Ethyltributylphosphonium Bromide: More Than a Mouthful in Modern Chemistry

Historical Development

The story of ethyltributylphosphonium bromide traces back to the blossoming era of quaternary phosphonium salts. Early research through the latter half of the 20th century marked a turning point in how chemists approached ionic compounds. Early pioneers found phosphonium-based salts less prone to hydrolysis than ammonium types. Industrial chemists working with older catalysts ran into trouble with air and moisture, often in the form of broken reactions or wasteful side-products. Switching to phosphonium salts, and eventually synthesizing ethyltributylphosphonium bromide, brought smoother reactions and durable products. Over time, the compound grew out of specialty labs and made its way into mainstream applications, finding its place in organic synthesis, catalysis, and ionic liquid research.

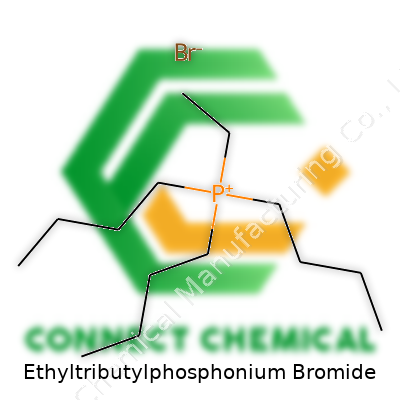

Product Overview

Ethyltributylphosphonium bromide isn’t the sort of thing you pick up at the hardware store. Chemically, it looks like a compact structure with a positively charged phosphorus atom sitting at the center. Three butyl groups and one ethyl group cling to the phosphorus, flanked by a bromide as the counterion. This structure gives it real versatility, working as both an ionic liquid precursor and a phase-transfer catalyst. Laboratories appreciate the stability that comes from its design, and companies value how it adapts to specialized tasks in pharmaceuticals and fine chemical production.

Physical and Chemical Properties

In the jar, ethyltributylphosphonium bromide typically appears as a white or off-white solid, neither fragrant nor volatile under usual conditions. It boasts a high melting point, usually between 115 and 130 °C, and dissolves well in polar organic solvents. Due to the unique spread of electron density around the phosphorus center, it resists decomposition at ambient temperature, refusing to play along with typical hydrolysis reactions. That kind of stability grants longer shelf life and confidence in storage. On occasion, under the sharp gaze of high heat or strong base, it can break down and relinquish its more delicate side, but most users never encounter those extremes in the field.

Technical Specifications and Labeling

Manufacturers tend to certify a purity of at least 98% for ethyltributylphosphonium bromide, with strict controls over water and residual solvents. Labels carry the molecular formula C14H32BrP, and the molecular weight tips the scale at about 327.28 g/mol. Many suppliers rely on NMR and FTIR to validate each batch, backing up their claims with a tightly maintained Certificate of Analysis. Regulatory expectations loom over the packaging, pushing for clear hazard labeling, batch numbers, and recommended storage instructions. Nobody wants to play the guessing game with a chemical that demands careful handling.

Preparation Method

The most common route to ethyltributylphosphonium bromide involves quaternization. Chemists take tributylphosphine and react it with ethyl bromide, usually cooling the mixture to keep the exotherm in check. With precise addition rates, the reaction unleashes ethyltributylphosphonium bromide in nearly quantitative yields. After completion, solvents and byproducts clear out through recrystallization or filtration. In industrial settings, larger reactors get the job done, but the principle stays grounded: keep things clean, minimize side reactions, and track every input. Labs opt for anhydrous conditions to dodge unwanted hydrolysis, sealing up glassware and keeping everything bone dry.

Chemical Reactions and Modifications

Ethyltributylphosphonium bromide serves as both a catalyst and a key component in phase-transfer reactions. In organic synthesis, it helps ferry ions between layers that otherwise refuse to mix. Many chemists turn to the salt to prepare ionic liquids, using simple ion exchange techniques to swap out the bromide for other anions. Under strong nucleophiles, the compound swaps its bromide with rivals like tetrafluoroborate or hexafluorophosphate. As a phase-transfer catalyst, it shines in alkylation, esterification, or even halide exchange, freeing up product mixtures and helping stubborn reactions reach the finish line.

Synonyms and Product Names

This compound hides under many names, depending on catalog or context. Some suppliers list it as ETBPB. Others refer to it by its systematic title: ethyltributylphosphonium bromide. Occasionally, you’ll spot trade-specific brand identifiers, but the fundamental ingredient never changes. For regulatory paperwork, the CAS Number 3118-71-2 appears, helping users and customs officials track the same substance across international borders.

Safety and Operational Standards

Ethyltributylphosphonium bromide expects users to show respect. Direct contact with the solid or its solutions can irritate the skin and eyes. Dust control matters, and accidental inhalation of fine particles warrants fresh air and medical evaluation. On the job, lab workers reach for gloves, splash goggles, and good ventilation. Storage rules require a cool, dry spot away from acids and reactive agents. Emergency protocols rely on knowing the right spill procedures—use inert absorbent, sweep up without raising clouds, and dispose of waste following local regulations. Companies include detailed Safety Data Sheets, and oversight agencies audit compliance for good reason. Letting down your guard can draw sharp reminders; even a short lapse might lead to expensive cleanup or health risks.

Application Area

Ethyltributylphosphonium bromide plays a starring role in chemical research, especially in syntheses demanding a reliable phase-transfer agent. Pharmaceutical companies use it to simplify complex reaction mixtures and improve yields where classic methods stall. The compound finds its way into the development of new ionic liquids, which researchers prize for their environmental profile and tunable solvent abilities. Battery technology pushes for salts like this to form conductive electrolytes, shifting away from traditional solvents and making safer, more robust lithium batteries. Catalysts built around ethyltributylphosphonium bromide turn up in green chemistry campaigns, knocking out toxic alternatives for selective reactions. Water treatment, extraction processes, and even polymer science pull from the same inventory, always looking for consistency and adaptability in a demanding industrial world.

Research and Development

Current R&D efforts dig deeper into ethyltributylphosphonium bromide’s role in advanced materials and molecular engineering. Academic labs tailor new derivatives, testing out different anion partners to craft fluids with sharp melting points or specialized conductivity. Commercial teams develop anchored catalysts, fixating the salt onto resin beads for easier recovery after batch processing. Environmental focus increases every year, with startups investigating how these salts break down under long-term storage or accidental release. Some researchers run toxicity assays on aquatic life, aiming to better predict routine disposal outcomes. The wave of innovation around battery electrolytes and solar cells keeps drawing in funding, linking basic research with practical rollout.

Toxicity Research

People often feel uneasy around new chemicals, especially with ‘phosphonium’ in the name. Recent toxicity studies suggest ethyltributylphosphonium bromide doesn’t pose acute risks in small quantities, but long-term effects raise open questions. In controlled lab tests, exposure above threshold limits irritated skin and mucous membranes. Animal testing (limited due to ethical trends) pointed out possible bioaccumulation and liver changes from persistent contact. Regulatory agencies, prompted by these data points, set occupational exposure limits to err on the side of caution. Environmental scientists express caution over uncontrolled disposal, since many ionic compounds resist breakdown in soil or water. So far, the compound sits well below acute danger levels for most industrial users, but prudent waste management and monitoring still feature in compliance audits.

Future Prospects

Demand for specialty chemicals like ethyltributylphosphonium bromide won’t run out soon. The shift toward sustainable chemistry encourages further adoption, especially in green solvent research and energy storage materials. Technology trends point toward safer, high-performance battery chemistries built on ionic liquid foundations, with this salt often near the top of the candidate list. Policy shifts in environmental regulation drive companies to proof-test the compound’s breakdown products, aiming for safer lifecycle outcomes. Academic journals publish each incremental advance, connecting fundamental chemistry to emerging applications in electronics or pharmaceutical manufacturing. The more we learn about handling, modifying, and recycling this compound, the stronger its case becomes for broad adoption across sectors that value both innovation and responsible practice.

Making Lab Work Happen

Ethyltributylphosphonium bromide might sound like one of those chemicals that never leave the dusty shelves of a research lab, but dig into what scientists do with it, and a different story unfolds. This compound steps up as an ionic liquid, a kind of salt that flows at room temperature. What gets chemists excited? Its stability, its friendliness with water and various solvents, and its knack for making reactions faster or more selective. In a lot of ways, it’s a quiet workhorse for anyone working on specialty materials, greener processes, or some of the newer ways of making life-saving drugs.

Far Beyond Basic Chemistry

I got my start in a lab where solvents made up much of daily life. Traditional solvents not only smelled strong — they also felt like a challenge to safety. Ethyltributylphosphonium bromide rewrites part of this story. As an ionic liquid, it stands out for not evaporating into the air the way volatile organics do. This reduces inhalation risks and cuts down on flammable hazards, which is something anyone working in a crowded lab should welcome. The EPA and responsible researchers encourage moves toward “green chemistry,” and using less toxic solvents is a big part of that. Swapping out legacy chemicals for ionic liquids like this one helps chip away at the health and environmental risks labs have accepted for too long.

Building New Reactions

People overlook the versatility of phosphonium salts. In synthetic work, ethyltributylphosphonium bromide serves as a phase-transfer catalyst. That means it can help carry molecules from water into organic layers — basically acting as a chemical handshake across boundaries most compounds can’t cross. This opens up access to reactions that either wouldn’t run at all or would only work using dirtier and less friendly methods. I remember the frustration when certain steps in a reaction relied on traditional quaternary amines, bringing unwanted byproducts and headaches in purification. Phosphonium variants often improve selectivity, which saves time and prevents wasted effort on cleaning up the aftermath. Even in pharmaceutical development, small increases in yield and reduction of side-products offer real business benefits, keeping research both effective and responsible.

Solutions for Tech and Industry

Industries always look for ways to work smarter. Polymers, electronics, and catalysis stand out as three areas where ethyltributylphosphonium bromide pulls its weight. In polymers, it helps tweak molecular chains, letting researchers dial in toughness or flexibility. Electronics manufacturing relies on high-purity, stable additives. Here, phosphonium compounds help manage static and improve manufacturing reliability — which trickles down to longer-lasting devices or solar panels. In catalysis, their stability and ionic nature open up transformations that other agents simply can’t manage. There’s real progress here: chemical industries pay close attention to anything that raises yields and trims energy use.

Guiding Responsible Use

Green and safe chemistry isn’t just about the chemicals themselves. Training matters. Regulatory policies need to reflect real-world lab routines. Waste management systems have to keep up with the unique behavior of new compounds like ethyltributylphosphonium bromide. These aren’t just checklist items — they’re cornerstones that keep both researchers and the surrounding communities safe. Groups like the ACS keep pushing for education, policy, and real data on the risks and benefits. Every time a lab pulls an ionic liquid off the shelf instead of something more toxic, it’s not just progress on paper. It’s a lesson in responsibility that adds up, one experiment at a time.

Chemicals Shaping Everyday Solutions

Not every breakthrough needs to hit the front page. Sometimes, it’s the quiet changes — a new solvent in a rarely-discussed bottle — that help science move in a safer, smarter direction. Ethyltributylphosphonium bromide may not show up in every conversation, but its quiet revolution in labs, manufacturing, and even the way researchers think about environmental risk shows how progress often arrives: with steady, thoughtful choices.

Getting Familiar With This Compound

Ethyltributylphosphonium bromide isn’t just another tongue-twister from a chemistry textbook. Its layout, C14H32BrP, carries meaning for researchers and industries who rely on specialized ionic liquids and tailored catalysts. Each letter and number tells us what’s inside: 14 carbon atoms, 32 hydrogen, one bromine, and a phosphorus atom pulling it all together. Recognizing this formula opens the door to better understanding how chemicals like it end up in real-world applications, whether it’s advanced material design, extraction of rare earths, or sustainable chemical synthesis.

Building Trust Through Solid Science

The story behind this formula—C14H32BrP—starts with its roots in organophosphorus chemistry. The backbone, phosphonium, supports different groups: three butyl groups and one ethyl. This design sets the rules for physical behavior. People use ethyltributylphosphonium bromide as a phase transfer catalyst. It has solved problems for chemists who want two substances to react but find them stubbornly separated. I once watched a lab mate try and fail at a reaction until a compound like this pushed the molecules into the same room, so to speak. The results spoke loudly: better yields, less wasted solvent, and fewer steps between raw material and finished product.

Why This Formula Matters in the Real World

Science doesn’t exist in a vacuum. Anyone working in green chemistry or process optimization would tell you, tools that make reactions run easier, cleaner, and safer can shift an industry. Ethyltributylphosphonium bromide stands out in the world of ionic liquids. Unlike older, harsher solvents, many phosphonium salts come with lower toxicity and lower volatility. That shift matters. The chemical’s formula isn’t just trivia—it’s a guide to predicting if it can replace more hazardous reagents or find work in battery technology, biocatalysis, or even drug manufacturing.

The Human Factor: Safety and Sustainability

Chemists need to pay attention to more than yields and shortcuts. Regulations and best practices require critical evaluation of what goes down the drain. With its bromide anion and bulky phosphonium cation, ethyltributylphosphonium bromide offers lower flammability and evaporation rates than some traditional alternatives. But safe doesn’t mean risk-free. Its chemical stability calls for good handling—protective gloves, goggles, and responsible disposal. Companies and researchers who respect these guidelines show leadership by example, keeping teams and the environment safer.

Opportunities for Better Chemistry

There’s more on the horizon than just using a new chemical name. Researchers keep searching for ways to tweak phosphonium salts like this one, adjusting group size or swapping anions to design even greener compounds. I have listened to colleagues debate the best cation-anion pairing for a specific process; it’s this kind of teamwork and experimentation that leads to those small but crucial steps forward. Real learning happens not just from reading the formula, but from testing, sharing, and finding what truly works. If more labs aimed for thoughtful chemical choices—with eyes on both innovation and responsibility—the field would move faster, together, without forgetting the human impact behind every reaction.

Understanding This Chemical’s Role

Ethyltributylphosphonium bromide pops up in advanced labs and certain manufacturing operations. Chemists reach for it for specialized reactions, often as a phase-transfer catalyst or component in ionic liquids. Efforts in green chemistry, pharmaceuticals, and high-performance materials owe some progress to this compound’s unique properties. That means it demands solid respect in storage and handling practices.

Why Storage Conditions Matter

This chemical shows sensitivity to moisture and air, which can trigger degradation. A lot of research points out how improper storage knocks down quality and raises risks. For example, too much humidity leads to clumping, and excess heat can change its chemical behavior. To protect product integrity and the health of workers, strict control always works best.

Temperature control remains critical. Shelves near active machinery or radiators push temperatures beyond safe limits. Direct sunlight sneaks through windows and heats up containers in ways folks may not notice right away. Many seasoned lab techs, myself included, have learned that storing ethyltributylphosphonium bromide in a cool, dry place pays dividends in long-term reliability.

Good Practices for Safe Storage

- Keep it in tightly sealed original packaging, away from wet areas.

- Store at room temperature—ideally, in a climate-controlled environment around 20–25°C.

- Place containers on shelves off the floor, away from heavy foot traffic or chemical splash zones.

- Avoid glass containers unless specified by the supplier, since halide salts might corrode some glass types over time.

- Label containers clearly, including date received and date opened. This helps everyone stay aware of shelf-life concerns.

Handling With Care: Direct Experience

Ethyltributylphosphonium bromide rarely makes headlines for spectacular mishaps, but safe handling keeps little injuries and accidents away. I once worked at a lab where this compound triggered a minor skin irritation, which taught me fast to double-check my gloves and always use a chemical fume hood.

- Wear disposable nitrile gloves and lab coats every time.

- Use safety goggles because mistakes happen—even to steady hands.

- Open the container inside a fume hood or with proper local exhaust ventilation. Vapors or powder can harm the eyes and lungs, especially after repeated exposure.

- Never pipette by mouth or add water directly to the powder. Slow and steady steps prevent dust clouds and chemical splashes.

- After working, wash hands thoroughly—residue lingers longer than people expect.

Managing Hazards and Spills

Experienced teams keep clean-up kits within reach. Silica-based absorbents work for small spills. For bigger incidents, evacuate and call in trained personnel. Prompt disposal of waste into clearly marked containers stops cross-contamination—key in shared facilities.

Improving Safety Systems

Facilities that update training every year spot risks before accidents begin. It helps to keep Material Safety Data Sheets (MSDS) handy in every work zone, not buried in a cabinet. The best labs make a habit out of clean benches, regular inventory reviews, and detailed incident logs. These low-tech steps prove their worth every single day.

Looking Ahead

As newer chemicals make their way into research, the basics still hold true. Storing and handling ethyltributylphosphonium bromide safely isn’t glamorous, but it keeps science moving forward, keeps people out of hospitals, and keeps lab budgets on track. Eyes on the details carry far more weight than fancy gear or half-hearted shortcuts.

Why People Care About This Chemical

Many workers and researchers find themselves dealing with new chemicals almost every year—ethyltributylphosphonium bromide happens to fall into that growing category. Chemical companies market it for various uses, mostly in research or specific industrial tasks. As demand for new materials rises, questions about health and environmental impact get pushed into the spotlight.

Health Risks: What Happens if You Get Exposed?

Experience in chemical handling shows us one simple thing—never take odd-sounding compounds for granted. Ethyltributylphosphonium bromide brings some legitimate concerns. Touching or inhaling the powder or dust may irritate skin, eyes, or airways. Data from the European Chemicals Agency and a handful of published papers confirm possible acute toxicity if swallowed, inhaled, or absorbed through the skin. High doses in lab experiments impact the central nervous system of animals. No one should shrug off the possibility of headaches, dizziness, or longer-term effects.

Most people won’t come face-to-face with this stuff at home, but industrial workers might. Gloves, goggles, and protective clothing aren’t just a formality. Good labs and production floors always carry safety data sheets that call for strict ventilation and rapid cleanup of any spills. Doctors in occupational medicine see rash cases and breathing trouble regularly—good hygiene and quick decontamination still stand as the best prevention.

Environmental Concerns: Is There a Real Threat?

Throwing out used chemicals or splashing them down the drain rarely goes unnoticed anymore. Wastewater plants aren’t designed to break down complex quaternary phosphonium salts like this one. Some studies suggest these molecules don’t biodegrade well, which means they linger, possibly harming aquatic life. Research from China and Europe hints at moderate toxicity to certain water fleas and algae. Because scientists haven’t seen all the long-term consequences in rivers, a cautious approach makes sense.

Spills or leaks during transport could trigger cleanups that cost local governments and companies serious money. Add in rising water-testing costs and public concern, and the message becomes clear: minimize environmental discharge wherever possible. Chemical firms adopting closed-loop systems, recycling processes, and treating effluent streams make a difference. The alternative—facing angry communities and stricter regulations—rarely ends well.

Who Tracks Risks and Pushes for Solutions?

Companies hauling or using this compound have to answer to regulatory groups. The European Union keeps detailed records and scores chemicals for possible inclusion on restrictive lists. In the United States, authorities at OSHA and the EPA monitor workplace safety and environmental impact. Transparent reporting and regular staff training mean fewer accidents. Health researchers urge more funding for studies, so future generations aren’t left guessing about the risks.

Cleaner technology sometimes comes as a side product of public scrutiny. Alternatives with a lower impact—biodegradable ionic liquids or salts fitting green chemistry frameworks—look attractive these days. With public pressure and better scientific knowledge, chemical safety keeps moving forward. Businesses and communities benefit when the risks get managed well and long-term thinking wins out over short-term profit.

Understanding Purity in Chemical Supply

Ethyltributylphosphonium bromide plays a role in research and industry settings, especially for its function as a phase-transfer catalyst and ionic liquid precursor. Purity levels steer the outcome of a synthesis or experiment. Most suppliers offer this material at 98% or higher purity, which removes many headaches around trace contaminants interfering with product performance or analytical clarity. Researchers expect high standards, because even tiny impurities can throw off catalyst efficiency or skew results—painful lessons I’ve picked up in lab work, especially during sensitive organometallic reactions.

High purity also eases regulatory worries. If you work in pharma, electronics, or specialty chemical sectors, impurity profiles might trigger audits or jeopardize certification. Sourcing ethyltributylphosphonium bromide at 98%+ purity offers some peace of mind, but it’s smart to request a certificate of analysis from your supplier. That’s the document that actually lists impurity data batch-by-batch, and it provides transparent proof in case of quality questions later on.

Real-World Packaging Sizes and Why They Matter

Chemists and engineers order ingredients in sizes that match their scale of use. I’ve seen ethyltributylphosphonium bromide show up in glass bottles holding just a few grams, all the way up to kilo-sized jugs sealed for industrial runs. Small packs, such as 5 g or 25 g bottles, show up most often in research labs where bench-scale experiments rule the day. Bulk uses, such as pilot plant or manufacturing, tend to drive demand for larger bags or drums—500 g, 1 kg, and sometimes even 5 kg or more.

Packaging ties into both safety and convenience. Smaller quantities reduce the risk in case of spills or errors, but larger packs save time and cut costs on repeat orders. Anyone who’s spent half a day weighing and transferring powder while juggling tiny glass containers will appreciate the simplicity of scooping from a single large drum. But there’s a trade-off: with bigger packages come more rules for storage and extra attention to moisture exposure and contamination. Even a brief exposure to air can clump powder forms or create cleanup headaches, so proper packaging goes beyond simple convenience.

Core Factors for Choosing the Right Source

My own experience has taught me to look past catalog numbers and prices. Consistent quality beats occasional deals in most labs. Finding suppliers that disclose both purity data and packaging specs signals accountability and helps build trust. Clear labeling on purity—ideally with method of determination and date of analysis—prevents surprises during peer review or customer audits.

Handling and disposal instructions add another level of reassurance. Since ethyltributylphosphonium bromide isn’t trivial to dispose of at scale, professional guidance helps teams plan for responsible use and downstream costs. At the end of the day, buying just enough for today's project, in packaging sizes that minimize transfer steps and waste, tends to maximize both safety and budget control.

Practical Solutions for Purchasing and Use

Sourcing chemical stocks can frustrate even seasoned scientists. By focusing on suppliers that provide not only the required high purity but a sensible range of package sizes, you limit waste and lower risk. It helps to have a protocol in your lab outlining preferred vendors, quality checks on incoming materials, and clear guidelines for repackaging if bulk supply must be split. Most teams find that building strong relationships with trusted suppliers and seeking transparency in labeling makes routine chemistry—and scaling up—a more predictable, less stressful process.