Ethyltributylphosphonium Hexafluorophosphate: A Commentary on Its Story and Impact

Historical Development

Nothing about chemistry stays the same for long. The story of Ethyltributylphosphonium Hexafluorophosphate started in the pressure cooker days of organophosphonium salt research, right as folks began hunting for stable and versatile ionic compounds. Back then, the need for reliable phase-transfer catalysts and ionic liquids pushed chemists to widen the phosphonium catalog. Hexafluorophosphate anion, with its remarkable stability, caught attention quickly. It wasn’t some overnight wonder—decades of gradual trial, error, and adjustment led researchers to focus on this specific combination. The more chemists learned about safe handling of fluoro compounds and phosphonium chemistry, the more useful this molecule became. Laboratories and industry, particularly in Europe and East Asia, dug deep into such compounds during the 1970s and 1980s, the same era that gave rise to widespread interest in ionic liquids for greening up old reactions and unlocking new ones.

Product Overview

Ethyltributylphosphonium Hexafluorophosphate stands out in labs as a white to off-white crystalline solid. The alkylphosphonium cation comes paired with the robust and non-nucleophilic PF6- anion, making it quite a flexible ingredient in synthesis. Unlike some older salts that break down or explode in humid air, this compound holds up. It finds use in organic synthesis, electrochemistry, catalysis, and even as a component in ionic liquids. Researchers appreciate its relatively high melting point and convenient handling in both research and production scale settings.

Physical & Chemical Properties

Diving into the specifics, Ethyltributylphosphonium Hexafluorophosphate boasts a molecular formula of C16H36FP2 and a molecular weight hovering around 410 grams per mole. Its crystalline appearance changes little with typical temperature swings in the lab, and it absorbs minimal moisture when left exposed. Melting temperature sits above 150°C, which means it can survive many reaction conditions without losing integrity. The non-coordinating nature of the PF6- anion keeps this salt resistant to hydrolysis and compatible with a range of solvents, both polar and non-polars. Neither the cation nor the anion tends to participate in side reactions, which matters because other salts sometimes gum up reaction mixtures or cause byproduct disasters.

Technical Specifications & Labeling

Looking at the label, suppliers need to give clarity. Purity for research-grade Ethyltributylphosphonium Hexafluorophosphate often hits 98% or better, with careful checks for water content (Karl Fischer typically below 0.5%), chloride content, and heavy metals. Labels must mention batch number, CAS number, hazard warnings, and standard pictograms required by GHS regulation. Transporters and buyers should receive SDS paperwork detailing thermal stability, recommended storage around room temperature in airtight containers, and immediate first aid advice in case of accidental contact.

Preparation Method

Industrial and academic labs usually produce this compound by quaternization. Tributylphosphine reacts with ethyl bromide to give the phosphonium bromide salt, which is then metathesized with potassium hexafluorophosphate. Careful washing, drying, and recrystallization steps weed out both unreacted organics and inorganic byproducts. This two-stage method keeps operations straightforward but requires attention to detail. Sloppy precipitation or filtration leads to salt that fails purity checks. The main challenge comes from handling PF6- anion—vigorous ventilation and protective equipment are non-negotiable. Side reactions involving trace water or oxygen sometimes spoil the yield.

Chemical Reactions & Modifications

Ethyltributylphosphonium Hexafluorophosphate acts as a phase-transfer catalyst in biphasic organic syntheses, encouraging reactions that otherwise stall out because the reactants won’t mix. Its bulk and charge help shuttle ions across boundaries in electrochemical cells and extraction workups. The molecule itself stands tough, rarely changing structure under ordinary synthetic conditions. In recent work, chemists have tinkered with swapping other alkyl groups for the ethyl and butyl chains, exploring how different alkylphosphonium cations affect ionic liquid properties or encourage greener reaction pathways. The hexafluorophosphate anion sometimes gets substituted for tetrafluoroborate or similar stable anions in order to tailor physical characteristics for custom applications.

Synonyms & Product Names

In catalogues and safety bulletins, Ethyltributylphosphonium Hexafluorophosphate crops up under alternate names like ETPPhos PF6, Ethyltributylphosphonium hexafluorophosphate, and often by the shorthand ETP PF6. Some vendors simplify things with abbreviations, while regulatory listings jot down full IUPAC names for clarity during import/export and safety reviews. These synonyms matter for anyone tracing supply chains or reading cross-disciplinary research—mistaken identity leads to expensive misorders and sometimes even dangerous lab incidents.

Safety & Operational Standards

Anyone using this compound has to stay alert, especially in the prep room. The hexafluorophosphate group can give off hydrogen fluoride if mishandled around strong base, acid, or open flame, and that’s no joke for lungs, skin, or eyes. Gloves, goggles, and stubborn ventilation are minimum standards in every responsible lab. Disposal involves neutralization and specialized waste channels, never down the drain or in municipal trash. Storage works best in cool, dry lockers, far from acids and moisture. All hands in the lab benefit from regular safety refresher sessions, and newcomers always need up-to-date training before they go near containers of this salt. While not the most dangerous substance in the stockroom, it deserves respect. Deliberately lax procedures turn minor issues into full-blown emergencies.

Application Area

Ethyltributylphosphonium Hexafluorophosphate sees action in a surprising range of fields. Synthetic organic chemists value its phase-transfer abilities for coupling, alkylation, and nucleophilic addition reactions in both academic papers and industrial-scale syntheses. Electrochemistry labs swap in this salt for older quaternary ammonium analogs because it enables wider solvent compatibility and better current efficiencies in some battery setups. A recent wave of research has also involved the development of phosphonium-based ionic liquids for green chemistry, solvent-free synthesis, and separation science. Those exploring next-generation electrolytes for energy storage have found this compound promising, especially for high-voltage lithium-ion batteries and supercapacitors. Process engineers see real potential in swapping out traditional and frequently toxic reaction media for phosphonium salts, which often can be recycled.

Research & Development

Over the last decade, labs worldwide have ramped up work on tuned phosphonium salts. New protocols focus on optimizing synthesis to step up purity and minimize waste. Researchers experiment with alternative quaternization strategies that replace petroleum-based feedstocks or cut down on hazardous byproduct generation. Physical chemists continue dissecting characteristics like melting point depression and viscosity for ionic liquid blends, always looking for tweaks that grant unique solvation or catalytic properties. New analytical data on thermal stability, NMR signatures, and reactivity profiles keep trickling in as groups push boundaries on where this salt may shine, whether in cleaner catalysis or clever new separation platforms.

Toxicity Research

Toxicologists do not overlook Ethyltributylphosphonium Hexafluorophosphate. Repeated inhalation, ingestion, or skin contact can cause headaches, respiratory irritation, and sometimes more severe reactions depending on dose and duration. Early animal studies suggest it shows moderate oral toxicity and must not be ingested or inhaled. Chronic exposure risks stem mainly from the potential hydrolysis to hydrofluoric acid or metabolites of tributylphosphine. Fortunately, routine handling in properly ventilated and equipped manufacturing environments limits worker exposure. Regulatory bodies in the EU, US, and East Asia require clear hazard labels and insist on the right personal protective equipment at every step from factory to lab bench. The compound’s overall hazard profile falls below that of many transition metal salts, but complacency invites trouble.

Future Prospects

Few chemicals straddle the world of old-school synthesis and future-facing tech quite like Ethyltributylphosphonium Hexafluorophosphate. Researchers see real promise in its performance for catalysis that cuts down on solvent waste, along with its compatibility in constructing task-specific ionic liquids for gas absorption and metal recovery. Electrochemical engineers keep talking about the prospect of using this salt and its cousins as building blocks for safer, longer-lasting batteries and fuel cells, especially as power grids shift toward renewable sources. Regulatory pressure to shrink hazardous solvent use only increases the opportunities for robust salts like this one to find fresh niches in circular chemistry and smarter material recovery. Continuous investment in greener manufacturing and safer disposal will matter if its use keeps growing, since the global market keeps swinging based on trends in electronics, energy storage, and fine chemical production.

A Closer Look at a Niche Chemical

Few people ever hear the name ethyltributylphosphonium hexafluorophosphate. Most of us don’t spend our workday thinking about ionic liquids or specialized salts. Yet in chemistry labs and high-tech material facilities, this compound plays a subtle but important role in advanced research and development.

Behind Closed Doors in the Lab

If you pop into a well-equipped organic chemistry lab, you might find small bottles labeled with long, tricky names. Under the right glass, you see pale crystalline powders or colorless liquids. Ethyltributylphosphonium hexafluorophosphate sits among these bottles, ready for scientists pushing boundaries in chemistry and materials science.

Chemists often look for ways to create new reactions that make something impossible just a few years ago. This salt gives them a unique option. As an ionic liquid, it carries a set of really unusual properties — low melting point, high thermal stability, and the ability to dissolve/react with things ordinary solvents just can’t touch. The result is a playground for synthetic chemists who want to build new molecules for batteries, medicines, catalytic processes, or flexible electronics.

What Do Researchers and Industry Folks Use It For?

Ethyltributylphosphonium hexafluorophosphate supports several tricks in the chemist’s tool kit:

- Electrochemistry: People working with batteries, electrolysis, and fuel cells rely on stable and conductive environments for moving ions around. This compound lets them test new designs for safer, longer-lasting, or more efficient power cells.

- Catalysis: If you want to speed up a tricky chemical reaction, using unusual ionic salts like this one can create conditions that coax out higher yields or lower temperatures, making production safer and cheaper. Industries that produce specialty chemicals or advanced plastics look closely at these options.

- Solvent Applications: Ionic liquids can replace volatile organic solvents that threaten worker safety and the environment. Using ethyltributylphosphonium hexafluorophosphate, researchers dissolve stubborn reactants or explore reactions impossible with water, alcohol, or acetone. Less vapor, less pollution — better for the planet and the people handling it.

- Material Science: Curious about new carbon materials, sensors, or polymers? This compound can serve as a medium for shaping or modifying them, helping push innovation in coatings, displays, and flexible electronics.

Why This All Matters

Every time we plug in a phone, diagnose a disease, or rely on smart materials, we trust someone sweat the details deep in a lab. Substances like ethyltributylphosphonium hexafluorophosphate let researchers push past old limits. If we’re serious about better batteries, safer factories, and breakthroughs in renewable energy, these tools open doors.

There’s a real cost to sticking with old chemicals, especially those that pollute or demand harsh conditions. The push for greener technology and safer workspaces means innovations in chemistry ripple out to impact daily life. Regulatory trends in both the United States and Europe push industries to find alternatives to older, toxic solvents. Making the switch involves scaling up production, ensuring purity, and ironing out costs, but every new use case for ionic liquids gets us closer to safer, cleaner answers.

The Future Depends on Collaboration

I spent years in a research lab, trying to find “just the right” medium for one reaction or another. I remember how a new ionic salt could turn a failed experiment into a publishable finding. Engineering these options isn’t glamorous work, but it underpins real scientific progress. New ionic liquids don’t just fix today’s headaches — they lay the bricks for next-generation batteries, bio-compatible devices, and cleaner chemistry everywhere. The right mix of careful research, regulatory support, and investment opens paths for safer, better ways to build the world around us.

Respecting Chemical Hazards at Work

Lab work brings both discovery and risk to the bench. Years of working around strong chemicals like Ethyltributylphosphonium Hexafluorophosphate (ETBP-HFP) has taught me to look beyond the datasheet and dig into the nuts and bolts of daily safety. ETBP-HFP stands out for its uses in ionic liquids and as a salt, but its handling needs more than a glance at the safety data sheet. Trust builds between colleagues when everyone keeps safety habits sharp, and carelessness can shatter that trust in a moment.

The Risks: Don’t Treat ETBP-HFP Like Table Salt

ETBP-HFP brings risk from multiple angles. Exposure irritates the eyes, skin, and lungs. Its hexafluorophosphate part carries added hazard – moisture contact sometimes releases toxic hydrogen fluoride, which burns tissue and corrodes glassware. People often talk about PPE, but personal experience shows that one weak spot in a glove or mask breaks the shield. I once watched a colleague rush to rinse their eye after a splash, and that memory sticks every time I suit up.

Effective Safety Precautions

1. Suit Up, Head to Toe: Proper gloves matter. Nitrile holds up better than latex when handling ETBP-HFP. Use long-sleeved lab coats and real chemical splash goggles, not lightweight safety glasses. Shoes should cover the whole foot. Leave rings, watches, or jewelry outside—they trap powder against the skin.

2. Ventilation Handles Vapors and Dusts: Always open storage vials or transfer this compound inside a certified fume hood. Even with solid forms, fine dust gets airborne. Mechanical ventilation pulls vapors and dust away from breathing space. I never skipped a fume hood, even if it meant walking halfway down the hall. Fume hoods sometimes get crowded, but that’s better than risking exposure.

3. No Shortcuts With Storage: Store ETBP-HFP in a tightly sealed container, away from moisture or acids. Moisture sneaks into screw tops; extra sealing with parafilm helps. Clear labeling prevents accidental mix-ups. My habit is to set up a drying agent nearby, just in case.

4. Spill and Exposure Protocols Must Be Muscle Memory: Spills can happen, even with slow and careful work. Team members know who covers which part during a spill. Scoop up solids with a dedicated dustpan, not bare hands or disposable wipes that might tear. Make sure everyone knows the nearest eyewash and emergency shower stations. Keep calcium gluconate gel on hand, as it’s the go-to first aid for hydrofluoric acid exposure. Train often, not just once a year.

5. Simpler Is Better With Waste Management: Label ETBP-HFP waste separately from other organic or halide-rich compounds. I’ve seen folks forget this and get a strong talking-to after a chemical compatibility scare. Use double containment—bottle inside another container—to keep leaks at bay as waste builds up. Never assume the custodial staff will know what’s inside an unmarked jar.

Building Good Habits Beats Regret

My experience shows routine beats panic. Double-checking seals, working at the hood, wearing that extra layer—none of these steps slow down a good day’s work. Familiar faces in the lab stay safe when the whole group treats chemicals like ETBP-HFP with the caution it deserves. Everyone goes home with all their fingers and eyesight, and that outcome matters most.

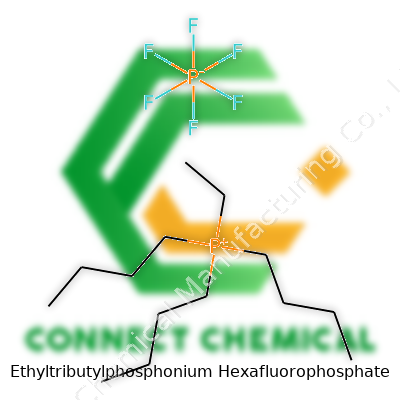

Digging Into the Formula

Ethyltributylphosphonium hexafluorophosphate brings together elements that sound like a mouthful, but its purpose and structure deserve a closer look. Chemically, its formula looks like this: C14H32FP6. Here’s how you break it down. The compound pairs an organic phosphonium cation—ethyl and tributyl groups attached to a phosphorus atom—with a hexafluorophosphate anion, which consists of one phosphorus and six fluorine atoms. The cation and anion together balance out in electric charge. Chemists often write it as [P(C4H9)3(C2H5)]PF6 to give a better visual of the two parts.

Why Does This Chemical Show Up?

I’ve seen ethyltributylphosphonium hexafluorophosphate in research labs focused on ionic liquids, electrochemistry, and specialized solvents. The quest for new, efficient materials leads folks to try out rare combos like this. Unlike table salt or baking soda, these chemicals play their part behind laboratory doors, not kitchen counters. Because it falls under the ionic liquid umbrella, it offers a near non-volatile, thermally stable alternative for solvents, electrolytes, and catalysis.

The push for green chemistry has only gotten stronger in recent years. Traditional organic solvents come with evaporation worries, health risks, and sometimes tough disposal. Hexafluorophosphate salts and their cousins step in to offer lower vapor pressure and high thermal reliability. Scientists want fluids that won’t evaporate away at a summer barbecue, and this sort of ionic compound fits that bill.

Hazards and Responsibility

Nobody should overlook the risks, though. The “hexafluorophosphate” part flags a need for care. Fluorinated chemicals sometimes degrade into toxic byproducts, especially under the wrong environmental conditions. There are reports of hexafluorophosphate salts producing hydrogen fluoride (HF) gas, which can cause real harm if mishandled. Eye protection, gloves, and top-notch ventilation must be standard every time. I’ve learned from experience never to treat “routine” chemicals casually—safety data sheets aren’t just paperwork.

Disposal practices matter. Labs and companies have a duty to ensure these chemicals don’t get flushed into municipal systems. That means collecting waste, arranging specialist disposal, and monitoring for accidental leaks. Many accidents stem from improper storage, not from dramatic spills. Tightly capped containers in dry, cool places reduce the risks.

Outlook for Use and Safer Solutions

Demand for ionic liquids shows no signs of slowing, as industries hunt for smarter, safer materials. Companies can help by supporting research into less toxic alternatives that retain the good parts—stability, electrical properties—without carrying so much baggage. Regulatory agencies push for greater transparency; chemical suppliers now post supporting data and provide guidance for users. Experience tells me that no matter how much training you have, asking questions and double-checking new compounds always saves headaches in the long run.

For students, teachers, and professionals, understanding the formula and the bigger picture gives better control over risks. Chemistry doesn’t stand still, and neither should the way we handle the tools of the trade. When a formula like C14H32FP6 lands in a syllabus or procurement list, it’s worth a second look—not just for its atoms and ions but for all the real-world impacts tied to it.

Why Storage Choices Make a Difference

Some chemicals act like ticking time bombs if ignored, and Ethyltributylphosphonium Hexafluorophosphate falls in that category. Plenty of folks picture chemical storage as a row of old cabinets in a dusty corner, but with this compound, environment matters. Controlling the surroundings matters as much as reading the label. I’ve seen entire batches ruined because containers stood in direct sunlight or near moisture sources—problems that never make the headlines but lead to lost money and wasted work.

Understanding the Risks

This compound will react negatively to water and moisture in the air. The risk involves more than just product breakdown; exposure can lead to corrosive byproducts. A humidity-controlled cabinet or dedicated dry room makes all the difference. At my previous job, a hasty intern used a regular storage closet, thinking “it’s just for a week,” and several vials corroded before anyone caught on.

Temperature Realities

People cut corners on temperature controls, thinking that as long as the container stays sealed, nothing bad will happen. Heat speeds up decomposition for Ethyltributylphosphonium Hexafluorophosphate, and that leads to weaker compound strength and safety risks. Based on peer-reviewed research, storage below 25°C helps retain purity and keeps unexpected reactions at bay. I’ve dealt with the aftermath of a breakdown: ruined samples and a clean-up crew scrambling to handle a sticky, irritating mess.

Container Choice and Compatibility

This compound belongs in airtight containers, preferably glass with PTFE-lined caps. I learned the hard way that some plastics leach or crack when exposed to this salt over time. In one case, we traced contamination back to cheap polypropylene vials. With glass, you avoid unexpected chemical reactions and slow leaching. Stretch your budget for high-quality storage and you sidestep a lot of headaches.

Avoiding Light and Contaminants

Even short bursts of light will mess with this chemical’s stability. An opaque or amber-colored bottle blocks out most rays. Put these containers far from bright workstations and always reseal right after use. I remind every new lab member—never leave materials out on a benchtop, no matter how short the break. Contaminants like dust, fingerprints, or residues from gloves change the composition. Every experienced chemist I know avoids cross-contamination by dedicating tools and containers to sensitive salts.

Training Over Shortcuts

Nothing replaces good habits. Even the best safety data sheet can’t fix another person’s shortcut or misunderstanding. New team members should handle this compound after briefings, and supervisors should keep watch for mistakes. Spills and accidents stop happening once everyone understands the why, not just the how. At our lab, weekly “walkthroughs”—five minutes at the start of every shift—reminded everyone to double-check seals and monitor temperature logs. Those small steps saved product and protected our team’s health.

Real-world Solutions for Long-Term Safety

Successful labs plan ahead with robust training and strict environmental controls. Use glassware, airtight seals, and storage in cool, dark, dry spaces. Document container opening dates, so nothing lingers past its prime. Set clear rules for handling, and don’t rely just on instinct. Proper storage protects both people and bottom lines.

A Closer Look at a Niche Chemical

Ethyltributylphosphonium hexafluorophosphate doesn’t draw headlines, but it plays a quiet role in chemical research and advanced manufacturing. Anyone who has spent time in a lab learns quickly how important chemical safety is—not just for the person wearing the gloves, but for coworkers and the environment. Handling unfamiliar agents always raises nagging questions about what they might really do if something goes wrong.

Risks to Human Health

This compound presents several hazards that call for respect. During my university years, bottles with similar names would sit in the back of the solvent cabinet, labeled with a string of letters and bright warning stickers. Phosphonium salts, like this one, bring risks of skin and eye irritation. Chemical burns aren’t just unpleasant; they can leave scars and lingering pain. Simple contact might trigger redness, itching, and sometimes persistent swelling. Accidental splashes near mucous membranes often require immediate and thorough rinsing, but even then, people sometimes deal with days of discomfort. Inhalation risk, though lower due to its limited volatility, should not be ignored. Even dust from powders takes a toll after repeated or careless handling. The lungs rarely forgive easy exposure to airborne toxins.

Some of the gravest worries grow with chronic exposure. There’s reason to believe that phosphonium salts may irritate deeper tissues over time, potentially leading to longer-term respiratory, kidney, or liver complications. While strong, clear studies on this specific compound remain sparse, it shares structural traits with other toxic substances. Taking chances with unknowns in the lab isn’t just foolish; it undercuts years of work that technicians, researchers, and regulators put into building a culture of safety.

Environmental Impact

After a long day running experiments, we rarely want to think about what happens after pouring solutions down the drain. Persistent chemical residues often slip through municipal water treatment. Hexafluorophosphate anions in particular don’t tend to break down quickly in nature. Contamination can linger, seeping into water tables or accumulating in local ecosystems. Experience shows that even trace chemicals in drinking water cause havoc in small communities, undermining public trust and threatening vulnerable organisms.

Fact-Based Solutions for the Lab and Beyond

Good sense starts with proper handling. Decades of research into chemical safety promote strong protective measures: sealed gloves, safety goggles, fume hoods, and careful record-keeping. Simple habits—like clear labeling and easy access to safety data—help everyone in a facility breathe a little easier. Large institutions and hobby labs alike benefit from these small acts.

Safe chemical disposal stands as another crucial step. Never dumping waste down a regular drain prevents ecosystem exposure. Designated hazardous waste containers cut accidental releases and encourage accountability. In my lab days, return visits from environmental inspectors drove home the importance of following the letter, not just the spirit, of proper disposal.

Groups that manufacture or sell these substances bear responsibility too. Clear, accurate safety information and honest toxicity data help buyers and users make smart choices. Regulation isn’t just bureaucracy; it shields society from avoidable harm. Investing in research to close data gaps builds a better shield for future generations, as new chemicals enter the market and old problems linger.