Ethylbenzyl Chloride: A Deep Dive into a Key Organic Intermediate

Historical Development

Ethylbenzyl chloride didn't emerge from a vacuum. Chemists in the early 1900s started exploring substituted aromatics, searching for materials that could unlock the next wave of synthetic dyes and pharmaceuticals. This compound, carrying both ethyl and benzyl chloride functional groups, emerged as a result of industrial pushes after World War II, when mass chemical synthesis was ramping up for everything from plastics to pesticides. The rich chemistry of benzyl derivatives gave birth to whole families of related molecules. Ethylbenzyl chloride benefited from increased interest in tailored organochlorides, securing a role within both the lab and the factory floor.

Product Overview

Ethylbenzyl chloride acts as a useful intermediate in a wide range of chemical processes. What makes it stand out is the combination of reactivity and accessibility. This compound lands in the sweet spot for manufacturing: stable enough to store and transport with the right setup, reactive enough to act as both a building block and a transformational agent in organic chemistry. Over the years, industries have leaned on it to help build custom molecules, especially in specialties like pharmaceuticals, agrochemicals, and surfactants. What gets overlooked is its role as a stepping stone—one that rarely makes headlines but quietly shapes plenty of end products that touch daily life.

Physical & Chemical Properties

Ethylbenzyl chloride appears as a colorless to pale yellow liquid, carrying a pungent aromatic odor, reminding you quickly of its benzene backbone. Its boiling point hovers near 220°C, meaning most standard lab glassware can handle it without special tricks. The density outpaces that of water, so it sinks in most mixtures. The molecule holds a chloro group, making it highly susceptible to nucleophilic substitution. Water does not dissolve it readily, which plays into its industrial handling protocols—but it mixes with common organics like ether and benzene, giving chemists options in process design. This blend of reactivity and stability keeps it valuable for manufacturing environments needing reliability and predictable chemistry.

Technical Specifications & Labeling

Manufacturers ship ethylbenzyl chloride under strict chemical labeling regulations. The packaging details reflect both global standards and local rules: hazard statements warn about irritation to skin and respiratory tract, and pictograms flash the typical warnings—flame, exclamation mark, dead fish and tree for environmental warnings. Each shipment arrives barcoded with batch numbers and date codes for traceability, a non-negotiable after a string of contamination scares in the chemical trade over the past few decades. Color, purity (usually >98% for technical or lab grade), and stabilizer content get listed. Hard-won experience proves that skipping details leads to legal headaches or unsafe conditions.

Preparation Method

Industrial chemists favor Friedel–Crafts alkylation or direct chlorination of ethylbenzene in the presence of Lewis acids, such as aluminum chloride. Scaling up from benchtop to reactor vessel takes more than just multiplying recipe quantities: temperature control, stirring rate, and pressure settings all dictate success. Hydrogen chloride gas, generated as the byproduct, gets scrubbed or recovered because nobody wants acid cloud leaks. Yields can vary depending on catalyst choice, reaction time, and purity of starting material. Old plants sometimes use batch processes; newer facilities often deploy continuous flow setups to regulate reaction kinetics and minimize hot spots.

Chemical Reactions & Modifications

Chemists rarely stop at ethylbenzyl chloride. Its chloro group can be swapped for a whole gallery of nucleophiles: hydroxide for alcohols, amines for amides, or cyano groups for nitriles. Alkylbenzenes like this one serve as precursors for surfactants, via sulfonation or ethoxylation. Its dual nature—being both aromatic and aliphatic—allows for ring substitutions, oxidation, or reduction. A clever hand can coax it into more elaborate drugs or polymers. In my years tinkering with aromatic chlorides, I’ve watched labs pivot to ethylbenzyl chloride for short runs thanks to its reliability and versatility.

Synonyms & Product Names

As chemical names go, ethylbenzyl chloride doesn’t spark much poetry, but it’s sometimes cataloged as 1-chloro-1-phenylethane or alpha-chloroethylbenzene. Product catalogs and shipment forms bounce between those labels, plus trade-specific numbers or in-house batch names from chemical suppliers. Globalization and the spread of e-commerce mean anyone ordering this material needs to double-check registry numbers and local names to be sure they’re getting the intended compound—mislabeling still rears its head, especially with cross-border shipments.

Safety & Operational Standards

Daily work with ethylbenzyl chloride underscores why safety isn’t an afterthought. Direct exposure—especially to skin, eyes, or lungs—triggers negative reactions such as burns or respiratory distress. Inhalation hazards top the list, urging the use of fume hoods and proper PPE, including nitrile gloves and goggles. Regulatory bodies such as OSHA and REACH mandate strict exposure limits and spill response plans. I’ve seen firsthand how training and planning spell the difference between safe handling and accidents. Proper storage—cool, tightly sealed cans, away from heat and incompatible substances—forms the backbone of operational discipline. Old stories of fires and chemical burns echo through plant histories, shaping today’s rules.

Application Area

Ethylbenzyl chloride finds its way into more applications than people suspect at first glance. Chemical manufacturers convert it to intermediates for herbicides, antiseptics, and textile auxiliaries. It serves as a strong alkylating agent for pharmaceutical synthesis, helping build molecules with activity against bacteria or fungus. Surfactant and detergent industries use it to construct specialty cleaning agents, where a tweak at this stage can impact both effectiveness and biodegradability. Older uses included photographic chemicals and plasticizers, reflecting a past before green chemistry took hold. Its continued presence in process chemistry shows how versatile a single reactive site can be in forming new bonds for custom products.

Research & Development

Plenty of labs spend time trying to wring new value from ethylbenzyl chloride. Techniques to lower energy input, cut waste, or use greener reagents draw investment from both young startups and established producers. High-throughput screening and computational chemistry give new pathways for conversion, pushing old standby reactions into higher territory for selectivity or atom economy. I've watched collaborations between academia and industry gain momentum here, as tweaks at the base material level feed breakthroughs in polymer science or electronics. Sourcing feedstocks from renewable resources grows more popular, nudging research toward sustainable supply chains.

Toxicity Research

Toxicology studies show that ethylbenzyl chloride ranks as moderately hazardous, with acute toxicity if inhaled or absorbed through the skin. Animal studies on repeated exposure point to potential impacts on the liver and kidneys. Carcinogenicity data lands in the unclear zone—there’s no definitive link, but related compounds in the chloroarene family trigger health concerns. Environmental toxicity also crops up, with risks to aquatic organisms if released untreated. Safety data sheets catalog the numbers, but what sticks is the lived reality—workers report skin irritation and respiratory complaints if PPE lapses or ventilation numbers slip. Long-term risk management requires robust engineering controls and strict adherence to exposure limits.

Future Prospects

Looking at the road ahead, demand for ethylbenzyl chloride isn’t fading. As the chemical sector keeps pushing toward specialty products with ever-tighter regulatory scrutiny, this intermediate’s stability and versatility give it staying power. Advances in green chemistry and process intensification aim to cut emissions and energy load, which means cleaner routes for synthesis could reshape both sourcing and waste management. Some R&D labs explore biocatalysis or photochemical techniques to make or convert this molecule with fewer byproducts. There’s also a push for products that degrade safely and reduce environmental harm. Ethylbenzyl chloride, standing at the intersection of classic organic chemistry and sustainability challenges, keeps drawing interest from anyone chasing a better way to build the next generation of chemicals.

What Exactly Is Ethylbenzyl Chloride?

Ethylbenzyl chloride doesn’t usually land in the stuff folks use every day, but it’s present behind the scenes in industries most people rely on. In my own experience during a university research stint, I learned that small chemical tweaks on a molecular level end up shaping entire supply chains. Ethylbenzyl chloride is one of those tweakers. This compound sits on the edge of many manufacturing stories, playing a key role in building specialty molecules.

Big Player in Chemical Synthesis

In the chemical world, ethylbenzyl chloride shows up most often as a building block for making more complicated compounds. Manufacturers use it to add a piece, or “functional group,” to a wide range of chemicals. This ability makes it helpful in producing pharmaceuticals, especially medicines designed to target specific aches or infections. Say a lab needs to develop a new medicine or revamp an old formula. Ethylbenzyl chloride brings flexibility for tinkering with those molecules—sometimes leading to drugs that work better or are safer.

Helping Out in Agriculture

Modern farming depends on specialized chemicals to fight pests and weeds. Ethylbenzyl chloride has earned a spot in this world as an intermediate—the part used to make active crop-protection ingredients. The process often comes down to adding just the right twist to a molecule so it works better and breaks down safely. Decades of research show that safer, more targeted farm chemistry helps protect both the land and the food people eat. As someone who grew up eating produce from a family garden, I see how making these chemicals safer pays off in the long run.

It’s Found in Everyday Items, Too

Though not a household name, the compound plays a role in making fragrances and dyes. Companies use it to create certain scents used in detergents, soaps, and perfumes. The chemical structure adds both lasting power and complexity to scent formulas. On top of that, color chemistry often taps into ethylbenzyl chloride for building dyes used in textiles or plastics. Personally, this hits home every time I pull on a brightly colored shirt or smell clothes fresh from the washer.

Why People Should Care

Safety matters with chemicals like ethylbenzyl chloride. It’s reactive, so workers need protective gear and tight controls to keep it away from skin and airways. The good news: industry guidelines and government rules set the bar high for handling and disposal. Companies track spills closely because even a small leak can spark health and environmental trouble.

That said, not everyone trusts chemical industries to put safety before profits. Stories of leaks and poorly managed waste make headlines every year. I remember digging through news reports for a class assignment—it was clear public oversight keeps companies honest. More folks asking tough questions pushes industry toward better practices. Solutions come from real transparency, stronger regulations, and investment in cleaner technology. It’s possible to keep both innovation and safety alive by keeping public interest front and center.

Looking for Safer Solutions

The push for safer chemicals runs strong these days. Researchers look for alternatives with less toxicity and better environmental outcomes. For ethylbenzyl chloride, this means finding greener ways to make it, and some day possibly using less of it with smarter chemistry. Supporting this kind of progress takes investment and a culture of responsibility.

People don’t need to memorize every compound used in industry, but knowing how these building blocks shape lives and systems helps. It puts the spotlight on the balance between science, public health, and the choices shaping the next generation of products and medicines.

A Closer Look at the Chemical

Ethylbenzyl chloride crops up in a handful of industries, mostly as a starting point for other chemicals or as part of lab research. The way it smells sharp and harsh gives an early clue: This is not something you want to breathe or spill. It's a colorless liquid, but don’t let the clear look fool you. Handling it without respect brings real risk.

The Science and the Risks

I’ve spent years working in environments where chemicals like ethylbenzyl chloride show up. Safety rules get hammered into your head early on. Anyone who’s splashed a chemical on a hand or caught a whiff of something burning knows the feeling—skin stings, lungs tighten, you need a shower and fresh air. Ethylbenzyl chloride acts as a strong irritant. Direct contact with skin or eyes usually leads to burning, redness, and sometimes blistering. Get it in your eyes? That can mean real, sometimes lasting damage. Inhaling vapors brings its own troubles: coughing, headache, maybe nausea. Some people even feel dizzy or lightheaded after just a whiff, especially in a small room or lab.

Records from agencies like the U.S. Centers for Disease Control and Prevention and Occupational Safety and Health Administration back this up. They list ethylbenzyl chloride as hazardous, and not just because of its effect on skin or lungs. It reacts with water, giving off corrosive fumes. In a fire, it can release nasty gases like hydrogen chloride, which stings eyes and throat immediately. Long-term studies on high exposure remain thin, but enough red flags exist for concern.

Stories from Experience

Years ago, I watched a seasoned colleague work without gloves. A drop landed on his hand, and by lunchtime the skin looked angry and red. He shrugged it off, but by the next day it blistered, and he ended up in the nurse’s office. Smart people make mistakes when they trust their memory or cut corners. I’ve seen lab coats tossed, eye protection skipped, and every shortcut regretted sooner or later.

Respiratory protection isn’t just a piece of gear for show. A team member once inhaled a puff from an open bottle. He staggered back, coughing and blinking hard. He felt sick the rest of the day and needed follow-up checks to make sure his lungs bounced back. Small exposures add up; the risk often hides behind the fact you don’t feel symptoms right away.

Solutions and Safer Practices

Plain talk: respected safety guidelines are written in blood, sweat, and real injuries. Gloves, goggles, and tight-fitting lab coats protect against splashes. Fume hoods do most of the heavy lifting for vapors. Training helps workers spot risks before something goes wrong. Spills get cleaned immediately with materials designed for chemicals, not just a paper towel. Anyone handling ethylbenzyl chloride ought to have quick access to eyewash stations and showers. Good ventilation makes a huge difference. MSDS (Material Safety Data Sheet) should stick close by, not collect dust in a binder somewhere.

Companies can invest in better containment systems and encourage staff to report close calls, not just actual injuries. I learned that regular drills and honest conversations about what nearly went wrong prevent accidents in the future. Accountability means everyone helps keep everyone else safe. Respect the chemical, follow the basics, and risk shrinks to a level where people can do their jobs without dread.

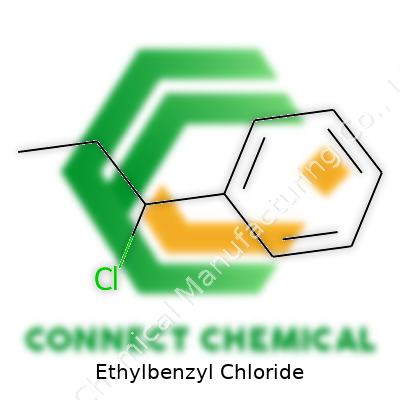

The Chemical Formula: Bridging Lab and Life

Ethylbenzyl chloride, with the formula C9H11Cl, doesn't just sit on a dusty shelf in a research lab. It tells a story of how a single change in a molecule can open new doors in chemical manufacturing. Every time I handled aromatic hydrocarbons in a university lab, I learned that structure makes all the difference. Adding a chlorine atom and two different alkyl groups to a benzene ring can change everything from smell to reactivity. In this case, ‘ethyl’ and ‘benzyl’ groups join forces on a benzene ring, and then a chlorine atom tags along. That’s how you get C9H11Cl.

How This Molecule Shapes Materials

Anyone who’s mixed chemicals knows certain compounds bring more than meets the eye. Ethylbenzyl chloride isn’t just another laboratory curiosity. It's often found acting as an intermediate, making way for the synthesis of useful molecules—whether that's in making pharmaceuticals, fragrances, or even specialty polymers. Some of my mentors in college used it in organic synthesis projects. They would tell stories about how chlorinated aromatics like this one can help form carbon-carbon bonds in ways you just can’t do with the parent hydrocarbon. That tiny chlorine atom packs a bigger punch than people expect.

Health and Environmental Impacts

Talk to any chemist old enough to remember leaky fume hoods and there’s one lesson: safety comes first. The presence of chlorine on organic molecules like ethylbenzyl chloride should always push us to think about safe handling. Volatile organochlorine compounds can irritate airways and skin, and some have a reputation for lingering in the environment if not managed properly. The EPA tracks chlorinated hydrocarbons closely for a reason. Clean-ups of chemical waste sites often trace problems to overlooked chlorinated organics.

From my own experience working in schools without strong ventilation, I learned to never take short-cuts with chemicals like this. Scrubbing glassware with simple detergent won’t do the job. Proper disposal down a solvent waste stream could save costly remediation down the road. Problems show up over time—so a little extra care during use saves a lot of trouble later on.

Moving to Green Chemistry

Industries relying on chemicals such as ethylbenzyl chloride face questions that can’t be ignored: how do we make things safely, and how do we protect the people in and around these workplaces? Modern manufacturers turn to safer solvents, automated systems, and stricter monitoring to cut risk. I’ve seen companies invest time in training for workers, switching over to containment hoods, and supporting disposal with better documentation. These real improvements come from a willingness to acknowledge past mistakes and embrace new protocols.

Bringing the Science Closer to Home

Reading a formula like C9H11Cl might seem technical, but getting to know molecules like ethylbenzyl chloride gives a sense of how chemistry shapes daily life while highlighting the responsibility that comes with each discovery. Every step from lab to factory and beyond needs careful choices backed by real knowledge. This molecule reminds us that chemistry always delivers both opportunity and obligations, keeping scientists, workers, and communities connected by the results of those choices.

Real-World Reasons for Caution

If you’ve ever worked around chemicals, you know the wrong move means more than a ruined project. One careless storage choice with something like ethylbenzyl chloride can put health and safety on the line. This isn’t some by-the-book haze — it’s about real risk. Take fumes, for example. This compound releases irritating vapors that sting the eyes and nose. Leaky containers in a stuffy closet can turn a small lab mishap into a building evacuation fast. OSHA flags ethylbenzyl chloride for its hazards, warning that even short-term exposure will leave a mark on skin or lungs. I once watched a seasoned tech develop red, itching patches on his arm after a small splash; he learned in seconds that even gloves have limits when not changed regularly.

Solid Storage Solutions

Locked storage alone won’t cut it. Ethylbenzyl chloride needs a well-ventilated, cool space — around 20°C, definitely below direct sunlight or heat sources. Think of the difference between a calm garage in spring and a sun-blasted shed in July. Heat ramps up pressure inside containers, boosting the risk of leaks or even rupture. On-site, I’ve seen plastic jugs buckle under steady warmth. Someone thought a stockroom bench would do, but by noon the walls felt hot to the touch and the jar’s cap was nearly off.

Non-reactive containers make all the difference. Glass works well, but only if caps seal tightly; the wrong plastic can get brittle or soften over time. The right containers block air and moisture while resisting corrosion. Storage away from acids, bases, and oxidizing agents means chemicals won’t mix and kick off an unexpected reaction. I've heard old hands in the industry tell stories about forgotten bottles sitting near bleach, stoking a near-miss that could have been a disaster.

The Care Factor: Health and Environment

Spills can’t always be avoided. That’s why a proper spill tray—something with raised edges and non-reactive coating—pays for itself the first time a bottle tips. Absorbent pads close by mean nobody’s scrambling if the worst happens. Some might say overkill, but it’s easier than handling a call to the fire marshal. I remember a case at a small plant where a minor leak, caught quickly thanks to those simple safeguards, meant cleaning up in minutes instead of shutting down for days.

Labeling means more than a sticker. Each container tells its own story: hazard signs, chemical name, and date received or opened. This isn’t bureaucracy—it stops mix-ups. Once, someone in a hurry reached for a nearly identical bottle, thinking it was a common solvent. The only thing that stopped a chemical mix was a sharp-eyed coworker spotting the right label at the last second.

Getting Prepared: Training and Access

The safest setup in the world won’t help if no one respects it. Training becomes routine but shouldn’t turn into background noise. Teams with frequent refreshers—hands-on and realistic—catch more mistakes before they snowball. Small steps like controlled access help, too. Only folks with a reason step into the chemical storage area, and nobody cuts corners to save a minute.

There’s no magic trick here, just old-fashioned care. Getting these basics right does more than protect property. It lets everyone head home at the end of their shift, headache-free, skin intact, and secure in the knowledge that no short-term fix ever trumps long-term safety.

Real Risks, Not Just Labels

Ethylbenzyl chloride rarely appears in daily life unless you work in labs or handle fine chemicals. It looks clear and almost harmless when you see it in a flask on the shelf, but most people who’ve worked with it recognize the sharp, pungent smell — a sign your nose and lungs won’t be happy with exposure. Anyone who’s gotten just a splash on their skin or whiff of its vapor knows pain or irritation sets in quickly. So, safety isn’t just about box-ticking.

Personal Protective Gear: Not Optional

Every single time I handle ethylbenzyl chloride, I keep my eyes protected with safety goggles and wear snug, chemical-resistant gloves. Without this layer, the compound can burn skin or cause nasty rashes. Cotton lab coats help, but for splashes, only a real chemical apron stands up to the job. After a close call when a coworker forgot her gloves and got a small chemical burn, nobody in our lab ever risked going unprotected again.

Air Matters: Good Ventilation is Non-Negotiable

Ethylbenzyl chloride lets off fumes that catch in your throat. Working in a well-ventilated fume hood handles that risk. During one summer, the building HVAC failed — everyone who tried to keep working outside the hood started coughing. That day drove home the point: being casual about ventilation isn’t worth the gamble. Even short-term exposure can irritate the lungs, so there’s no sub for a good fume hood and working extractor fans.

Smart Storage Reduces Accidents

Some chemicals can sit for years, rarely noticed on storage shelves. Ethylbenzyl chloride isn’t one of those you should shove in the back. It decomposes slowly when exposed to light or air, so screw caps tight and keep bottles in dark, flammable storage cabinets. After seeing a sticky mess from a cracked, old bottle, I check our stock every few months to toss out damaged or expired containers. The smell alone convinced me that old containers go straight to waste disposal.

Cleaning Up Spills: Quick and Calm

Spills happen. The trick is not to panic but to act fast, using absorbent materials solid enough to scoop up droplets without smearing. I keep eye-wash and safety showers within reach, close by on purpose, since in chemical labs nobody can promise they won’t ever need them. Those rinse stations rescued a technician I worked with once when a cap stuck, flipped off, and a burst of liquid splattered nearby. She doused herself in the shower right away — and avoided any serious injury.

Resourceful Solutions and Ongoing Training

Sticking to written protocols makes safety predictable, but regular training drives the habits home. At work, we run refresher drills: practicing glove changes, cleaning fake spills, and pointing out warning signs of exposure. People remember hands-on lessons much better than printed warnings. It also helps to print Safety Data Sheets and emergency phone numbers big on the wall, within sight of anyone using these chemicals.

Respect, Not Fear

Ethylbenzyl chloride can intimidate, but it commands respect more than fear. Staying safe means recognizing its risks through experience, keeping basic safety gear in place, giving spills immediate attention, and sharing stories about what’s gone wrong before. That lived knowledge protects better than any long list of instructions could. With a bit of vigilance, most trouble can be avoided and normal work continues without drama.