Ethyl 6-Chlorohexanoate: Exploring Its Journey and Role in Modern Chemistry

Understanding the Evolution of Ethyl 6-Chlorohexanoate

Chemistry never stops moving, and Ethyl 6-Chlorohexanoate proves the point. Back in the mid-20th century, organic chemists looked for simple, reliable building blocks to create longer aliphatic chains and modified esters. The push came from pharmaceutical labs that wanted to design new ester compounds for prodrug candidates and personal care chemistries eager to change the texture, absorption, and stability of lotions and emulsifiers. With its six-carbon skeleton holding a single chlorine atom, combined with an easily modifiable ester group, Ethyl 6-Chlorohexanoate carved its place at the intersection of pharmaceutical and specialty industrial chemistry. Early research focused on method development and cataloging the physical and reactive properties. Over the years, the molecule found its way into a variety of synthetic pathways, underpinning industrial-scale preparations for intermediates and specialty solvents.

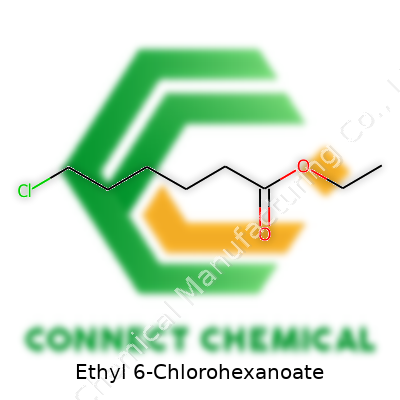

The Product Up Close

Ethyl 6-Chlorohexanoate stands out as a colorless to pale yellow liquid. The slight aroma signals the ester group’s volatility. What matters to many production chemists is its melting point falling well below room temperature, making it handy in standard glassware setups without worrying about crystallization. With a density slightly less than water and a boiling point hovering around 220°C, storage and transfer working at scale rarely create unexpected problems.

Physical & Chemical Properties

Looking at the molecular structure, you’ll find a straight six-carbon chain with the key differences: an ethyl ester at one end and a chlorine atom attached to the sixth carbon. Its molecular formula, C8H15ClO2, gives an exact mass just under 180, making it manageable for both research and bulk applications. Chemists appreciate its solubility in organic solvents like ether and dichloromethane, but it resists mixing with water. This hydrophobic behavior lets it slip into downstream extraction protocols or surface modification processes where water solubility gets in the way. The presence of the reactive chlorine atom and the easily cleaved ester group give it a double advantage in laboratories that rely on functional group manipulation.

Technical Specifications & Labeling

Manufacturers often provide Ethyl 6-Chlorohexanoate in 98% or higher purity grades for research and industrial use. Product containers come labeled with batch numbers, synthesis date, recommended storage temperature, and hazard pictograms in line with GHS standards. The label also calls out its status as an irritant and offers quick guidance on emergency handling. Typical packaging ranges from amber glass bottles for lab use to steel drums lined with inert polymers for bulk deliveries, all of which prolong shelf life and prevent unwanted reactions from exposure to light or air.

Preparation Methods That Dominate the Industry

The most reliable pathway to Ethyl 6-Chlorohexanoate uses 6-chlorohexanoic acid and ethanol in the classic Fischer esterification, in the presence of an acid catalyst like sulfuric acid. This old-school method often remains unmatched for yield and purity when scaled properly. Alternative methods involve transesterification, especially for preparing isotopically labeled variants, or halogenation of ethyl hexanoate using N-chlorosuccinimide if selectivity is critical. Each method comes with unique challenges in work-up, namely ensuring complete removal of byproducts and control of residual acidity, which influences downstream reactivity.

Chemical Reactions & Modifications

Ethyl 6-Chlorohexanoate often acts as a stepping stone in multi-stage organic syntheses. The ester group undergoes hydrolysis under basic or acidic conditions, converting it to the free acid, which can be subsequently activated for coupling reactions. The chlorine atom, a good leaving group, offers room for nucleophilic substitution, giving access to amines, nitriles, and even thioesters. Researchers use this dual reactivity to build up more complex molecules—something I’ve seen firsthand in the development of specialty surfactants and small molecule APIs. Beyond substitution, the molecule holds up well in reductive conditions, though extreme base can lead to side reactions.

Synonyms & Alternate Product Names

Commonly, Ethyl 6-Chlorohexanoate appears in literature and online catalogs under names including 6-Chlorohexanoic acid ethyl ester, Ethyl caproyl chloride, and Ethyl 6-chlorocaproate. Both regional differences and vendor branding can add to the mix. The synonym list isn’t just academic—it matters in lab procurement, where a subtle difference in naming can result in wrong shipments or failed compliance checks.

Safety & Operational Standards

Personal experience working with halogenated esters such as Ethyl 6-Chlorohexanoate demonstrates the need for basic PPE, including gloves, goggles, and efficient ventilation. Skin and eye irritation come up as the most common health hazards. Splash or inhalation at higher concentrations leads to respiratory discomfort. Lab protocols call for containment—closed systems, dedicated fume hoods, and spill kits at the ready. In an industrial setting, process automation and monitoring reduce exposure risk, and strict labeling helps avert mix-ups. SDS documentation and training go hand in hand, especially where scale-up introduces fresh hazards like vapor accumulation or accidental mixing with bases.

Key Application Areas

Ethyl 6-Chlorohexanoate isn’t a household name, yet it finds steady demand in places where chemical innovation meets large-scale utility. Agrochemical companies use it to build up insecticide or herbicide intermediates—reacting the ester or chlorine functionality to add complexity or increase bioactivity. Pharmaceutical labs deploy it in prodrug design, exploiting its ester group for targeted hydrolysis in the body. Polymer manufacturers look at it for cross-linking or grafting chemistry, making the most of the chlorine atom’s reactivity. In fragrance chemistry, this compound pops up in the search for new volatile esters that tweak scent profiles or evaporation rates.

Research & Development: What’s Moving the Needle

Labs worldwide keep exploring new couplings and substitutions that start with Ethyl 6-Chlorohexanoate. Green chemistry researchers study more sustainable synthesis—replacing traditional acid catalysts with reusable solid acids or finding milder chlorination agents to lower hazardous waste. In pharmaceutical R&D, the molecule turns up in the synthesis of odd-chain fatty acid analogs, feeding into the quest for new antimicrobial or anticancer candidates. Analytical labs use labeled versions for tracking and quantitation in complex mixtures. Technology advances, such as high-throughput screening and microreactor setups, offer faster optimization and greater safety in both academic and applied research contexts.

Toxicity Research

Every day in the lab, safety sits front and center. Studies show Ethyl 6-Chlorohexanoate ranks as a moderate irritant, with LD50 values pointing to relatively low acute toxicity in rodents. Still, the risks of repeated or prolonged exposure—either via skin or inhalation—raise concerns about inflammation or organ effects. Researchers track breakdown products, since hydrolysis can leave behind 6-chlorohexanoic acid, which maintains its own safety profile. Regulatory watchdogs call for routine monitoring and documentation of exposure, with animal testing and in vitro assays guiding the safety levels for workplace contact and accidental environmental release.

Looking to the Future: Where Does Ethyl 6-Chlorohexanoate Go From Here?

Ethyl 6-Chlorohexanoate’s future links directly to the challenges and opportunities across specialty chemicals, green manufacturing, and drug discovery. Digital synthesis planning already pulls this molecule into automated workflows. Legislative shifts toward cleaner chemistry mean producers feel pressure to lower emissions and move away from heavy metals or harsh conditions in its preparation. New research into biodegradable polymers and slow-release agrochemical agents may open doors to more sustainable uses, provided toxicity and environmental persistence can be tightly managed. For me, the molecule feels like a practical test of how chemists can balance reactivity, safety, and innovation in a single package.

The Backbone of Chemical Building

Ethyl 6-Chlorohexanoate carries a name that trips up most tongues, but behind its clunky label sits quiet importance. Many folks who’ve never set foot in a lab use products shaped by chemicals like this each day, without a clue where they start. Here’s the thing: substances like ethyl 6-chlorohexanoate build the foundation for broader industries, from pharmaceuticals to agriculture. Back when I worked with a small team focused on specialty chemicals, we’d keep an eye out for ingredients like this—useful in multiple ways but rarely getting any spotlight.

What Happens With It in Pharmaceuticals

One of the cleaner truths about ethyl 6-chlorohexanoate comes from its value as an intermediate. No magic or mystery—just chemistry. Drug makers rely on small, targeted molecule tweaks. Ethyl 6-chlorohexanoate serves as a connector, making it easier to add new pieces onto chemical frameworks. Take gabapentin, a medication prescribed for nerve pain or epilepsy: chemists often use similar esters in its synthesis process. In my experience, researchers choose these intermediates not just for their reactivity, but for how predictably they behave under pressure—cutting down on time and wasted resources. This benefit trickles to the end user because efficient manufacturing often lowers costs and manages supply chain reliability.

Agriculture: Protecting What We Plant

Farmers don’t walk around with vials of ethyl 6-chlorohexanoate, but they do depend on the pesticide and herbicide formulas that start with compounds like this. Insecticides and plant growth regulators rely on sturdy synthetic routes—every fail pushes up the price and time for field-ready products. This chemical helps craft building blocks for molecules that repel pests or stop weeds. I watched a project pivot in real time when we swapped in an accessible ester like this, saving budget as well as weeks of lab time. Less cost and predictable supply mean more accessible solutions reaching farms of every size.

Broader Chemicals and Daily Use

Look at the shelves at home—you’ll find solvents, coatings, and even plasticizers in common products. The chemicals behind those labels start off with intermediates like ethyl 6-chlorohexanoate. In the coatings industry, the structure lets it slip into formulations for more specialized finishes, helping products resist wear and tear in busy spaces. In my years around R&D testing, small chemical swaps in a formula could mean the difference between a finish that wears off or one that stands tall against scraping kids’ shoes or spilled coffee.

Moving Forward: Safety, Sustainability, and Solutions

Chemical intermediates always bring safety and environmental responsibilities. In recent years, regulators and producers have stepped up. Industries want safer manufacturing with less waste, and there’s ongoing work to design processes with fewer byproducts and easier disposal. The sector could go further by investing in advanced monitoring systems for emissions, and educating end-users about chemical handling—reducing accidental exposure down the line. The lesson I take from my own experience is this: transparency and training keep everyone safer and hold the door open for greener chemistry down the road.

Conclusion

The role of ethyl 6-chlorohexanoate might seem technical, but its impact runs broader than its name suggests. Reliable supply, safe use, and constant innovation mean this unassuming chemical quietly steers the development and delivery of some of society’s everyday essentials. Telling its story means paying attention to the journey from raw material to finished product, and building better practices as science—and society—evolves.

Getting to Know Ethyl 6-Chlorohexanoate

Ethyl 6-chlorohexanoate comes up in plenty of lab settings. It draws attention in chemical manufacturing, flavor chemistry, and even in materials research. To figure out its chemical formula, you break the name down: “ethyl” shows up as a familiar group you’ll find in many esters, “6-chloro” hints at a chlorine atom tied to the sixth carbon, and “hexanoate” tells you it’s a six-carbon chain, ending with a carboxylate group, but in this case, it’s an ester. Put it together: Ethyl ester of 6-chlorohexanoic acid leads to the formula, C8H15ClO2.

Building Blocks: Why Structural Details Count

Every formula tells a story. In C8H15ClO2, “C8” signals eight carbon atoms, “H15” stands for fifteen hydrogens, “Cl” brings in chlorine, and “O2” marks the oxygen atoms that come from both the ester group and the original carboxylic acid. Chemists rarely just care about the formula—they study structure because they want to predict reactivity, toxicity, and even handling hazards. In my own experience handling esters with halogen substituents, the position of that chlorine changes everything: from how the molecule smells to how fast it breaks down during hydrolysis.

Real-World Uses and Why It’s Not Just Another Compound

Chemicals like ethyl 6-chlorohexanoate don’t just sit on shelves. Companies, researchers, and labs turn to this molecule for a few good reasons. Its structure offers unique reactivity, especially for synthesizing more complex organic compounds. That “6-chloro” spot creates a handle for further modification—a place where you can swap in other atoms or groups. Over the years, a chain with a chlorine near the tail has proven efficient for making pharmaceuticals, flavors, or specialty monomers for polymers.

Ethyl esters commonly release pleasant fruity odors, making them interesting to flavor and fragrance designers. The added chlorine tweaks both the profile and the safety considerations. I’ve seen lab teams carefully track the presence of chlorinated molecules, especially since persistent organochlorines sometimes raise environmental flags.

Safety and Environmental Questions

Chlorinated molecules always come with extra questions about waste and byproducts. Regulations keep tightening because of how some chlorinated organics behave in water and soil. Studies link certain groups of them to environmental or health risks. In my lab, strict tracking of anything with a “Cl” on the formula sheet kept waste bins sorted and minimized risk of accidental mixing. Education around material handling and disposal keeps mistakes down and people healthy.

Proper chemical knowledge extends beyond formula memorization. Labs and industry groups partner up to publish safety sheets, and responsible disposal programs get better each year. Transitioning toward greener alternatives or swapping out tricky chlorinated steps with safer chemistry makes a real difference over time. For anyone weighing options, considering both utility and long-term impact pays off.

Moving Forward: Practical Chemistry

The chemical formula C8H15ClO2 defines more than a name in a catalog. Recognizing the importance of structure, responsible use, and environmental impact keeps research moving forward in the right direction. Understanding molecules like ethyl 6-chlorohexanoate on a deeper level helps people make smart choices in the lab and beyond.

What This Chemical Means for You

Ethyl 6-chlorohexanoate probably sounds like something you’d only hear about in a chemistry lab. Yet, this compound turns up more than you might think, with uses in research and some specialty industrial processes. Folks working with it often want to know: does handling it bring serious risks? Having spent years on and off the bench, I’ve learned that assumptions can lead to accidents. Let’s break it down one step at a time, because the health and safety angle matters for everyone—from the graduate student to the factory line technician.

Physical Properties Lead to Real Concerns

Ethyl 6-chlorohexanoate looks like a light liquid and has that faintly sweet, lingering solvent smell. If you’ve worked with similar esters, you might expect volatility and skin absorption risks. The chlorine atom in the structure brings another layer: halogenated organics stay stubbornly stable and can irritate mucous membranes. Even experienced chemists sometimes let their guard down, assuming “just an ester” won’t bite. The reality: this compound can burn eyes and skin in a hurry, and contact with it leaves a slick, hard-to-wash feeling.

Spill cleanup turns into a scramble. The vapors hang around, irritating throats or causing dizziness if workspace ventilation isn’t up to snuff. A quick check of the safety data shows this is not an “innocent until proven guilty” material. Chronic exposure stories and workplace incident data document headaches, nausea, and respiratory sensitivity from repeated handling—even when initial effects look mild.

Environmental Persistence Is Directly Linked to Handling Risks

Spilled organochlorines do not disappear quietly. They linger in drains and open air, breaking down slowly and posing a threat to water and soil nearby. I’ve seen drain pipes get replaced after a single big spill. Jumping from plant to ground to water, tiny amounts start a chemical legacy in local ecosystems. Some places have tight rules for any waste stream containing chloro-organic compounds, not just in the pharmaceutical industry. Splashing this liquid in the sink is a fast track to trouble with both regulators and the community.

Practical Steps for Protection

Protective gloves stand as the first line of defense. Basic nitrile works, though I always double up if there’s a chance for spills. Mandatory goggles and splash face shields aren’t overkill. Fume hoods, not just a cracked window, keep vapors down where they belong. Every bottle needs clear labeling and secondary containment, because accidents start with a single absent-minded refill or pour. In case of skin contact, copious water rinsing beats fancy soaps.

Waste disposal calls for special bins, not regular trash. Labs and plants need regular training refreshers, especially if new staff rotate in. Building a culture of caution is the only way to curb the restless “shortcut” mentality that creeps in after weeks or months on the job. In my experience, close calls don’t always end up in incident logs, but they build habits that keep teams sharp.

Bottom Line: Respect Earns Safety

Any direct exposure to ethyl 6-chlorohexanoate—eyes, skin, breathing in—can bring quick trouble. Local environmental effects shouldn’t be taken lightly, either. Personal protections, rigorous waste management, and a safety-first attitude stop injuries before they happen. No chemical deserves blind trust, especially one with a chlorine tag. It doesn’t take much to make things safer for everyone in the room.

Understanding the Compound’s Nature

Ethyl 6-Chlorohexanoate offers a strong example of why respecting chemical properties helps avoid headaches down the line. Known for its role as an intermediate in pharmaceutical and specialty chemical manufacturing, this compound lands on the desk with two main red flags: volatility and the potential for slow hydrolysis. Both of these traits underline the need for close attention to storage—especially in settings where safety incidents can quickly spiral.

Temperature and Environment

This chemical does best in a cool environment. Leaving a bottle near sunlight or in a room that regularly climbs above 25°C lets both the ester and the chlorine group start to break down. On my bench, I’ve seen samples degrade quicker than one would expect. A dedicated chemical storage fridge, set between 2°C and 8°C, maintains quality over time. Lab air conditioning helps if cold storage space runs tight, but it’s never a true substitute.

Humidity and Moisture Control

Water vapor poses more trouble than most think. Esters react with moisture—producing acids and alcohols that no one wants in a reaction flask. Fiddling with desiccant packs or setting up storage in a low-humidity zone tremendously reduces the risk. Safeguarding containers from accidental splashes and always tightening stoppers after use keeps the compound away from unwelcome hydrolysis. I lost nearly half a bottle once because a loose cap let in lab humidity over a weekend.

Light Exposure

Light gradually nudges chloro compounds toward decomposition. Storing Ethyl 6-Chlorohexanoate in amber bottles or at least away from bench windows slows down this process. I came to appreciate the difference after realizing the pale yellow color in old samples didn’t just suggest age—it signaled real chemical breakdown.

Container Selection

Glass containers with chemically resistant caps offer peace of mind. Polyethylene or polypropylene bottles often survive, but glass keeps out diffusion and helps spot cloudiness fast. Every time I swapped cheap caps for PTFE-lined ones, shelf life and safety improved. Labeling bottles with opening dates and hazard symbols keeps everyone honest and up-to-date.

Ventilation and Isolation

Strong odors and reactive vapors call for storage in a vented cabinet or chemical hood. The compound can trigger irritation, so open containers inside a fume hood. Isolating it from corrosive acids and bases avoids cross-contamination that could start a larger mess—life gets busy, and it’s easy to forget what fumes next door may set off.

Fire and Contaminant Risks

Although not especially flammable, Ethyl 6-Chlorohexanoate belongs far away from heat sources and open flames. A fire-resistant cabinet limits exposure during emergencies. On occasion, simple lapses, like letting it sit close to oxidizing agents, led to ruined stocks and reordering headaches. Separating incompatible materials saves not just time, but also lab budgets.

Handling Spills and Accidents

Accidental spills happen often enough to warrant routine checks. Using secondary containment trays and wearing gloves lowers the risk of skin contact. Anyone who’s had to stop mid-experiment to pull on new gloves and wipe an oily bench learns quickly about spill containment.

Continual Vigilance Pays Off

The habits developed around Ethyl 6-Chlorohexanoate storage translate well to handling any higher-risk compound. Simple steps—chilling, sealing, isolating—go a long way toward safe workspaces and reliable results. Regular audits, date checks, and refreshers for new team members keep standards up and surprises down.

Real-World Expectations

Ethyl 6-chlorohexanoate shows up in plenty of research labs and industrial synthesis for good reason. This chemical lands in more than just one field. It’s part of the toolkit for pharmaceutical intermediates, fragrance creation, and specialty chemical manufacturing. The question of purity actually changes from one bottle to the next, depending on who made it and why.

What’s Actually Inside the Bottle?

Looking at reputable catalogs like Sigma-Aldrich and TCI America, typical advertised purity for ethyl 6-chlorohexanoate hovers at 97% or better. Some suppliers claim 98% or even 99%, though jumping from 97 to 99% increases the cost noticeably. I’ve ordered both grades, and the difference boils down to the end use and budget.

Impurities generally include residual solvents, unreacted starting material, and sometimes water. NMR or GC shows exactly how clean your batch is, assuming you have the tools to check. If absolute precision matters—think active pharmaceutical ingredient work—demanding a certificate of analysis makes sense. Less-critical applications like initial reaction trials or non-human use, 97% works fine. Trying to shave off extra costs by picking a bulk or technical grade often bites back, since unknown contaminants defeat your experiment or scaleup.

Why Purity Really Affects the Work

I’ve learned from experience that chasing the highest percentage without a real need torpedoes your resources. Strict regulatory environments, like FDA or EMA pathways, force your hand toward top-purity lots. In those cases, every impurity poses a risk for downstream processing, be it toxicity, yield, or regulatory headaches.

On the other hand, a personal story from grad school sticks with me: Our project needed ethyl 6-chlorohexanoate for a fragrance building block. We grabbed a 97% bottle from a standard supplier. No issues getting clean conversion. Only after upscaling to a 99% batch, the cost nearly doubled, but those extra two percent honestly did not change the synthetic outcome.

A simple rule saved money and stress: match the grade to your purpose. Labs doing routine synthesis or proof-of-concept screening get more done with standard-grade stock. For regulated or medical projects, skip the risk—ask for a full analytical breakdown.

What Counts as “Pure Enough”?

Most research-grade suppliers guarantee above 97% purity. For most bench and pilot processes, that level covers what you need. Support data usually comes with every lot, outlining GC or NMR traces. These records prove the supplier stands by their certification, and serve as a reference for internal QA.

If you’re involved in process validation or need to gain regulatory approval, trace levels of every impurity start to matter. Contaminants, even below 1%, could trigger costly delays or failures in high-stakes pharma runs. In those cases, you ask the supplier about their purification protocol, possible custom purification, or at the very least, a full impurity profile.

Improving Quality Where It Counts

If purity trouble shows up, working with suppliers who offer batch-specific data, consistent customer support, and clear labeling makes a huge difference. Some companies allow pre-shipment analytical confirmation or custom purification, which safeguards your process. If the project budget allows, splitting orders between high-purity and regular grades lets you choose the best value each step of the way.

The chemistry world doesn’t need to overcomplicate a simple fact. Ethyl 6-chlorohexanoate, as sold for research, usually comes at 97% or a touch better. If you need more, check the lot data, talk with your supplier, and be ready to pay more for that final percent or two. Matching grade to the actual job always beats chasing theoretical perfection.