Methyltriphenylphosphonium Iodide: A Deep Dive into Its Past, Present, and Future

Historical Development

The story of methyltriphenylphosphonium iodide goes back to the burst of interest in organophosphorus chemistry in the middle of the twentieth century. Researchers craved new tools for organic synthesis. Chemists like Wittig and his colleagues opened doors once thought shut, discovering the value of phosphorus compounds for making carbon-carbon bonds. In this surge, phosphonium salts started appearing in labs around the world, and methyltriphenylphosphonium iodide quickly gained favor. The substance powered reactions that changed the direction of both academic chemistry and industrial processes, showing up in synthesis schemes everywhere from university teaching labs to the benches of raw material suppliers for active pharmaceutical ingredients.

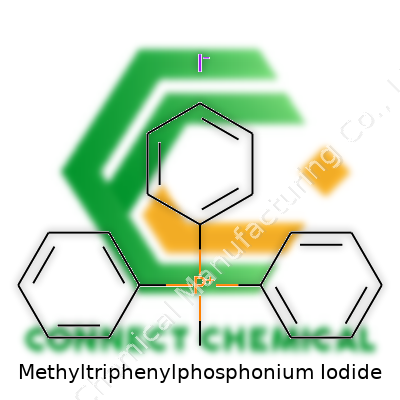

Product Overview

Methyltriphenylphosphonium iodide, commonly supplied as a white to off-white crystalline powder, stands out by pairing a positively charged phosphorus center with an iodine anion. The structure makes it useful not only for organic transformations but also for bridging a wide variety of research needs. Researchers often find this compound in glass bottles, sometimes packed under inert gas, with tight labeling to avoid any mix-up. Whether someone is targeting a novel pharmaceutical scaffold or a tricky industrial additive, this material delivers a punch that organic laboratories turn to again and again.

Physical & Chemical Properties

On the bench, methyltriphenylphosphonium iodide looks pretty tame. The free-flowing crystals share the consistency of coarse salt, and the first whiff reveals almost nothing. Owners of sensitive balances notice the mass adds up quickly: the molecular weight tips over 500 g/mol. It dissolves well in polar solvents like dimethyl sulfoxide, acetonitrile, and methanol, but resists water and most hydrocarbons. Heat does little until you push above 225°C, where it finally melts. Its apolar region, from the phenyl groups, contrasts with the methyl on phosphorus; this push-pull tension explains why it works so well in Wittig reactions and as a handy methylation tool.

Technical Specifications & Labeling

Manufacturers detail purity, moisture, and sometimes residual solvents. Purities above 98%, sometimes hitting 99%, set the standard. Labels break down batch number, shelf life, and warnings for skin and eye contact. Some suppliers add special GHS pictograms, but everyone agrees that the simple iodide salt form masks a core that shouldn’t be underestimated. Extra data—like trace metal content or residual halides—sometimes catches a buyer’s eye, especially when people need high-grade material for medicinal chemistry or electronics.

Preparation Method

Preparation relies on a reaction between methyl iodide and triphenylphosphine. In practice, the liquid methyl iodide gets dripped onto solid or dissolved triphenylphosphine, often in a polar solvent, with constant swirling to keep it from clumping. The mixture, left for hours at room temperature or slightly above, yields a thick precipitate. Filtering and washing wring out the crude product, and one or two extra crystallizations polish the yield to high purity. Solvents come and go; acetone, ether, and ethanol all see regular use, but every chemist tweaks the protocol. In an industrial setting, process engineers tune solvent exchanges or temperature ramps to scale up while avoiding unnecessary loss or safety hazards.

Chemical Reactions & Modifications

Methyltriphenylphosphonium iodide finds fame in the Wittig reaction, a core process for building alkenes. After reacting with a strong base—potassium tert-butoxide or sodium hydride—one gets the ylide, a key intermediate that attacks carbonyl groups. This chemistry launches everything from dyes to key pharmaceutical intermediates. The phosphonium ylide created this way doesn’t sit idle; chemists have coaxed transformations for everything from asymmetric carbon-carbon bond formations to cycloaddition strategies. Aside from that, the parent iodide salt undergoes halide exchange, giving chemists the option to swap in bromide or chloride as needed for downstream applications. Its structure, both robust and easy to modify, opens doors for tweaking and tailoring molecule reactivity.

Synonyms & Product Names

Suppliers sometimes label it as methyltriphenylphosphonium iodide, methyltriphenylphosphonium salt, or simply PPh3CH3I. Catalogs might substitute “methyltriphenylphosphorane iodide,” and literature can abbreviate to MTPPI or even just Ph3PCH3I. Regardless of the label, researchers know they’re working with a compound that speaks to decades of synthetic breakthroughs.

Safety & Operational Standards

Using methyltriphenylphosphonium iodide doesn’t allow for laziness. Gloves, goggles, and a working fume hood come first. The iodide can stain, and contact risks irritation and, rarely, sensitization. Inhaling dust introduces risk, and if it hits water, it may break down to release trace methyl iodide, which ranks as a well-known health hazard. Waste management involves segregated organophosphorus waste and acid/halide cleanup, preventing accidental release into drains. Emergency responses, like eyewash and spill kits, need to sit close at hand for labs handling this or any other phosphorus compound, especially if scaled above a few grams.

Application Area

Organic synthesis claims the broadest space for this phosphonium salt. In work ranging from undergraduate instruction to postdoctoral research, methyltriphenylphosphonium iodide helps unlock access to unnatural amino acids, challenging alkene-containing targets, and complex heterocycles. The pharmaceutical industry values its ability to build key frameworks, and agrochemical designers use it for tailored bioactive molecules. Material scientists and polymer chemists have dipped their toes into modifications, often for designing specialty coatings or charge-carrying monomers in advanced plastics. The discovery of its flexibility doesn’t end there—combinatorial chemistry and even microelectronics fabrication borrow its stability from time to time.

Research & Development

Labs stretching from academic departments to industrial powerhouses have probed new applications for methyltriphenylphosphonium iodide over the past decade. Some project teams modify its core to grow libraries for medicinal chemistry; others focus on tuning the reaction conditions for Wittig chemistry to reduce byproduct formation or energy use. Computational chemists run quantum studies on the phosphonium center, looking for tweaks to its reactivity profile. As green chemistry has taken a firmer hold, research has drifted toward less hazardous reaction partners, recycling methods, and methods to recover and reuse phosphorus-based reagents—an effort that has drawn in both fundamental and applied researchers.

Toxicity Research

Toxicology groups don’t see methyltriphenylphosphonium iodide as a major risk when handled with respect, but studies on its acute and chronic effects have turned up enough red flags to call for care. In cell cultures and small animal models, phosphonium salts in general show potential for disrupting mitochondrial function, with some reports highlighting cell membrane effects and weak dermal toxicity. Literature tags it as irritating if it gets in the eyes or on the skin. Chronic inhalation studies haven’t delivered clear answers, but given its chemical similarity to methyl iodide and triphenylphosphine, many labs lump it in with materials that demand extra vigilance. Waste handling rules reflect this caution, ensuring that environmental exposure stays at a minimum and that workers log any extended contact.

Future Prospects

The push away from hazardous alkyl halides has set the stage for new entries, but methyltriphenylphosphonium iodide isn’t disappearing yet. Green chemistry pushes for recyclable reagents and catalytic variants have spurred creative developments, with some researchers developing supported phosphonium reagents or variants that use solid-support recycling. Machine learning and automation in synthetic chemistry put a fresh spin on reaction design—high-throughput platforms now turn to classes of phosphonium ylides to interrogate reaction scope with hundreds of substrates in weeks. The drive for higher selectivity, lower environmental burden, and better atom economy keeps the compound in view for the next wave of organic methodology. Whether the goal sits in drug development, polymer materials, or academic benchwork, methyltriphenylphosphonium iodide demonstrates a staying power born of flexibility and a track record of chemical transformation that continues to evolve with the science.

Where You Find It in Real Work

Methyltriphenylphosphonium iodide sounds complicated at first glance. For anyone who ever worked in a chemistry research setting, the name brings up images of glassware, gloves, and the measured rhythm of routine. This compound might look unremarkable as a white powder, but it pulls some real weight in the lab. Most people outside the field won’t ever run into it, but inside the world of chemical manufacturing and university labs, it’s a regular fixture.

How the Chemical Steps Up

This compound’s main claim to fame lies in how it helps form carbon-carbon double bonds. That’s a rich vein in organic synthesis, the process of building big, useful molecules from small pieces. Methyltriphenylphosphonium iodide becomes truly valuable in the Wittig reaction—a bread-and-butter tool for anyone building new molecules for medicines, plastics, or advanced materials. With this one reagent, chemists can swap out an oxygen atom stuck on a molecule and replace it with the double-bonded carbon, creating something entirely new. The pharmaceutical industry uses this kind of reaction all the time to tweak drug candidates, chase higher yields, or create the next big antiviral.

Why This Matters in Real Life

Most of us never think about the link between a powder in a brown bottle and a tablet at the pharmacy. I remember years ago, during a stint on a student research project, we puzzled over drug molecules that didn’t quite work. The answer sat hidden inside laboratory bottles like methyltriphenylphosphonium iodide. Without tools like this, modern chemistry would fall back to slower, costlier, maybe even impossible syntheses. Polyethylene plastics, hormones, pigments, and novel antibiotics—these all might stall out in development without these reagents smoothing the way.

Pushing For Safer Labs and Cleaner Manufacturing

While it does its job well, methyltriphenylphosphonium iodide doesn’t do it quietly. It brings some hazards. Exposure to the skin or lungs provokes real health risks. Industrial chemists and students alike use gloves, goggles, and fume hoods every time they handle it because one slip, and things go sideways. Disposal, too, can turn tricky; dumping chemical waste without care leads straight to polluted rivers, sick workers, poisoned neighborhoods. These risks leave people calling for greener, safer alternatives.

Scientists hunt for fresh ways to make the same chemical transformations with milder, less toxic chemicals. Catalytic chemistry, where tiny amounts of metals or enzymes replace bigger doses of harsh reagents, moves things in this direction. Digital tools and artificial intelligence also help—by predicting new synthesis routes or flagging less hazardous ingredients before a project even starts.

Big Picture Thoughts

Taking methyltriphenylphosphonium iodide for granted feels easy, but behind every small bottle stands a complex web of research, safety protocols, and practical thinking. It reflects the constant balance between what’s possible in a laboratory and what’s better for working people, for the community, and for the world. We can’t ignore its impact—either on everyday medicines or the effort to grow cleaner, safer industries. Even the smallest white powder can spark a big conversation about the future of chemistry.

Understanding the Challenge

Methyltriphenylphosphonium iodide isn’t something most of us keep in the garage. This chemical often finds its place in universities and specialty labs, where students and researchers rely on it for advanced organic synthesis—especially the Wittig reaction. The thing is, keeping this compound stable hinges on the environment you provide for it. Mess up storage, you can end up with a product that’s degraded, contaminated, or a plain headache to handle down the line.

Why Storage Makes All the Difference

Speaking from years in and out of academic labs, improper storage tends to cause more trouble than nearly any other oversight in chemical handling. With methyltriphenylphosphonium iodide, moisture and light are enemies. This salt can absorb water from the air, leading to caking or an unwanted reaction. Labs I’ve worked in have sometimes pushed containers to the back of a shelf, only to pull out clumpy stuff months later—barely usable.

A sealed bottle is your first line of defense. Manufacturers usually deliver it in dark, airtight containers. Keeping it in its original package, or transferring it very quickly and resealing tight, cuts the risk of air exposure. Forgetting this may seem minor until your weighed powder clumps or stinks of decomposition.

The Role of Temperature and Light

Experience tells me the storeroom fridge is a friend for many reagents—but not everything requires the coldest setting. Methyltriphenylphosphonium iodide prefers a cool, dry spot, away from sunbeams or any light sources. Some users slip it into secondary containers—an extra layer can’t hurt during humid months, especially in buildings with fickle air conditioning. Once I worked in a lab where someone left a jar out under direct fluorescent lights. The resulting degradation wasn’t a minor loss; it blew weeks of grant-funded work.

Cleanliness Cuts Down Contamination

Lab mistakes rarely happen in a vacuum. Contamination becomes a bigger concern as soon as you ignore good habits—like using clean scoops or wearing gloves every time you reach for the bottle. Cross-contamination isn’t a theoretical risk; it actually happens. Students often forget, and pretty soon you’re dealing with impurities in a reaction, straining budgets and wasting lab time.

Some records point out that according to the Sigma-Aldrich safety data sheet, keeping the chemical in a tightly closed container and away from incompatible materials—like oxidizers—helps maintain purity. One slip with storage and you can introduce risks to the person next to you or waste an entire batch.

The Layer of Accountability

Chemical safety rules count for the public as much as professionals. Accidents and exposures track back to weak habits more often than complex failures. Label each jar clearly. Refresh schedules so stock doesn’t languish for years. Track the opening of every package. It all comes back to treating these chemicals with the respect they ask for, no matter how routine your work may feel.

Smart storage for methyltriphenylphosphonium iodide is pretty simple: keep it dry, dark, cool, and clean. Practice that every time, and you’ll save money, protect people, and get more reliable science—all from a small shift in daily routine.

Understanding the Compound

Methyltriphenylphosphonium iodide often finds a niche on the benches of organic chemists. Its chemical formula, C19H18IP, hints at its building blocks: a methyl group, three phenyl rings, a phosphorus atom, and an iodide ion. This compound forms by combining methyl iodide with triphenylphosphine. Watching those white crystals fall out of solution, I remember my first time preparing it and feeling the moment of discovery—chemistry transforms invisible bonds into something you can weigh and hold.

Why Formula Details Matter

Understanding what goes into C19H18IP makes a difference. Chemists count on knowing the exact formula every time they plan a reaction or scale up in the lab. It’s not just about counting carbon or hydrogen atoms. The structure controls how the molecule behaves. One extra atom or misplaced group and nothing works the way you expect. More than once, sloppy attention to formulas has led to failed syntheses and wasted reagents. The information cuts down on trial and error, saving both time and budget for research teams.

Laboratory Impact and Practical Use

This iodide salt appears most often as a precursor in the Wittig reaction. The organic shops in every research center keep it stocked, because it delivers reliable performance for ylide generation. In the lab, these ylides bring carbonyl compounds to react, building up new double bonds and shaping molecules that serve as drugs, fragrances, and specialty materials. Training my own students, I stress how one molecule with the right configuration sparks breakthroughs in medicinal chemistry or material science.

Safety and Handling Concerns

Methyltriphenylphosphonium iodide comes with its risks. The iodide ion and triphenylphosphine bring hazards—skin, eyes, even air quality, if not handled with respect. Every researcher learns that a moment of carelessness—breathing a little plume or touching the crystals bare-handed—can translate into headaches or worse. Reliable data from material safety datasheets, as well as organizations like the CDC’s NIOSH, remind us to work in a hood, wear gloves, and keep this compound sealed up tightly. Safety consciousness extends beyond your research bench; it's a habit I’ve seen save careers and health.

Improving Laboratory Practices

Lab accidents involving methyltriphenylphosphonium iodide still happen in schools and small companies. Regular review of handling practices helps researchers prepare for spills or exposure. Investing in better ventilation and providing clear training for less experienced team members pays dividends over time. Personally, I’ve seen that keeping emergency eye washes clean and ensuring safety protocols are followed takes the fear out of working with compounds like this iodide. Campus safety officers and faculty can strengthen compliance simply by showing up during syntheses and offering real feedback, not just written reminders.

Supply and Environmental Footprint

Access to clean, well-characterized C19H18IP calls for trust in your supplier. Adulteration or contamination affects yields and quality of research. Some groups now look at greener ways to make this compound, using less toxic methylating agents or recycling solvents. More labs turn their attention to minimizing chemical waste from Wittig reactions, because tighter environmental standards are coming. Last year, a team I worked with switched to smaller scale runs, reducing by-product waste and solvent consumption by nearly half—a practical step to protect air and water in our communities.

Understanding the Chemical

Methyltriphenylphosphonium iodide shows up in many labs working with organic synthesis or phase-transfer catalysts. Its value roots in its ability to help build carbon bonds, making it a regular player in advanced chemistry. The question pops up: Is it dangerous just to handle?

Evaluating Hazards from Real Experience

I worked with this compound at my university’s chemistry department. Right away, you learn respect. White, powdery, not particularly volatile, but don’t let the mild appearance fool you. Direct skin contact can bring irritation. Any dust floating up will nag at your eyes and nose. Swallowing it, of course, could end even a productive day in a hospital bed.

Every Material Safety Data Sheet I’ve checked lists the compound as hazardous, though not in the way a strong acid or cyanide is hazardous. The main worries center on respiratory irritation, skin reactions, and the long-term threat many phosphonium salts can pose if you don’t keep surfaces, hands, and tools truly clean.

The Facts Scientists Care About

Researchers point to limited evidence connecting phosphonium salts and acute toxicity, but the risk isn’t imaginary. Animals show common signs of distress when given large doses. Longer exposure can bring tissue damage. Data on chronic human toxicity is thin, so guessing safe levels over months or years remains just that—a guess.

Methyltriphenylphosphonium iodide contains iodine, which most people tolerate in trace amounts but which can cause problems at higher concentrations. People with existing thyroid problems or iodine allergies face even more caution flags.

Safe Handling Means Clear Habits

Use this stuff in a fume hood if you’re at work in a lab. That cuts down on dust and vapor mistakes. I once spilled a small amount during a hurried synthesis, and dealing with the white powder on my gloves and bench left a sour taste. Nitrile gloves, goggles, and a lab coat make up the basic armor. Remove gloves and wash up every time, no exceptions.

Label everything. I’ve seen a shared research fridge with unlabeled bottles—surefire way to trigger confusion or accidents. Bring spills under control immediately with wetted wipes, and toss those wipes in sealed hazardous waste bins. Don’t take work home, and always wash up thoroughly after handling.

Disposal also matters. Pouring this into any sink causes problems down the line. Waste goes in designated hazardous containers sent to proper disposal sites. That way, nobody downstream faces unwanted chemical exposure.

Looking Toward Better Solutions

It’s tempting to see chemicals like methyltriphenylphosphonium iodide as necessary hazards. The best chemists challenge that view. Lab managers worth their salt push for new processes that use less hazardous alternatives or eliminate these chemicals altogether. Taking steps to switch to greener chemistry saves headaches, health costs, and time lost to clean-up or accidents.

Making sure staff get the right training and that each container carries an up-to-date label stops most problems before they start. Simple communication and accountability do more than expensive new gear ever could. My old department put daily emphasis on risk logs, and it paid off in a cleaner, less anxious place to do science.

Is this compound hazardous? Definitely. Smart habits, updated practices, and ongoing caution draw the line between incident-free research and a serious emergency.

Unpacking the Basics

Methyltriphenylphosphonium iodide doesn’t exactly roll off the tongue, and it’s hard to forget how fussy this chemical can be in the lab. Solubility isn’t just a buzzword—getting a compound to dissolve shapes everything from how research is run to what kind of reactions are even possible. With this specific salt, the way it interacts with different solvents means the difference between a productive afternoon and a week of washing glassware.

Practical Insights from the Lab Bench

Anyone who’s handled this phosphonium salt before has probably noticed it laughs at attempts to mix it with water. The strong ionic character, thanks to both the big triphenylphosphonium cation and the hefty iodide anion, drives this compound straight to the bottom of aqueous solutions. Water solubility just isn’t in the cards.

Chemists looking to actually use methyltriphenylphosphonium iodide reach for polar organic solvents. Take acetonitrile, dimethylformamide (DMF), and dimethyl sulfoxide (DMSO) as examples—they make this salt break apart and spread out evenly. Acetonitrile stands out—not too viscous, not too smelly, and strong enough to disrupt those electrostatic forces. DMF and DMSO work well too, but they bring handling headaches, from high boiling points to questionable safety records.

Knowing What Works—And What Fails

Throwing this salt into alcohols like ethanol or methanol barely nudges the needle. Partial solubility, sure, but not enough to satisfy most reactions. Going nonpolar with solvents like hexane or toluene turns the whole process pointless. Nonpolar liquids can’t break those electrostatic locks, so the salt just clumps up and refuses to play ball. Most undergraduate organic labs confirm this: dissolve it in DMSO or acetonitrile, and you’re golden. Experiment with water or anything nonpolar, and frustration follows fast.

Why These Solubility Properties Matter

These quirks matter beyond the prep table. In the Wittig reaction, methyltriphenylphosphonium iodide transforms carbonyl compounds into alkenes—cornerstone chemistry for building all sorts of molecules. If the salt won’t dissolve, the whole process grinds to a halt. Poor solubility results in incomplete reactions and painful purification steps. The choice of solvent can mean wasted time, lost reagents, and missed deadlines. Labs that ignore this either have deep pockets or really patient graduate students.

Solving the Solubility Problem

Faced with limited options, chemists get creative. Heating sometimes boosts solubility, though the risk of decomposition rises. Grinding the salt into a fine powder before mixing often increases the surface area in contact with solvent, which sometimes boosts the dissolving rate. Pressure from green chemistry pushes folks to swap out toxic solvents like DMF for safer alternatives or use less harsh conditions, but good results depend on the right balance between safety and performance.

Reliable references back all this up. Multiple chemical databases and synthesis guides land on the same page about poor solubility in water and high performance in polar organics. In-person experience matches these facts: there’s a reason PhD students keep DMSO and acetonitrile stocked high.

Looking Ahead

Safer solvents and greener practices remain on the horizon. Research into ionic liquids, solvent-free protocols, or modified phosphonium salts could rewrite the narrative. Until then, practical experience, verified literature, and a willingness to learn from solubility headaches guide the way.