Ethyl 8-Chlorooctanoate: A Commentary on the Substance in Research and Industry

Historical Development

Ethyl 8-Chlorooctanoate carries a backstory rooted in the ongoing race to build new molecules for both industry and science. Chemists started tweaking fatty acid esters, like ethyl octanoate, many decades ago: they searched for ways to enhance chemical stability or tweak reactivity, and one approach involved simple halogenation. Adding a chlorine atom to the eighth carbon in octanoic acid didn’t happen overnight. Improvements in organic synthesis opened the door for more efficient and selective chlorination, so specialty labs could produce this compound with better yields and purity. Demand didn’t just spring from curiosity—it followed the growing recognition that halogenated esters offered new functionalities, both as building blocks and as agents in more complex chemical syntheses.

Product Overview

Ethyl 8-Chlorooctanoate stands out among straight-chain fatty acid esters because its single chlorine atom transforms the behavior of the molecule. Handling a product like this, I’ve noticed a subtle shift in aroma—a faint, sharp edge replaces the oily, fruity odors that come from pure ethyl octanoate. In small-batch labs, the substance often arrives as a clear, sometimes slightly yellow liquid, highlighting the importance of storage and purity control. Stakeholders look for tight control over the chlorine content and minimal impurities due to the compound’s tailored uses.

Physical & Chemical Properties

One can spot ethyl 8-chlorooctanoate as a clear, viscous liquid at room temperature. Its boiling point often climbs above 220°C, and its modest solubility in water means it prefers organic solvents like diethyl ether or dichloromethane. The presence of that one chlorine atom brings about a heightened density and a lower volatility than unchlorinated versions. On the chemical front, the ester bond remains susceptible to hydrolysis, especially under acidic or basic conditions, and the chlorine atom at the eighth carbon draws in nucleophiles, narrowing the range of direct transformations but allowing for some useful downstream substitution or elimination reactions.

Technical Specifications & Labeling

Labeling regulations demand a full accounting of identity, purity, and potential contaminants, so suppliers provide CAS registry numbers, molecular weights, formulas, and hazard statements. During my own time in a research setting, I came to rely on these labels: they cut down uncertainty and help with regulatory compliance. Product data sheets usually specify a purity threshold above 97%, and labs often receive containers with clear warning labels about irritancy and flammability, reflecting evolving safety culture in both academia and manufacturing. SDS documents, accessible to all handlers, also include first aid advice and handling instructions.

Preparation Method

Laboratories produce ethyl 8-chlorooctanoate using an established series of steps. Most syntheses kick off with octanoic acid, which goes through esterification with ethanol under acidic conditions to create ethyl octanoate. A direct chlorination then targets the eighth carbon, with careful temperature and catalyst management to avoid unwanted byproducts. The real challenge comes from achieving regioselectivity to ensure the chlorine lands exactly where it’s needed on the carbon chain. Modern routes employ N-chlorosuccinimide or even phosphorus trichloride to keep conditions mild and yields high, reducing waste and minimizing byproduct management headaches.

Chemical Reactions & Modifications

Once synthesized, the molecule’s utility turns on its chemical reactivity. The chloro group serves as an access point for further elaboration: nucleophiles swap in for the chlorine, opening up routes to amines, thiols, or even azides. Researchers often favor these transformations to create analogs for pharmacological evaluation or surfactant development. The ester group remains vulnerable to both enzymatic and chemical hydrolysis, so storage and use require vigilance: any exposure to water, especially at high or low pH, puts the product at risk of breaking down.

Synonyms & Product Names

Ethyl 8-chlorooctanoate sometimes appears in the literature under similar names, such as 8-chloro-caprylic acid ethyl ester or ethyl monoclorooctanoate. Suppliers will occasionally use catalog product codes, adding to the tangle of names, but the chemical structure—a straight eight-carbon chain with a chlorine atom at the eighth position—anchors its identity. I’ve learned over time that double-checking synonyms and registry codes rescues one from costly ordering mistakes.

Safety & Operational Standards

Handling ethyl 8-chlorooctanoate calls for vigilance, not only due to its own low acute toxicity, but also because esters like this can irritate skin and eyes. Working in a synthesis lab, I wore gloves and goggles religiously when moving this compound between reactors or storage jars. Engineering controls, like fume hoods and spill kits, matter just as much as the right PPE. Emergency procedures and labeling reinforce a safety-first mindset. Storage calls for cool temperatures, with strong ventilation to curb build-up of any vapors, and clearly marked, tightly sealed containers to prevent both evaporation and moisture ingress.

Application Area

Chemists turn to this molecule mainly as an intermediate in the quest to build more complex materials. Sectors such as agrochemicals, functional polymers, and even pharmaceuticals take advantage of the unique reactivity introduced by the chloro group. In research, the compound’s selective reactivity means it often finds its way into the custom synthesis of surfactants or specific drug candidates, where subtle shifts on a molecular level can drive big changes in biological activity or material properties. For specialty chemical producers, it’s a valuable step along routes to longer chains or branched derivatives, especially when aiming for products that pack both hydrophobic and slight polar tweaks.

Research & Development

Academic and industrial labs alike push the envelope on using halogenated fatty acid esters, seeking new paths for functional group interconversion. I’ve seen graduate students experiment with transition-metal catalysis and enzymatic methods, looking to improve yields or create less waste. Process improvements in flow chemistry and microwave-assisted synthesis mean that what was once a niche product can now be made faster and cleaner, feeding into smart, automated platforms. Across the board, the race is on for more sustainable and scalable chlorination methods.

Toxicity Research

Toxicologists evaluate these compounds mainly for their acute and chronic impacts. Animal studies suggest limited bioaccumulation, but caution remains—the chloro group can raise persistence in the environment and may impact aquatic organisms. During my years spent reviewing MSDS documents and risk evaluations, I learned to respect these warnings and factor them into disposal plans. Regulatory scrutiny remains steady, especially as the push for greener and less persistent chemicals grows across the globe, driven by evolving REACH and EPA guidelines.

Future Prospects

Demand for halogenated esters links closely to the evolution of specialty chemicals and next-generation materials. As precision medicine, tailor-made surfactants, and smart polymers gain ground, unique intermediates like ethyl 8-chlorooctanoate come under sharper focus. Researchers crave substances that can serve as both reactive platforms and selective modification agents. With green chemistry methods marching forward, future production may lean more toward biocatalysis or electrochemical chlorination, reducing both carbon footprints and hazardous byproducts. The market rewards versatility, so any tweaks that make these compounds more controllable or less toxic could unlock new applications from drug delivery to precision agrochemicals.

What Makes This Chemical Interesting?

Ethyl 8-chlorooctanoate often flies under the radar, yet the reach of this compound extends further than most might expect. I once worked at a midsize research facility where niche chemicals like this arrived in unassuming brown bottles. Lab techs and project leads paid close attention to both quality and sourcing—mistakes wasted not only resources but time we couldn’t afford to lose. The compound’s unique structure, marked by that chlorinated octanoate backbone, drew some curious looks from the chemists on my team. They saw more than data sheets; they saw potential routes and reactions, each application offering a new challenge.

Real Work in Fragrance and Flavor Creation

Fragrance and flavor industries often turn to specialty esters to add complexity and depth. Ethyl 8-chlorooctanoate serves as a building block or a blending component for perfumes and food additives. Manufacturers don’t just seek an “ingredient”—they look for consistency, safety, and traceability. Attention gets paid to purity grades and storage conditions. Any unexpected impurity alters the profile of the finished product, forcing reformulations. When used right, this molecule helps develop fruity or green notes for fragrance blends, lending a crisp freshness that can't be mimicked by simpler esters. The compound also sees some use in synthesizing intermediates required for these industries, particularly in processes that target unique aromatic effects.

Role in Organic Synthesis

Sitting down in a university lab, as I did during my earlier years, students and instructors utilize ethyl 8-chlorooctanoate as a substrate or starting material in research projects. The compound opens the door to a range of chemical transformations. Chemists rely on its stability and predictable reactivity, using its structure for chain elongation or introducing new functional groups. It’s far from just a text-book example; it provides a springboard to more elaborate molecules, sometimes even bioactive candidates. That sort of flexibility matters, especially for teams on tight grant deadlines. If a reaction goes sideways, the students quickly learn—good planning and an understanding of the underlying chemistry prove more valuable than fancy equipment.

Safety, Sourcing, and Regulation

Every time I handled ethyl 8-chlorooctanoate, gloves and goggles came out. Companies and labs must document every handoff and keep proper storage methods. Regulatory agencies demand thorough risk assessments, tracking this chemical from purchase through disposal. Nothing about its usage gets left to chance. Compliance not only prevents legal trouble—it also protects health and upholds product integrity. After a minor spill in our research lab, the safety officer drilled into us the importance of incident logs and swift containment. Lessons like that stick.

Troubleshooting and Looking Ahead

Access to specialty chemicals like this can create hurdles, especially for smaller organizations. Quality fluctuates between suppliers. Not all regions have streamlined shipping, lengthening lead times. Teams need to verify every batch before use and maintain open communication with trusted vendors. Budget constraints force tough choices. Scaling up, especially for commercial fragrance production, becomes a logistical puzzle—a dance between costs, timelines, purity levels, and regulatory paperwork. The rise of green chemistry principles hints at new methods ahead; some companies experiment with renewable resources and greener synthesis routes, shaping an industry that feels both responsible and innovative.

Building Trust and Value

Consumers rarely see what goes on behind closed doors—the certificates of analysis, the rigor of supplier audits, or the troubleshooting that unfolds when recipes change slightly. My own routine involved more emails with regulatory teams than I'd ever imagined starting out as a chemist. Integrity matters. Reputable suppliers must prove their worth through transparency and consistency, not just marketing promises. End products reflect every choice made along the supply chain, translating to real trust among buyers and brand loyalty that can’t be faked.

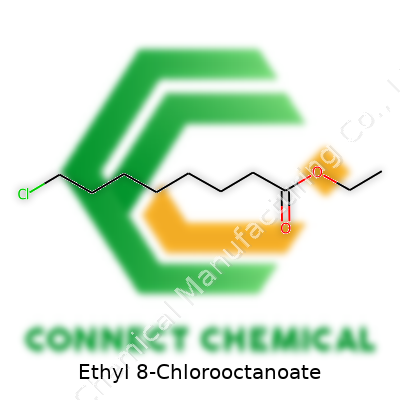

Understanding the Structure: What’s in a Name?

Ethyl 8-chlorooctanoate sounds complex, but with a little chemistry know-how, its formula starts to break down to something familiar. The heart of the molecule is octanoic acid, a fatty acid with an eight-carbon backbone. Take off the hydrogen from its carboxylic acid group, swap in an ethyl group (—CH2CH3), and then toss a chlorine atom onto the eighth carbon of that chain. Now, the formula becomes clear: C10H19ClO2.

How Does Molecular Weight Stack Up?

Digging into molecular weight, each atom needs some calculating. Carbon brings about 12.01 g/mol, hydrogen at 1.01 g/mol, chlorine at 35.45 g/mol, and oxygen weighs in at 16.00 g/mol. Put these together:

- 10 carbons: 10 × 12.01 = 120.10 g/mol

- 19 hydrogens: 19 × 1.01 = 19.19 g/mol

- One chlorine: 35.45 g/mol

- Two oxygens: 2 × 16.00 = 32.00 g/mol

Total it up and Ethyl 8-chlorooctanoate checks in at roughly 206.74 g/mol. In lab work, that’s a number folks rely on for everything from precise mixes to inventory.

Why Details Like Formula and Weight Matter

Back during my research years, small details—like a single misplaced number or missing atom—often shifted experiments in the wrong direction. That number, 206.74, isn’t just a stat; a miscalculation means the difference between a clean reaction and gunky glassware. Sticky messes not only frustrate progress, but they also waste time and resources.

Consider anyone crafting custom molecules for a new drug or a scent. These numbers guide them from paper to beaker. The molecular weight shows how much goes on the scale, and the formula lets chemists double-check that every part is in place. In the era of data, these aren’t dry numbers—they’re the language of trust between researchers, suppliers, regulatory bodies, and consumers.

Safety and Handling Insights

Chlorinated compounds bring unique chemistry, including reactivity and concerns over toxicity. The presence of a chlorine atom affects how the molecule interacts with living systems and environments. In most labs, extra steps get taken for storage, ventilation, and waste disposal when chlorine’s on a molecule. Mixing mistakes or wrong weights can mean real risks.

I’ve seen teams cut corners, skipping careful weighing or not double-checking the molecular formula. Quick work saved no time in the end—errors triggered repeat runs, accidental exposures, or disposal issues. Paying attention to these details avoids headaches and upholds everyone’s safety.

Spotting Solutions for Accuracy and Transparency

Fact-checking every new shipment, batch, or published recipe protects everyone. Digital databases, open sharing of lab data, and frequent training on molecular formula basics all play a part. As scientists move fast toward automation, these simple chemical facts provide the foundation. An accurate formula and solid understanding of weight give scientists confidence to innovate, troubleshoot, and protect health.

Careful work doesn’t stifle discovery—it powers the next leap forward, one formula at a time.

Ethyl 8-Chlorooctanoate plays a role in chemical synthesis you can’t really ignore, spanning everything from research labs to industrial manufacturing. Keeping this compound stable doesn’t just protect an investment—it keeps people safe and ensures reliable results. It’s easy to overlook storage details until something goes wrong, so handling this particular ester offers a real lesson in everyday lab discipline. People like to think storage is simple, but practice often proves otherwise.

Why Storage Matters

Not all esters give you trouble, but chlorinated analogs sometimes cause headaches. The moment an environment gets too warm or exposed, degradation can kick in. Nobody feels like finding out about impurities or dangerous fumes after opening a careless container. The fact is, compounds with chlorine react more than you’d hope, and repeated exposure to air or light speeds up this process. Looking at Ethyl 8-Chlorooctanoate’s data sheet isn’t enough; experience tells you real damage happens with just a hint of moisture or sunlight over time.

Real-World Storage Considerations

The simplest thing anyone can do is pick a tightly sealed, chemical-resistant container. Glass with a secure cap beats plastic, which sometimes reacts with chloro-compounds and leaches out. Keeping the container in a cool, well-ventilated space helps. All it takes is one hot day or lab backroom with poor airflow for vapors to build up. Some people think a regular shelf in the shared chemical area works fine, but that risks temperature swings and contaminating other supplies.

Dryness matters more than most realize. Once water vapor gets in, esters hydrolyze, and a clean substance becomes a test-case for failed syntheses. I learned the hard way after a batch sat too long in a humid storeroom. Labeling also helps keep track of when bottles were opened. Over time, even well-stored compounds break down. The rule I now stick to is logging open dates and tossing containers that pass their use-by date. This habit saves time and prevents accidents down the line.

Prioritizing Ventilation and Fire Safety

Volatile organics and heat really don’t mix. Storing this ester away from direct sunlight and heat sources isn’t just cautious—it’s essential. Most people don’t worry about chemical fires until the alarm actually rings. Labs and production spaces can’t afford that kind of oversight. Classifying Ethyl 8-Chlorooctanoate as a flammable liquid raises the bar for handling. Fire-resistant cabinets make sense in any environment where volumes climb past gram-scale work.

Respecting Regulatory Guidance

Regulations set by occupational safety agencies reflect actual experience. In Europe and North America, storage requirements for substances like Ethyl 8-Chlorooctanoate follow well-studied hazard codes. Storing it by itself, away from oxidizers or acids, reflects lessons learned over decades. Simple routines, such as double-checking MSDS sheets, reduce surprises and downstream disposal problems.

Building a Culture of Safe Handling

People cut corners out of habit or pressure, but that never ends well with sensitive chemicals. Teaching proper storage to every team member and performing spot checks go a long way. Having spent years managing shared lab spaces, I’ve seen the consequences of carelessness. The right containment, combined with a reliable labeling and inspection routine, prevents emergencies and keeps both people and science on track. In the end, careful storage of Ethyl 8-Chlorooctanoate protects more than product quality—it puts responsibility into action every day.

Why You Can’t Cut Corners on Chemical Safety

Ethyl 8-chlorooctanoate shows up on lab benches and in synthesis projects. It isn’t as familiar as bleach or acetone, but the rules for safety never take a holiday just because a compound sounds less famous. Give this one the same respect you would any chemical with “chloro” in its name. Most folks working with organochlorines know gloves are not optional. This ester can seep through standard latex, so nitrile or neoprene gloves tackle the risk better.

The Real-Life Dangers Lurking in the Bottle

This stuff isn’t something to sniff for fun. Fumes can irritate your nose, lungs, and throat. Getting it on your skin could lead to burns or red, cracked hands. Splashes in the eyes sting and may damage vision. Keeping the bottle closed and using it in a ventilated fume hood matters more than saving a trip across the lab. Opening a bottle at a crowded bench never works out well — one careless move and the whole room notices the sharp odor or worse, someone ends up with a trip to the eyewash station.

Storing and Moving with Care

A sealed, labeled container in a flammables cabinet works best. Don’t trust glassware with loose stoppers or chipped edges. I’ve seen caps fail and leaks eat through shelves or cardboard boxes. Mixing this ester near acids, bases, or metals brings on fire or dangerous gas if things go sideways. Checking the storage area’s ventilation every few months makes a difference, especially in older buildings where airflow sometimes gets ignored.

Protecting Yourself and Your Team

Working alone with hazardous chemicals gives bad odds. Always let someone know in advance before starting a run or cleaning up a spill. Long sleeves, splash goggles, and closed-toed shoes don’t weigh much but offer real protection. If anyone smells something sweet or sharp, or if their eyes start watering, it’s time to step outside and report it — don’t just crack a window.

Spill Response Without the Panic

Spills tend to shake up even the most experienced people. For something like ethyl 8-chlorooctanoate, grab spill pads or absorbent granules that handle organic solvents. Baking soda won’t work here. Ventilate and call for assistance rather than taking a chance with homemade solutions. After soaking up the liquid, seal it all in a chemical waste bag — never toss it in regular trash. If any gets on your skin, rinse with water for minutes, not seconds.

Training: The Real Hidden Ingredient

People often skip refresher training or ignore safety data sheets. I’ve learned more from stories of near-misses than from any warning label. Real-world practice drills—like handling mock spills or testing emergency showers—stick better than lectures. Supervisors can set the tone, but everyone plays a part in keeping the lab safe. New hires should shadow someone with experience their first week; nobody learns caution from paperwork alone.

Proper Disposal Isn’t Just Red Tape

Tossing leftover ethyl 8-chlorooctanoate down a drain or in regular trash isn’t safe or legal. Follow hazardous waste rules—use clearly labeled containers and let the waste handler know exactly what’s in the bottle. It keeps you compliant with local regulations and protects downstream workers from surprises.

Making Safety a Habit

Lab safety habits don’t grow on their own. Keep safety gear handy and double-check the protocols every time. Talk with coworkers about close calls to build a learning culture. Real safety relies on paying attention to small details, not just crossing fingers and hoping for the best.

Why Chemists Pay Close Attention

The purity of any chemical, including ethyl 8-chlorooctanoate, isn’t just a technicality. It’s the difference between success and trouble in a laboratory or a manufacturing plant. I’ve seen more than once how a misjudged grade leads to ruined batches or data that don’t add up. That’s why the conversation about purity grades matters to everyone who works with this compound.

Purity: Not Just a Number

If you check with suppliers or chemical catalogs, ethyl 8-chlorooctanoate doesn’t come looking the same every time. You might spot grades labeled “technical,” “analytical,” or “research.” These grades mean different levels of unwanted side products or residual moisture, and these details can’t be shrugged off. Laboratories testing drug candidates often demand purities above 98%—one less decimal and the data can turn unreliable. Manufacturers making specialty chemicals usually accept lower grades, especially if minor residues don’t mess with their end product.

Real-World Impacts of Choice

In real work, chasing high purity isn’t always about snobbery. Some reactions stall or head in the wrong direction if the starting material isn’t clean. I remember a university project where a batch with sub-95% purity caused chromatography headaches—instrument signals multiplied because each impurity introduced another peak. That meant lost hours sorting through confusing results. Every extra percent of purity isn’t just a number on a label; it’s hours of work gained or lost.

Trade-Offs in the Market

Instead of a one-size-fits-all approach, suppliers adjust based on common demand. If the pharmaceutical industry comes calling, chemical vendors stock up on higher-purity lots. If a bulk application like flavor ingredients needs large quantities and can tolerate trace contaminants, grades labeled “industrial” or “technical” often work out. Purity always walks hand in hand with cost. Higher grades take more effort and better equipment to make. Producers perform extra distillation or specialized washing steps, and those don’t come free.

Supplier Transparency

I always check certificates of analysis from suppliers rather than trusting catchy catalog descriptions. Good suppliers spell out exact purity percentages, list known contaminants, and occasionally provide chromatograms. These details separate trustworthy operations from the rest. Sometimes, smaller suppliers offer a custom synthesis route, but that bumps up costs. I’ve noticed that large, reputable chemical distributors provide greater confidence on batch consistency, but boutique shops sometimes cater to oddball purity requests.

Helping Buyers Make Solid Choices

If you’re stocking up on ethyl 8-chlorooctanoate for a research group or a start-up, communicate with your supplier about what you plan to do. Request the specs and ask for recent analyses. Double-check if the grade fits your planned use, whether that’s benchwork, pilot scale-up, or a consumer-facing product. Never assume a fine-sounding label matches your needs. If a project is heading for regulatory scrutiny, document your source and the purity verification steps.

Paving the Way for Better Standards

The chemical supply sector still has a way to go on transparency and harmonization. More standard labelling, clear reporting of batch traceability, and easy access to test results would help the whole industry steer clear of headaches. Until then, asking the right questions before the purchase remains your best bet.