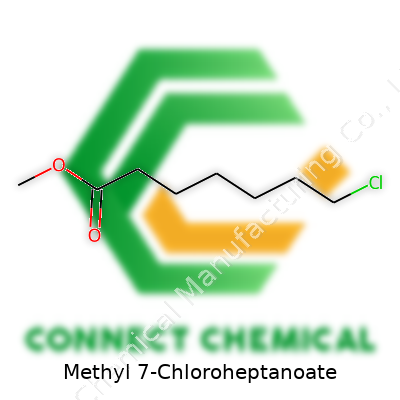

Methyl 7-Chloroheptanoate: Exploring a Versatile Chemical Compound

Historical Development

Back in the mid-20th century, chemists began to take a serious look at aliphatic esters for use in both industrial and pharmaceutical applications. Research labs wanted to understand how tweaking the carbon chain or playing around with halogen substitutions would affect the performance of esters. The emergence of Methyl 7-Chloroheptanoate fit into this era of experimentation. Early references in scientific literature pinpoint its creation as a targeted effort to combine the reactivity of methyl esters with the unique properties that a chlorine atom brings to a molecular backbone. Over time, the science community saw this compound step into more focused research, especially as the chemical industry expanded into new synthesis routes and more sophisticated functional derivatives.

Product Overview

Methyl 7-Chloroheptanoate finds use thanks to both its manageable structure and its ability to serve as a building block. The ester group at one end gives chemists plenty of options for modification, while the seven-carbon chain supplies enough molecular heft for it to hold value in a variety of organic transformations. The key twist here is the seven-carbon length, rare enough to solve certain problems that shorter or much longer chains can’t. The presence of chlorine on the seventh carbon alters the reactivity and unlocks possibilities for downstream transformations, so you often see it in exploratory syntheses or as an intermediate for other specialty compounds.

Physical & Chemical Properties

On the bench, this compound shows up as a colorless to slightly yellow liquid. Its molecular weight comes in at 194.67 g/mol, which gives it just enough size to handle while still keeping it easily dispensed with common pipettes. It carries a boiling point in the range of 110°C to 115°C at reduced pressure. Its density hovers around 1.05 g/cm³. One key point for handling: it brings a slight but characteristic ester odor, a reminder of its underlying structure. The molecule stays stable under ordinary storage conditions but doesn’t like strong bases, strong acids, or exposures to open flames. That chlorine atom impacts both polarity and its reactivity toward nucleophilic substitution reactions.

Technical Specifications & Labeling

Manufacturers supply Methyl 7-Chloroheptanoate to laboratory and industrial customers in purity grades suited for synthesis—often above 98%. A batch run will always include a certificate of analysis, listing GC purity, residual solvents, moisture content, and chemical identity matched by NMR and IR spectroscopy. Each container gets labeled with its chemical name, required hazard pictograms, batch number, net weight, and supplier contact information. UN classification and hazard statements, such as “Causes skin and eye irritation,” appear where required by local and international regulations.

Preparation Method

Labs typically prepare this molecule via esterification. Starting with 7-chloroheptanoic acid, technicians combine it with methanol in the presence of acidic catalysts like sulfuric acid or p-toluenesulfonic acid. Slow distillation or water-trap techniques remove water and drive the reaction forward. The reaction mixture then cools before workers wash it with sodium bicarbonate, dry it over anhydrous magnesium sulfate, and separate the organic phase. A final distillation step under reduced pressure purifies the ester. Sometimes, alternative routes begin with the chlorination of heptanoic acid or its derivatives, achieving substitution at the terminal carbon before moving into the esterification stage.

Chemical Reactions & Modifications

Methyl 7-Chloroheptanoate acts as a handy substrate for several transformations. Researchers often subject it to nucleophilic substitution: the chlorine atom allows swaps for nitrogen, oxygen, or sulfur-based nucleophiles, leading to compounds that serve as pre-cursors for further pharmaceutical or agrochemical development. The ester group itself can hydrolyze under acidic or basic conditions, giving the corresponding acid. Hydrogenation over catalysts can remove the halogen, leading to the parent methyl heptanoate, while reduction can convert the ester to an alcohol. Chemists frequently use this ester as a starting point for making amides or for ring-closing reactions when aiming to create macrocycles in medicinal chemistry.

Synonyms & Product Names

This compound shows up in catalogs and research literature under a few other designations besides Methyl 7-Chloroheptanoate. Some sources use the title “Heptanoic acid, 7-chloro-, methyl ester.” You may also see synonyms like “Methyl 7-chloro-n-heptanoate” or “Methyl 7-chloroheptanoate (CAS: 63187-42-8),” though the CAS number helps chemists quickly identify the exact structure worldwide. Specialty chemical companies sometimes market it under proprietary names, especially if it’s produced at large scale for a set of recurring buyers.

Safety & Operational Standards

Anyone handling Methyl 7-Chloroheptanoate walks into familiar territory for halogenated esters. The compound can irritate the skin, eyes, and respiratory tract, so basic lab gear—gloves, goggles, lab coat—is essential. Work carried out inside a functional fume hood leaves little risk of inhalation. Storage in amber-glass bottles, away from open flames or oxidizers, preserves both the quality and safety profile of the product. Disposal flows into the regulated waste stream, and facility standards dictate spill response and emergency containment practices that stem from the general protocols for organochlorine compounds. In the event of a spill, standard procedures like absorbing with inert material and ventilating the area come into play.

Application Area

The value of Methyl 7-Chloroheptanoate comes from its flexibility in synthesis. Medicinal chemists often use it as a starting material to access more complex molecules, sometimes finding a fit for derivatives in early-stage drug research. The chlorine handle allows further functionalization, such as linking with azides or amines, sparking broader investigations in experimental pharmacology. Agrochemical developers use this compound as a stepping stone for herbicide design, particularly when aiming for molecules that require both lipophilic character and a reactive halogen. Polymer researchers sometimes introduce this ester to modify backbones or side chains, tuning properties without overwhelming the system with polar groups or excessive steric hindrance.

Research & Development

Over the last decade, the spotlight has swung onto halogenated esters like this one as interest grows in “lead hopping” for drug discovery. Methyl 7-Chloroheptanoate sometimes features in structure-activity relationship studies where researchers adjust chain length or halogen position to tweak biological activity. In university labs, students practice nucleophilic substitution or ester hydrolysis using this compound, gaining firsthand experience with classic organic mechanisms. Patent filings show that novel derivatives built from this starting point hit the market every year, often aimed at therapies in inflammation, pain, or metabolic disease. Some research teams evaluate modifications to reduce environmental impact, seeking “green” methods for both the manufacture and downstream use of these halogenated esters.

Toxicity Research

Questions about toxicity drive much of the regulatory landscape for organochlorines. Standard studies on Methyl 7-Chloroheptanoate look at skin, eye, and inhalation effects using both cell-based and animal models. Acute exposures cause irritation at levels above those used in routine handling, but studies generally rank this ester as less hazardous compared to aromatic or polyhalogenated cousins. Long-term data remain limited, largely because most users work with it in strict laboratory settings under controlled conditions. Environmental persistence emerges as a concern, though degradation under sunlight and oxygen proceeds at a modest rate. Chemists interested in product stewardship keep pushing for data on chronic and aquatic toxicity, aiming to close gaps before wider-scale industrial use.

Future Prospects

The story of Methyl 7-Chloroheptanoate stretches on as laboratories look for new reaction strategies and pharmaceuticals designers keep reshaping small molecules to match emerging targets. Advances in continuous flow chemistry promise safer and more scalable approaches to its manufacture. Scientists keep exploring catalytic systems that swap out traditional acids for more selective, less hazardous catalysts. The move toward “greener” chemistry continually pushes the search for alternative halogen sources and bio-based starting materials, offering the possibility of sustainable production routes in coming years. At the interface between chemistry and biology, new analytical technologies speed up the screening process for derivatives, letting research teams close discovery loops faster than ever before. Those in the field stay watchful over potential regulatory changes, with anticipation for data-driven shifts that balance innovation with environmental and workplace safety.

Stepping Into the World of Chemical Building Blocks

Methyl 7-chloroheptanoate doesn’t pop up in grocery stores or pharmacies. It belongs to a group of specialty chemicals. These compounds play a bigger role than many realize. Chemists rely on methyl 7-chloroheptanoate as a building block for more complex molecules. Once you learn where it fits in, its value becomes clear.

Why This Chemical Gets Attention

In my experience, synthetic chemistry often feels like solving a puzzle where each piece needs to fit just right. Methyl 7-chloroheptanoate works as one such piece. Its main draw comes from its structure: a seven-carbon chain, a chlorine atom tucked near one end, and an ester group on the other. This unique setup lets it act as a versatile intermediate. Pharmaceutical research teams pay attention to molecules like this because they can transform it into a wide range of other chemicals. Think of it as a springboard.

If you’ve ever depended on modern medicine, there’s a fair chance small intermediates—like methyl 7-chloroheptanoate—showed up somewhere in the production line. Drug makers use these kinds of molecules to assemble antibiotics, antiviral treatments, and medications for chronic illnesses. The exact transformation steps stay closely guarded by each company, but the principle stays the same: start simple, then build complexity.

Beyond Pills: Where Else It Turns Up

Manufacturers see value beyond the lab bench. Methyl 7-chloroheptanoate finds its way into the synthesis of certain agricultural chemicals too. Pest-resistant crops and effective weed treatments stem from research into chlorine-containing intermediates. Protecting the food chain involves many steps, starting from chemical research and trickling all the way to the farm.

Specialty polymers sometimes arise from similar starting points. Not every plastic gets made the same way. Companies that want to introduce specific performance traits—like flexibility, adhesion, or chemical resistance—often play with intermediates that look a lot like methyl 7-chloroheptanoate.

Safety, Ethics, and Responsible Use

Working with tailored building blocks means safety becomes critical. Chlorinated compounds don’t always behave gently with living things or the environment. Chemists receive plenty of training to use gloves, goggles, and fume hoods. The right practices matter. Poor disposal or careless handling exaggerate risks. At the same time, using substances like methyl 7-chloroheptanoate remains key for innovation. Regulatory guidelines keep these efforts in check.

It's easy to lose track of where the chain begins when medicines and better materials arrive at our doors ready to use. Insight comes from following their story back to the molecules that made them possible. The bigger conversation involves keeping chemical progress balanced with environmental responsibility. Tighter monitoring, safer alternatives, and green chemistry keep improving industrial processes.

Looking Forward

Scientists keep searching for smarter ways to build molecules, lower costs, and lower hazards. Training new chemists to think both as problem solvers and stewards of safety makes progress possible. As for methyl 7-chloroheptanoate, its quiet presence in the lab fuels much of the invisible work that supports health, agriculture, and materials every day.

Understanding the Structure

Methyl 7-chloroheptanoate isn’t some exotic compound found in warehouses brimming with scientific oddities. Chemists come across it for good reason—it provides a handy shortcut for synthesizing more complex molecules. Looking at the name tells a clear story: it is a methyl ester derivative of 7-chloroheptanoic acid. The "hepta-" signals a seven-carbon chain. Plug in a methyl group on the carboxyl, throw in a chlorine atom at the seventh position, and there it stands.

This gives the molecular formula: C8H15ClO2.

Molecular Weight: The Practical Side

Now, the molecular weight means more than just a number for the paperwork. We calculate it by adding up the atomic weights: eight carbons (8 x 12.01), fifteen hydrogens (15 x 1.008), one chlorine (35.45), and two oxygens (2 x 16.00). The calculation lands at 178.66 g/mol. There is no substitute for accuracy in formulation or synthesis. If a gram off shows up in a medicinal batch, results go sideways. That's why research and manufacturing folks check and double-check the figures.

Why These Numbers Matter

Every time a scientist prepares a reaction, the formula and weight steer the entire process. With the wrong molecular weight, measurements fall short or go overboard, ruining outcomes or leading to waste. Cost aside, there’s safety on the line as well. Chemical reactions involve energy, and nothing derails a day like an unpredictable result because someone guessed the mass or didn’t check the starting material’s structure.

My own experience in chemical labs drilled this in early. I’ve seen batches ruined from wrong stoichiometry because a supplier swapped two compounds with almost identical names. Only later did someone flag the mismatch—those extra hydrogens and incorrect weights made a mess. Chemistry isn’t forgiving about shortcuts here.

Quality, Purity, and Reliable Data

A simple formula supports the supply chain. Manufacturers rely on tested data so every drum or vial arrives as promised. Researchers trust that formula when building out new pathways or scaling up. Regulators request proof, and so do procurement officers. Any deviation brings more paperwork, slower timelines, and riskier product development.

Chemists and technical writers hold a professional duty to document formula and mass precisely. These values end up in patents, regulatory filings, safety sheets, and the daily grind of mixing and testing. Skipping steps or relying on uncertain data invites error, waste, or worse—danger in the workplace.

Best Practices and Solutions

Companies and labs avoid these problems by sourcing from certified suppliers, checking every batch with analytical methods like NMR or mass spectrometry, and training staff to double-check references. Open access databases and publications help, but internal verification—the old-fashioned elements-and-atoms sum—protects against simple mistakes. Consistently cross-referencing numbers in publications with experimental values improves reliability across the board.

In chemical work, cleaner data and clear communication win the day. Accurate molecular formulas and weights form the backbone of safe, effective, and efficient results—whether you’re in research, manufacturing, or teaching.

Understanding What’s At Stake

Methyl 7-chloroheptanoate serves as a building block in the world of organic chemistry, especially when research or pharmaceutical synthesis calls for unique structures. A lot of folks might not think twice about the shelf where they keep their chemicals, but skipping over storage details only invites problems later. I've seen more than one research project slow to a crawl because someone decided to store their bottle of methyl 7-chloroheptanoate in a humid closet next to an open window.

This compound isn’t wildly exotic, but that doesn’t make it forgiving. It’s a colorless to a pale-yellow liquid, known for a mild odor that lingers in the air. Like many esters and halogenated chains, the chemical breaks down or corrodes equipment if left in the wrong spot. That’s not just a concern for your glassware; mishandling poses health risks you don’t want to deal with at the end of a long day.

Humidity, Heat, and Light: Enemies of Stability

Room temperature doesn’t always mean a laboratory is safe. Most sources, from chemical suppliers to safety data sheets, agree: dry, cool, and dark — these are the top priorities. I keep methyl 7-chloroheptanoate in sealed glass bottles, away from the window, and never above 25°C. High temperatures accelerate hydrolysis and can kick off slow decomposition, producing hazardous fumes nobody wants in the air.

Sunlight isn’t a friend, either. Any sustained UV exposure breaks down the compound faster than you’d expect. I’ve heard stories of researchers noticing a darkening color after just a week of sunlight in clear bottles. In those cases, the chemical’s purity tanks, and reliable results fly out the window.

Humidity sneaks in and reacts with many organics, especially esters like methyl 7-chloroheptanoate. That spells hydrolysis — your precious building block starts turning into acid and alcohol. The equipment starts to corrode. Unexpected by-products start showing up in your work, and now you’re left scrubbing glassware or explaining to your boss why your yields are unpredictable.

Practical Tips for Every Lab

Label every container with clear handling instructions and dates. Too many accidents start with a faded label or something scrawled with a sharpie. If the original packaging seems flimsy, transfer into amber glass with airtight seals. Desiccators are a bonus, not just for powders. Even liquids like methyl 7-chloroheptanoate benefit from low-moisture environments.

Secure storage isn’t just about product quality; it's about health. Direct contact brings risks like skin dryness, irritation, or worse, given the chloro group. Always handle it in a ventilated area and store away from oxidizers and acids, as mixing these can create unforeseen hazards.

Disposal also matters. Don’t pour extra down the drain or toss it out with everyday lab debris. Hazardous waste containers and regular pickup schedules reduce both environmental harm and headaches with regulatory bodies.

Room for Improvement

Automated monitoring saves time. Digital thermometers with alerts keep long-term storage from drifting above safe limits. Dedicated chemical management systems track expiration dates, so nobody ends up using degraded stock. Proper training and a touch of daily vigilance protect both research outcomes and the well-being of those working behind the scenes.

Understanding the Hazard Profile

Methyl 7-chloroheptanoate isn’t splashed across news headlines, but take a look beyond the lab shelf and there’s a story to tell. Anyone who spends time in a laboratory, whether as a chemist, technician, or student, recognizes the pattern: an unfamiliar bottle with a long chemical name, an even longer data sheet, and an undercurrent of uncertainty about what happens if you spill, breathe in, or touch what’s inside.

This compound often shows up in the early stages of organic synthesis or pharmaceutical work. Structurally, it balances between an ester and a halogenated fatty acid derivative. That might look innocent. Don’t let that fool you. Chlorinated hydrocarbons sometimes bring risks tied to toxicity, environmental persistence, or challenges with storage.

Where Experience Meets Safety

I remember the first time handling a methyl ester with a halogen attached. Protocol demanded gloves and goggles, and the old lab coordinator’s voice echoed in my head: “Don’t guess with unknowns—assume they bite.” Years later, I’ve seen that bit of wisdom save hands, lungs, and careers. Methyl 7-chloroheptanoate doesn’t read as a high-risk chemical in every manual, but skin and eye contact still prompt irritation. Accidental inhalation? That can leave you hacking or worse.

Chemicals in this category occasionally hide their punch. They might not corrode metal or ignite spontaneously, but metabolic effects in humans and animals often stay under the radar. Chlorinated organics have sometimes shown delayed toxicity or unexpected effects, especially if handled often or improperly.

Facts You Won’t Find Buried in Data Sheets

A closer look at safety documents for compounds like methyl 7-chloroheptanoate highlights a few red flags:

- Skin and respiratory irritation shows up in most summaries, even if acute toxicity scores seem modest.

- Chlorinated esters, in general, can release noxious fumes if burned or strongly heated. That’s reason enough to work under a fume hood.

- Absorption through the skin isn’t out of the question, especially if you’re in contact for extended periods or skip gloves.

I’ve watched seasoned chemists skip the “boring” risk step, only to regret it after headaches, skin redness, or worse. It’s better to set that standard yourself—gloves, goggles, proper ventilation. Don’t let casual handling become routine because so far, nothing happened.

Potential Solutions and Smarter Approaches

Every workplace can tighten safety standards without turning staff into anxious wrecks. Practical steps work better than scare tactics—clear labels, up-to-date safety data, and reminders about the simple trio: personal protective equipment, fume hood use, and spill protocols. Expecting a full risk review for every obscure ester isn’t realistic, but a culture that encourages questions and reports near-misses brings results.

Disposal shouldn’t slip through the cracks either. Chlorinated organics, including methyl 7-chloroheptanoate, call for collection as hazardous waste. Pouring down the drain isn’t just laziness; it invites environmental harm or regulatory headaches.

Schools and smaller labs sometimes cut corners by necessity, but sharing access to safety resources—whether that means up-to-date inventory lists, shared spill kits, or even just a well-maintained eyewash station—means a cleaner record and healthier staff.

Treat methyl 7-chloroheptanoate with respect. As experience and more data pile up, you may find new reasons to up your standards. Until then, gloves, goggles, and an ounce of caution always cost less than a trip to the emergency room.

A Look at Purity Standards

Methyl 7-Chloroheptanoate draws the attention of chemists for its unique role in fine-chemical synthesis and pharmaceutical research. In practice, buyers and users expect a purity above 98%. This benchmark supports downstream applications and gives consistent, reliable results during chemical reactions. Higher purity limits the interference from contaminants, which could alter reaction yields or introduce unwanted byproducts. For specialty chemicals like this ester, even a few percentage points of impurity can throw off analytical results and the quality of end products.

The certification of purity usually relies on gas chromatography with mass spectrometry (GC-MS) or nuclear magnetic resonance (NMR). Manufacturers often share detailed spectra so users aren’t guessing what’s in the drum or bottle. Labs and companies tend to source only from suppliers who publish transparent batch test results. That trust is earned, since any deviation—whether leftover solvents or unconverted starting materials—leads to unnecessary troubleshooting or safety concerns.

Visual Clues: What the Compound Really Looks Like

Methyl 7-Chloroheptanoate doesn’t stand out visually, but those familiar with esters can recall its clear, colorless to pale-yellow liquid appearance. Room temperature keeps it fluid, similar to vegetable oil, with no tendency to crystallize under regular lab conditions. Some might catch a faintly sweet or fruity odor, though not all batches smell the same due to trace impurities.

Yellowing or cloudiness points to either hydrolysis or oxidation. Exposure to air, heat, or contaminated glassware can accelerate decomposition, leading to the slow formation of acids or alcohols. Chemists are quick to spot changes; that pale color growing darker signals that the compound lost its edge, possibly affecting reactivity. It’s a small but reliable detail for those who spend time with organic syntheses daily.

Quality Control Challenges

Everyone in the supply chain fights to keep compounds within spec. Impurities often sneak in from incomplete synthesis or careless storage. Sometimes, the shipping method—plastic drum versus glass bottle—has an impact. Fill lines and packaging material can leach unwanted compounds, especially in large-scale operations.

Routine QC checks go beyond paperwork. In hands-on labs, technicians might run a quick thin-layer chromatography or sniff for the telltale ester aroma, adding an informal layer of quality control before committing a reagent to a big reaction. If something’s off, even a minor tint or odd smell, production halts until questions are answered. While regulators have their guidelines, those on the ground know that small warning signs save time and money.

Better Practices, Fewer Surprises

Many supply headaches disappear by locking down airtight storage and following strict batch documentation. Controlled temperatures and limiting light exposure keep the ester stable longer. Some labs track arrival dates and monitor compounds as they age, pulling suspect inventory before they end up in a research flask. Simple steps like purging bottles with inert gas or double-sealing can slow down hydrolysis, especially in humid climates.

Direct communication with trusted suppliers solves most sourcing issues. Labs that ask about every lot’s history—how it was shipped, who handled it, how long it sat—get better results and fewer recalls. By prioritizing transparency and active observation, users of methyl 7-chloroheptanoate maintain consistency, boost safety, and cut down on endless troubleshooting. That experience—being able to spot small changes and take action—beats any blanket standard.