Hexadecyltrimethylammonium Bromide: A Deep Dive Commentary

Historical Development

Let’s rewind a bit. Early chemists, poking into the world of cationic surfactants in the 1930s and 1940s, realized quickly that not all salts are created equal. Researchers in textile finishing labs grew interested in molecules like Hexadecyltrimethylammonium Bromide long before its broader fame. Laundry scientists figured out, even before synthetic detergents swept the market, that certain compounds played a key role in shifting oils off fabric. These ammonium bromides became essential just as textile and cosmetic industries moved away from natural soaps. In graduate school, I remember seeing beat-up glass bottles from that era, their labels hand-written — proof that curiosity and chemistry make an enduring team. Today’s bottle might look slicker, but the fascination remains the same as that early promise for controlling molecular interactions bloomed into wide industrial importance.

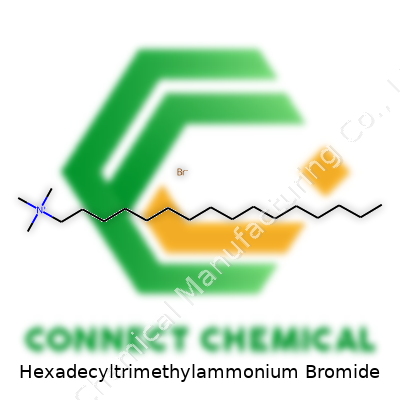

Product Overview

Hexadecyltrimethylammonium Bromide, which rolls off the tongue as CTAB, pops up far outside the chemistry lab. In the real world, it helps purify DNA, treat wastewater, and stabilize nanoparticles. The product comes as a white, waxy powder or sometimes as crystalline flakes. It dissolves in water quite well and gives a soapy feel. Buy a lab-grade pack, and you’ll see attention to moisture content and purity — things that matter in everything from gene editing to making shampoo. Sometimes, the name might hide: look for CTAB, cetrimonium bromide, or even just “cationic surfactant” on datasheets. Each has its place depending on the industry and the story behind the label.

Physical & Chemical Properties

CTAB stands out because it brings structure and behavior that chemists love to tweak. Its long alkyl chain (hexadecyl means sixteen carbon atoms, lined up in a row) gives it a hydrophobic tail, with the trimethylammonium group forming a positively charged “head.” This amphiphilic structure is what lets it act as a surfactant, lowering the surface tension of water, trapping grease, and organizing itself into micelles. A melting point near 237°C, strong water solubility, and sensitivity to temperature shifts keep it interesting. Years ago, I watched CTAB crystals melt and flow on a hotplate — almost a rite of passage — and seeing this simple compound flip structure with heat sticks with you. Chemically stable under most storage conditions, but it reacts sharply with anionic compounds, sometimes dropping out of solution completely.

Technical Specifications & Labeling

Manufacturers set purity specs usually above 98%, and label for water content since CTAB loves to hang onto moisture. Standard packaging often lists both its chemical name and the CTAB abbreviation, with CAS numbers and storage advice rattled off in every safety data sheet. If you’ve worked in quality control or procurement, you know that lot-to-lot consistency matters. Mass spectrometry or titration tests back up those purity claims, showing how established companies support trust with hard data. Labeling rules extend to transport, since CTAB counts as a hazardous material when shipped in bulk — and nobody wants surprises in the warehouse.

Preparation Method

Manufacturers typically react trimethylamine with hexadecyl bromide under controlled conditions, making sure the reaction runs clean and doesn’t leave behind toxic by-products. The process needs good ventilation, consistent temperature, and plenty of washing to remove unreacted amines or bromides. Years ago, I handled a small-scale batch, nervously measuring out reagents and using cold traps to capture stray fumes. Plenty of rinsing, filtering, and drying finished the process, turning a runny mixture into waxy pure CTAB. Big-time production works on the same principles but adds industrial reactors and strict process control to ensure each ton matches the last.

Chemical Reactions & Modifications

CTAB offers a simple platform for chemists to tweak. Its cationic center can form ionic pairs with dyes, drugs, or anionic surfactants, making it a molecular Swiss Army knife in formulation chemistry. Anionic contaminants, like sulfate ions, will throw CTAB out of solution, a trick that’s useful in purification and extraction. Modify the alkyl chain length or swap bromide with chloride, and you tweak solubility, toxicity, and binding strength — a big deal in nanoparticle synthesis or drug delivery. In my lab days, we’d sometimes deliberately “salt out” CTAB from solution to collect DNA precipitates, a testament to its quirks and usefulness.

Synonyms & Product Names

On chemical supply catalogs, you spot hexadecyltrimethylammonium bromide as CTAB, cetyltrimethylammonium bromide, and sometimes just cetrimonium bromide. Each label signals the same compound, but industries pick names that suit tradition or regulation. In hair care products, cetrimonium bromide has a long history, while medical labs cling to CTAB for clarity during critical prep steps. It shows how trade, science, and safety shape even something as basic as a name.

Safety & Operational Standards

Handling CTAB demands respect. Exposure to high concentrations can cause skin and respiratory irritation, while chronic exposure raises questions about long-term impacts. At industrial scale, operators follow strict rules: lab coats, fume hoods, gloves, and eye protection as non-negotiables. Emergency protocols deal with accidental spills or dust clouds. The safety data sheets outline exposure limits, first-aid procedures, and environmental disposal recommendations — things that make working with CTAB manageable rather than risky. In labs, we kept a spill kit on the ready because any fine powder that foams up needs quick, careful containment. Experience teaches that safety rules exist because even useful materials bite back under the wrong conditions.

Application Area

Walk into any molecular biology lab, and CTAB will likely sit in the reagent fridge, right alongside agarose and Taq polymerase. Its knack for busting open cell walls while protecting DNA from enzymatic breakdown makes it a backbone for plant DNA extraction kits. At wastewater plants, CTAB’s ability to neutralize charges and drag out dyes or heavy metals from solution turns it into a partner in clean water efforts. Industrial formulators lean on its surfactant abilities in cosmetics, where smoothness in lotions, cream stability, and anti-static properties in hair conditioners matter. Every sector seeks reliability — CTAB’s greatest strength, learned through steady use and plenty of published data. I once used it to prep gold nanoparticles, with CTAB acting as a stabilizer that controlled shape and prevented clumping. No amount of high-tech promise quite replaces the dependable behavior chemists expect from this handler of molecules.

Research & Development

CTAB continues to draw attention from the R&D crowd, especially for its self-assembly skills. Chemists marvel at how its molecules create micelles, vesicles, or nanorods, all driven by concentration and temperature. Current research explores new applications in drug delivery, gene therapy, and photothermal medicine. Studies reveal how slight tweaks in structure lead to shifts in biocompatibility, prompting teams to search for analogs that reduce toxicity without killing performance. In nanotechnology, tinkering with CTAB enables precise control of particle growth and surface characteristics, a trick that’s inspired thousands of journal articles since the early 2000s. My own experience with CTAB showed how a “simple” chemical sometimes gives rise to entire new subfields, as materials scientists chase the dream of smart, responsive surfaces for diagnostics, sensors, and smart coatings.

Toxicity Research

Despite its many uses, CTAB remains under scrutiny for its toxicity potential. Low concentrations handle themselves without fuss, but higher doses spell trouble for aquatic life and sometimes for people with sensitive skin or lungs. Animal studies flagged CTAB as an irritant, and some regulatory bodies now set limits in finished consumer products. Wastewater treatment must remove it before effluent reaches rivers. Academic labs keep rechecking dose-response curves, hunting for safer alternatives or methods to neutralize or recover CTAB from effluent. I remember a summer spent testing CTAB solutions on algae cultures, watching how life in the petri dish faded above certain ppm levels. This memory sticks and shapes how I think about chemical stewardship. Tighter rules for disposal and exposure line up with public calls for greener, safer surfactants — and researchers hear that call routinely.

Future Prospects

What comes next for CTAB? The surfactant market shifts toward sustainability, demanding biodegradable options and lower toxicity. Chemists dig through compound libraries, hunting for next-generation analogs that keep CTAB’s perks but ditch its worst side effects. New synthetic routes trim waste streams and cut down on hazardous precursors. In biotechnology, CTAB’s role might expand as new cell lysis techniques merge old-school surfactants with enzyme cocktails. Nanotechnology labs push CTAB into uncharted projects, from precision drug carriers to hybrid solar cells. My sense, after seeing endless cycles of hype and discovery, is that tradition and innovation walk together — old favorites like CTAB keep finding their way into tomorrow’s headline breakthroughs, backed by evidence, safety improvements, and a lot of hard-won trust from the labs and industries that rely on them.

Lab Bench to Manufacturing: The Range of CTAB

Hexadecyltrimethylammonium bromide, better known as CTAB, has made regular appearances in my years of lab work and reading up on chemistry advances. Stepping into any research space focused on biology, material science, or environmental studies, I quickly realized CTAB rarely gathers dust on a shelf. Its practical value comes from its ability to act as a surfactant—a sort of chemical team player that breaks surface tension and helps oil and water, or any two reluctant substances, come together.

Researchers making nanoparticles lean on CTAB. Take gold nanoparticles, for example: CTAB wraps around new crystal faces as they grow, ensuring the final particles have consistent shapes and don’t stick together. I’ve watched scientific groups use CTAB to fine-tune nanomaterials for electronics, sensors, and drug delivery. Reliable shape and size of nanoparticles mean better performance in products, not just attractive images in publications.

DNA Extraction: A Biology Workhorse

In my own experience, CTAB solutions remain the gold standard in plant DNA extraction protocols, especially for tough species that pack in plenty of secondary compounds. Without it, getting high-quality, usable DNA from roots and leaves often turns into a frustrating weekslong chore. CTAB disables proteins and polysaccharides that normally foul up DNA, leaving geneticists with cleaner samples. This straightforward extraction approach underpins a lot of agricultural and biodiversity research, which feeds into food security and conservation work.

Antimicrobial Effects and Real-World Impact

Hospitals and biotech manufacturing face persistent contamination troubles. Surfactants like CTAB offer reliable antimicrobial properties—several studies point to its ability to bust up the membranes of bacteria and fungi. Medical device builders and cleaning crews in sensitive production lines use CTAB in cleaning solutions and coatings, aiming to cut risks of infection by orders of magnitude. The COVID-19 pandemic just reinforced this real-world link between chemical choices and public health outcomes.

Environmental Remediation: More Than a Lab Curiosity

Some early projects I joined looked at wastewater and pollution clean-up. Here, CTAB played a surprising role. By sticking to certain pollutants, including heavy metals or dyes, CTAB let engineers and scientists separate toxic compounds out of large water streams. It’s not flawless, and critics rightly question the environmental load if surfactants reach rivers, but CTAB has backed several prototype treatments that handled hazardous waste better than earlier methods. Creative adaptation of CTAB and related chemicals could scale up solutions for growing pollution concerns, provided we keep a close eye on what heads downstream.

Looking Ahead with Responsibility

CTAB’s practical success shows what well-understood chemicals can do when the stakes are high. That said, safe handling guidelines matter, since CTAB shows toxicity to aquatic life and people. Strong regulations, training, and regular monitoring can reduce the risks tied to large-scale applications. Supporting ongoing research, labs and factories can find alternatives for sensitive contexts or develop better containment strategies. Awareness of both risks and successes keeps us from short-sighted fixes, pushing us towards safer living and working environments.

Chemistry at Work and at Risk

Hexadecyltrimethylammonium bromide, or CTAB as a lot of lab folks call it, finds itself involved in everything from DNA extraction to industrial cleaning. You shake up something in a research lab and, odds are, that white powder could be CTAB. The surfactant properties help get cells to break open, so scientists get what they need from them. It doesn’t take more than a few minutes in a biosciences lab to spot a plastic bottle with the CTAB label. That direct contact with skin or lungs, even by accident, isn’t just uncomfortable. It poses a real risk.

Toxicity Isn't Just a Statistic

CTAB works well in breaking membranes because it also annoys living tissues. Eye and skin irritation pop up instantly with low doses. On the skin, redness, burning, even blistering show up fast if you skip gloves or get careless with rinsing. Breathe in the dust, especially in a poorly ventilated room, and it stings your nose, throat, and lungs. Swallowing, rarely intentional but not impossible with chemical handling, means abdominal pain, vomiting, and diarrhea.

Lab guides say wash up and avoid contact, but the message hits harder in practice. Once, back in my grad school days, someone prepped a CTAB solution without gloves; within minutes, her skin itched and flared red. The safety shower became a sudden necessity. That moment etched in a real lesson: this compound bites back fast. OSHA’s database isn’t just there for policy; it’s filled with case reports just like that one, people harmed when routines slip.

Looking Beyond the Lab Bench

Environmental effects of CTAB demand respect, too. Runoff or improper disposal finds its way to water systems. Aquatic life comes under attack. Research out of Germany and Canada points to CTAB reducing crop yields and killing off fish at concentrations far below industrial waste levels. The compound disrupts membranes in the same way it attacks lab cells: fish and amphibians suffer, even at 0.1% dilutions.

This shows why it’s everyone’s business, not just folks in white coats and goggles. Whether it’s a small college lab or a big pharmaceuticals plant, untreated waste can leak into local ecosystems. That’s not easy to undo or filter out. It piles up in sediments and stays persistent. With global awareness rising on chemical pollution’s long reach, companies and universities get extra scrutiny for their waste streams. Fines mount, but more than money, the local community pays in contaminated water and lost habitats.

Fixing What Needs Fixing

Mitigating CTAB hazards starts long before the bottle arrives. Suppliers label containers clearly and often provide MSDS sheets. That only helps if people read them. In the lab, wearing gloves, goggles, lab coats, and working under fume hoods isn’t just another routine. It’s basic respect for the chemical’s ability to harm. Facilities need to check that their chemical storage areas allow no cross-contamination or powder spills. Spill kits belong right next to the compound, not down the hall.

Disposal separates the careful from the careless. No one solves the CTAB problem by pouring it down a drain. Neutralizing agents work, but only if used consistently. Some universities partner with waste management firms, sending containers for incineration or controlled landfill. More industries now monitor effluents with automatic sensors, so any breach gets flagged before harm spreads. Training keeps everyone on alert. Every lab safety seminar should feature real-world mishaps, not just theory, to drive home what’s at stake.

Setting stricter handling, enforcing waste management, and holding chemical suppliers and users responsible shifts the balance away from risk. In the end, a lab or plant wired to think safety-first keeps CTAB contained and out of trouble. That’s good for people and the planet alike.

Understanding the Substance

Hexadecyltrimethylammonium Bromide, sometimes known as CTAB, shows up in a lot of lab and industrial work, especially in biology and chemistry. This white powder or crystalline solid gets used for DNA extraction, surfactant work, and as a cleaning agent. Some folks see chemicals like these as mundane to store, but my experience says treating them with respect pays off.

Attention to Storage

Let’s talk about what any solid lab or workplace should do with CTAB. Temperature swings spark trouble, and damp air causes clumping or worse, leads to degradation. Find a cool, dry spot—locked cabinets work. Ordinary shelving next to heat sources or water lines spells risk. My lab found out the hard way once, after a humidity spike ruined a big batch. Now everything stays sealed and labeled in climate-controlled, ventilated shelving.

Seals matter more than most folks imagine. An open bottle invites moisture and eventually leads to compromise. I always check that the lid screws tight after grabbing what I need. Glass or rigid plastic jars with sure-fitting caps keep this material stable. For long-term work, desiccators pull out extra moisture and give extra peace of mind.

The Human Factor in Handling

CTAB causes skin irritation and can harm your lungs in powdered form. Handling without gloves and a mask leaves you open to accidents. Rushed folks skip these steps now and then and end up with red, itchy hands or worse. I’ve seen good technicians sidelined after a moment of carelessness. Never rely on memory—post clear labels everywhere and keep gloves, goggles, and dust masks well stocked near storage or work benches.

Spills happen, even to careful workers. Never sweep the powder or push it aside with bare hands. Slow things down, grab a damp cloth for small amounts, and for bigger spills, reach for dedicated spill kits. Do not toss messes down the drain or into ordinary trash—CTAB lingers in water and harms aquatic life. Local regulations matter here; always check SDS sheets and disposal guidelines before tossing anything out.

Organizational Responsibility

Clear communication stands at the core of chemical safety. Every new member at my lab sits through a rundown of handling and storage, not just a quick look at a safety poster. MSDS (Material Safety Data Sheets) stay updated and visible. Everyone knows who to call for help, and storage logs keep track of batch dates. If you make checks part of the weekly routine, mistakes become rare. No one expects perfection, but forgetting a step opens the door for real harm.

Improving Standards and Routine

Routine helps, but so does investment. Investing in training, signage, and modern storage cabinets beats dealing with fines, sick staff, or lost product. Consider regular audits, not as punishment, but as learning tools. Encourage folks to report near-misses or mistakes without blame—open culture prevents big accidents. I’ve worked in places where watchfulness and honesty turned troubling trends around in a matter of months.

In my experience, giving CTAB and similar chemicals a little respect saves cash, time, and ensures you keep everyone healthy. Practical steps—good storage, proper protection, timely cleanup—say more than any alarmist policy. It comes down to treating the job as a responsibility to your coworkers and community.

Getting to Know Hexadecyltrimethylammonium Bromide

Hexadecyltrimethylammonium Bromide, often carried by the shorthand CTAB, shows up in more places than most folks realize. On paper, its molecular formula stands as C19H42BrN. Breaking that down, you see a chain of 16 carbons with hydrogens hanging off each, linked to a trimethylammonium group sitting at one end. The positive charge on the nitrogen pulls in a bromide ion, forming a solid salt. Looking closer at the structure, it has a long hydrophobic tail and a small, charged head, perfect for forming micelles in water.

The Science Behind Its Structure

Visualizing CTAB helps a lot. Imagine a long, skinny carbon chain—sixteen atoms long—straight as a broomstick. One end switches gears with a nitrogen holding three methyl groups, making it the business end of this molecule. Bromide, a simple anion, partners up thanks to the charge. This shape isn't random. The hydrophobic tail slips away from water, crowding together with others just like it. The nitrogen side loves water and sticks out, giving this molecule its surfactant power.

Everyday Value Beyond the Lab

CTAB’s unique structure turns it into a workhorse for chemists, biologists, and everyday manufacturers. During my time working summer jobs in a chemistry lab, CTAB showed up in nearly every bottle marked “Surfactant.” It binds to DNA and helps scientists purify it with ease, pushing biological research forward. Away from research, folks rely on this compound in everyday shampoos and conditioners, helping those products cleanse and spread evenly. The same structure that lets it wrap around oil and dirt, lifts it away, and washes it down the drain, offers a solution many people count on without ever reading the ingredients list.

Evidence and Health Questions

It’s important to remember that this molecule, while useful, needs careful handling. Studies point out the potential for irritation if it lingers on skin too long. The European Chemicals Agency and others list data showing it can cause problems at high concentrations. In daily use, levels stay low and well below thresholds for harm, but regulations keep an eye on it. Researchers weigh long-term exposure in water treatment, wastewater plants, and household settings. This constant review reflects the balance between usefulness and safety. In the lab, we wore gloves and measured carefully, which always drove home respect for the substance.

Looking Toward Better Practices

CTAB’s widespread utility means we owe it to ourselves and the environment to use it wisely. Some manufacturers work on greener replacements, carving out roles for biodegradable surfactants with similar abilities. Open conversations about ingredient transparency build trust, pushing the industry to higher standards. Keeping up regular monitoring of water streams and considering alternatives doesn’t just help researchers and scientists, it protects regular people, too. Smart use—balanced by good science and careful oversight—makes sure molecules like CTAB benefit us today, without leaving a mess for tomorrow.

Introduction

Hexadecyltrimethylammonium bromide shows up in a lot of chemistry labs, especially in university research and industry settings. People often call it CTAB. Students run into it during experiments involving DNA extraction, protein work, or materials science projects. Since it gets used so often, folks want to make sure they know what to expect when they crack open a fresh bottle.

What People Notice First: Appearance

I remember the first time I used CTAB. I opened the jar, and there sat a waxy, white powder. Sometimes it looked like small crystals or a clumpy solid, but always white. If you see brown, yellow, or gray tints, something’s probably wrong. Color changes shout contamination. Moisture in the air can also transform CTAB into sticky clumps, which makes weighing it out a messy job. That’s not great because the extra water skews results.

CTAB smells faintly, a bit like some detergents because it’s a surfactant. Normally, there’s no strong odor. Off-putting smells can mean it picked up something from the environment or has begun to degrade. Labs with good practices always store the bottle tightly capped, in a cool and dry spot, away from direct light. That helps preserve that powdery, white look.

Expectations for Purity

Purity matters a lot in lab work. Most research-grade CTAB hits about 98-99% purity, according to certified chemical suppliers. If you look at the bottle, the label usually lists the purity, and many suppliers offer a technical data sheet. For critical experiments—like those in molecular biology—students and researchers pay more for the highest grade. Any dirt or leftover byproducts can mess up delicate reactions or analyses. In my own lab time, I ran an experiment that failed until I switched to a new, unopened CTAB bottle. The difference turned out to be trace contaminants in the older batch.

SDS-PAGE tests for protein work and nucleic acid extraction both demand really clean CTAB. Impurities such as unreacted bromide or trace metals throw off these techniques. Some suppliers offer high-purity, or “ultra pure,” CTAB graded for molecular biology—aiming for less than 1% impurities and low moisture content. University labs usually keep both standard and molecular grades on hand, depending on the budget and the sensitivity of their tests.

Why Purity and Appearance Matter

Using CTAB with the right purity and appearance isn’t just about getting pretty data; it’s about trust in results. If students or professional researchers skip quality checks, their conclusions might not stand up later. Impurities hamper reproducibility—a cornerstone in research.

Also, safety plays a role here. Contaminated chemicals may behave unpredictably. They can spill, form unexpected byproducts, or interact with other reagents in risky ways. I’ve seen students struggle with clogged filters and failed reactions all because of a clumpy, impure chemical. It wastes money and time, too.

What Can Help

One solution comes down to buying from suppliers known for quality and requesting a certificate of analysis. Lab staff can run basic checks on appearance right after opening a new batch. If the chemical starts clumping or showing odd color, it makes sense to talk to the supplier or seek a replacement. Keeping chemicals dry and away from direct light guards against breakdown.

Sharing experiences with colleagues helps, too. Sometimes advice on a supplier or a brand travels faster in conversations than official channels. Routine tests like thin-layer chromatography spot impurities early, and regular training keeps everyone alert to changes in appearance or performance. In short, careful observation and steady habits preserve trust in results, lab safety, and budgets.