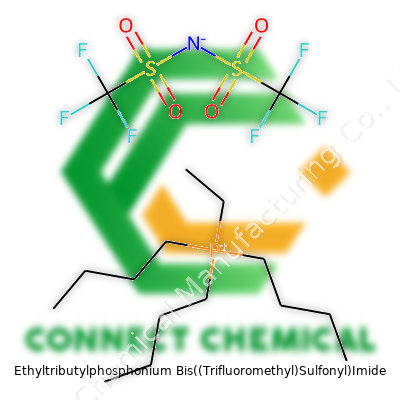

Ethyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide: A Practical Overview

Historical Development

Chemical research in the late twentieth century changed rapidly after the push for new functional solvents in the drive for green chemistry. Ethyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide, often abbreviated as [P4442][NTf2], comes from this disruptive chapter, fueled by the need for versatile ionic liquids that fill gaps left by the usual solvents. The bold direction taken by researchers in the 1990s moved from imidazolium salts to phosphonium-based structures, seeking to crack issues like hydrolytic instability and volatility. By tweaking side chains and settling on this heavy-duty anion, chemists found a stable, low-volatility compound with a broad liquid range and chemical resilience. Each year, journals churn out new tweaks that deepen what we know about its performance in electrochemistry, materials science, and synthesis.

Product Overview

[P4442][NTf2], also marketed under names such as ethyltributylphosphonium NTf2 or phosphonium ionic liquid 104209-95-8, boasts a performance profile that carries it into electrochemical devices, separations, and advanced catalysis. Commercial samples typically present as a faintly yellow, viscous liquid, shipped in amber glass containers since light and air slowly degrade purity. Standard packaging emphasizes proper labeling—CAS 104209-95-8, purity statistics exceeding 98%, and handling instructions tailored for technical staff. On the bench, its nearly odorless profile and manageable viscosity make routine transfer and dosing as straightforward as any other nonvolatile solvent.

Physical & Chemical Properties

At room temperature, ethyltributylphosphonium NTf2 stands out for its liquid state, avoiding the crystallization fuss that bothers many of its ionic cousins. You find a density over 1.3 g/cm³ and a viscosity prominent enough for slow pours but workable with pipettes and syringes. Its thermal stability lasts beyond 350°C yielding a tolerance for higher temperatures in synthetic work or process lines. Hydrophobicity measures strong—water picks up only at the trace level. Conductivity checks in lower than imidazolium liquids, but its electrochemical window stretches: over 4 volts under careful control, opening real doors in energy storage labs. Its chemical backbone resists the breakdown from acid, base, or moisture, so it serves in alkaline or acidic process streams without much degradation.

Technical Specifications & Labeling

Producers ship this compound by weight, listed as net volume or mass, with batch analysis documenting water content, halide impurities, and exact phosphonium cation composition. Safety data sheets must warn of both acute and chronic exposure risks, details about thermal decomposition, as well as recommended storage at cool temperatures away from sunlight. Proper chemical labeling usually includes the hazard pictograms for irritation, even if most exposures cause only mild symptoms under standard lab culture.

Preparation Method

Typical synthesis routes involve quaternization of tributylphosphine with ethyl bromide or chloride, followed by a careful ion exchange reaction using lithium bis((trifluoromethyl)sulfonyl)imide. This process liberates the corresponding halide salt and swaps the anion for NTf2, demanding slow addition and rigorous exclusion of water to suppress unwanted side reactions. Good yields come with control over temperature, excess reagents, and careful purification—vacuum stripping or washing with low-polarity solvents like hexanes. Well-run operations keep these steps contained, using closed flasks and filtered air to avoid product contamination or staff exposure.

Chemical Reactions & Modifications

[P4442][NTf2] holds up in reactions that challenge less rugged ionic liquids. Chemists have blended it with other solvents to customize polarity or tune solvation power for specialized catalysis. Modification of the cation through introducing bulkier alkyl chains, or even replacing ethyl with benzyl or functional groups, creates a playground for research teams looking to push phase behavior or selectivity. Degradation under oxidative conditions has been studied, and while it resists most, strong oxidants eventually chop the alkyl chains. Electrochemical reduction or oxidation in bench devices usually spares the backbone, making it a safe bet for redox cycling experiments.

Synonyms & Product Names

Across catalogs and the literature, ethyltributylphosphonium bis((trifluoromethyl)sulfonyl)imide appears under a patchwork of names. On a supplier’s site, you might find it called tri-n-butyl(ethyl)phosphonium bis(trifluoromethanesulfonyl)imide, phosphonium ionic liquid [P4442][NTf2], or just by its CAS registry number, 104209-95-8. Research articles prefer the [P4442][NTf2] shorthand, and many patents simply refer to it as “ethyltributylphosphonium NTf2” for brevity. Knowing each of these helps avoid confusion on an order sheet or in multi-disciplinary project meetings.

Safety & Operational Standards

Lab and industrial staff follow strict protocols with any ionic liquid, and phosphonium NTf2 is no exception. Those with direct contact wear nitrile gloves, safety goggles, and use chemical hoods for operations likely to produce vapor or aerosol. Standard protocols address the need to collect spills with absorbent, segregate waste streams, and send residues to specialized disposal services. Inhalation is rare, but teams keep MSDS binders nearby and maintain eyewash stations in case of accidental splashes. Training emphasizes limited skin contact and careful weighing to avoid cross-contamination, and secure long-term storage at 2–8°C.

Application Area

Ionic liquids offer possibilities far past being just solvents. In my time visiting university labs, I have seen [P4442][NTf2] in batteries where its non-flammability and low volatility improve safety over common electrolytes. Its thermal stability and chemical inertness draw attention in industrial separations, to extract heavy metals or rare earth elements that resist capture using water or volatile organics. In organic synthesis, it acts as a reaction medium for cross-coupling, oxidation, and transition metal-catalyzed processes. Pharmaceutical teams working on green chemistry protocols like its low vapor pressure and ease of recovery. Tech startups have experimented with it as a lubricating or anti-static agent on critical surfaces, pushing the edge for specialty materials.

Research & Development

Work on phosphonium ionic liquids plows ahead in both basic chemistry and real engineering trials. Data builds on their ability to dissolve tough-to-handle substances—cellulose, fluoropolymers, or even gases like CO2. Teams at leading institutes model cation–anion interactions using quantum-level simulations, hoping to optimize next-generation energy devices. At conferences I’ve attended, postdocs swap methods for tuning viscosity and wettability to target uses in microelectronics or as new supports for catalysis. Even companies in waste treatment hunt for ways to employ these salts to mop up toxins, eager to publish results on regeneration and reuse.

Toxicity Research

As with all synthetic chemicals, toxicity studies run side by side with product development. Animal studies suggest that phosphonium-based ionic liquids can stir mild irritation on skin and mucosa, and high-dose exposures in aquatic settings sometimes harm sensitive species. Careful review points to low bioaccumulation, which lowers environmental risk, but the F–S bonds from the NTf2 anion mean that breakdown can possibly produce perfluorinated contaminants. In my own training, data on phosphonium cations consistently show less human-cell toxicity than imidazolium salts, though responsible use depends on worker education, spill management, and clear standard operating procedures in every setting.

Future Prospects

The years ahead look to build on this strong footprint. Ongoing research into cost-cutting production may open bulk uses in energy storage and raw material extraction where current prices limit adoption. Engineers work to design task-specific ionic liquids that copy [P4442][NTf2]'s best features, aiming for faster biodegradability or improved environmental profile. Specialized applications in next-gen electronic materials and green chemical manufacturing depend on improving recycling and purification techniques. Real breakthroughs sit at the interface—combining computational design with lab curiosity to deliver safer, stronger, and smarter products for tomorrow's challenges.

Unlocking Ionic Liquid Advancements

Many researchers see Ethyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide as a building block for innovation in the world of ionic liquids. The structure gives it a low melting point and high thermal stability, so labs look to it for advanced chemical processes. Working with it, I’ve seen how it resists water and has high electrochemical windows, offering advantages over more common salts that break down or corrode gear. This chemical matters most in jobs where basic salts just can’t handle the heat or the voltage.

Electrolyte for Batteries and Capacitors

In the push for better energy storage, battery makers test out all sorts of electrolytes. I’ve worked on teams searching for a substance that lets lithium ions flow freely but stays stable after thousands of charge cycles. Ethyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide carries ions smoothly at high voltages. Electric vehicles and large-scale batteries use these kinds of electrolytes to stretch out lifespan and squeeze every bit of power from cells. According to recent journal articles, swapping in this chemical sometimes improves cycle life by up to 30% in lab testing.

Green Solvent for Reactions and Separations

Many solvents still depend on fossil fuels, sometimes causing pollution or accidents. Using this ionic liquid as a solvent, researchers cut down on hazardous waste in pharmaceutical and fine chemical production. Its low volatility means fumes aren’t a problem, so workspaces become safer. I remember watching a demonstration where a reaction with this compound swapped out three shelves of toxic bottles for a single, sturdy flask. Several studies show that reaction yields stay high, especially in tasks like alkylations and extractions, while reducing emissions.

Catalyst and Medium for Special Chemistry

Catalysts need a sturdy playground, and ionic liquids like this one give them that space. In some synthetic routes, this compound acts as both solution and partner, prodding along reactions that would crawl with classic solvents. I’ve seen pharmaceutical labs switch to this approach to synthesize new molecules that simply won’t form with older chemistry. A few years ago, a group used this compound in transition metal catalysis, in part because it speeds up reactions and lets them run cleaner, producing less waste—crucial for green chemistry goals at scale.

Electroplating and Material Science

Metal finishing shops and electronics foundries hunt for better ways to deposit metals cleanly. Ethyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide helps get consistent metal films on circuit boards and microchips without the rough spots you get from water-based solutions. The chemical keeps metals dissolved in a workable form even under high current. In one project we worked on, this led to more reliable conductive patterns for flexible screens and wearables, which struggle with traditional plating fluids that dry up or break down under heat.

Challenges and Paths Forward

Not all stories end neatly. Costs stay fairly high, and large-scale recycling of ionic liquids remains an open question—the industry needs better infrastructure. Investing in closed-loop systems and taking lessons from green chemistry keeps advances balanced against safe handling. Open-source sharing of best practices helps labs and factories lower risks and stretch budgets. As more industries shift toward safer, more stable materials, practical breakthroughs with compounds like this will push recycling and production up to the next level.

Why Chemical Stability Matters in Real Life

Anyone who's opened an old bottle of medicine and wondered if it's still safe understands the importance of chemical stability. If a compound doesn't stay stable, it might not work as intended or could even become dangerous. From antibiotics in a rural clinic to cleaning agents in a school, people rely on chemicals doing their job well and safely over time.

Factors Affecting Chemical Stability

Light, moisture, air, and temperature work together to influence how long a compound remains reliable. Oxygen can change a compound’s makeup. Water causes hydrolysis in some chemicals, which breaks their structure apart. Heat usually accelerates these processes. Even the container makes a difference: glass, plastic, or metal all interact differently, with some offering better protection from sunlight or air.

Take vitamin C as an example. Left open in a humid bathroom, it oxidizes and loses power fast, sometimes within weeks. Kept in a cool, dry, dark place, it lasts far longer. The lesson: storage often matters as much as the chemistry.

Shelf Life in the Real World

On every medicine bottle or cleaning product, there’s an expiration or “best by” date. This isn’t just bureaucratic red tape. These dates come from testing how the compound holds up over time. Scientists store the product in different conditions—sometimes for years—and check whether it remains effective or safe.

From my own time in a hospital pharmacy, expired medication presented real problems. A once-reliable antibiotic sitting months past its date may lose potency and put patients at risk. A few years ago, the American Medical Association found that some drugs kept their strength far longer than expected, while others lost it quickly once packages opened. Freshness isn't always obvious from looking at a pill or powder.

The Real Consequences of Ignoring Stability

Breakdown products sometimes create new toxins or allergens. Classic cases include aspirin turning into acetic acid (which smells like vinegar) or the musty scent from expired cold tablets. But issues aren’t just about health. In agriculture, farmers rely on stable crop chemicals. If a weedkiller degrades, farmers waste money and risk crop failure. Factories using chemicals past their prime might see equipment corrosion or product recalls.

Ensuring Safety and Prolonging Shelf Life

Smart packaging helps a lot. Manufacturers use blister packs, amber bottles, or sealed aluminum foil to keep out air and light. Desiccants, those little packets labeled “do not eat,” are another tool.

Constant education goes a long way. Workers need to check expiration dates and recognize warning signs like changes in smell, color, or texture. Digital inventory systems flag batches coming close to the end of their usable life. Some companies use chemical indicators that change color if storage conditions slip.

What Helps Most: Attention and Respect for Science

Anyone storing chemicals—doctors, teachers, farmers, or parents—should treat storage instructions as serious safety advice. Dismissing expiration dates or using chemicals that look “just fine” can cause more harm than most imagine. Research keeps improving packaging and storage guidance, but personal responsibility makes the biggest difference.

Science can predict a lot, but it can’t fix carelessness. People who respect the true shelf life of a compound help protect health, safety, and budgets every day.

Practical Experience with Specialized Chemicals

Nobody walks into a chemical storeroom expecting the Wild West, but I’ve seen my share of chaos—rusty shelves, open containers, mystery puddles. Most accidents start with poor storage and end with ruined materials or, worse, damaged health. If you’ve handled something like Ethyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide (commonly called an IL or ionic liquid in the industry), you soon realize not all chemicals play by the same rules as table salt and water.

The Real Risks Behind the Science

This compound falls in the family of ionic liquids, which means it doesn’t vaporize and stink up your lab, but that’s no excuse to throw it on any available shelf. Anyone who’s worked with phosphorus-based chemicals or fluorinated sulfonamides knows they matter in everything from battery research to specialty catalysts. They’re also moisture magnets, often pulling water in from the air. Left uncapped even for a few hours, these materials can turn gunky or lose purity.

Liquid or solid, the compound doesn’t explode on contact with air or light, which feels like a relief. Still, the damage from air, especially humid air, sneaks up over weeks. Even small chemical changes lead to performance drops in sensitive applications. I've seen researchers scratching their heads over a failed test, never suspecting lazy storage wiped out the sample long before they touched it.

What Simple Steps Make the Difference?

A cool, dry place works for most chemicals, but for Ethyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide, a tightly sealed bottle is non-negotiable. I prefer using amber glass for even moderate light protection, though the chemical itself won’t decompose under fluorescent lights. A desiccator cabinet is worth the investment. Silica packs and vacuum desiccators aren’t overkill when humidity spikes or in climates where mold loves to grow.

I’ve seen labs tuck these bottles into common refrigerators. That works, but only if the container stays tightly closed and clearly labeled. Cross-contamination with volatile solvents or acids, which sneak into the air of shared fridges, causes subtle breakdowns. A dedicated cold storage spot solves those headaches.

People Overlook Safety for Convenience

People skip gloves, splash-proof goggles, and the fume hood, especially with ionic liquids. Ethyltributylphosphonium compounds don’t evaporate or smell hazardous, so folks get complacent. I’ve seen skin rashes on the careless. Safety data sheets—yes, those boring packets—recommend nitrile gloves and working in a space with proper airflow.

Paths to Fewer Mistakes and Waste

Getting organized doesn’t take heroic effort or fancy equipment. Durable secondary containment, reliable labeling, and a habit of checking seals save money and time. Training the whole team once a year beats rushing to fix mistakes later. Fully documenting temperature limits, expiration dates, and any discoloration or separation keeps everyone honest and the chemical pure.

Look at waste disposal, too. This isn’t something to dump down the drain. Coordination with environmental services or chemical waste handlers ensures compliance and safety for everyone long after the research ends.

Why Small Details Add Up

Ethyltributylphosphonium Bis((Trifluoromethyl)Sulfonyl)Imide doesn’t require a fortress to stay stable, but thoughtful storage keeps its value. Protect it from stray moisture, temperature swings, light, and curious hands, and you avoid hidden losses that bite down the road. These habits don’t just guard your bottom line. They keep people and results safe, reliable, and reproducible.

Knowing the Risks That Come With Certain Products

Some products found in stores might look harmless on the surface, tucked away in household aisles or hardware shelves. Beneath that packaging, though, there could be risks worth taking seriously. Take, for instance, cleaners containing strong acids, glues packed with fumes, or even something as simple as a battery. Familiar items sometimes surprise people with unsafe reactions once they are misused or mixed with the wrong things. I’ve seen folks try to clean out pipes with drain openers just by reading a label too quickly, only to end up with burns or ruined clothes. The stakes get higher with chemicals at work, but even at home, trouble crops up without some basic know-how.

Recognizing Signs that a Product Needs Respect

Labels serve up warnings in plain language for a reason. Phrases that signal serious trouble, like "causes severe skin burns," "fatal if swallowed," or "harmful vapors," deserve real attention whether you’re at a jobsite or at your own kitchen sink. Sometimes, it’s easy to shrug these off, especially with products you’ve used for years, but that comfort can turn into injury fast. Burns, lung irritation, allergic reactions—these aren’t rare mix-ups. Even with something like powdered pool shock or paint thinner, cases of accidental poisoning and ER visits keep popping up every year. In 2022, the U.S. poison control centers took nearly 2 million calls about household exposures—many avoidable had someone given the warnings a bit more thought.

Why Practices Make a Difference

Personal experience taught me early on that hurrying isn’t worth the risk. Years back, while helping a neighbor fix up an old shed, I reached for a rust remover without gloves. Not even ten minutes later, my hands felt like a hornet’s nest. Since then, the simple rule stands—protection comes first, curiosity or impatience second. Gloves, goggles, and a splash of common sense save a lot of pain. Good ventilation helps with fumes. Keeping chemicals away from food stops accidental ingestion, especially with kids or pets around.

Simple Steps Lead to Safer Outcomes

Plenty of problems get solved by reading the instructions—boring, but effective. Before opening anything new, I look for hazard pictograms, key warnings, and surprisingly, I’ve found even familiar brands sometimes change their formulas or recommendations. It pays off to double-check before mixing or using something in a new way.

Disposing of hazardous stuff responsibly matters too. Pouring old paint thinner down the drain doesn’t just ruin pipes; it can contaminate water and harm wild animals. Municipal waste programs, community clean-up days, or even special collection centers take that burden off your hands and keep the neighborhood safer.

Staying Smart Makes a Difference

Staying safe comes down to habits. Every time someone ignores a label or shrugs off a splash, trouble waits in the wings. Sharing knowledge goes far, whether that’s a workplace safety chat or teaching a teenager the basics before they take on a home improvement chore. Learning from close calls, not just instructions, creates better safety—for yourself and anyone around these products.

Navigating Choices Means Getting Informed

People who buy raw materials can end up facing a maze of numbers and terms. Purity levels listed as 97%, 99%, and sometimes topping out near 99.99% might look similar on paper. They aren’t. Experience in the lab taught me that using a chemical of 97% purity in a sensitive reaction can change everything—from yield to safety to whether a process even works. It’s not just the percentage. It’s what those other percentages mean: contaminants, trace metals, byproducts. If the end application involves food, pharmaceuticals, or electronics—those decimal places on the label count for a lot more than price or paperwork.

Most beginners believe they can use the cheapest available material. I used to think that too, until I learned through a costly failed synthesis that some adulterants can poison entire batches or interfere with machinery. Take sodium chloride as an example. The same compound can be called “lab grade,” “ACS reagent grade,” or “pharmaceutical grade,” based on purity, and that simple distinction determines if it ends up in a kid’s science set or inside an IV drip.

Packaging Isn’t Just a Box

Once you settle on a purity level, you run into another fork in the road: packaging. Bulk buyers, research labs, and manufacturers all need something different. You’ll find 25 kg drums stacked in distribution centers, 1 kg bottles lined up in school laboratories, and sometimes even single-use ampoules on hospital carts. These choices affect safety, cost, efficiency, and environmental impact.

Anyone who’s handled hazardous or hygroscopic compounds knows the heartbreak of opening a poorly sealed bag only to watch the contents cake up or degrade. I can remember a time when a shipment arrived in simple polyethylene bags; the product went lumpy from absorbed moisture, and our lab burned time and money trying to salvage the lot. Now, smart buyers look for moisture-proof, tamper-evident packaging, often with clear certification and tracking. Some companies seal high-purity products under argon in amber glass bottles, keeping sensitive chemicals stable. For routine workhorse chemicals, high-density polyethylene containers or fiber drums with tamper seals do the job.

Trust, Traceability, and Well-Being

Easy access to purity levels and proper packaging options isn't just about convenience—it’s a matter of health, safety, and trust. Reliable suppliers should let buyers review certificates of analysis, which help confirm the product meets published claims. A clear label or a downloadable data sheet listing impurity profiles, batch numbers, and shipping history gives buyers the evidence they need to make informed choices.

At its best, transparency protects everyone in the chain—from workers shipping the product, to users who might be ingesting or inhaling the final compound. It also helps trace back any issues, driving recalls or improvements. Once, an audit forced our team to provide years’ worth of receipts and safety records because a single product lot had traveled from one factory to several hospitals. Documentation saved us and reassured the public. Now, digital platforms make it easier than ever for businesses to share details upfront.

Better Solutions Start with Information

Stronger standards benefit everyone. Companies should prioritize purity validation, invest in research that tracks impurities, and offer variable packaging tailored for real-life storage and use scenarios. Regulators and buyers alike must keep questioning and demanding: Who tested this? How? How much risk comes from that last percent? With full information, everyone—from new students to seasoned professionals—can protect both their work and their well-being.