Methyl 7-Bromoheptanoate: An In-Depth Commentary

Historical Development

Exploring the journey of methyl 7-bromoheptanoate, I am struck by its evolution since halogenated fatty acid derivatives began transforming the synthetic landscape in organic chemistry. The compound traces its roots back to advances in alkyl halide chemistry during the latter half of the 20th century, right around the same time chemists ramped up their pursuit of practical intermediates for pharmaceuticals and specialty chemicals. Over the decades, demand spiked for longer-chain bromoesters, especially as medicinal chemists and industrial researchers connected their reactivity with new catalytic and synthetic tools. In those early days, labs depended on fairly crude methods—yields were all over the place, purification was a headache, and the environmental concerns hadn’t made it into textbooks yet. Nevertheless, as attention shifted to scalable, greener practices, routes to methyl 7-bromoheptanoate got cleaner and more reproducible. From simple batch preparations to sophisticated continuous-flow syntheses, what used to be a challenging compound to prepare now occupies a solid place in chemical manufacturing and research labs all over the world.

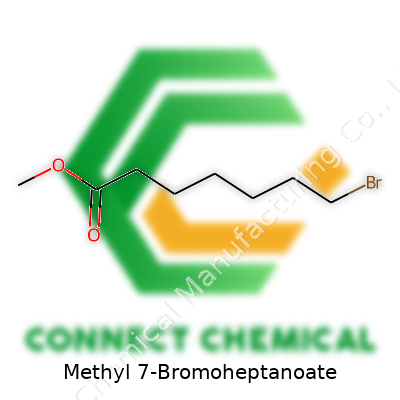

Product Overview

Methyl 7-bromoheptanoate, with its clear, colorless oil appearance and a mild ester aroma, serves as a bridge between laboratory reagents and functional building blocks. I see it often stored in amber vials to protect from light, though its chemical stability sits above average for esters containing a bromine atom. Researchers prize its utility—starting from the reactive terminal bromine on a seven-carbon chain to the methyl ester at the opposite end. This lets methyl 7-bromoheptanoate operate as a cross-linker, functional group carrier, or as a key step in more complicated syntheses. In pharmaceutical R&D, its bromide atom is easily swapped out or serves as a hook for nucleophilic substitution—key for building up more intricate carbon skeletons or introducing polar groups where needed.

Physical & Chemical Properties

Handling methyl 7-bromoheptanoate, I notice right away its smooth liquid form at room temperature and relatively low viscosity. Its molecular formula, C8H15BrO2, packs a molecular weight around 223.11 g/mol. The boiling point climbs to roughly 110°C at reduced pressure (0.5 mmHg), while its flash point remains low enough to demand respect during storage and handling. The density approaches 1.27 g/cm³, reflecting halogenation, while solubility falls into predictable nonpolarity—miscible with ethers, alcohols, and dichloromethane, but stubbornly separates from water. Chemically, the electron-withdrawing effect of the bromine atom makes the terminal carbon distinctly reactive for nucleophilic substitution, which underpins a lot of its value as an intermediate. Stirring up this compound with strong nucleophiles slaps new groups onto the chain, yet the methyl ester tolerates moderate bases and mild acids, delivering a nice balance of stability and reactivity.

Technical Specifications & Labeling

Purchasing or handling this compound, I check for minimum assay—often 97% or higher—as low purity hampers downstream chemistry. The liquid must show only minimal water content, less than 0.5%, since trace moisture can hydrolyze the ester. Most suppliers include a clear CAS registry number for global reference, UN hazardous materials labeling, and comprehensive documentation on storage practices. Labels always remind me of the need for tightly sealed containers, storage below 30°C, and “keep away from sunlight and ignition sources” warnings. Every bottle comes with a Safety Data Sheet (SDS), offering quick access to information on spills, accidental contact, and recommended personal protective equipment during handling.

Preparation Method

In my own lab experience, the Fischer esterification route supplies the backbone for this compound’s synthesis. Beginning with 7-bromoheptanoic acid—sometimes itself made by brominating heptanoic acid with phosphorus tribromide—one combines it with methanol and either sulfuric acid or p-toluenesulfonic acid as catalyst. Refluxing this mixture under a water-capturing setup (Dean-Stark trap does the trick) efficiently drives the reaction toward full esterification. Once cooled, extraction with dichloromethane lets the product out of the water layer, drying the organic phase with magnesium sulfate strips out last traces of moisture, and rotary evaporation drops you to a dense oily residue. Distilling at reduced pressure sharpens up the product for storage or further reactions. Commercial producers often scale up with continuous-flow columns or employ greener acid catalysts in solvent-minimized processes, keeping environmental impact under control and boosting yield consistency—something every chemist can appreciate in bulk orders.

Chemical Reactions & Modifications

On the bench, methyl 7-bromoheptanoate offers a useful reactive handle that supports all sorts of chemistry. The benchtop nucleophilic substitution hooks up a big range of compounds to the bromo terminus—think amines for making amides, alkoxides for simple ether synthesis, or thiolates to drop a sulfur atom into the chain. The ester group often stays quiet under these conditions, but when targeted, transesterifications or basic hydrolysis lead to the free acid or various alkyl esters. Reduction with lithium aluminum hydride transforms it to the primary alcohol much faster than unadorned aliphatic esters, thanks to the polarizing effect of the bromide. I’ve used the Grignard reaction to substitute the bromine with organometallic fragments, which helps build more complex molecules for medicinal chemistry work—once, I even used it for generating intermediates for surfactant research.

Synonyms & Product Names

Reading chemical catalogs, I’ve seen methyl 7-bromoheptanoate called out under several names. Most standardized databases just reference it as "Methyl 7-bromoheptanoate," but I’ve also spotted "7-Bromheptansäure-methylester" and "Methyl 7-bromo-n-heptanoate." Some industry vendors simply list it under its CAS number (or 7-bromo-heptanoic acid methyl ester for clarity in ordering systems). This collection of synonyms streamlines searches across languages and distribution networks, but it can throw off newer chemists, especially if they’re looking for one and miss the alternates.

Safety & Operational Standards

From direct experience, gloves and safety goggles are non-negotiable here. Methyl 7-bromoheptanoate can irritate skin and mucous membranes with direct contact, and all halogenated esters raise a flag for moderate inhalation hazard. Working under a well-ventilated hood, with secure storage away from incompatible or reactive chemicals like strong bases or oxidizers, shields against most of the routine risks. Spills clean up with absorbent pads, but any spill above a few milliliters calls for chemical waste protocols. Waste management means collecting even small amounts as halogenated organics—these never go down the drain—and shipping off to certified disposal facilities. I find that lab safety training lapses only set the stage for accidents, so regular refreshers make sense.

Application Area

Researchers in my network keep coming back to methyl 7-bromoheptanoate for making specialty pharmaceuticals, cosmetic ingredients, agricultural agents, and surfactants. Its controlled reactivity and relatively straightforward purification steps make it a foundational intermediate for active pharmaceutical ingredients, especially those needing a flexible seven-carbon backbone for hydrophobic tuning. In polymer chemistry, chemists graft this building block onto longer chains to tweak solubility and functional access. It finds a home in flavor and fragrance research: while not used directly, it shows up in the complicated paths required to make macrocyclic musk compounds, where the seven-carbon chain length mediates volatility and sensory punch. Because of the bromine anchor, specialty coatings and lubricant additives use this compound to tether functional pieces, enhancing both performance and weather-resistance properties in finished products.

Research & Development

My time in research collaborations highlights a lot of recent action around new synthetic routes—greener chemicals, recyclable catalysts, and solvent minimization for smaller environmental footprints. Universities test enzyme-catalyzed esterification strategies, searching for energy savings and fewer byproducts. Meanwhile, pharmaceutical start-ups target the unique reactivity of methyl 7-bromoheptanoate for constructing drug candidates that bypass previously intractable synthetic bottlenecks. R&D groups focus on mechanistic studies, using NMR, MS, and IR to track the expected reactivity under modified conditions—insights here can cut costs and save batches from hard-to-remove impurities. In my own projects, iterative small-batch syntheses unravel which nucleophiles run cleanly and which produce messy side reactions, helping optimize every dollar spent on reagents and purification.

Toxicity Research

I’ve pored over toxicological data on methyl 7-bromoheptanoate, pulling from both regulatory filings and academic screening studies. Animal exposure tests show moderate acute toxicity, with LD50 values suggesting it causes harm at moderately low doses, especially by ingestion or severe skin contact. Inhalation—though less common as vapor at room temp—carries enough risk to keep air monitors running during scale-up. As metabolism studies reveal, this compound’s ester function can hydrolyze in vivo to yield 7-bromoheptanoic acid, which undergoes further transformation before excretion. Brominated metabolites sometimes cause concern for nervous system or reproductive toxicity, but methyl 7-bromoheptanoate falls short of the red-flag chemicals in its structural class. Still, I’d never drop it among poorly trained staff—PPE, engineering controls, and monitoring matter. Environmental fate tests show slow breakdown in soil and water; thanks to its lipophilicity, it resists leaching but does not evaporate rapidly, meaning controlled disposal stays essential.

Future Prospects

Looking ahead, I see methyl 7-bromoheptanoate taking on a bigger role as researchers chase better ways to make molecules with lower energy inputs and fewer waste streams. Biocatalysis could nudge this compound into truly sustainable production levels, nudged along by advances in enzyme engineering and renewable feedstocks. Its structure inspires new polymer architectures, especially as scientists look to design “smart” materials tuned by the length and substitution of carbon chains. In drug discovery, the flexibility of introducing substitutions at the terminal bromine, and altering the ester group, opens up chemical space for targeting neurodegenerative, antimicrobial, or rare-disease compounds. Regulatory scrutiny on halogenated chemicals keeps tightening, so future production methods need to highlight near-zero emissions and closed-loop processes for spent reagents. For labs and factories alike, continuous process optimization paves the way for methyl 7-bromoheptanoate to transition from a specialized intermediate to a safer, greener, and more indispensable player in synthetic and industrial chemistry.

The Backbone of Synthesis

Methyl 7-Bromoheptanoate doesn’t catch attention at the grocery store or show up in news tickers, but it plays a big part behind the scenes in chemical labs and factories. At its heart, this compound is a building block. Every chemist I know who’s ventured into organic synthesis has come across bromoalkane esters, and this one’s length—seven carbons—fits a sweet spot for crafting longer and more interesting molecules. Labs use it to stitch together molecules that show up in drugs, coatings, agricultural tools, and sometimes even specialty perfumes that need stable, long carbon chains.

Building Blocks Lead to New Medicines

Drug research leans on flexible starting tools, and Methyl 7-Bromoheptanoate delivers. With that bromo handle, skilled chemists swap it for other ingredients or stretch the chain, helping push research past stale dead ends. It forms the backbone of many chemical reactions—especially when making molecules that block disease pathways or bind to cell targets. In my own time at the lab bench, we often looked for molecules with this kind of bromo group; it’s simple to react and lets us connect odd shapes in trial drugs quickly, then test which ones actually work against bacteria or viruses.

Specialty Chemicals and Material Science

Beyond pharma, this ester shows up in making more durable plastics and specialty coatings. Manufacturers use it to build polymers that won’t wilt in the heat or under chemical stress. Bromoheptanoate-based compounds help strengthen plastics for automotive coatings or flexible electronics. The long carbon chain doesn’t just serve a theoretical role—it translates to stronger bonds and longer-lasting materials. Chemists appreciate how swapping out the bromo group for other atoms leads to tailored end products with less environmental waste, which helps keep industrial pollution down.

Challenges and Safety Concerns

With almost every specialty chemical, risk comes with the territory. Handling Methyl 7-Bromoheptanoate requires respect; inhaling its vapor or getting it on your skin isn’t wise. Labs and factories teach clear protocols because brominated chemicals can irritate or, in stronger cases, trigger hazardous reactions. I had a close call early on, rushing through a synthesis and skipping gloves—never again did I go without full protection after seeing how quickly even a small spill can burn skin. Regulatory bodies like OSHA and the European Chemicals Agency push strict labeling and handling guides, aiming to keep accidents rare.

The Future: Greener Alternatives and Responsible Sourcing

Changes in chemistry demand constant balance. Researchers work to develop steps that produce less waste. Some teams explore greener routes—using renewable feedstocks to make esters like this, or tweaking the reactions to cut down on byproducts. Companies search for suppliers who comply with tough global standards, knowing that sloppiness in one step can lead to lasting problems across the supply chain. That means both chemists and industry buyers keep a close eye on the source and purity, betting that better practices upstream protect workers and the environment.

Final Thoughts

Methyl 7-Bromoheptanoate might not make front-page news, but its role stretches across modern technology and medicine. Every improvement in its use, handling, and sourcing shapes the materials, drugs, and future innovations people depend on each day.

Understanding The Basics

Methyl 7-bromoheptanoate carries the chemical formula C8H15BrO2. After years dabbling in academic labs and handling routine analyses for pharmaceutical research, I’ve seen many folks hesitate at the sight of such a formula. Truth is, every letter and number tells a story, especially for chemists, pharmacists, and industry workers moving chemicals for synthesis or study. Breaking down this formula, you find eight carbons, fifteen hydrogens, one bromine, and two oxygen atoms. It forms an ester, and the bromine at the seventh carbon makes it quite useful for further modifications.

Real-World Chemistry: Why This Structure Is Useful

Organic chemists like clear cut access points for reactions. Bromine attached to the end of a heptanoate means modifying the molecule is straightforward. Think back to that college project where someone always struggled to get a reaction site just right—having a bromine one step away from the chain end can save weeks of trial and error. This saves time, money, and sometimes prevents a lot of lab frustration.

Esters also play big roles in pharmaceutical development. With this particular compound, a simple nucleophile can swap out bromine for a new group. Drug designers benefit by being able to tune molecules with ease, inching closer to better-tolerated and more effective treatments. Data backs it up—thousands of patent filings every year involve clever tweaks to side chains, usually right where this sort of functional group sits. Research journals point out how halogenated esters often serve as stepping stones to larger, more sophisticated molecules.

Health, Safety, and Environmental Concerns

No commentary is ever complete without watching out for the people who handle these compounds day in and day out. My earlier days on the lab floor taught me that spills and fumes are more than an inconvenience—they’re a risk. Methyl 7-bromoheptanoate can cause skin and respiratory irritation. Gloves and goggles become a necessity, not a suggestion. Looking at Material Safety Data Sheets, it’s clear this isn’t something to pour down the drain. Brominated compounds have a reputation for being persistent in the environment, with some causing long-term harm to aquatic life. I’ve always advocated for closed-loop disposal or return systems, especially for facilities handling halogenated organic compounds.

Availability and Future Paths

In my experience, the ease of synthesis drives a lot of research direction. Methyl 7-bromoheptanoate is made by reacting 7-bromoheptanoic acid with methanol under acidic conditions. Reagents aren’t exotic or out of reach for most standard labs. This convenience opens doors for students, small-company researchers, or independent innovators to put it to use without much red tape or special order delays.

As green chemistry standards gain traction, the community can look at replacing hazardous solvents or limiting halogenated waste at every stage. There’s a lot of talk about bio-based alternatives, but even incremental steps—such as solvent swaps and stricter process controls—count toward a safer, more responsible workflow.

Building on Solid Information

Clear communication about molecules like this supports accuracy in research and safety in the workplace. The more transparent we are about composition and chemical behavior, the easier it becomes to spot opportunities for improvement—whether in synthesis, safety, or downstream applications. The details in the formula C8H15BrO2 aren’t just numbers; they mean something tangible for everyone from the lab bench to the production floor.

Understanding the Risks

Handling chemicals in the lab never comes without real risks. Methyl 7-Bromoheptanoate fits this mold, carrying both health and environmental concerns. The compound can irritate the eyes, skin, and respiratory system. Sometimes a single splash sets off a nasty rash or burning sensation. Inhalation doesn’t help either, often leaving you with a sore throat or headache. During my own time working in a chemical research facility, improper glove use led to a colleague developing chemical burns from a similar brominated ester. That made the need for robust safety measures clearer than ever.

Personal Protective Equipment

Sensible gear forms your first line of defense. Protective eyewear, such as splash goggles, blocks out stray droplets. Nitrile or neoprene gloves offer solid resistance against methyl esters and brominated organics—they’re tougher than cheap latex pairs, which sometimes swell or break. Lab coats should snap or button up, shielding your skin and everyday clothes. Closed-toe shoes, not sandals or flats, protect your feet if a spill occurs. A lab once replaced open wastebaskets with bins fitted with vapor-tight lids because staff started feeling faint—this wasn’t paranoia, but a practical fix to real exposure.

Proper Ventilation and Storage

A decent fume hood stops vapors from escaping into shared air. Staff often overlook vent fans, thinking “It’s just a small run.” But it only takes a few minutes for a poorly ventilated bench to fill a room with harmful fumes. Containers need tight caps; I’ve watched a careless tech use improvised parafilm instead, only to return hours later to a sticky counter and a lingering burnt odor. Separate methyl 7-bromoheptanoate from acids and oxidizers on clearly labeled shelves. Flammable storage cabinets sorted by chemical compatibility help avoid dangerous mix-ups.

Personal Responsibility and Training

Reading a safety data sheet (SDS) can feel dull, but it offers clear instructions about hazards, first aid, and handling. I was taught early on to memorize sections on accidental release and exposure; these points stick with you during an emergency. A quick rinse in an eyewash station can cut permanent injury odds way down. Reporting spills straight away—rather than trying to cover things up—guarantees others don’t stumble into trouble.

Spill Response and Waste Disposal

Spill kits must remain stocked and within reach—absorbent pads, neutralizing powders, and sturdy containers for clean-up debris. The trick is not to improvise with paper towels or household cleaners. Dedicated bins for hazardous waste, firmly shut and labeled, keep used gloves and contaminated glassware from mingling with ordinary trash. According to the EPA, brominated compounds like methyl 7-bromoheptanoate can persist in soil, making responsible disposal crucial.

Potential Solutions and Continuous Improvement

Some labs switch to less hazardous alternatives whenever possible, which minimizes overall risk. Regular safety audits spot forgotten shortcuts and nudge old hands out of risky habits. Peer reminders and updated training keep everyone alert to evolving safety standards. Above all, respecting the chemical—never rushing, never skipping steps—keeps you safe for the long haul in a busy lab.

Straight Talk on a Serious Chemical

Methyl 7-Bromoheptanoate’s name alone sounds like something that belongs in a chemistry textbook, and those instincts are spot-on. This chemical isn’t a household product, but it shows up in plenty of labs and industrial settings. Nobody picks this up at a pharmacy or finds it in a supermarket aisle. Still, handling this stuff can lead to problems if the basics of safety and storage get ignored.

A Storage Job That Demands Real Care

From years working with lab chemicals, you see every shortcut people try. People toss containers on any empty shelf or squeeze bottles side by side, labels facing in all directions. This usually works when you’re talking about sugar or dish soap, but that habit sets you up for real trouble with methyl 7-bromoheptanoate. Its chemical properties demand a space that resists moisture. Damp air sneaks in, and strange things start happening with esters and halogen atoms. That’s why a tightly-sealed container — think glass with a proper cap or a specialty lab-grade bottle — turns from a suggestion into a rule.

Why Temperature and Light Make or Break Safety

Every chemist who learns the hard way knows the problems that come from piling chemicals by a window or beside a radiator. Methyl 7-bromoheptanoate doesn’t explode in sunlight, but heat and direct rays start to compromise purity, speed up breakdown, and occasionally make the fumes worse. For anyone who’s opened a bottle and caught a nasty whiff, you’ll recognize the value of keeping things below room temperature. A fridge built for chemicals earns its keep here, unlike a dorm fridge where lunch leaks and temperatures swing. Light-blocking containers help too, since less light means slower decomposition, fewer impurities, and a safer product.

Keep It Separate, Keep It Safe

Over the years I’ve seen labels smudged off by leaky bottles or stored next to things nobody checked twice. This chemical should always have a clear, durable label. Keep it away from bases and strong acids. In a crowded lab cabinet, a spill or container mix-up can mean skin burns or ruined research, and sometimes worse. Isolate methyl 7-bromoheptanoate on a dedicated shelf, away from incompatible reagents. Chemists don’t store tomatoes with bleach; this follows the same logic. Use secondary containment like a tray or bin, since even the best containers fail sometimes.

Ventilation and Real-World Precautions

You’ll hear stories about stuffy storerooms and headaches nobody explained. Those stories usually turn out to be about chemicals like this one, leaking fumes that build up overnight. I found out after the fact that a simple fan or exhaust system could have saved some misery for colleagues. A well-ventilated room makes a real difference. Glove and eye protection protect skin and eyes from surprises if a container cracks. Tough habits — wearing goggles, double-checking lids, tracking inventory — set apart the labs that avoid disaster from the ones always fighting minor crises.

Accountability and Clean Records

The most important part of chemical storage comes down to tracking who stored what, when, and how. Every sensible lab manager keeps a log of what comes in and goes out, especially with specialty chemicals. I’ve seen situations where weeks of work disappeared because nobody updated the inventory. Mistakes multiply in places where records sit on paper slips or vanish in someone’s email inbox. Electronic tracking or a simple, dated sheet by the storage cabinet helps to keep accidents from multiplying.

Empowering Safe Habits With Experience

Years of safe storage aren’t built on luck. Understanding a chemical’s quirks, using the right container, keeping things dry, keeping compounds cool, and making sure each bottle is properly labeled, all make a difference. Mistakes can sideline a project or send someone to the ER. The best storage plan is one built from practical knowledge, tough routines, and the confidence that comes from doing things the right way every time.

What It Means to Source Reliable Methyl 7-Bromoheptanoate

Methyl 7-bromoheptanoate surfaces in many research settings and manufacturing environments, especially among chemists aiming for precision. Quality here is more than just a lab specification — it affects yields, safety, and the outcome of much bigger processes. From anyone who’s spent time on a project only to find impurities stalling the results, there’s a deep respect for careful sourcing and strong supplier credentials.

Grade Isn’t Just a Label

The marketplace sets most chemical standards using “grades.” Usually, buyers encounter terms like “analytical grade,” “reagent grade,” and “technical grade.” Analytical grade stands out as the cleanest, meant for high-stakes applications where contaminants can throw off everything from NMR readings to synthesis yields. For methyl 7-bromoheptanoate, analytical or reagent grade material usually tests above 97% purity. The difference between a bottle labeled 95% and another showing 99% can change how a process plays out, especially in pharmaceutical development or high-tech material synthesis.

Reagent grade often follows behind, rarely dropping below 95% purity, and suits general laboratory work. Technical grade tends to land lower, sometimes closer to 90%, and might show up in non-critical applications or early-stage R&D. Knowing the difference matters; once, working with an intermediate in small-scale hydrogenation, a technical-grade batch introduced inconsistency that wasted hours of trouble-shooting. After switching to a higher-purity source, the reaction ran cleanly, as expected.

Certificates and Reality in Purity Claims

Trust but verify — that old standard has real value here. Manufacturers usually issue a Certificate of Analysis (COA) with each lot, showing purity, assay method, and sometimes detailed impurity profiles. This paperwork can flag whether the compound meets advertised specs or falls short. Two suppliers might claim 98% on the label, but side-by-side, differences in water content or presence of related esters can sway results. Having access to the raw COA helps researchers confirm that what gets delivered matches internal requirements. Even today, I call for a COA before any purchase for sensitive work, and comparing those numbers saves both headaches and budget.

Global Supply and Regulatory Differences

Not every country holds chemical suppliers to the same bar. In the US, European Union, or Japan, suppliers face stricter quality demands due to both regulatory oversight and market reputation. In some other regions, standards drift or lack proper checks, putting more weight on a lab’s screening and in-house analytics. Testing a new supplier’s methyl 7-bromoheptanoate against a known standard underlines those gaps; FTIR, GC-MS, or HPLC methods can work for confirming purity. For work funded by grants or regulated for human or environmental safety, this level of scrutiny isn’t optional.

What Can Improve Confidence?

Supply chains for specialty reagents can move quickly, but transparency drives trust. Suppliers publishing not only up-to-date COAs but details of their synthesis routes, batch consistency, and stability data set themselves apart. For buyers, sourcing from established vendors, reading through third-party reviews, and running small-scale test lots before full commitment reduce surprises. If problems or impurities show up, quick feedback loops with sales and QC teams cut downtime.

The bigger point stands: in research or production, choosing the right grade isn’t just a detail. It shapes whether the next steps move forward smoothly or get bogged down by the unexpected. A little extra diligence upfront can turn frustration into repeatable, trustworthy outcomes.