab. Chronic exposure studies receive more attention in recent years, especially regarding downstream products and long-term environmental fate. Labs look for improvements in workup protocols that minimize operator exposure and generate less hazardous waste. Companies pay close attention to regulatory guidance, keeping all safety data sheets up-to-date as regulations continue adjusting to new findings.

Future Prospects

Future opportunities for Ethyl 6-Bromohexanoate look promising as heteroatom-rich esters and similar building blocks take center stage in green chemistry and novel pharmaceutical development. Researchers chase milder and cleaner techniques that rely on renewable feedstocks and produce benign byproducts. Advances in catalysis and continuous-flow synthesis stand ready to modernize its manufacture, making safer, scalable, and more affordable syntheses possible. Regulatory agencies keep pushing for higher transparency and lower residual solvent levels, which pressures manufacturers but drives innovation in purification and analytical QC. In my view, this compound will stay relevant as chemists push the boundaries of what small, cleverly modified molecules can deliver—whether in treating disease, protecting crops, or building new materials for a cleaner future.

Not Just Another Chemical: Where Do We See It?

Ethyl 6-Bromohexanoate shows up in many labs and industries that work with complex, custom-designed molecules. Spend enough time in a chemistry department, and someone will bring up a need for a bromo-alkyl ester like this one. From my experience in a synthetic chemistry environment, requests for it come up in protocols for building blocks that serve bigger projects, especially when there’s a need to string together longer carbon chains with precision.

The Backbone Role in Drug Science

Pharmaceutical research leans on chemicals like Ethyl 6-Bromohexanoate. Larger molecules start to take shape only after this building block gets added to a reaction mix. Chemists turn to it because the bromine atom makes a reactive target for transforming the six-carbon ester structure. For example, drug developers working on anti-viral or neurological compounds see value in these customized side chains, thanks to work showing that small tweaks at this spot can shift a molecule’s properties entirely.

The U.S. National Institutes of Health highlights how alkyl bromides, like this one, pop up in libraries of experimental drugs. A study documented in the Journal of Medicinal Chemistry traced a handful of molecules, designed with help from this compound, that went on to play pivotal roles in trial phases. The task isn’t easy, and these fine-tuned syntheses often decide whether a promising new cure advances past animal trials.

More Than Medicine: Sprouting Up in Chemistry Labs

One look at the research side, and it’s easy to see that undergraduate students handle Ethyl 6-Bromohexanoate during their first experiences with nucleophilic substitution or esterification methods. Lab exercises use it to teach young chemists about real-world reactivity. I tried the reaction with sodium cyanide myself in a supervised lab, and the cyanide replaced the bromine to create a nitrile compound—a staple transformation in organic synthesis.

The chemical’s reliability matters in fields ranging from materials science to fragrance production. Researchers report using these six-carbon linkers to join together surfactants or polymers. Scanning patent filings at the U.S. Patent Office, examples pop up—everything from advanced adhesives to grease-resistant coatings rely on it for the backbone.

Safety and Environmental Impact

Working with halogenated esters, practical safety habits come first. I’ve felt the irritation from mishandling solutions with this kind of molecule, so gloves and ventilation gear become the norm. Companies must watch for releases into water streams since brominated organics can harm ecosystems if uncontrolled.

The U.S. Environmental Protection Agency recommends close management of waste streams, using incineration or activated carbon filtration. Companies that deal with these compounds invest more in training and monitoring, not just for legal reasons but because mistakes can have lasting consequences. Action here reduces risk on job sites and to surrounding communities.

Looking Ahead: Greener, Smarter Use

Green chemistry methods keep advancing. I see labs working to reduce waste by shifting to one-pot or solvent-free reactions with this compound. Sourcing brominated intermediates from less hazardous processes ranks high for young chemists joining the field. Better waste management and tighter safety standards have helped some companies win recognition for sustainable practices. Open dialogue with regulatory agencies, clear labeling of reagents, and pushing for Reagent Guides in academic settings could shrink risks for the next generation that will use Ethyl 6-Bromohexanoate.

The Basics: Core Identity of Ethyl 6-Bromohexanoate

Chemists and anyone dabbling in organic synthesis cross paths with names like Ethyl 6-Bromohexanoate. Under that label is a molecule shaped by a chain of six carbons, ending with an ester and peppered with a bromine sitting at the sixth carbon. Writing its formula gives us C8H15BrO2. I remember my first brush with it, mainly as a starting ingredient on the long road to building more complicated molecules in the lab, especially for pharmaceutical experiments.

What Makes the Formula Matter?

The formula isn't just a random string. Each letter and number directs how this compound reacts, bonds, and ultimately shows up in research or industry. Seeing the molecular formula paints a clear picture—eight carbons lay down the backbone, fifteen hydrogens fill in the smaller spaces, and that heavy bromine adds both bulk and reactivity. Two oxygens mark the ester group, creating the signature for both synthesis and analysis.

People underestimate how a single atom swap can rewrite chemistry’s rules. Slip a bromine onto a chain, reaction options open up. Attach an ester, and new possibilities come into play for pharmaceuticals or flavors. At times, just trying to weigh an exact amount on a scale or to balance a reaction relies on knowing not only what sits in your flask, but exactly how much mass comes with it.

Pinning Down the Molecular Weight

Numbers drive every action in a research lab. No measurement, no progress. The honest answer to “What’s the molecular weight?” is key. Take the formula, add up the weights: carbon (12.01 g/mol) times 8, hydrogen (1.008 g/mol) times 15, bromine (79.90 g/mol) times 1, and oxygen (16.00 g/mol) times 2. The sum lands at approximately 223.11 g/mol for the carbon/hydrogen/oxygen portion, plus the heavy lift from bromine, bringing the total to about 239.11 g/mol.

Every time I prepped a new batch or designed an experiment, calculating out these weights was ground-level stuff. Strict measurements keep reactions from flopping, wastes from piling up, and budgets from ballooning. Wrong weights cause headaches—wrong dosages, failed purifications, and sometimes hours lost tracking down where things went off track.

Why This Matters Beyond the Lab Bench

Undergrad classes may skim through formulas and weights, but precision runs deeper. In pharmaceutical research, the exact structure of Ethyl 6-Bromohexanoate often determines what can be made next, especially when tailoring new drugs or specialty chemicals. Even companies mixing up flavors and scents take these numbers seriously, because one wrong mass and the product slides off spec.

Labs—and the people running them—count on accuracy. Consistent methods, tools calibrated to the last decimal, and people double-checking every value, build trust. Part of that trust comes from sticking to standards, like calculating molecular weights before launching any project or investment. Mess with the basics, and everything built on top wobbles. I’ve seen this up close: a team lost weeks to poor formula-checking, only to learn their starting material had been miscalculated from the start.

Good Habits and Better Research

Sharing real numbers and formulas, giving context, and learning from mistakes helps everyone—students, lab technicians, and entrepreneurs. In my experience, using reliable sources like PubChem or Sigma-Aldrich for reference keeps processes transparent and protects projects from derailing. Engaged, detail-focused work makes for good science, safe products, and fewer wasted resources.

Ethyl 6-Bromohexanoate, with its formula C8H15BrO2 and weight near 239.11 g/mol, offers a window into why chemistry rewards patience and vigilance. Grasping these fundamentals bridges textbooks with real-world applications and turns clean calculations into success stories.

Why Chemical Storage Deserves Attention

Years of working with lab chemicals taught me that safe storage isn’t something you follow just for compliance or convenience. Stories run through the industry about ruined experiments, lost inventory, or – far worse – health scares, all from sloppy chemical storage. Ethyl 6-Bromohexanoate, with its moderate volatility and reactivity, reminds us that doing things properly protects both people and work.

The Core Problems with Wrong Storage

I once watched a colleague cap a container hastily, only to find the chemical had degraded after just a few weeks. Organic esters, like Ethyl 6-Bromohexanoate, tend to hydrolyze if they pick up moisture or get exposed to warmth. If vapors escape or spills happen, you can end up cleaning for hours and worrying about everyone’s safety in the lab.

What Good Storage Looks Like

To keep Ethyl 6-Bromohexanoate reliable and safe, reach for a glass bottle with a solid seal. Keep it away from plastics that can leach or react. A metal can might tempt some, but it corrodes surprisingly fast with certain chemicals. Park the chemicals in a cool, dry cabinet away from direct sunlight. My old boss never let anything flammable or reactive rest on the same shelf, and I stick to that habit. In most labs, a lockable ventilated chemical cabinet does the trick, far enough from heat sources like water baths or radiators.

Humidity creeps into labs in all seasons and likes to pick on esters. Silica gel packets do a solid job keeping moisture low, so I toss a fresh one in each time I open a bottle. Don’t trust the building’s AC system to do all the work – those little details make or break your chemical’s shelf life.

Labeling and Inventory Can’t Get Ignored

Every label needs the full name, date received, and any big hazards. This might seem basic, but I’ve rescued mystery bottles from the back of cabinets too many times. If there’s a spill or emergency, nobody wants to guess what’s inside. Proper inventory with reminders to check expiration dates keeps surprises to a minimum.

If the container gets even a hint of damage – chips, cracks, a failing cap – swap it out before anything leaks or reacts with the air. Never top off an old bottle or mix leftovers from two containers. Cross-contamination costs way too much in the long run.

Regulations Matter and Pay Off

Agencies like OSHA and EPA don’t hand out their storage rules to make life hard. They’ve seen too many injuries from shortcuts. Flammable storage cabinets, fire extinguishers, eye wash stations, and good signage keep everyone working with chemicals a lot safer. In my experience, folks who treat these requirements as helpful – not hurdles – run the labs with the fewest close calls.

Building a Culture of Everyday Safety

Training happens on day one in any decent lab, but habits keep people out of danger long after the training slides fade. Sharing stories of small slips and big lessons makes chemical safety routine, not just a line in a manual. If someone misses a step, a gentle reminder beats regret.

Store smart, label well, keep your gear tight, and let good habits drive everything. None of these steps take much effort, but they protect both people and research from costly mistakes.Understanding the Risks Involved

Working in a lab, you run into chemicals that demand respect, and Ethyl 6-Bromohexanoate is no exception. This colorless liquid carries both risks and rewards in organic synthesis, but safety isn’t something to skim over. The molecular structure points toward possible irritation—expect trouble if it gets on your skin, near the eyes, or in your lungs.

Direct Hazards: Why Pay Attention?

Skin and eye contact top the list of concerns. I learned early on that even a single dropped glove can turn an ordinary day into an ER trip. This compound can trigger irritation, redness, and burning sensations right away. Getting it in your eyes might mean sharp pain and even lingering injury if you don’t act fast. Breathing in the fumes can irritate airways, especially if ventilation isn’t up to scratch.

Personal Protective Steps that Work

Working with chemicals like this asks for more than just hope and a steady hand. Real safety comes from habits—think safety glasses, well-fitted nitrile gloves, and a buttoned-up lab coat. Chemical splash goggles beat regular specs by a mile. I’ve seen a colleague dodge a close call just because he zipped up his face shield before pouring.

Good practice sticks with you: work under a chemical fume hood. Never trust open air, even for a “quick transfer.” Closed-toed shoes keep your feet safe; no one plans to drop a flask, but it happens.

Air Quality: Don’t Ignore the Basics

Nothing beats proper ventilation. A fume hood does more than move air—it pulls hazardous vapors away before you get a whiff. If you crank up a reaction in a stuffy room, you’re gambling with your lungs. Any strong odor signals you’ve crossed a safety line; get out and fix the setup.

Storage Means More Than a Label

This isn’t something you store on the edge of a crowded shelf. Keep Ethyl 6-Bromohexanoate in a tightly sealed glass container, safe from sunlight and heat. I like to double-check labels and records myself—never leave it for tomorrow. Segregate it from acids, bases, and anything with oxidizing power. Accidents find the weakest spot, so shore up storage every week.

Handling Spills: Speed Matters

No matter how careful you are, spills sometimes win. Speed and clarity make all the difference. I grab absorbent material right away, working from the edges inward, always with fresh gloves on. Ventilation fans should roar. Once the liquid’s soaked, place everything in a fume hood-safe container for waste disposal, and wipe everything down with detergent solution.

What if Exposure Happens?

If skin contact happens, water fixes more than any fancy chemical wash. Flush the area for at least 15 minutes, then seek help, especially if symptoms stick around. An eye wash station saves vision—make sure one’s within arm’s reach. Never blink away exposure or hope for the best; action always beats delay.

Looking Ahead: Building a Safer Routine

No single rule covers all scenarios, but routine care builds a culture where mistakes stay small. Review safety data sheets before every session. Sharing tips among teammates helps everyone dodge the kind of accidents you don’t walk away from easily. In my experience, small daily habits—double-checking labels, rinsing gloves, testing the fume hood—do more for safety than any wall poster.

Ethyl 6-Bromohexanoate will never be harmless, but clear steps and real habits keep risks under control. My advice is simple: never shortcut the basics, and you’ll protect both your project and yourself.How Purity Shapes Lab Success

In the world of organic chemistry, reliable building blocks lay the groundwork for everything that follows. Ethyl 6-bromohexanoate crops up in research labs as well as industrial settings, thanks to its role in pharmaceuticals and specialty chemicals. Purity is more than a line on a safety sheet here. From years working next to fume hoods and LC-MS machines, I’ve learned that even a little contamination can skew results, trigger failed reactions, or raise safety red flags.

Suppliers ship this compound in grades tailored to what researchers or manufacturers expect. The standard most folks see boasts a purity of at least 98%. GC or HPLC analyses back up these claims. 98% or higher really matters where yields ought to reflect only the chemistry, not side-products or leftover starting materials. Sometimes, scientists demand higher, up to 99%, if a synthetic step sits close to a final API or if enantiomeric excess is a concern.

Key Specifications to Check Before Purchase

Many buyers scan more than just the purity number. Reputable suppliers list molecular weight — for ethyl 6-bromohexanoate it’s 239.13 g/mol. Physical appearance becomes a silent quality check: this compound usually shows up as a colorless to pale yellow liquid. A faint tint can signal breakdown or oxidation, even when purity checks out. The listed boiling point—usually hovers between 107-111°C at reduced pressure (1 mmHg)—helps distinguish between genuine ethyl esters and what might sneak in from mishandled synthesis or storage.

Water content shouldn’t get overlooked. Excess moisture can tank reactions, especially for moisture-sensitive coupling steps. Many suppliers provide Karl Fischer titration results, showing levels usually below 0.5%. Look for flash point data too. This helps anyone planning to scale up or store the chemical for long periods, since fire risk deserves attention even at the gram scale.

What the Market Shows Right Now

Prices for ethyl 6-bromohexanoate swing with global supply-chain factors. Still, the top suppliers publish detailed certificates of analysis. These reports back up purity numbers and guarantee identities using NMR, IR spectra, and detailed chromatograms. Suppliers that take quality control seriously often supply recent SDSs and TDSs with each batch, noting any stabilizers or inhibitors added to keep the product from degrading.

Tackling Quality Gaps and Sourcing Shortages

Not every vendor holds the same standard. High throughput projects stay on track with timely deliveries and reliable QC, but not every provider rises to these expectations. For consistent results, stick with vendors who welcome batch-specific questions and supply supporting documentation without hassle. Crowd-sourced reviews, personal contacts, and pilot reactions give a clearer picture than brochure claims or rushed phone calls. Large projects or pharmaceutical work typically call for extra tests—think residual solvent screening, chiral purity checks, or microanalysis—on top of routine assays.

I’ve seen teams forced to halt synthesis for weeks, waiting for consistent material after a single slip in quality. Labs with strong documentation practices and good relationships with trusted suppliers dodge many headaches. Open communication and clear documentation help spot potential sources of error, saving time and money in the long run.

Building Trust and Results with Quality Chemicals

In every chemical order, there’s more riding on quality than product labels cover. Top-tier ethyl 6-bromohexanoate usually means purity above 98%, solid documentation, and rapid answers from the supplier. Skipping checks on these details takes the risk from manageable to unpredictable, whether for a few grams or bulk drums. A little extra diligence pays off in every successful synthesis and smooth production run.