Ethyltributylphosphonium Diethylphosphate Salt: A Closer Look

Historical Development

Chemists have spent decades exploring better solvent systems, and ionic liquids like ethyltributylphosphonium diethylphosphate salt have become one answer to challenges faced in synthesis and processing. Early organophosphonium salts showed promise but lacked the necessary thermal stability and flexibility for widespread industry use. In the late twentieth century, researchers dug deeper into customizing ionic liquid structures. By 2003, mainstream studies had marked the phosphonium family as more stable and less susceptible to hydrolysis than ammonium analogs. This pushed both pharmaceutical researchers and engineers to pivot toward such salts for their robust oxygen sensitivity and reliable platform for green chemistry. Even now, labs and startups keep reaching for modified cations and anions to tune performance, knowing that these tweaks may unlock new generations of ionic liquids tailored for everything from catalysis to extraction without the hazards familiar to older solvents.

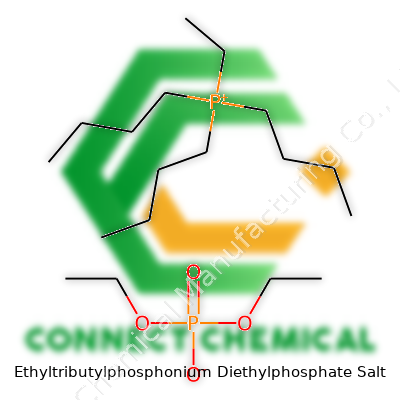

Product Overview

Ethyltributylphosphonium diethylphosphate salt is an ionic liquid that usually presents as a clear, sometimes slightly viscous fluid. Its backbone consists of a phosphonium cation paired with a diethylphosphate anion. The structure allows for a low melting point and high ionic conductivity, features valued in emerging battery and supercapacitor technologies. Unlike typical organic solvents, this salt doesn't evaporate at room temperature, which makes it less prone to contaminating air and safer for workers in labs and industrial plants. Consumers mostly find this material packed in airtight, amber glass bottles or high-density polyethylene containers, designed to shield against moisture and ultraviolet light that could degrade the compound.

Physical & Chemical Properties

The measured melting point for ethyltributylphosphonium diethylphosphate lands near 40°C, which puts it within easy reach for most laboratory procedures. Its density often sits around 1.07 g/cm³ at standard conditions, providing a heavier alternative to most solvents people use. The salt dissolves readily in water and a spectrum of polar organic solvents—a property that accelerates its adoption for specialized extraction and catalysis workflows. Thermal analysis demonstrates stability up to about 250°C before decomposition, well beyond most conventional organics. Importantly, this stability under a range of chemical environments reduces the risk of dangerous breakdown products or exothermic reactions, lessening incident rates at busy facilities.

Technical Specifications & Labeling

Producers usually supply ethyltributylphosphonium diethylphosphate with a purity exceeding 98%, checked using techniques such as NMR and ion chromatography. Labels list batch number, date of manufacture, recommended shelf life, and hazard symbols mandated by GHS regulations. Most suppliers supply detailed COAs, including elemental analysis and residual solvent data to meet procurement standards of pharmaceutical and electronics manufacturers. It’s common to see suggested storage temperatures just below room temperature to slow hydrolysis, and a stern warning not to allow moisture ingress.

Preparation Method

Making this salt usually involves direct alkylation of tributylphosphine, where it reacts with ethyl halides in an inert solvent. The intermediate phosphonium halide then sees metathesis using a diethylphosphate source like sodium diethylphosphate. After filtration and solvent removal, the pure salt undergoes further drying under vacuum to achieve the right level of water content for specialized uses. Every chemist I’ve known working with this type of material stresses the importance of anhydrous conditions because water impairs its utility as a true ionic liquid and fouls analytical instruments. The DIY route at small scale never matches the cleanliness attained with industrial-scale purification, so reputable sourcing matters.

Chemical Reactions & Modifications

Ethyltributylphosphonium diethylphosphate serves as both a reagent and reaction medium for numerous chemical transformations. It stands up to strong bases and acids, expands the types of metal-catalyzed cross-couplings possible, and sometimes boosts yield or selectivity by gently polarizing reactants. Chemists seeking greater hydrophobicity can swap out one or more of the alkyl groups on the phosphonium center, or pick alternate phosphate esters for the counterion. These structural adjustments let researchers fine-tune miscibility or match compatibility with bioactive compounds when synthesizing new drug candidates. Sometimes, after use, the salt can be recovered through vacuum distillation, supporting efforts at reagent recycling across green chemistry projects.

Synonyms & Product Names

Some catalogs list this compound as (tributylethylphosphonium) diethylphosphate or occasionally by the shorthand ETPDEP. A few vendors may attach proprietary trade names, leaning into branding to stake their claim in the specialty chemicals market. End users—whether in academic or private labs—often fall back on the more systematic IUPAC name or well-known abbreviations when ordering or publishing research.

Safety & Operational Standards

Lab safety officers keep a close eye on ionic liquid inventories, because safety data on many newer phosphonium salts is still evolving. Ethyltributylphosphonium diethylphosphate generally exhibits low vapor pressure, but it can irritate skin and eyes. Long-term exposure has not revealed systemic toxicity at low doses, yet lack of long-term population studies demands cautious handling. Researchers wear gloves, splash goggles, and ensure strong ventilation to prevent accidental contact or inhalation. Procedures involving the salt include written protocols for cleanup and disposal, with all waste routed through hazardous collection services. Spills get absorbed with inert materials and stored in sealed drums until professional treatment. Transport teams work under similar restrictions, logging shipments and verifying containers to comply with international UN numbers and GHS guidelines.

Application Area

Technologists see real promise for ethyltributylphosphonium diethylphosphate in fields that demand stable solvents able to dissolve both organic and inorganic materials. In battery research circles, the salt enables safer electrolyte formulations that outlast existing standards and suppress flammability. Chemical process developers exploit the salt’s award-winning solvation for separation of biomolecules, recycling precious metals, and driving greener catalysis. Some pharmaceutical researchers use it to boost yields in tricky, multi-step syntheses that falter with conventional solvents, especially those needing controlled polarity profiles. On a personal note, talking to R&D staff at enzyme companies, they’ve shared stories of how these salts help stabilize proteins in solution, unlocking new bio-catalysis routes and laying groundwork for sustainable industry.

Research & Development

A lot of current research focuses on designing new phosphonium salts with tailored features—thermal resilience, biocompatibility, or low toxicity. Teams at leading universities probe structure-property relationships using NMR, IR, and advanced spectrometry tools. Consortiums, teaming up with industry, drive pilot plant studies, evaluating how these salts behave in continuous-flow operations and non-standard conditions. Patents keep rolling out for new derivatives designed for carbon capture, next-generation batteries, and rare metal extraction. In the literature, citations for ethyltributylphosphonium diethylphosphate keep trending upward, especially in sustainable chemistry and chemical engineering fields. Since reproducibility underpins any scientific claim, labs often repeat and share exact protocols, down to moisture control steps, helping push broader adoption and technology transfer.

Toxicity Research

Toxicologists have done early acute toxicity screening on both cell lines and small mammals using ethyltributylphosphonium diethylphosphate. So far, evidence suggests that, handled right, the compound does not pose acute systemic health threats—unlike older alkylphosphates that proved dangerous in agricultural use. Nevertheless, chronic exposure studies are still underway. Regulators want to see clear data matching internationally agreed standards before they allow freer use outside of controlled environments. Landfill and water treatment plant trials look at long-term breakdown pathways so operators know what happens under disposal or accidental release scenarios. This conservative, data-driven stance reflects lessons painfully learned from legacy solvents, ensuring that new green alternatives offer real safety for workers and the environment.

Future Prospects

As more companies hunt for sustainable chemicals, phosphonium salts like ethyltributylphosphonium diethylphosphate look ready for wider spotlight. Automation in chemical synthesis, moving into continuous cycles and miniaturized flow systems, benefits from ionic liquids able to endure harsh conditions and help recycle rare reagents. Energy storage researchers look at these salts for improving next-gen batteries and supercapacitors, where stable, nonflammable electrolytes open new design doors. The pharmaceutical pipeline increasingly features synthetic steps championed by such salts, aimed at trimming waste and improving process safety. If the industry continues investing in better toxicity profiling, stronger recycling solutions, and reliable large-scale production, this unique ionic liquid might underpin a new wave of cleaner, safer, and more efficient manufacturing.

The Story Behind Ethyltributylphosphonium Diethylphosphate Salt

Folks in the chemical world often chase innovation by finding new molecules with unique talents. Ethyltributylphosphonium diethylphosphate salt proves itself as a quiet workhorse behind the scenes. It doesn't show up in household shopping carts, but the ripple it sends out in labs and factories can touch plenty of lives.

Why Industries Turn to It

This salt steps into a realm called ionic liquids, fancy words for substances that stay liquid even below the boiling point of water. In my own work in chemical research, I’ve watched scientists swear by these ionic compounds for their knack at dissolving tough materials and serving as green alternatives to more toxic solvents. The conversation often circles back to reducing hazard in synthesis, making this salt a favorite for teams who want to avoid fire risks or volatile organic chemicals.

Powerful as a solvent, ethyltributylphosphonium diethylphosphate can break down stubborn molecules in chemical reactions where traditional options flounder. Synthetic chemists use it to boost yields and nudge reactions at lower temperatures. Less energy means smaller utility bills for companies, not to mention fewer greenhouse gases heading into the air.

Working for a Safer Planet

This salt supports the push for greener chemistry. Regulatory pressure keeps climbing for businesses to phase out old-school, nasty solvents that hurt workers or nearby communities. Ionic liquids like this one offer a pathway forward. Reports from the American Chemical Society point out lower flammability and reduced release of noxious fumes when these types of chemicals get used in the workplace. As someone who’s spent my fair share of time with my head over beakers, I don’t take safer breathing air for granted.

Advanced Materials, Cleaner Future

Materials engineers look to this salt when they produce new plastics, membranes, or specialty coatings. It helps carry out reactions cleanly, limits leftover byproducts, and often gives the material a longer shelf life. Researchers in battery science explore it for next-generation electrolytes—lifting hopes for electric vehicles that store energy more reliably or even recharge faster on the fly.

Weighing the Risks and Tough Choices Ahead

No chemical magic comes without pitfalls. Hidden dangers sometimes surface after years in use, so companies and universities devote resources to toxicology studies and waste treatment solutions. Proper training and storage matter. Those working with it need respect for its potential risks, just like with any strong tool in a craftsman’s shed.

Room for Growth

One challenge I see: price. High-purity chemicals chew through lab budgets. As large-scale manufacturers adopt greener practices and boost production, supply increases, helping to tame costs. Governments and non-profits have stepped in, funding research to push safer, affordable alternatives into the mainstream. Education and transparency keep progress steady, giving the public a seat at the table whenever risks and rewards are weighed.

Watching a specialty chemical evolve from niche curiosity, to versatile tool, to possible environmental ally gives real-world science a pulse. Fewer hazards, smarter manufacturing, and better products fuel a cycle that shapes our health and environment for the better. If ethyltributylphosphonium diethylphosphate salt finds more homes in science and industry, there’s real promise for safer—and more sustainable—tomorrows.

Understanding The Risks

Not every chemical you find in the lab shows its teeth right away. Ethyltributylphosphonium diethylphosphate salt hides potential dangers that make respect the key word here. I’ve worked with phosphonium salts before—gloves, goggles, fresh air always on my mind. People get drawn in by the science, but a slip-up with chemicals like this brings trips to the emergency room, not new discoveries. Inhalation, ingestion, and skin exposure can lead to a range of problems, from irritating rashes and eye burns to respiratory damage. Even a quick splash on bare skin has left colleagues scrambling for the safety shower more than once.

Why Protection Comes First

Experience drives my respect for the basics. Polyvinyl gloves keep chemicals from breaking through, and nitriles offer even better peace of mind. A sturdy cotton lab coat shuts out splashes, and protective goggles go beyond the day-to-day reading glasses. Chemicals in this class seep through latex and linger on skin far longer than people realize. Washing with hot water and soap right after work stops many trips to health services. In settings where I saw less discipline, I saw more skin complaints and eye injuries.

Always Work With Ventilation

Fume hoods become a lifeline with salts and solvents. One friend decided to skip them on a busy day, thinking they’d only be mixing for a few minutes. Vapor exposure knocked them out for an afternoon—and the headaches stuck around for days. Even if a material seems solid, breakdown products turn airborne in ways that catch people off guard, especially at scale. Exhaust fans and local ventilation keep the room safe for the next person. Good air quality isn’t a bonus in the lab; it’s the foundation that keeps people healthy year after year.

Labeling and Storage Battles Complacency

With so many white powders and colorless liquids stacked on shelves, keeping labels fresh and storage dry really matters. Mixed up chemicals rarely announce themselves. Once, a colleague grabbed the wrong salt, thinking it was benign, and ended up ruining an entire batch and risking a chemical reaction that could have exploded the glassware. Double-checking labels, using secondary containment like trays, and storing everything at the right temperature keep drama out of the lab. Humidity breaks down the compound faster than some expect, producing sneaky byproducts that nobody wants to handle. Clear hazard marks and dedicated storage space cut down the guesswork.

Quick Response Saves More Than Just Projects

Every spill, even a small splash, deserves a fast, organized cleanup. I learned after seeing someone wipe an unknown splash with a bare hand. Burns appeared, and the follow-up cost time, money, and well-being. Emergency eye wash stations and safety showers need regular checks—blocked basins during inspections signal that the safety culture has slipped. Training never ends, even for those who feel they’ve seen it all before. Running through spill response basics every month helped my old team cut mishaps to almost nothing.

Building Good Habits

Chemistry can inspire, but only when handled with respect. From my years in research, one truth stands out: the safest teams work on skills constantly and call out short-cuts on the spot. This attitude, plus solid personal protective equipment, saves more skin and eyesight than anything else. Reading every chemical’s MSDS, keeping open lines to supervisors, and watching colleagues’ backs—these habits outlast the compounds we use and keep research possible for everyone.

Digging Into the Details

Chemistry likes to give us formulas that don’t exactly roll off the tongue. Ethyltributylphosphonium diethylphosphate salt is one of those. To figure out its formula, it helps to break the name down. The cation—ethyltributylphosphonium—has three butyl groups and one ethyl group attached to a phosphonium center, making it [C2H5P(C4H9)3]+. The anion—diethylphosphate—carries the formula [C4H10O4P]–. Put them together, and you get C14H34P+ · C4H10O4P–, often simplified to C18H44O4P2.

Understanding the Building Blocks

I remember working in a university lab trying to make sense of phosphorus-containing salts for some unusual experiments. It became clear to me quickly that skipping over a compound’s structure—or its formula—leads to all sorts of mistakes. These compounds don’t just sit in glass bottles. They take part in reactions, carry charges, and split apart in solvents. Ethyltributylphosphonium diethylphosphate belongs to the ionic liquid family. These salts don’t fit the stereotype of table salt; they often flow like oil at room temperature, and that opens doors in chemistry that table salt never could.

Why the Formula Has Real-World Impact

If you work in chemical engineering, you know the frustration of tracking trace contamination. That’s where this particular salt comes in—a hefty, chunky molecule that brings a special set of properties. Ionic liquids like this one can dissolve other tough-to-dissolve materials, sometimes even cellulose from plant waste, so that scientists can break down wood and other biomass into new fuels or plastics. Their low vapor pressure means fewer fumes to worry about, encouraging safer and more efficient lab practices.

Cutting through the confusion is important for anyone handling these liquids. Get the formula wrong, and you risk loading up a reactor with the wrong compound, or ordering the wrong starting chemicals and losing weeks of work. Even worse, overlooking the phosphonium center or the structure of the phosphate group might mean misjudging how the salt will interact with other molecules. That’s not an error that can be shrugged off with a simple “try again.”

Hazards, Benefits, and Future Questions

This phosphonium-based salt is gaining ground in green chemistry circles. Traditional solvents release volatile organic compounds, polluting the air and putting workers at risk. By switching to ionic liquids, chemical facilities can aim for cleaner processes that stick with safety and environmental guidelines. Regulatory boards keep a close eye on novel materials, pushing companies to show that their chosen solvents won’t bring hidden hazards into the workplace.

Chemists testing these compounds also need to keep one eye on cost. Some phosphonium salts get pricey fast. This matters for scale; a process might look promising in a beaker but break the budget in a larger vat. Practical chemistry always circles back to availability and real-world economics.

Making Progress in the Lab

Lab safety and environmental health drive a lot of the recent research into these salts. The backbone of ethyltributylphosphonium diethylphosphate’s usefulness lies in its structure. The phosphonium center gives it high chemical stability, while the diethylphosphate anion broadens the range of things it can dissolve. Chemists look for these unique salts while trying to improve extraction efficiencies or lower toxic emissions. The right formula is more than just numbers and letters—it’s a gateway to safer workplaces and better outcomes for everyone involved.

Understanding What’s at Stake

Anyone who’s worked around chemicals for a while knows that plenty of substances behave differently than you expect. It only takes a minor mistake—like letting moisture leak into the wrong place—to turn a routine procedure into a real hazard. That’s exactly why storing chemicals such as Ethyltributylphosphonium Diethylphosphate Salt calls for more than tossing it on a generic shelf and forgetting about it. At its core, this task’s about protecting both human health and investment in research or production.

The Simple Rules for Storage

Storing this salt starts with keeping it cool and dry. From experience, once ambient humidity gets into chemical storage, clumping, degradation, and sometimes outright dangerous reactions can follow. Always look for a space with consistent temperature control—usually not above room temperature works best—and steer clear of direct sunlight. Even with overhead lights, sources of heat lying too close to shelves act as trouble magnets.

Sealing matters just as much. Never trust a loosely fitted lid or a jury-rigged cap. Whether the salt arrived in a glass bottle or a plastic container, check for chemical compatibility and ensure an airtight seal every single time. Manufacturers recommend containers that keep atmospheric moisture out, and nothing beats actually following those directions. Chemical-resistant labels help a lot because faded or misplaced identification invites accidental mix-ups that no busy lab needs.

Handling Moisture: The Not-So-Small Details

Moisture doesn’t just damage Ethyltributylphosphonium Diethylphosphate Salt; it can produce byproducts that interfere with experiments or processes. Once, I saw a batch of a similar salt ruined simply because someone left the desiccator lid unfastened. The whole project set back by days, if not weeks. So keeping silica gel or another desiccant inside storage cabinets makes life easier. Checking the desiccant regularly helps catch any saturated packets before real problems start.

Avoiding Mixing and Accidents

No one wants to clean up a spill of reactive phosphorus compounds. Dedicating a section of the storage area to each family of chemicals cuts risk. Never put incompatible chemicals close together, even if they look harmless at a glance. Double-check storage recommendations for solvents and oxidizers—almost every serious chemical accident in labs stems from ignoring these basic separation tactics. If the Material Safety Data Sheet says avoid strong acids or bases, follow it to the letter.

Keeping Safety at the Forefront

Personal protective equipment matters not just during active use but also while handling containers. Gloves, goggles, and a lab coat become second nature over time—no one should “make a quick grab” without them. If a spill happens, proper containment materials and trained staff play a major role in minimizing harm. Regular training and reminders keep everyone on the same page, whether you're deep into academic research or managing an industrial supplier shelf.

Solutions for Better Chemical Management

Digital inventory systems help track chemical age and storage status. Barcoding, combined with clear logs, avoids awkward surprises like finding expired or degraded materials years later. Manufacturers and suppliers offer guidelines and often recommend secondary containment. These extra trays or bins catch leaks before they hit a wider area, offering peace of mind and keeping workspaces safer and more compliant with regulations.

Taking small steps every day—cleaning up after each use, checking container seals, rotating inventory—goes further than dramatic once-a-year overhauls. In the end, good storage isn’t only about ticking boxes; it’s about protecting lives, research outcomes, and sometimes, the environment outside those lab walls.

The Practical Reality of Solubility Questions

People working in laboratories know how frustrating it gets chasing reliable data on newer chemicals. Ethyltributylphosphonium diethylphosphate salt doesn’t show up in most textbooks, so you have to dig deeper. Some folks spot “phosphonium” in the name and bet it acts like an ionic liquid, making some big leaps. Years of spent afternoons struggling with unexpected precipitates have made me cautious about treating any compound as an obvious case.

What Matters in the Real World

Solubility isn’t just some idle curiosity—people care because it affects how a chemical works in catalysis, extraction, electrochemistry, and even environmental impact. Products living up to a promise of “green” in industry often depend on whether something dissolves in water or a less hazardous organic solvent.

I’ve spent time watching lab mates add expensive powders into water, only to stare at cloudy suspensions that refuse to clear. It wastes money. It also slows research and lets deadlines slip for projects that count on quick answers. So the question about ethyltributylphosphonium diethylphosphate isn’t just theoretical—it saves wasted effort, reagents, and fuel for the heater plate.

Dissecting the Chemistry

This salt comes from a family known in ionic liquid circles. Phosphonium cations tend to be chunky, and the “ethyltributyl” variation stacks up a lot of carbon. Diethylphosphate forms the other half, which is polar but not especially eager to make friends with water like chloride or nitrate would.

Academic papers on similar salts give some clues: the mix of bulky organic cations with mid-sized anions usually means lower melting points and less tendency to dissolve in plain water. Many toss the word “hydrophobic” around for these combinations, which my experience backs up. I remember weighing out similar salts—ethyl groups just enough to mess with hydrogen bonding, and butyl chains refusing to stay anywhere near water.

In organic solvents, the outcome depends on what you use. Ethanol, acetone, and acetonitrile sometimes coax phosphonium salts into solution, especially where the salt’s hydrocarbon parts outnumber the polar patches. I’ve watched colorless liquids go cloudy when switching from ethyl acetate (not much luck dissolving) to dichloromethane (works better). Polar aprotic solvents usually do the job fastest, but again, not always. You pick, test, and sift through results.

What Researchers and Industry Need

The stubbornness of these salts to mix with water changes how chemists design processes. It often helps with selective extraction, or enables phase-transfer catalysis. Those designing greener chemistries should know the full story. Running computer models or logging solubility test results in open-access databases would help everyone avoid surprises and needless bench work. It’s not just about convenience—a single mistake dumps hours of labor and valuable reagents into the waste bottle.

Regulations now push for safer, lower-impact materials and processes. Knowing which solvent to grab means you don’t chase your tail, and you respect safety sheets. The moment chemists share real, direct experience with this salt in solvents both aqueous and organic, it saves time across the research world. If more lab groups reported firsthand, properly peer-reviewed measurements on ions like these, fewer students would stand in front of a fuming flask, muttering about their luck with mystery chemicals.

Every gram wasted because someone couldn’t guess solubility multiplies across university and industrial labs. Reporting what works and doesn’t—plainly, with as few inferences as possible—gets results, cuts costs, and supports that growing need for greener chemical practice. Sharing the truth about where this salt dissolves brings the lab bench a little closer to sanity.