Hexadecyldimethylethylammonium Bromide: A Deep Dive into Its Journey, Properties, and Role

Tracing the Story: Historical Development

Scientists and engineers have always looked for ways to make everyday processes more efficient. Decades back, people working in laboratories started noticing a family of chemicals known as quaternary ammonium compounds. Some, like Hexadecyldimethylethylammonium Bromide (often called Cetyldimethylethylammonium Bromide), began to stand out. Early research in surfactant chemistry from the 1950s and 1960s pushed ahead, looking at their ability to break up oily residues, control microbe growth, and form stable mixtures in water. As detergent chemistry evolved through the late 20th century, the practical value of these molecules grew. Demand for better disinfectants, antistatic agents, and emulsifiers provided a clear path for the adoption of this compound. People may not hear about this molecule in daily conversation, but its fingerprint shows up across industrial and research histories.

Product Overview: What Are We Dealing With?

Hexadecyldimethylethylammonium Bromide has carved its niche. It belongs to the quaternary ammonium salt family and looks like a white crystalline powder at room temperature. Chemical supply catalogues list it as a cationic surfactant, wielding both strong surface activity and the ability to bind onto a huge variety of surfaces. These twin properties make it useful far beyond the beakers and flasks of research: it finds purchase in textile treatment, cleaning products, and microbiology labs. For me, the real-world interest comes from seeing how industries pivot this compound to solve a problem—whether breaking up stubborn grease or controlling bacterial growth on surfaces.

Physical & Chemical Properties

This compound comes with a long hydrocarbon tail (sixteen carbons) dangling off a charged nitrogen center. That long hydrocarbon section pushes the substance toward low solubility in water but lets it slide into oily substances with ease. Melting temperature sits typically in the range of 50–60°C, which brings up handling considerations in warmer climates or manufacturing setups. In water, it forms a colloidal suspension, making it ideal for use in formulations where delivering small, evenly dispersed droplets really matters. The molecular weight hovers around 370 grams per mole, and researchers track its high purity grade by checking for off-white coloration or impurities, a cue to process errors. These properties stack up to deliver the mixture-spreading, cleaning, and antimicrobial features that drive its success.

Technical Specifications & Labeling

Chemical manufacturers list Hexadecyldimethylethylammonium Bromide under CAS Number 56703-42-3, with packaging usually stamped with purity ratings that commonly exceed 97%. Ingredient panels must highlight its cationic nature, since it doesn’t always play nicely with anionic detergents or reactive chemicals. Packaging must remain airtight, as this salt can clump with any influx of moisture. Pharmaceutical and bio-lab buyers pore over product certificates detailing endotoxin levels, trace metal impurities, and particle size distribution. Local law—across North America, Europe, and much of Asia—demands precautionary hazard labels. These spell out chemical irritation risks and eye contact warnings, a far cry from the off-the-shelf cleaning sprays found in the home improvement aisle.

Preparation Method: From Lab Bench to Bulk Drums

Manufacturing tends to follow a straightforward reaction: starting from cetyl bromide and mixing with a solution containing dimethylethylamine. Controlled heating and stirring drive the formation of the quaternary ammonium center, then filtration and recrystallization purify the salt. On the industrial side, precise temperature control stops unwanted side-products, while vacuum drying addresses the tendency to soak up moisture from air. Anyone who has spent time in a synthetic chemistry lab recognizes the smell and the sticky residue often left behind after purification. Large-scale producers invest in better filtration equipment, since any residue can impact not only performance but also downstream safety.

Chemical Reactions & Modifications

Beyond its basic form, Hexadecyldimethylethylammonium Bromide sits at the junction of an active research whirlpool. Chemists tweak the alkyl chain or the ammonium head to sharpen its antimicrobial action or blend-compatibility for new detergent systems. I’ve watched researchers play with this—replacing the ethyl group for isopropyl or methyl, or chopping the alkyl chain by a carbon or two—which can flip properties like foaming and solubility on their head. Acid or base treatments tend not to degrade it quickly, but concentrated mineral acids can cause hydrolysis over long periods. Under UV light or oxidizing environments, researchers track breakdown pathways to understand how it lingers or disappears in wastewater. Every tweak or remix opens new frontiers for use in specialty cleaners, biocides, and even drug delivery constructs.

Synonyms & Product Names

In the marketplace and across scientific papers, the same molecule may pop up with several identities: N-Ethyl-N,N-dimethylhexadecan-1-aminium bromide, Cetyldimethylethylammonium Bromide, or even abbreviated as CDEAB. Vendors may trade under slightly snappier brand names. This complicates online searches and regulatory checks, since synonyms become attached to safety records, application notes, and research reviews. In my experience, asking for the CAS number is the quickest way to cut through the confusion, as it remains the constant among all the trade names and catalog numbers.

Safety & Operational Standards

Anyone who has spent time around quaternary ammonium compounds recognizes both the efficacy against microbes and the real risks these substances present. Hexadecyldimethylethylammonium Bromide is no exception. Contact can cause skin and eye irritation, and inhaling dust poses hazards to respiratory health—chronic exposure can exacerbate asthma or trigger other breathing problems. European REACH regulations and North American OSHA guidance set strict workplace thresholds, driving regular air monitoring and dust control. Operators wear gloves, goggles, and respirators in manufacturing environments. Liquid spills need quick neutralization, since run-off can persist in waterways. Training on spill procedures and emergency response improves workplace safety results, but compliance remains a challenge in lower-margin manufacturing settings.

Application Area: Far Beyond the Laboratory

Hexadecyldimethylethylammonium Bromide claims roles across an impressive span of industries. At home in cleaning products, it boosts effectiveness against bacteria, making floors safer in hospitals and schools. Textile and leather tanneries depend on its antistatic and softening traits, especially for synthetic fibers that cling or fray. In the oil and gas sector, workers use solutions for breaking up crude residues in pipelines. Even in pharmaceuticals, it pops up in formulations stabilizing emulsions and creams. Water treatment plants call on it as a biocide, holding the line against bacterial blooms in cooling towers and ponds. In agriculture, researchers experiment with it as a possible pesticide adjuvant. The variety springs from core chemical features—surface activity and a knack for targeting microbes—proving that a single molecule can span several worlds.

Research & Development: Relentless Pushing for Better Solutions

Academic and private-sector researchers never stop exploring new niches for this compound. Lately, interest clusters around antimicrobial resistance, since the cationic surfactant family disrupts cell membranes in ways that differ from traditional antibiotics. Early-stage medical research tries to leverage Hexadecyldimethylethylammonium Bromide in drug carriers and gene delivery systems. Materials scientists eye its use in nanotechnology, hoping to produce nanoparticles with smoother coatings or enhanced longevity in medical devices. Environmental engineers study breakdown products in wastewater, seeking paths to minimize environmental impacts. This constant churn, driven by both regulatory pressures and market demand, keeps this family of molecules at the cutting edge. Even after decades of use, the push for greater eco-safety and smarter performance keeps research flowing.

Toxicity Research: Understanding and Managing Risks

A molecule that can kill bacteria will sometimes also threaten human or ecological health. Toxicity studies show that Hexadecyldimethylethylammonium Bromide proves acutely toxic to aquatic organisms, especially small crustaceans and fish. In humans, strong evidence links exposure to moderate-level skin and eye irritation. Some workplace studies track chronic lung impacts and changes in liver function in people subjected to years of low-level airborne exposure. Toxicologists urge manufacturers to reduce release into waterways and step up on-site containment. Waste treatment facilities test for quaternary ammonium residues, setting stricter discharge limits. While no widespread cancer risks have shown up in long-term animal studies, the margin for safety remains slim, and regulators keep tightening standards as new experiments produce more granular data about risks at the cellular level.

Future Prospects: Where the Story Heads Next

The need for improved safety and greener chemistry promises to shape the future of Hexadecyldimethylethylammonium Bromide. Biotechnology firms look for ways to replace classic chemical surfactants with those sourced from renewable feedstocks, but matching performance proves stubbornly difficult. On the regulatory front, market access depends increasingly on cradle-to-grave impact studies—how long the compound sticks around, how it breaks down, and how well plants remove it before water returns to rivers and lakes. Industry talk centers on next-generation surfactants that provide the same antimicrobial punch while breaking down more easily, or causing fewer side effects for workers and end-users. As international trade in chemicals tightens, competing products from Asia and Eastern Europe challenge older supply chains, sometimes with lower production standards. Only by keeping a sharp focus on safety, environmental effects, and technical improvement can this class of compounds secure its place in the coming decades.

Everyday Chemicals, Hidden Roles

In daily living, complex-sounding chemicals often shape outcomes more than we realize. Hexadecyldimethylethylammonium Bromide falls straight into this category. Most people have never scratched the surface of its many jobs behind the scenes, but in laboratories and industries, it’s one of those staples that people count on.

Disinfectant Powerhouse

Germ control keeps public spaces, clinics, and homes safer. Hexadecyldimethylethylammonium Bromide, part of the quaternary ammonium family, does heavy lifting in disinfectant formulas. This class of compounds takes out bacteria and some viruses by breaking down their cell walls, keeping spread under control. For me, doing research work meant cleaning lab benches and instruments with solutions mixed from these sorts of substances. I saw firsthand how persistent contamination can be, and how a proper disinfectant can be a lifesaver for consistent experimental results.

Cross-checking the latest scientific studies, emerging pathogens, and public health concerns makes reliable disinfectants a priority worldwide. The importance of using them correctly helps reduce the growing risk of resistance, a concern public health agencies have raised over the past decade.

Surfactant For Science and Industry

Soap and cleaning agents rely on surfactants to trap oils and dirt. Hexadecyldimethylethylammonium Bromide goes beyond cleaning. It’s used to change how water and oil interact in manufacturing and research. This property smooths over problems during chemical synthesis, including the making of nanoparticles. Chemists favor such compounds for their ability to stabilize emulsions, which keeps mixtures from separating and extends shelf life for certain products.

I remember a project on nanoparticle drug delivery in grad school where experiments hit a wall until the right surfactant joined the mixture. That simple change opened new avenues, showing how a single ingredient can carry a project to the finish line.

Antistatic Agent and Fabric Treatment

Laundry and textile makers use antistatic agents to stop fabrics from sticking or sparking. Hexadecyldimethylethylammonium Bromide holds a chemical charge that coats fibers, leaving clothes and upholstery smoother to touch. Static build-up isn’t just inconvenient; it can disrupt sensitive electronics and equipment. Engineers and textile designers alike lean on these treatments for safety and comfort.

Potential Health and Environmental Concerns

While the focus lands on its uses, discussions about safety can’t be skipped. Overuse of quaternary ammoniums may trigger allergies in sensitive groups and introduce environmental buildup. Research shows some of these compounds do not break down easily, which means overuse can lead to water system contamination. I always felt a pull between selecting the strongest cleaner and choosing something more gentle on wastewater systems when working in shared spaces.

Strong uses do not erase responsibility. Safety guidelines, protective gear, and proper disposal make a real difference in reducing risks. Limiting unnecessary use and opting for newer, more biodegradable options where possible offers hope for a cleaner future.

Balanced Choices for a Safer Tomorrow

Relying on chemicals like Hexadecyldimethylethylammonium Bromide shapes outcomes in medicine, manufacturing, and day-to-day cleaning. The key lies in using them smartly, pushing research for safer alternatives, and educating people about handling and disposal. From cleaning benches to fine-tuning industrial batches, responsible use of these compounds paves the way for both progress and protection.

What I’ve Learned in the Lab

Hexadecyldimethylethylammonium bromide isn't a household name, but anyone who has handled chemicals in a teaching lab or research setting probably knows molecules like it. This compound, often seen in specialty products or niche research, is a quaternary ammonium salt—a class that covers many cleaning agents, disinfectants, and surfactants. I remember the first time I worked with a quaternary compound: nobody glossed over the need for gloves and eye protection, because even “ordinary” chemicals can surprise you.

How It Interacts with People

Molecules in this category can irritate skin or eyes. Not everyone reacts the same way. I’ve seen a colleague’s fingers turn red from careless contact with a similar ammonium compound, no matter the immediate washing up. Prolonged or repeated exposure can lead to allergic reactions. Accidental splashes near the eyes can sting more than a bee. Inhaling dust from a powder like hexadecyldimethylethylammonium bromide is a bad idea. The lungs don’t like these compounds. Even years out of the lab, I still find myself double-checking airflow and the location of the nearest eyewash station.

Real-World Evidence and Regulatory Guidance

Many safety sheets mark the substance as an irritant, and its Material Safety Data Sheet lists potential for respiratory, skin, and eye responses. The European Chemicals Agency, along with the U.S. National Institutes of Health’s databases, offer similar details—it’s not considered a huge toxicity risk, but no official body endorses direct, careless contact. Washing hands afterward, using proper lab coats, and working with decent ventilation seem like routine steps, but skipping them isn’t worth it. The logic is simple: even small risks stack up over a long lab career.

The Layers of Risk

My own experience shows that risk isn’t just what you inhale or splash today; sometimes, long-term habits matter most. People sometimes treat familiar substances as less risky the more they handle them. That’s when mistakes pile up. I’ve watched someone use their phone with gloves still on, then forget to clean the phone—carrying the chemical onto their skin hours later. Simple lapses, but real health impacts.

Solutions Rooted in Common Sense

The best way to avoid trouble with chemicals like hexadecyldimethylethylammonium bromide isn’t only about elaborate equipment; it’s about small habits that add up. Always store the powder in tightly-sealed containers, away from food or drink. Never eat or drink in the same space you open a bottle like this. Wearing gloves and goggles should feel as normal as tying your shoes. If you work in a group, make sure everyone keeps up those habits. If a spill happens, don’t chase after it with paper towels—get trained on proper cleanup kits.

I trust the people who stay careful. Academic programs and companies could do a better job of keeping up reminders, not just posters on walls but “in-your-face” teaching. I learned fastest from instructors who explained the stories behind the rules, not from reading another long data sheet.

Everyday Perspective

Few of us feel nervous about a bag of salt, but that false sense of security is what gets people in trouble. Hexadecyldimethylethylammonium bromide isn’t deadly, but it isn’t harmless either. Just because something doesn’t cause trouble right away doesn’t mean it never will. Those chemical-safety lessons in college ended up mattering more than almost anything else I learned there. I don’t skip the gloves—and I don’t let others skip them either.

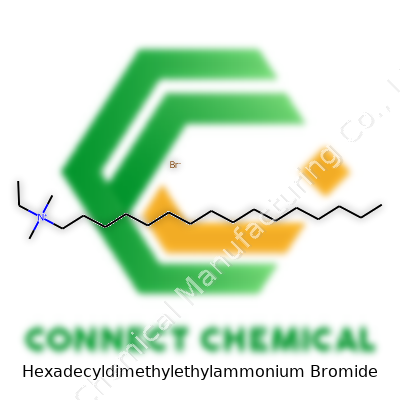

The Chemical Formula Up Close

Hexadecyldimethylethylammonium bromide shows up in chemistry labs with the formula C20H44BrN. This formula comes from breaking down its name. The structure includes a long hexadecyl (C16H33) chain, two methyl groups, one ethyl group, and a positively charged nitrogen bound to them. Bromine tags along as the counter ion. So you get twenty carbons, forty-four hydrogens, a single nitrogen, and a bromine atom. These aren't just numbers—they say something real about how the compound acts.

Why Chemical Structure Counts

As someone who's mixed a few things in a flask, I can tell you that every atom pulls its own weight. In quaternary ammonium compounds like this, the big hydrocarbon tail gives the molecule a split personality. One end loves water; the other shrugs it off. This lets it sneak between oil and water, breaking up greasy messes. It's no surprise that, out in the world, formulas like C20H44BrN take the lead in cleaning agents, disinfectants, and phase transfer processes. Their structure makes them good at busting up bacterial cell walls and dissolving stubborn residues.

Risks and Responsibility

At the lab bench, following the recipe matters. Get your formula wrong and you risk a lot more than just wasted chemicals. Quaternary ammonium salts can irritate skin, eyes, and lungs. Some reports have linked overexposure to breathing problems in people working with disinfectants every day. Workers in janitorial, healthcare, and lab jobs face that risk at a higher rate. That's not fear-mongering; the CDC keeps data on cleaning chemical injuries for a reason. Gloves, goggles, and ventilation matter as much as the beakers and balances.

Environmental Questions

It's not just about personal safety. These compounds hitch a ride into rivers and soil once they wash down the drain. Studies show they stick around, for weeks or longer, before they break down. That long life in the environment isn't always welcome. Fish and aquatic life face trouble even at low concentrations. Wastewater treatment plants can remove some, but not all. Relying on traditional cleaning habits adds to a cycle of pollution. Industry and science have started pushing for better breakdown methods, and I've seen more green chemistry approaches these days.

Seeking Better Outcomes

People often ask whether safer options exist. The big step forward comes from reducing unnecessary use, finding new biodegradable surfactants, and tightly regulating industrial runoff. At home or work, checking product labels and picking those with less persistence can help cut environmental load. In research, exploring enzymes or microbial treatments for wastewater can speed natural breakdown. Companies with transparency about what goes into their cleaning products build greater public trust. Each step, no matter how small, shrinks the footprint left by these useful but stubborn chemicals.

The Challenge of Storing Active Compounds

Many labs and industrial sites use tough-sounding chemicals like Hexadecyldimethylethylammonium Bromide. Even saying the name is a mouthful. Yet behind the technical jargon, stories of real mishaps often start with something as basic as poor storage. It’s easy to shrug off small steps. Nobody sets out to spill a hazardous substance or breathe in strange dust, but I’ve seen accidents happen just by forgetting proper storage. It pays to get it right, not just for regulatory checklists, but because people can get hurt when details get skipped.

Why Moisture and Heat Matter

From what I’ve seen, this compound draws water from the air. Give it a humid shelf, and the container quickly clumps up or turns sticky. Moisture triggers slow breakdown or changes in how the chemical looks and acts. On top of that, heat loves to play tricks. Leave the bottle near radiators or in sunbeams and you risk ruining the sample or, worse, starting a chemical reaction that nobody wanted. Dry, cool space isn’t a luxury here—it’s just part of responsible work. A spot between 15 and 25 degrees Celsius keeps most shelf-grade chemicals stable, and this rule fits for Hexadecyldimethylethylammonium Bromide too.

Respecting Container Choices

I remember finding dusty glass jars capped with crumbling parafilm in more than one old storage room. Modern standards prefer sealed, clearly labeled containers with tight screw caps. Hexadecyldimethylethylammonium Bromide shifts with exposure, so even small leaks mean other items get contaminated fast. Plus, good labeling prevents that awkward “mystery powder” problem down the road. Clear warning stickers, hazard icons, and a date on each bottle tell the next user what they’re working with.

Avoiding Reactive Neighbors

This chemical falls into the cationic surfactant group, so it can react with strong acids or bases. Don’t cram it between cleaning acids or alkali bottles. One bad shelf arrangement can cause a small spill to mix with the wrong neighbor, multiplying hazards. Separate shelves for oxidizers, corrosives, and organics are a lesson hard-learned by anyone who’s seen a storage fire or had to call for spill response.

Protecting People, Not Just Products

Personal experience tells me air quality inside storage rooms makes a real difference. Any spill or vapor release can go unnoticed if vents don’t keep the air fresh. A basic fume hood or local exhaust pulls stray dust or accidental vapors away from noses and lungs. Easy access to goggles, gloves, and spill kits helps too. Co-workers often skip these steps because “it’s just a quick transfer”—but the quickest accidents are the ones nobody plans for.

Checks, Training, and Accountability

Periodic inventory checks turn up misplaced samples and leaking bottles before problems grow. Training both new and veteran staff lowers the risk of mistakes. I’ve seen compliance slip when folks think storage rules are all the same. It helps to share stories, not just protocols. Seeing how small errors can grow serious makes storage more real for everyone.

Long-Term Thinking Beats Shortcuts

Safe storage for chemicals like Hexadecyldimethylethylammonium Bromide means respecting the environment it sits in, watching the neighboring chemicals, and remembering the people sharing the space. Attention to containers, climate, and habits reduces incident reports and hospital visits. Practical steps aren’t just bureaucracy—they protect lab budgets, data, and most of all, health.

What You Might Be Dealing With

Hexadecyldimethylethylammonium bromide isn’t something most folks have sitting on a kitchen shelf, but it shows up in plenty of industrial settings. Folks handling this compound in labs or factories can run into some trouble if they aren’t careful. Surfactant chemicals like this one show up in cleaning products and disinfectants, which means people can come into contact with them more often than they realize. Even if you do not work with chemicals every day, understanding what it can do to your health is not a bad idea.

Skin and Eye Irritation

The skin doesn’t always take kindly to this compound. A splash or spill might bring on redness, burning, or itching, and folks with sensitive skin usually notice it most. Eyes need extra protection—a bit of this stuff splashed near the face can mean severe stinging and, if not rinsed right away, some long-lasting pain. Moist areas and cuts let chemicals in easier, so gloves and safety glasses matter more than you’d think. The Centers for Disease Control and Prevention notes that quaternary ammonium compounds (like this one) are well-known irritants.

Respiratory Issues

Breathing dust or fine mist from hexadecyldimethylethylammonium bromide may bring on coughing, wheezing, or a sore throat. Some workers report headaches and chest tightness after handling quaternary ammonium compounds in poorly ventilated areas. Asthma-like symptoms can show up in folks with pre-existing lung sensitivities. Researchers from the National Institute for Occupational Safety and Health have linked repeated exposure to “quats” in disinfectants with increased cases of occupational asthma, especially in healthcare and cleaning staff.

Toxicity Concerns Beyond Irritation

Accidentally swallowing this chemical can trigger nausea, stomach pain, vomiting, or diarrhea. Large doses need emergency medical help right away. People who deal with this compound every day have learned to keep food and drinks away from their work areas for a reason. There have been cases of workers developing chronic issues after years of handling similar substances without gloves or masks. Liver or kidney problems might develop if a lot gets into the body over time, though this usually only happens after very high exposure.

Environmental Impact Is No Joke

Rinsing waste down the drain does more harm than most people realize. This compound can kill aquatic organisms, especially small fish and water fleas, if enough makes it into waterways. Quaternary ammonium compounds tend to stick around in water and soil, building up slowly—something environmental agencies watch closely. I’ve seen some small businesses switch to less hazardous cleaners after local rivers started showing trace amounts linked to nearby industrial runoff.

Controlling Exposure and Finding Safer Options

It’s not just workers behind the scenes who have to pay attention. Schools, hospitals, and restaurants run through gallons of cleaning products each month, and staff might handle them with just a spray bottle and a rag. OSHA recommends gloves, goggles, and using ventilation fans. Safety training goes a long way, especially for new hires. In some places, managers now try swaps for hydrogen peroxide- or alcohol-based cleaners, which tend to break down quicker in the environment and carry fewer chronic health risks. Choosing safer products can help reduce both health and environmental headaches down the road.