Ethyltributylphosphonium Chloride: Insights, Uses, and Future Direction

Historical Development

Back in the mid-twentieth century, phosphonium salts attracted serious attention among chemists interested in ionic liquids and phase transfer catalysis. Ethyltributylphosphonium chloride didn’t just pop up by accident; it arose from a search for salts that could stay stable under tough conditions. Early on, most of the focus went to ammonium and imidazolium compounds, leaving phosphonium cousins under the radar. Yet stories began piling up in the patent literature, especially coming out of specialty chemical firms in the ’80s, and folks began to notice its odd knack for holding up under heat, even when others broke down. This particular salt eventually crept up the list for researchers hunting for better solvents, more rugged electrochemical materials, and adaptable catalysts. With the first documented industrial-scale syntheses, manufacturers leaned into developing purposeful blends meant for separation processes, high-performance lubricants, and extraction applications. Today, ethyltributylphosphonium chloride sits firmly among the more adaptable members of the phosphonium family, drawing its pedigree from decades of trial and error mixed with real-world use.

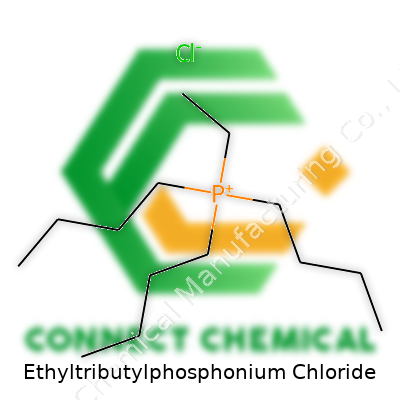

Product Overview

Ethyltributylphosphonium chloride drops into the family of quaternary phosphonium salts, featuring a chloride anion paired with the ethyltributylphosphonium cation. This combination brings together enough size and charge delocalization to knock down the salt’s melting point and boost its solubility in polar solvents. Bulk suppliers tend to market this material as a pale, powdery solid or a viscous liquid, depending on how meticulously dry it’s kept. Chemists value this salt for its strong ionic character, chemical resilience, and adaptability for catalysis or as a building block in ionic liquids. Those who study new materials often bump into its name on short lists of phase transfer agents or non-aqueous reaction media. For anyone curious about packaging, most product datasheets offer purity levels, bulk density, recommended storage temperatures, and shelf life, showing just how much business and lab environments have come to depend on detailed, reliable supplies.

Physical and Chemical Properties

Inside a chemistry lab, the details matter: ethyltributylphosphonium chloride boasts a modest melting point, often landing between 60 and 80°C. The salt dissolves well in common polar organics like ethanol, acetone, or acetonitrile, giving researchers flexibility in choosing solvents for reactions and extractions. Structurally, the molecule comes with three butyl groups and one ethyl stuck to the phosphorus, making the cation both bulky and flexible, but not so big it gums up the works in liquid processes. Its ionic character ensures it stays stable in water and alcohols but can show sensitivity if strong bases or potent oxidizers enter the picture. The product rarely gives off much odor and doesn’t present the typical volatility headaches seen with smaller amines or similar organics. Its crystalline or viscous state depends heavily on water content, making storage and handling just as important as chemical design.

Technical Specifications and Labeling

Industry players stick with IUPAC labeling rules and international safety tags to keep customers confident. Ethyltributylphosphonium chloride usually gets listed with a purity of 96% or higher, and packaging details often warn against moisture pickup, noting it tends to clump if exposed too long. Labels flag the need for airtight, inert containers and recommend storage below 25°C, often away from direct sunlight. Suppliers provide detailed certificates of analysis showing actual chloride content, residual metals, and water level, often backed up by spectroscopic methods. For transport, regulatory codes for quaternary phosphonium compounds and mild irritants come into play, nudging companies to standardize shipping and documentation. Identifying marks such as batch numbers, hazard pictograms, and clear UN codes help downstream users know exactly what’s inside each drum or bottle, reducing the chance of mix-ups or misuse.

Preparation Method

Production starts with tributylphosphine reacting with a suitable ethyl halide—commonly ethyl chloride—in an organic solvent under pressurized or refluxed conditions. The product forms as a precipitate or oily phase, depending on the solvent and batch size. Washing and filtration kick out most of the leftover reactants. After extraction with a polar solvent, further drying uses rotary evaporation or mild vacuum, often finished in a glovebox or under nitrogen to keep out water. Industrial producers often take this a step further by recycling unreacted phosphine or halide to cut cost and waste. Purification steps matter, especially for sensitive catalyst uses, so quality control teams lean on NMR and IR spectroscopies along with elemental analysis to spot impurities before packaging up the finished product. Every year, labs find ways to tighten up yield, cut down steps, or squeeze out better purity from the same batch equipment.

Chemical Reactions and Modifications

Ethyltributylphosphonium chloride steps into a range of chemical scenarios. In organic synthesis, it acts as a phase transfer catalyst in heterogeneous reactions, shuttling reactive ions from one phase to another. Researchers have built on its backbone to create other phosphonium salts by swapping the chloride with alternative anions—like tetrafluoroborate or hexafluorophosphate—stretching its usage into new ionic liquids. Under strong base, it holds up well, but fierce oxidizers or energetic nucleophiles will break up the phosphonium structure, releasing smaller phosphines or butyl fragments. In electrochemical setups, the salt sometimes lands in the electrolyte mix, thanks to its low melting point and robust conductivity. Scientists have also anchored the cation onto polymers or solid supports, chasing tougher catalysts for tough reaction environments. Each tweak in structure spins out different reactivities, whether for better solubility, thermal stability, or compatibility with green chemistry goals.

Synonyms and Product Names

Chemistry brings a long list of aliases. The most searched synonyms for this compound include ETBPCl, ethyltributylphosphonium chloride, and tributylethylphosphonium chloride. In trade, vendors may roll out unique catalog names or stock codes, but the CAS number and IUPAC designation remain anchoring facts to avoid confusion. Product literature from major chemical houses keeps these details front and center so academic and industrial customers can cross-check authenticity against batch data, ensuring what arrives in the mail matches expectations. Support staff answering hotline queries have these names memorized, especially since similar-sounding phosphonium salts sit just a syllable or two away, sometimes leading to expensive—if avoidable—mistakes.

Safety and Operational Standards

With any organophosphorus compound, users pay close attention during handling. Ethyltributylphosphonium chloride shows mild irritation potential if it gets on skin or in the eyes, prompting gloves, eye protection, and lab coats as standard kit. Good ventilation reduces risks tied to dust or fine particles during weighing or mixing. Should a spill occur, dry absorbents handle cleanup without water, which can help prevent unwanted hydrolysis or clumping. Inhalation rarely poses a risk in everyday lab use because of low volatility, but a fine particulate can still linger in the air—respirators see action in big industrial setups. Training materials and online guidelines point to immediate washing with soap and water following exposure, and storage in marked, sealed containers. Safety data sheets outline emergency protocols, disposal methods—usually involving organic waste incineration—and contact info for poison control or chemical response teams. Global regulations, including REACH in Europe and TSCA in the US, require full disclosure of manufacturing details and toxicity data.

Application Area

The real power of ethyltributylphosphonium chloride shows up in how often it pops up across industries. It plays a starring role as a phase transfer catalyst in organic synthesis, moving ions in reactions that would otherwise crawl along at a snail’s pace. Electrochemical researchers deploy it in ionic liquids for high-performance batteries, where its low melting point cuts down internal resistance. In pharmaceutical pilot plants, it offers a handy workaround in reactions requiring strong bases, protecting sensitive functional groups that break down under harsh conditions. Separation chemists use its customizable ionic character to extract rare metals or recycle solvents from dense mixtures. Polymer science teams blend it as an antistatic agent in specialty plastics and advanced coatings, fighting dust or debris accumulation in high-value parts. Environmental labs experiment with it in extraction protocols to pull out pollutants, especially heavy metals, from waste streams. Each application asks a different side of the molecule to take charge, explaining the persistent interest among engineers and scientists looking to solve everyday bottlenecks in bulk processes or small-batch discovery work.

Research and Development

Academic and private labs pour resources into refining both the salt itself and new applications using its structure. Recent focus turns toward greener synthesis, chasing reactions that use less solvent, chop down side products, and recover expensive starting materials. Teams investigate novel anion swaps, stirring up a pool of related ionic liquids for ecofriendly catalysis, recyclable electrolytes, or advanced lubricants. In electrochemical R&D, emphasis shifts to tuning ionic conductivity and understanding how the cation structure alters thermal and charge-transfer properties. Safety and handling methods also see continuous improvement, as smaller, busy labs adopt the compound and need practical, up-to-date protocols. Pharmaceutical teams look for variants that can function in drug synthesis without kicking up regulatory red flags. Each year, patent reports and specialty journals add fresh data—measured conductivities, phase diagrams, application case studies—building a foundation for even broader adoption.

Toxicity Research

Historical reports put organophosphorus chemicals under the social microscope, drawing scrutiny owing to their links to pesticides or nerve agents. In practice, ethyltributylphosphonium chloride has not shown strong acute toxicity in animal models, but its irritation to eyes and skin mirrors many salt-based chemicals. Chronic exposure brings more uncertainty—hence the need for gloves and closed systems. Researchers remain alert to possible breakdown products, which, depending on the route of decomposition, could harbor their own risks. Metabolism and excretion studies in mammals indicate slow to moderate clearance, underlining the importance of proper disposal. Environmental data stays slim, though most working scientists support limited, controlled use and targeted incineration of waste material. Long-term workplace studies help set occupational exposure limits, and as better analytics surface, data will fill in more blanks about cumulative risk or ecological impact, reassuring regular users and industrial partners about safe protocols.

Future Prospects

Ethyltributylphosphonium chloride’s journey looks far from over. The rise of ionic liquid technologies drives new research dollars into better, customizable salts, and academic curiosity keeps sharpening understanding around thermodynamic and transport properties. Pressure keeps building for chemical supply chains to offer greener, less energy-intensive production and end-of-life routes, possibly steering manufacturers toward renewable feedstocks or closed-loop recycling. Battery designers search for next-generation electrolytes that need resilience, conductivity, and manageable cost—qualities this salt and its kin can bring to the table. Look for upcycled variants or functionalized derivatives to test next-generation solvent systems, separation membranes, or antistatic plastics in consumer electronics. As environmental regulations toughen, future processes will likely shift from open-scale to more carefully monitored, small-batch syntheses, each guided by tighter data on health effects and environmental release. Collaboration across engineering, medical, and environmental teams will keep unlocking new use cases, but only as long as safety, transparency, and adaptability lead the way.

Chemicals Make the Modern World Tick

Walk into any advanced laboratory or manufacturing plant, and shelves of chemicals crowd the workspace. Yet, many of these names never show up in headlines. Ethyltributylphosphonium chloride doesn’t shout for attention, but its story matters. Over the years, people in research labs, pharmaceutical plants, and tech companies have reached for this compound because of its niche reputation. I remember my own first encounter with it—tucked in a corner of a university research lab, labelled with yellow tape and a warning sticker, yet highly prized by the scientists working there.

Behind the Science: What Does It Do?

Chemists appreciate ethyltributylphosphonium chloride for its role as an ionic liquid, which stands out because it handles tough jobs that water and many solvents simply can’t touch. It can dissolve and transport ions in strange environments, like inside batteries or fuel cells. In my own experiences, seeing how researchers relied on its ability to serve as a phase-transfer catalyst, helping chemical reactions run faster or more completely, it becomes clear why it crops up in technical conversations. Some specialty pharmaceuticals and advanced polymers rely on tricky reactions, and this chemical helps bridge that gap.

In the world of renewables, the shift toward more sustainable industrial processes means old-school toxic solvents fall out of favor. Companies have started using more ionic liquids like ethyltributylphosphonium chloride to make processes greener. Some of my former colleagues worked on scrubbers for power plants, where these liquids helped capture carbon dioxide more efficiently than classic approaches. In the end, this helps reduce the carbon footprint that’s fueling climate anxiety for many of us.

The Bigger Picture: Safety and Environmental Bumps

Every seasoned chemist learns about the risks tied to new chemicals. For all its upsides, ethyltributylphosphonium chloride calls for careful use. Safety data from regulatory bodies, like the European Chemicals Agency, highlight acute risks if someone handles it without gloves or spills it into a water supply. People can’t ignore the reality that some modern ionic compounds stick around in the environment or threaten aquatic life. Pushing for clear labeling, stricter storage policies, and regular training keeps high-performing substances from turning into accident statistics.

Waste disposal keeps popping up in industrial circles, too. Special collection bins, tracked inventories, and neutralizing treatments at disposal sites can lower the risks. I see more universities and workplaces insisting on full lifecycle analysis for every chemical on site. It slows down researchers sometimes, but it also protects the people and places we care about.

Innovation: Pairing Benefits with Responsibility

The search for the next generation of safe and effective catalysts runs up against a simple fact: there’s no perfect compound. Chemists, engineers, and safety officers share responsibility for reviewing research on alternatives and updating safety protocols. Governments and universities keep pushing for better awareness, and some tech companies are exploring new recycling methods for ionic liquids. If a process can use a less toxic cousin of ethyltributylphosphonium chloride, or recover it for a second use, the overall impact drops.

The value of chemicals like ethyltributylphosphonium chloride hangs on a balance—scientific potential on one side, human and environmental well-being on the other. My time spent next to flasks and fume hoods taught me that real progress means more than finding clever reactions. It’s about owning the whole process, from production through to disposal.

The Formula: Simple Yet Telling

Ethyltributylphosphonium chloride carries the chemical formula C14H32ClP. This formula spells out four butyl groups and one ethyl group attached to a phosphonium center, matched with a chloride anion. The structure might look complex to someone outside chemistry, but this arrangement unlocks more than meets the eye. For researchers and people working with advanced materials or specialty chemicals, knowing this formula gets you past the front gate. Before anything can happen—synthesizing, testing, or scaling—you need to know what you’re dealing with at the molecular level.

Why Names and Formulas Connect

Once I heard someone in a lab say that chemical names are like street addresses, but formulas are closer to Google Maps coordinates. If you’re tracking a compound like ethyltributylphosphonium chloride, you need the exact coordinates to reach your destination in synthesis or in an application. This compound, for example, belongs to a family called quaternary phosphonium salts. These molecules find their way into ionic liquids, materials used to dissolve other substances or conduct electricity without water. The chemical formula makes sure no mistakes happen when ordering or producing the compound, and in regulatory paperwork you can’t rely just on the name. Clarity matters, and a typo in a formula or a misstep in interpretation can put a whole project at risk.

Industry Impact: From Lab to Application

Ethyltributylphosphonium chloride doesn’t get the same spotlight as household chemicals, but its formula opens doors in research and industry. In some lab projects, especially those dealing with alternative solvents, I saw this kind of phosphonium salt used to create more sustainable chemical reactions. A friend who works in electrochemistry once said the formula made it easier to compare performance against similar salts. When a supplier offers a product, the chemical formula lets you double-check if what’s inside matches what you expect. Stories spread fast about botched shipments from using a similar-sounding compound. On the business side, the formula goes onto technical data sheets, ensures safe storage, and helps comply with safety regulations.

Issues with Nomenclature and Safety

One problem with chemicals like this lies in naming conventions. The name “ethyltributylphosphonium chloride” might still confuse someone new, yet the formula C14H32ClP cuts to the chase. That formula tells a chemist or safety officer right away how many carbon, hydrogen, chlorine, and phosphorus atoms to look for in a hazardous materials review. Consider the safety data sheets that must list details about toxicity, fire risk, and environmental effects. If the formula is wrong, the risk assessment won’t hold. I remember a case at a university lab where a mixing error due to a misread formula led to minor injuries—it showed how much rides on getting the chemistry right.

Pushing for Better Chemical Literacy

Professional experience tells me education lags where chemical literacy is concerned. Many people see a structure like C14H32ClP and feel intimidated, but that formula is less a barrier and more a common language. Promoting understanding of what these letters and numbers stand for reduces anxiety and limits mistakes. Training focus should shift to interpreting both names and formulas. If institutions invest in refresher training and make chemical labeling clearer, safer labs and workplaces will follow. Knowing what the formula represents keeps people safer and helps teams create new materials responsibly.

Reality Check on Chemical Safety

News about chemical hazards can spark worry, especially when the name feels like a mouthful—ethyltributylphosphonium chloride. This compound pops up in advanced technologies, mostly as an ionic liquid or catalyst. Its applications range from chemical manufacturing to some energy storage projects, places you won't regularly visit unless your day job involves lab coats and test tubes. Folks unfamiliar with chemical safety guidelines naturally ask if being near it means trouble for your health.

What We Know from Research

Most research focuses on how chemicals like ethyltributylphosphonium chloride impact workers and environments. The European Chemicals Agency lists this compound with warnings: skin irritation, possible eye damage, and trouble if inhaled in high enough concentrations. I remember a few years back, during a stint in a materials lab, the rule was to treat all unfamiliar substances with suspicion—gloves, goggles, proper ventilation—whether the hazard was confirmed or not. The basic advice holds here: don't touch, sniff, or taste unless you really understand what you’re dealing with and have safety gear nearby.

Exposure and Everyday Life

It’s rare to bump into ethyltributylphosphonium chloride outside controlled settings. This compound sits on shelves in specialty labs, not in household products like cleaning sprays or food packaging. If you’re not working in a factory or lab using these chemicals, you won’t be exposed. My farmer uncle never had to worry about phosphonium salts, but my chemist friends certainly check the safety sheets before opening new reagents at work. For anyone away from industrial zones, the risk feels remote.

Worker Safety and Industrial Responsibility

Actual health problems kick in at the production and research level. Breathing in the powder or vapor, direct skin contact, or splashes in the eye can result in irritation or worse, based on available toxicity data. Rigorous rules apply here. Employers should provide masks, gloves, united air handling systems. Regular training and drills give workers muscle memory for emergencies. I’ve seen firsthand how these steps work. Once, a dropped flask sent fumes into the air. Because the crew knew the drill—grab the mask, flip the vent fan, head for fresh air—nobody landed in the ER. These protections matter a lot more than paperwork regulations ever could.

Environmental Factors and the Bigger Picture

Left untreated, accidental spills can threaten water systems and wildlife. Not all phosphonium compounds break down easily, so monitoring run-off and waste streams makes sense. One solution involves investing in closed-system processing and robust containment. It’s a real cost, but lifelong harm from accidental exposure amounts to a bigger burden. Science keeps evolving, and newer methods for chemical recycling or safer substitutions keep entering the market. The process never stops, and neither should vigilance.

Smart Choices Support Community Health

Being alert matters more than fear. Trained professionals, solid rules, and upgraded technology keep ethyltributylphosphonium chloride on a short leash in most industrial settings. Normal life outside those doors continues without concern, as long as companies and regulators work with care and transparency. Open communication about chemical risk—what it means, who is exposed, what is being done for protection—gives everyone, from neighbors to employees, a voice in health and safety decisions. Countless chemicals serve important roles, but real expertise keeps people from paying the price. Facts and practical steps beat panic every time.

Why Proper Storage Makes a Difference

Safe storage of chemicals isn’t just a lab technician’s checklist item. It means protecting everyone working in the facility, and keeping processes running smoothly. Ethyltributylphosphonium chloride, a mouthful of a compound used in specialized chemical synthesis, calls for a careful plan on the storage side. Many folks focus squarely on handling, but it’s what happens between uses that can trip up even the most seasoned teams.

Understanding the Risks

Ask someone who has seen the results of improper storage: corroded shelving, containers that pop open from unnoticed pressure, or blurry labels leading to mix-ups. These troubles aren’t small. Ethyltributylphosphonium chloride forms part of the phosphonium salts crowd, holding properties that make it sensitive to moisture and heat. Keeping this compound dry and cool keeps both people and products out of trouble. I’ve seen labs lose whole batches and waste weeks of work simply because they left a drum sitting near a steam pipe over a long weekend.

Practical Steps for Safe Storage

Start by sealing the container. If the original packaging can’t be trusted—think tears, cracked caps, or faded security seals—it’s not worth the risk. Reseal using airtight containers. Anyone who has tackled cleanup after a minor spill knows: wiping up powder or crystals that have absorbed ambient moisture means facing sticky, hard-to-remove residues and potential hazards. Wet hands or gloves multiply the risk. Keeping things sealed isn’t a hassle; it’s a shield.

Store it in a cool, dry place. Out-of-the-way cabinets or chemical fridges work well, away from heat-generating equipment. Don’t let the storage spot slip below freezing, though. Temperature swings, especially in older buildings without good climate control, can create problems inside containers—condensation forms, crystals clump, and soon your supply isn’t pure or usable. Some organizations use digital temperature logs for high-value or hazardous chemicals. That system proved invaluable once in my experience, alerting staff to a faulty HVAC unit before any compounds reached a dangerous state.

Label and Segregate Wisely

Labels matter—clear, legible, up-to-date ones win every time. Tossing a marker-written tag onto a dusty lid risks errors, and on busy days, no one wants to slow down to double-check paperwork. Set up a routine to check labels every month. If you must store several types of phosphonium salts in the same room, keep compatible materials together on shelves, and add physical barriers between different chemical groups. This simple trick has helped avoid cross-contamination, which haunted one workplace I visited, resulting in expensive analytical do-overs.

Preparing for the Unexpected

Don’t bet on luck—keep the proper spill kits within reach, including absorbent pads, goggles, gloves, and a disposal container made of compatible material. Every year, I’ve witnessed new staff members discover firsthand why spill kits need restocking, whether a jug topples over or static discharge lifts powder from an open jar. Regular training makes the difference. Staff who know exactly where to find the eyewash station and neutralizer feel confident tackling minor accidents fast—before small stuff grows into a major event.

Moving Toward Smarter Storage Solutions

Building a storage routine that balances safety and convenience pays off. Tracking environmental conditions, scheduling regular training, and using the right gear leads to fewer surprises and less waste. With pressures mounting in chemical manufacturing and research, losing even a little of a tricky compound can lead to unhappy clients or missed deadlines. Storing ethyltributylphosphonium chloride isn’t just about following the rules; it’s about working smarter and keeping the next shift—and the next project—a little safer.

Recognizing Chemical Risks

Ethyltributylphosphonium chloride doesn’t show up on supermarket shelves, but it’s a staple in plenty of lab and industrial settings. Its applications range from ionic liquids to phase-transfer catalysts. Every bottle carries a risk profile that asks for respect well before popping a cap or transferring a gram to a beaker. Skin and eye irritation can sneak up quickly if splashes go unchecked. When powders float through the air, inhalation brings another set of issues. Anyone who’s opened up a forgotten container knows the surprise of a strong odor or a sting to the nose—that’s your red flag. Chemical burns, rashes, and persistent coughs aren’t rare stories from rushed or distracted work benches.

Personal Protection Every Time

No one ever regretted putting on goggles or gloves before touching Ethyltributylphosphonium chloride. Standard nitrile gloves, a long-sleeved lab coat, and comfortable splash-resistant goggles make up my minimum set before even cracking a seal. Skipping these steps turns a simple spill or sneeze into an hours-long clean-up or, worse, an emergency room visit. Clean air matters, too. Working with open reactions or weighing out this salt in a chemical fume hood keeps vapors and dust out of your lungs. A simple dust mask isn’t enough for real protection.

Storage Choices Matter

Mistakes often start long before handling—usually in the storage room. I’ve seen solvents stacked next to reactive salts, and nearly every incident could have been avoided with more careful sorting. Ethyltributylphosphonium chloride holds up best in tightly closed, labeled containers, sitting away from direct light or moisture. Room with a temperature below 25°C keeps breakdown risks lower. Any leaky bottle ruins more than just your day; it spells trouble for the rest of the shelf and the folks who follow after you.

Spill Response and Emergency Mindset

Quick thinking makes the difference after a spill. Long ago, a simple tip taught to me: keep a spill kit nearby, not around the corner, and check it every month. Absorbent pads, neutralizing agents, disposable gloves, and a designated container for cleanup waste belong right next to the workspace. Never sweep spills with bare hands or dry brooms since dust in the air multiplies exposure risks. Work in a team and be honest about spills—silent mishaps always come back worse for someone else.

Disposal That Respects the Community

Landfills and communal sinks can’t safely handle most specialty chemicals. Ethyltributylphosphonium chloride wastes need sealed containers, labeled with contents and date, heading for licensed hazardous waste collectors. Sewers and regular trash never qualify here. Check with the local environmental office for disposal guidance. It’s easy to forget about chemical fate once the container is off your bench, but groundwater contamination and landfill fires are real stories from poor choices. I’ve learned to keep my conscience clear by finishing every experiment with a cleanup plan, recorded and confirmed.

Training and Respect Build A Culture of Safety

Proper training changes how folks look at even the most routine task. Sharing experiences—both successes and mistakes—gets everyone thinking in advance. Since safety standards update over time, regular refreshers keep memory sharp. Auditing habits and updating safety sheets keeps everyone honest. A culture that values care over speed serves the entire team better. At the end of the day, trust grows in labs where respect for materials, space, and each other stays at the center of daily routines.