Ethyl 6-Iodohexanoate: A Deep Dive

Historical Development

Ethyl 6-iodohexanoate hasn’t grabbed headlines like some modern materials, but its history traces back to foundational organic synthesis. Chemists sought strong alkyl iodides for their readiness in nucleophilic substitution. In the early days of organoiodine chemistry, finding practical ways to introduce iodine atoms into straightforward molecules filled countless laboratory logs and mental notebooks. This compound quietly became a useful intermediate, especially once researchers realized the value of iodo-esters for assembling specialty pharmaceuticals and advanced materials. Year by year, technical know-how advanced, access to better catalysts and purer starting materials improved, and methods for making and tuning the compound reached predictable, scalable reliability. So, ethyl 6-iodohexanoate earned its stripes on the benches of research facilities in Europe, North America, and Asia, helping build larger, ever more complex molecules for both academic and industrial goals.

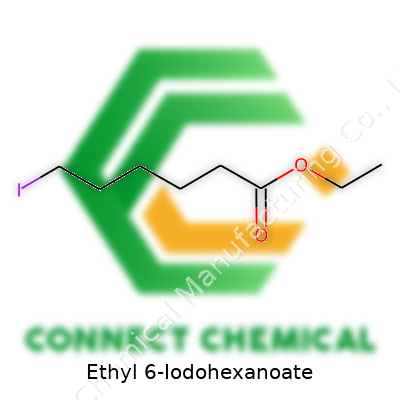

Product Overview

Makers turn out ethyl 6-iodohexanoate as an organic building block in the class of iodinated esters. Chemists run to it when they need a reliable source of both an ester group and a reactive alkyl chain with a terminal iodine. The presence of the iodine atom at the end of a six-carbon backbone throws open a host of synthetic opportunities. In industry, the product doesn’t sit on shelves in mountains but gets prepared in batches for custom syntheses—often in fine chemical sectors. Pharmaceutical, agrochemical, and advanced polymer specialties call it up for chain extension, further functionalization, or as precursor to more intricate targets. Researchers appreciate its manageable size, defined structure, and high purity when tracing reaction mechanisms or plotting out next-generation molecules.

Physical & Chemical Properties

Ethyl 6-iodohexanoate presents as a clear to pale hygroscopic liquid, and at the right storage temperature holds its stability without fuss. The molecule carries a molecular weight near 284 g/mol, and physical handling stays straightforward for a compound loaded with a heavier halogen. It dissolves easily in organic solvents common in research labs—dichloromethane, chloroform, and ethyl acetate all work pretty well. The iodine atom doesn’t just lend mass; it brings increased polarizability and higher reactivity compared to lighter halogenated cousins. Standard melting and boiling point data show it remains a liquid under normal laboratory conditions but boils at a temperature that requires careful control to avoid waste or hazard. The ester group keeps it hydrolyzable under both acidic and basic conditions, acting as both a point of stability and a functional handle for more chemistry down the line.

Technical Specifications & Labeling

Quality assurance takes front seat for specialty chemicals, and ethyl 6-iodohexanoate is no exception. Specification sheets list the product as surpassing 97% purity, with careful reporting on parameters like water content, residual solvents, and organic impurities. Most suppliers run lots through gas chromatography to assure purity levels don’t dip or stray batch to batch. Labeling on transport containers names the chemical, includes the UN number for hazardous materials, and provides hazard pictograms that speak louder than dry text for safe handling practices. The label also specifies date of manufacture, batch number, and storage warnings, reflecting due diligence in regulatory compliance and quality traceability.

Preparation Method

The process starts with 6-iodohexanoic acid or an appropriate halogenated precursor. Chemists activate the carboxylic acid functionality, often with agents like thionyl chloride or carbodiimides, to form an acid chloride or ready intermediate. The next move is esterification through reaction with ethanol, usually under mild heating with an acid catalyst, creating ethyl 6-iodohexanoate in moderate to excellent yields. Back in the days before fine-tuned instruments, yield optimization happened by trial and error. Now, process improvements watch for side reactions—like elimination or over-iodination—that could tank purity or bump up costs. Crude product gets purified using vacuum distillation or column chromatography. Final handling takes place under inert gas or in sealed containers to fend off unwanted hydrolysis. Today, automation and improved in-line sensors mean every batch gets greater reproducibility and environmental safety.

Chemical Reactions & Modifications

That terminal iodo group opens up countless transformations through nucleophilic substitution. Case in point: replace iodine with amines to create amides, or swap with cyanide to stitch new carbon-carbon bonds, branching off into synthesis trees that touch everything from drug candidates to smart polymers. The ester group reacts just as willingly, responding to hydrolysis, reduction, or transesterification. Taken together, these two reactive handles turn ethyl 6-iodohexanoate into a veritable playground for organic innovation. Laboratories use it to introduce the six-carbon scaffold into larger frameworks or as a linker for conjugation. Once I saw a team turn it into a radiolabeled tracer in a cancer drug, allowing precise tracking in vivo. The transformations add tools and flexibility, but demand tight control since deep-seated reactivity can lead to unwanted by-products without seasoned supervision.

Synonyms & Product Names

Chemists may run into alternative names and codes for the same compound across catalogs or scientific articles. Besides ethyl 6-iodohexanoate, expect to see the monikers “hexanoic acid, 6-iodo-, ethyl ester” or “6-iodohexanoic acid ethyl ester.” Commercial sources sometimes use trade codes or catalog numbers for easier inventory tracking. These synonyms help ensure research moves smoothly even when suppliers, languages, or journal conventions diverge. Still, the CAS Number, unique and unambiguous, ties every synonym together and keeps purchasing and safety procedures clear from bench to warehouse.

Safety & Operational Standards

No matter the scale, working with compact organoiodines mean taking chemical safety seriously. Ethyl 6-iodohexanoate can irritate skin, eyes, and respiratory tract, and deeper exposure brings risks not worth gambling. Safety data sheets outline necessary use of goggles, lab coats, and gloves. Facilities handling the product keep emergency showers and eyewash stations within easy reach. Waste from synthesis and purification needs proper handling; local environmental rules regulate disposal. Storage demands cool, dry conditions away from light or oxidizers. Facilities lock down protocols to prevent cross-contamination, especially when preparing materials for pharmaceuticals or food-related research. Production in industrial settings relies on robust fume extraction and continuous air monitoring to catch leaks early. Regular safety updates train new and veteran staff alike in recognizing danger signs and following emergency procedures.

Application Area

Ethyl 6-iodohexanoate holds strong value in organic synthesis. Synthetic chemists often seize it as a flexible intermediate for producing complex molecules in pharmaceutical development, where custom alkyl chains and selective reactions make or break a project. It finds roles in the production of surfactant materials, advanced polymers, and within life sciences as a building block for biologically active compounds. In radiochemical research, the iodine moiety enables isotopic labeling, tracking drugs or other molecules in metabolic studies. Even outside drug creation, the compound pops up in agrochemical innovation, materials science, and as a precursor to sensors or molecular electronics. Its dual functional groups—ester and iodo—mean it adapts to very diverse system requirements and unlocks creative paths for researchers and process engineers.

Research & Development

The ongoing pursuit of better, cleaner, and more efficient synthesis techniques puts ethyl 6-iodohexanoate in the crosshairs for R&D. Analytical chemists look at trace impurities, improving purification methods with high-performance liquid chromatography or crystallization tweaks. Process engineers reduce solvent consumption and develop greener esterification strategies, sometimes swapping classic reagents for less hazardous ones. That drive to leaner, safer, and more cost-effective production aligns with regulatory pressure from environmental agencies and company sustainability targets. Analytical method development covers not only quantitative purity but also potential reaction by-products, residual solvents, and long-term stability in integrated supply chains. Research teams collaborate across academic and industrial borders, sharing insights on new reaction conditions, novel catalysts, or alternative sources like bio-based alcohols for the esterification step. These continuous upgrades reflect the scientific community’s demand for progress in both yields and ecological responsibility.

Toxicity Research

Studies addressing toxicity of alkyl iodides, including ethyl 6-iodohexanoate, combine animal data, cell culture assays, and chemical structure-activity modeling. Most research highlights risks from skin absorption, inhalation, and accidental ingestion. The presence of an alkyl iodide group signals caution due to potential thyroid disruption and broader endocrine effects. Regulators and industrial hygiene teams monitor occupational exposure limits, especially during scale-up or bulk handling environments. Researchers work on quantifying and understanding both acute effects—such as irritation and allergic responses—and chronic risks like mutagenicity or long-term organ impact. Empirical data remains somewhat limited due to the narrow application window, but ongoing testing supports safer lab and production practices and informs updates to international safety guidelines. Newer efforts use non-animal-based models, reflecting both ethical progress and advances in predictive toxicology.

Future Prospects

Looking ahead, the relevance of ethyl 6-iodohexanoate will continue to pivot around next-generation pharmaceutical and material science applications. As bioconjugation strategies grow in medicine, demand for custom-tailored building blocks with good reactivity and clean transformation profiles will rise. Green chemistry trends will push synthesis workflows to lower waste, swap hazardous agents, and recycle solvents. Advances in catalysis, automation, and flow chemistry could slash costs and environmental footprints at the same time technical demand increases. Greater availability of isotopically enriched iodine expands uses in medical imaging and tracing. Rigorous toxicological research, coupled with emerging regulatory frameworks, ensures the compound is handled safely in whatever roles it takes on, from cancer therapy research to advanced electronics. By staying focused on efficiency, safety, and technical utility, chemists and manufacturers can maintain ethyl 6-iodohexanoate’s position in the demanding landscape of chemical innovation.

The Role of Ethyl 6-Iodohexanoate

Some chemicals don’t make headlines, but the work they do makes a big difference in research labs and manufacturing plants. Ethyl 6-iodohexanoate sits in that corner. This compound catches a lot of attention from chemists working in organic synthesis, medicinal chemistry, and materials science. In many labs, you might find it sitting on a shelf, waiting to serve as a building block for new molecules.

Building New Molecules

Instead of standing alone, ethyl 6-iodohexanoate often plays a supporting role in putting together larger, more complex chemicals. That iodine atom attached to its long carbon chain isn’t there for show—it gives chemists a starting handle for lots of chemical reactions. In the world of organic chemistry, “alkyl iodides” like this one make certain steps much smoother, especially when swapping out the iodine for something else.

Let’s say someone wants to produce a pharmaceutical compound or design a new polymer. Often, there’s a need to link together carbon chains or attach different groups to a base structure. Ethyl 6-iodohexanoate does this job well because its structure holds both an ester group (the ethyl end) and an iodo group. That’s a rare combo, giving chemists two places to tinker. One group can get swapped out, the other can be protected or changed later.

Supporting Drug Discovery

Many new drug candidates never leave the drawing board because it’s tough to put together all the right pieces. Ethyl 6-iodohexanoate helps by serving as a “molecular tool.” Medicinal chemists build a library of molecules, changing small pieces at a time to see what works best against certain diseases. The flexible nature of this iodo ester means more options and faster testing. Being able to make analogues quickly can save months during early drug development, making the process more cost-effective and increasing the chances that a promising lead will emerge.

Material Science and Synthesis

Research groups working on new materials—polymers, surfactants, or lubricants—often need a way to add long carbon chains to their designs. Ethyl 6-iodohexanoate steps in here, too. The iodo group acts like a plug-and-play connector. Polymer scientists who want to build specialty plastics or coatings use it to introduce specific features and fine-tune how the final product behaves. Even small tweaks can change the performance of the end material.

Challenges and Safety

Chemicals like this bring benefits, but there’s a challenge—halogenated compounds can be tough on people and the environment if not handled with respect. Iodo compounds, in particular, carry safety considerations such as potential skin and respiratory irritation. Waste management matters, too. Lots of labs follow strict guidelines for disposal, but some smaller setups cut corners. This opens the door for contamination, making training and oversight crucial. Investing in green chemistry alternatives can help reduce the risks.

A Step Toward Innovation

Ethyl 6-iodohexanoate isn’t a household name, but it plays a key part in a lot of scientific progress. Researchers using chemicals like this look for ways to work safely and reduce waste, embracing new protocols and improved lab practices. Longer chains with modifiable ends seem simple, but they’re vital for building everything from antibiotics to smart plastics. Building awareness and responsibility around specialty chemicals isn’t just good science—it’s good citizenship, too.

Bringing Chemistry into Daily Life

Chemistry often seems remote from everyday problems, but every chemical compound starts with the basics—molecular formula and weight. Knowing those building blocks unlocks a strong foundation for work in research, manufacturing, or anything that leans on accurate data and results. Today, let's dig into Ethyl 6-Iodohexanoate, a compound that sits quietly in organic synthesis labs but holds real relevance in biochemistry labs and industry-scale applications.

Molecular Formula of Ethyl 6-Iodohexanoate

Getting the right formula takes careful counting. For Ethyl 6-Iodohexanoate, the backbone is a hexanoic acid chain, meaning six carbons with an attached carboxylic acid group, and here, this group gets converted into an ester by joining with ethyl alcohol. An iodine atom lands on the sixth carbon. Piece these parts together and you get:

Molecular Formula: C8H15IO2

For students or experienced lab techs, finding this formula isn't just a numbers game. It represents the atoms you need to handle, the reactivity of the compound, and just how heavy things can get on a balance. One missed atom can leave results messy, or even dangerous on scale-up. That's why getting the basics straight matters.

Molecular Weight: The Heavy Details

Calculating the molecular weight always takes me back to the basics: add up the atoms, use accurate mass numbers, and respect the decimals. For Ethyl 6-Iodohexanoate, here's the breakdown:

- Carbon: 12.01 x 8 = 96.08

- Hydrogen: 1.008 x 15 = 15.12

- Iodine: 126.90 x 1 = 126.90

- Oxygen: 16.00 x 2 = 32.00

Add these together, and you get molecular weight: 270.13 g/mol. For those who do their work on tiny scales, just a fraction of this value means the difference between accuracy and wasted effort.

Why This Knowledge Matters

Every specialized molecule that winds up in a bottle or analysis runs up against the same problems: purity, reactivity, and labeling. If someone’s working in synthesis, whether developing pharmaceuticals or fine chemicals, a slip-up in molecular weight trips up stoichiometry—sometimes with expensive consequences. Order the wrong amount, measure things carelessly, or just trust a database blindly, and you land in trouble with regulatory agencies or lose grants because your methodology doesn’t check out.

Best Practices for Getting Chemical Data Right

As an old lab hand, I keep a copy of the CRC Handbook nearby, and always cross-check key data with trusted online databases. Time spent reviewing a paper or reagent label never feels wasted, and it prevents confusion during reactions or submissions. It’s easy to see why regulatory and safety standards focus on accuracy—even a minor slip can add up over years or in larger productions.

In my experience, teaching students about calculating and double-checking molecular details like these often prevents headaches down the road. Shared open-source resources help, but nothing replaces hands-on calculation and a critical eye. Database errors and typos happen enough that everyone benefits from following up, especially with less-common compounds like Ethyl 6-Iodohexanoate.

Look Beyond the Bottle

Every time I see students thumb through printouts or web pages, searching for formulae, the message stands out: real progress in chemistry rests on firm, simple facts. Like the molecular formula and weight of Ethyl 6-Iodohexanoate, those basics ground advanced understanding and responsible work. They keep experiments honest and outcomes trustworthy.

Understanding What You’re Dealing With

Ethyl 6-iodohexanoate isn’t a household name, but anyone who spends time around labs or in specialty factories knows these fine-chemical bottles pile up fast. Safety around chemicals usually gets built right into every good lab’s habits—often showing up as checklists nailed to doorframes and color-coded stickers on shelves. Still, a well-done routine can get sloppy with rare compounds like this one, and that’s when mistakes start landing people in trouble. I’ve seen an expensive batch leak all over a benchtop, so there’s value in taking a hard look at storage right from the start.

Chemical Stability and Temperature

There’s value in keeping ethyl 6-iodohexanoate cool and away from light. This compound, with its ester backbone and iodine atom, can break down quicker if left in a sunny or hot spot. Refrigerators set to typical lab standards—2°C to 8°C—offer enough chill to slow unwanted reactions without freezing the compound. I’ve watched too many researchers stick reagents on a windowsill “just for a day,” only to find a sticky mess or stinky bottle the next week. Darkness matters too; since light helps some chemical bonds snap, a dark cabinet or an amber bottle makes a real difference.

Moisture Control

Moisture sneaks into anything if you give it a chance. With ethyl esters like this, water brings hydrolysis, especially over weeks or months. Even a half-closed cap can let in enough humidity from the air to start trouble inside the bottle. Desiccators are a classic fix. Labs that run short on space sometimes tuck silica gel packets in containers. Clumsy as it looks, this step spares your budget and protects downstream reactions from surprise by-products.

Container Choice and Labeling

Glass wins every time for storing chemicals like ethyl 6-iodohexanoate, especially over plastic containers that sometimes react, crack, or let vapor escape. A tight, screw-cap lid keeps everything sealed. Clear, honest labels—date received, who opened it last, and hazard stickers—help the next person avoid confusion. I once grabbed the wrong bottle after a long shift because a faded label tricked me. Clear labeling could have turned my headache into just another easy day at work.

Avoiding Accidents: Secure Storage

Hazards multiply in cramped labs where bottles crowd together on one shelf. It pays to sort chemicals by family—halogenated esters with the organics, oxidizers separate, acids and bases on their own shelves. Ethyl 6-iodohexanoate can react if left next to strong bases or reducing agents, sometimes even causing fires. Locking cabinets or restricted shelves cut down on accidents, especially with new lab members who haven’t seen everything go wrong before.

Training and Routine Checks

No routine storage plan works without people. Everyone using the chemical should know the main risks, the basics of what to do in a spill, and where to find the SDS. Routine checks, once a month at worst, keep expired or leaking reagents from lurking in the back. Someone should own the storage chart, and I’ve learned that even the most stubborn researcher will check their habits if they know people are watching out.

Building Good Habits

Storing ethyl 6-iodohexanoate isn’t glamorous. Still, these steps—keeping it cold, dry, dark, well-sealed, and clearly labeled—keep teams safe, reactions reliable, and budgets in better shape. These aren’t big, flashy solutions; they’re steady routines born from years of both smooth days and messy close calls.

Why This Compound Matters

Ethyl 6-Iodohexanoate shows up in the toolbox for a fair number of synthetic chemists. It makes its way into pharmaceutical research or new material development. Working with any chemical brings responsibility. Stories crop up about minor accidents: a fume lingering in a stuffy room or a stray drop landing just outside the glassware. From my own days prepping reactions, one lesson stuck—no shortcut for safety feels worth the risk.

Knowing Your Risks

Start from a place of honesty. Not every bottle screams danger in the same way. Ethyl 6-Iodohexanoate lands in the organic iodide group. Most are not as immediately toxic as, say, cyanides or peroxides, but that doesn't grant a free pass. Organic iodides can affect the thyroid, irritate skin, or bring headaches with extended exposure.

Mist slips in when folks assume a liquid labeled as “reagent” holds no surprises. Standard data sheets report irritation risks for eyes, skin, and lungs. Small spills seep into gloves, and most nitrile gear eventually lets something through. Splatters from a shaker or slips during transfer happen even to careful workers.

Key Practices in the Lab

Setting concrete habits works. Keep handling inside a well-maintained fume hood. Trusting the air system protects your lungs from vapors, since even routine operations produce invisible fumes. I once forgot this, thinking a quick pour in open air made no difference—my nose proved me wrong.

Gloves matter. Nitrile gloves get you most of the way, but swap out pairs after spills or long sessions. No glove solves every problem—wiping an itch or answering the phone mid-task ruins the barrier. I learned to keep spare gloves in my pockets, not at the back of the drawer.

Eye coverage ranks high. Safety goggles block more than lab glasses. Liquid splatter hits hard and fast if you lean in for a closer look. Face shields can help if pouring larger amounts.

Protective coats and sleeves prevent skin contact. Rolled-up sleeves fail every time—I’ve seen small compounds soak through cuffs or seams. Wash hands with soap immediately after use, even if it feels unnecessary.

Smart Handling and Storage

Don’t pipette by mouth. Don’t lean over open bottles. Both seem outdated, but shortcuts creep in when routines set in. Pour and weigh small batches out of the main bottle, limiting exposure and helping track leaks.

Store Ethyl 6-Iodohexanoate in a cool, dry place, sealed tight, and away from incompatible substances like strong bases or oxidizers. Label bottles with date received and opened. A bottle with an unreadable label brings more hazard than most realize. Dispose of waste in marked containers, according to local guidelines—nobody wants a surprise at inspection or while sorting trash.

Final Thoughts: Experience Shapes Habits

Mistakes teach better than warnings. I remember hearing about a colleague rushing to finish before lunch. They left a spill on the bench, thinking a quick wipe would do the trick. The next person picked up a faint chemical burn and a load of paperwork. The easy routines protect the whole team, not just the person with the bottle. It’s not fear that shapes good lab work—it’s learning from real-world labs and treating every chemical with respect, no matter how ordinary the day may feel.

Understanding What You Actually Get

A lot of folks venturing into synthetic chemistry run up against the same question: What purity can you actually expect from Ethyl 6-Iodohexanoate? If you browse catalogs of major chemical suppliers, purity seems straightforward enough—most display numbers around 95%. Sometimes, it’s “95% minimum,” sometimes a supplier claims 97% or a little more, but few go beyond. For research labs, that’s usually plenty. In a commercial lab, working on non-pharmaceutical targets, that might seem like overkill.

Why Purity Standards Matter in Practice

Let’s be honest: purity makes or breaks a synthesis. As a chemist, I’ve seen reactions succeed or sputter just because the starting material carried a few extra impurities, overlooked because nobody bothered to check beyond a quick TLC. In the case of Ethyl 6-Iodohexanoate, traces of leftover acids, alcohols, or unreacted starting materials can interfere or even fully derail coupling or chain-extension steps. This hits especially hard when you need reliable yields for downstream esterifications or substitutions.

There’s more than performance on the line—think about safety. Organic iodides break down in air and light, sometimes leaving behind messy residues or making product purification a pain. Lower purity means more risk that something unpredictable happens, setting you up for a frustrating day in the fume hood or an unexpectedly stubborn chromatogram.

What the Big Suppliers Actually Ship

Review Sigma-Aldrich, TCI, Alfa Aesar, and other vendors. Their specs rarely promise above 97%, and most batches hit the 95–97% window. Cheap sources from trading platforms—those want to catch eyes with “98%” but rarely provide proof beyond a generic COA. Analytical details—GC, NMR, or HPLC traces—don’t always come standard unless you ask (and sometimes pay more).

From experience, these numbers reflect both the difficulty in synthesizing iodo-esters and the simple fact that purification, especially for relatively heavy esters with halogens, gets rough past a certain point. Flash chromatography helps a ton in small batches, but scale up and those last few impurities stick like glue.

Is Higher Purity Possible or Worth It?

Meeting tighter specs means extra processing—think repeated recrystallization, advanced chromatography, or fractional distillation. That eats into yield and profit. Most users just don’t need 99% for synthetic work; the chase adds cost without enough real benefit. In my own bench work, I learned quickly that going from “very pure” to “near-perfect” takes triple the hassle for little payoff, unless your target is pharma-grade API or some precise analytical calibration.

Solutions and Smart Buying

If your project really needs the cleanest possible Ethyl 6-Iodohexanoate, you’ve got choices. Start with a trusted supplier and always request detailed analysis—get NMR and GC/MS data if you can. If higher purity is truly essential, talk to a custom synthesis shop, but budget for higher costs and plan for lead time delays. Otherwise, a 95% sample often runs just fine, as long as you double-check impurity profiles before scaling up.

Forward-thinking chemists pair strong relationships with sellers and a skeptical eye on product specs. You get more out of your reactions, and the extra effort upfront keeps surprises to a minimum. That’s the kind of detail that separates a clean result from another ruined week at the bench.