Hexadecyltrimethylammonium Chloride: In-Depth Commentary and Analysis

Historical Development

Going back to the early part of the 20th century, scientists started exploring surfactants as a way to improve cleaning and chemical processing. Out of this research came quaternary ammonium compounds, a class now known worldwide. Hexadecyltrimethylammonium chloride (CTAC) appeared on lab benches during the post-war industrial boom. Back then, chemists worked tirelessly, stirring, analyzing, and testing, until they noticed CTAC’s strong knack for reducing surface tension and disrupting microbial membranes. The compound’s rise mirrored the story of chemistry itself: squads of researchers in universities and private labs kept pushing for new detergents and antimicrobial agents. By the late 1950s, CTAC had found its way into more than just chemistry sets—it gained traction in manufacturing, water treatment, and personal hygiene. This journey from small-scale synthesis to large-scale application tells a lot about our changing attitudes toward cleanliness, industrial efficiency, and public health.

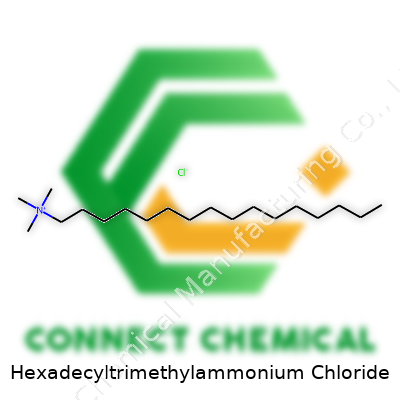

Product Overview

Hexadecyltrimethylammonium chloride sits among the family of cationic surfactants. It falls under the quaternary ammonium salts, which means it has a nitrogen atom carrying four organic groups—three methyls and one long alkyl chain made of sixteen carbon atoms. The chloride counterion tags along to balance the charge. Chemists give CTAC a nod for its solid reputation in dispersing, emulsifying, and, thanks to that sixteen-carbon "tail," breaking through grime and microbial biofilms. If you've ever wondered how disinfectants deal with oily deposits and bacterial colonies, much of the answer involves compounds like CTAC. In the lab, this material often shows up as a white or near-white waxy solid or powder, but it pools into a viscous liquid if you add heat. Many companies pack CTAC in drums for direct use, but in labs, I've weighed out grams at a time to see how it acts when making emulsions or testing new cleaning products.

Physical & Chemical Properties

Fresh out of a bag, hexadecyltrimethylammonium chloride looks like a fine, slightly sticky powder. Its melting point hovers around 232°C, high enough not to worry about storage at room temperature, yet low enough to process without specialized furnaces. It dissolves well in water and ethanol, and the solution turns slick to the touch—a telltale sign of a surfactant at work. It rests at a molecular weight close to 320 g/mol. The substance doesn’t smell, which spares workers the headaches that come from more volatile chemicals. CTAC doesn't burn easily, but intense heat breaks it down, yielding irritating fumes such as nitrogen oxides and hydrochloric acid. Chemical stability appeals to manufacturers, but reactivity with anionic detergents can cancel out its effects, so factory mixing lines must keep those separated. I remember once struggling to blend CTAC with a sulfate-based surfactant—lesson learned, the two don’t play nicely together.

Technical Specifications & Labeling

Labels for CTAC products have to do more than carry a name. Regulatory bodies in many countries control limits on impurities, such as residual amines, chloride levels, and water content. For technical-grade applications, purity often stretches beyond 98%. The labels detail the active content; for example, a 30% solution means 30 grams of pure CTAC per 100 grams of solution, critical for processes that need consistent behavior. Clear hazard statements warn about direct contact with skin and eyes or inhalation of concentrated dust or mist. Up-to-date safety data sheets accompany all shipments, providing spill cleanup directions and emergency advice. Given the risks involved—talking eye irritation and possible skin burns—these documents are more than red tape; they're a blueprint for safety. Looking back on my own lab experience, those sheets sat front-and-center every time I moved a drum or weighed the stuff out, no matter how routine the process felt.

Preparation Method

The synthesis of hexadecyltrimethylammonium chloride draws on classic organic chemistry. Starting from hexadecyl chloride—stripped from fatty alcohols through chlorination—and trimethylamine, manufacturers blend these two at controlled temperatures. A quaternization reaction attaches the trimethylammonium group to the long hydrocarbon tail. Byproducts, such as hydrochloric acid, get neutralized and washed away during workup. The process gives a raw paste that workers purify and dry before packing. Production scales vary; some plants churn out metric tons every year, while smaller specialty chemical firms stick to batch sizes that fill only a few drums per week. I recall touring a chemical plant years ago, standing behind thick glass as the reaction vessels frothed, and hearing operators describe their work—the blending, heating, cooling, and endless washing that turned basic feedstocks into CTAC pure enough for medical or cosmetic use.

Chemical Reactions & Modifications

Being a quaternary ammonium salt, CTAC doesn’t take part in redox games like some other surfactants. Its main trick comes from the positively charged nitrogen, which latches onto negatively charged surfaces—microbes, clay, textiles. Add a little acid or base, and CTAC holds up, though strong bases or oxidizers can eventually break it down. The sixteen-carbon chain leaves some room for modification, and researchers have swapped out the tail or played with the nitrogen’s side groups, trying for milder or more biodegradable analogs. In my own troubleshooting, I’ve tested these modifications for things like foaming in laundry soap or reducing biofilm in water filters. Most practical tweaks hinge on finding a sweet spot between germ-killing strength and environmental persistence.

Synonyms & Product Names

Ask a chemist about CTAC, and the answer you get might depend on country, manufacturer, or even product line. Some common aliases include cetyltrimethylammonium chloride, Cetrimonium chloride, and, less often, N,N,N-Trimethyl-1-hexadecanaminium chloride. In hair-care circles, “Cetrimonium chloride” reads on many labels. The CAS number remains 112-02-7 across the world, which serves as an anchor in the sea of trade names. In the industrial sector, products go under names like Arquad 16, Barquat CT, and Genamin CTAC; each brand comes with subtle differences in concentration, purity, and intended use. You might spot these names on barrels in a textile mill, or buried in the fine print of an antimicrobial wipe’s ingredient list.

Safety & Operational Standards

Strict personal care and industrial standards spell out how to use and store CTAC safely. Direct contact can cause moderate skin and serious eye irritation. If powdered, the dust irritates the nose and throat—ventilation and dust control become necessary. Standards set by OSHA in the United States and parallel agencies in Europe define acceptable exposure limits. Storage tanks must resist corrosion from chloride and remain tightly sealed. Emergency showers and eyewash stations stay ready near every handling area. Handling protocols also guard against mixing CTAC with incompatible chemicals, such as anionic surfactants or oxidizers. Hazardous waste rules cover disposal, pressing users to neutralize and dilute before entering wastewater streams. Training sessions never skip the story about what happens when safety rules get ignored—a month in the eye-wash room can drive home the point better than any written warning.

Application Area

CTAC sweeps across factories, treatment plants, and even bathroom countertops. In water treatment, it keeps pipes clear of slime and bacteria. Textile makers rely on CTAC to allow dyes to cling to synthetic fibers, fixing color and improving finish. In personal-care products—think conditioners, shampoos, and creams—it softens hair, untangles knots, and zaps microbes. You’ll see it in some disinfectants and sanitizers, especially in hospitals or food processing. Research labs often use CTAC in DNA extraction protocols. I’ve seen its fingerprints turn up in nano-material synthesis, where it controls particle size and shape during crystal growth. Wherever there’s a battle against dirt, germs, or tangled molecules, chances are CTAC has a seat at the table.

Research & Development

Research efforts keep driving CTAC’s evolution. Many studies now focus on reducing the environmental footprint by tweaking molecular structure for quicker breakdown in wastewater. Scientists also experiment with blending CTAC with plant-based surfactants to improve performance without leaving long-lasting residues. New analytical tools allow researchers to peer into how CTAC works at the molecular level on hair shafts, fabrics, and bacteria. The surge in antimicrobial-resistant infections turned more attention toward the class of chemicals CTAC belongs to, fueling innovation aimed at making it both more potent and less persistent in nature. At conferences, I see fresh ideas keep bubbling up: hybrid disinfectants, milder fabric softeners, greener production methods. The research never stands still, as consumer demand and regulatory pressure push the field forward.

Toxicity Research

Toxicologists scrutinize CTAC’s effects on people and the environment. Acute toxicity, both for skin and eyes, shows up clearly in lab animals, supporting the strict safety rules in plants. Chronic exposure studies reveal irritation but little evidence of lasting damage except at very high doses. More concern surfaces in aquatic ecosystems; CTAC’s positive charge means it binds tightly to cell membranes, stunting algae and harming small aquatic invertebrates at low parts-per-million concentrations. Environmental researchers push for more biodegradable alternatives or improved wastewater treatment, given lingering traces downstream from treatment plants. On the flip side, the well-established mechanism—membrane disruption—makes the toxicology profile somewhat predictable. In personal experience, most injuries happen from accidental splashes in the lab rather than slow buildup, but environmental labs have measured enough traces in rivers to keep the pressure on for better remediation.

Future Prospects

The future for hexadecyltrimethylammonium chloride depends on progress in chemistry, shifts in regulations, and changing market needs. As public concern grows over chemical residues in water and products, innovation focuses on greener processes, safer-by-design molecules, and tighter emission controls at factories. New uses emerge in nanotechnology, where CTAC shapes tiny crystals for electronics and medical diagnostics. Personal care keeps growing as a slice of CTAC demand, thanks to new formulas of shampoos and conditioners targeting hair repair and skin health. At the same time, the strict eye on environmental impact nudges the industry to find biodegradable variants or blend CTAC with other agents to cut down on aquatic toxicity. I expect the coming decade will keep pushing old chemistry to find new ways to balance performance, safety, and sustainability. Each step forward builds on a long, sometimes bumpy road from the benchtop to products on store shelves and into everyday life.

Understanding A Common Chemical

Walk through any industrial cleaning supply warehouse or chat with someone who formulates cosmetics, and you’ll eventually stumble onto a long, tongue-twisting name—Hexadecyltrimethylammonium chloride. For most folks, it’s just a chemical in a bottle. In practice, it works as a cationic surfactant, meaning it helps oil and water get along, which is rare in nature but essential in plenty of products we actually use.

The Role in Cleaning and Disinfection

I’ve cleaned public spaces and contributed to janitorial teams, where stains, germs, and grime never rest. Detergents that include this compound carry real muscle against dirt. Its structure helps it cling to surfaces and break down oily residues, so you see it in disinfectants, industrial cleaners, and fabric softeners. Hospitals use cleaners powered by this ingredient since it knocks out various bacteria and fungi, making medical environments safer for both staff and patients. It lands in mop buckets, laundry products, and even some pool algaecides.

The Beauty Industry’s Quiet Contributor

If you’ve checked conditioner bottles or salon-grade products, you’ll probably find words like “cationic surfactant” buried in the ingredient list. This chemical, known for its antistatic properties, brings the kind of softness to hair and textiles that actually matters when you brush or wear them. Hair detangles more easily, synthetic fabrics stop sticking to your skin, and we all benefit from that sense of smoothness. Having worked in both a commercial laundry and a small beauty supply shop, I’ve fielded enough customer questions to know that people chase effective conditioners—this stuff often does the heavy lifting.

Science Behind the Surface

Research backs up anecdotal claims. Published studies note its power to reduce microbial load, with action against E. coli, S. aureus, and various strains of fungi. Regulatory agencies authorize its use in measured concentrations and recognize its impressive ability to break down lipid membranes, which ultimately destroys many types of bacteria and viruses. Being a quaternary ammonium compound, it avoids the harshness of bleach but still packs a punch against germs.

Environmental and Health Considerations

My time as an environmental volunteer taught me to watch runoff from heavily sanitized places. Though this compound breaks down more easily than some older chemicals, it still brings concerns about aquatic toxicity. Some wastewater treatment plants flag the cumulative effect these ingredients can have on water quality. Contact with skin in concentrated forms or inhalation over time can irritate, so protective gloves and good ventilation go a long way during use.

Rethinking How We Use It

Transparency and responsible handling stand out as simple solutions. Manufacturers benefit from offering clear labeling and guidance on disposal. Households can limit waste and overuse, especially since most cleaning power comes from proper application rather than volume. For larger facilities, investing in more efficient wastewater treatment helps keep ecosystems safe. Regulatory oversight and ongoing research continue to fine-tune safety protocols, keeping this chemical both useful and less threatening to health and the environment.

Looking Forward

Industrial chemists and consumers both keep an eye out for ingredients that strike the right balance between power and impact. Hexadecyltrimethylammonium chloride plays a big role in our everyday products, and with ongoing attention to responsible production and waste management, it can stay part of the formula—in ways that actually clean, soften, and protect without leaving problems behind.

What We Know From Real Experience

Hexadecyltrimethylammonium chloride shows up pretty often in the lab, especially in chemistry and microbiology. Working with surfactants like this one can make your life easier for certain reactions or cell cultures. A big question always comes up in the break room: just how risky is it to work with this compound?

The Facts: Not Just an Innocent White Powder

This chemical doesn’t give off a rotten-egg warning or any noxious odor to alert your senses, but don’t let that fool you. Once, while refilling a big bottle, a tiny cloud of powder hit my skin and eyes. The irritation was no joke—red skin, stinging eyes, and a burning that stuck around for hours. Looking into safety data after, I discovered this compound scores a hazard warning for both acute toxicity and corrosiveness.

Scientific research and safety sheets agree: direct skin contact can cause rashes, while inhaling the dust may leave you coughing for the rest of your shift. The International Chemical Safety Cards (ICSC) and the US Occupational Safety and Health Administration (OSHA) label this chemical as hazardous, not something to treat with casual care. There’s plenty of documentation showing that quaternary ammonium compounds can damage the respiratory tract and eyes with repeated exposure. The World Health Organization points out the potential for occupational asthma as well.

Why It Matters

People tend to underestimate what a common chemical can do. I’ve watched new lab workers assume that as long as it isn’t glowing or bubbling, things are under control. This sense of false security gets risky. Safety goggles and gloves quickly become an afterthought. I remember the time a colleague skipped gloves while cleaning up a spill, thinking a splash wouldn’t hurt. Later, blisters and inflammation proved that even short-term skin contact is a problem.

This compound isn’t rare in hospitals or food processing, either. Used as a disinfectant or in formulations for preservation, it finds its way out of pure chemical labs. At higher concentrations, reports show that exposure leads to headaches, nausea, and long-term irritation for those without proper protection.

Solving the Safety Issue

One easy fix starts with how we teach chemical safety. Every student or new worker in a lab should practice full gear: goggles, nitrile gloves, and proper ventilation. These steps kept me safe, especially on days when handling large quantities. Having a safety shower and eye-wash station within reach became non-negotiable after that scary encounter.

Good habits go a long way. Labeling containers and using enclosed chemical hoods helped me avoid mistakes easily made on busy days. Workers outside labs, especially in facilities that use this compound for sanitation, need just as much training. Employers should post hazard signs and set up protocols for handling accidental spills. Offering regular refresher courses, especially as new evidence on toxicity becomes available, improves protection at every level.

New Insights and Personal Accountability

Staying updated matters. Regulations and scientific findings do not stand still, so workers must check new safety guidelines each time they restock this chemical. My own style shifted over years—going from relying on memory to double-checking Safety Data Sheets before opening a shipment. This habit protected me from new warnings about chronic effects that showed up in more recent publications.

If you have to work with hexadecyltrimethylammonium chloride, do not ignore what your senses and safety sheets tell you. Solid habits, good gear, and keeping an eye out for the latest science keep real people healthy on the job. The lesson, earned over years, sticks with me every time I see a new bottle come into the lab.

Getting Right to the Essentials

Many folks in chemistry, cleaning industries, or even cosmetics will bump into a name like Hexadecyltrimethylammonium Chloride. All those syllables pack a punch once they hit the lab. The formula, C19H42ClN, isn’t just a bunch of letters and numbers—it points to a specific structure. This compound combines a sixteen-carbon chain (hexadecyl group) with a trimethylammonium head, paired with a chloride ion. Chemists often call it CTAC.

Why the Formula Isn’t Just for the Textbooks

Having processed a fair share of surfactants, I can say names and formulas do more than fill up data sheets. The molecular formula gives away the backbone that determines behavior. CTAC holds nineteen carbons, forty-two hydrogens, one chlorine, and one nitrogen. This long hydrocarbon tail mixed with a positively charged nitrogen center gives CTAC its surfactant character. You see it pull double duty: one end bonds with grease, the other with water. That’s how it pulls dirt out of stubborn spots or serves as a conditioning agent in hair products.

The chemical structure isn’t just trivia. Nineteen carbons make it “hexadecyl,” meaning you get a nice, long hydrophobic tail. The nitrogen atom connected to three methyl groups (trimethylammonium) carries a positive charge, so it grabs the negatively charged chloride to keep things stable. Swapping out one atom or shortening the carbon chain alters performance. This precise formula, C19H42ClN, explains why CTAC cleans so well and why it’s mild on the skin, unlike harsher industrial surfactants.

Tied to Daily Use

I’ve seen CTAC in plenty of products. In a bottle of shampoo, CTAC keeps strands soft and easy to manage. Pool cleaners and disinfectants rely on the ability to disrupt bacteria membranes, with that positive ammonium center literally pulling apart microbes. In textiles, CTAC acts as an antistatic agent, which anyone folding laundry can appreciate. None of this happens without that mix of a bulky carbon tail and the ionic head, and the chemical formula spells out what you’re getting every time.

Safety and Environmental Impact

Anyone handling chemicals at a bench or in a production line watches out for health and environmental risks. CTAC, like other quaternary ammonium compounds, has shown some aquatic toxicity. Authorities in Europe, Japan, and the U.S. have flagged it for strict wastewater treatment and advised producers to keep concentrations low. Good chemistry means thinking about the whole lifecycle, from bottle to drainpipe to ecosystem.

Some companies are working with plant-based surfactants that keep features like a long carbon tail but use renewable resources instead of petrochemicals. Research pushes for formulas just as effective while breaking down faster in nature.

Solid Chemistry, Smarter Choices

As awareness grows about what lurks in household and beauty products, reading beyond the label makes sense. C19H42ClN isn’t just code for a random chemical—it's the recipe for a compound with real-world roles in cleaning, personal care, and industry. Knowing the formula means keeping eyes open to performance, safety, and environmental choices. That’s something I wish chemistry classes had talked about more: the story behind the symbols, and the impact every bottle can leave behind.

Everyday Choices Make a Big Difference

Not every chemical sitting on a shelf gives off the same level of comfort. Hexadecyltrimethylammonium chloride, often called CTAC in labs, isn't the sort of thing you want on your breakfast table. My years in research labs taught me that handling something like CTAC lets you see quickly who pays attention and who just wings it. Safety protocols, especially for storage, protect both people and places. It's easy to get sloppy or assume a bottle with a printed hazard label is under control. The problem grows bigger than just that one bottle.

Practical Storage Steps Save More Than Headaches

A fact that sticks with me: CTAC comes with corrosive effects and a knack for causing burns if it touches skin or eyes. Because it’s a cationic surfactant, it reacts with many other chemicals. Imagine a leaky container causing mixing or spills—now the stakes climb. Acidic vapors and incompatible mixes can damage storage rooms and harm anyone who breathes those fumes.

Solid plans work better than fancy words. Keep CTAC in airtight containers made from material it can’t break down. I’ve seen glass and hard plastics do the job, with clear labels so nobody grabs the wrong bottle by mistake. Keep it away from direct sunlight and high heat. Even a small lab fridge works wonders by limiting temperature swings. Never store this chemical near acids or oxidizing agents—mishaps turn dangerous fast if chemicals like these meet each other.

Experience Teaches the Power of Redundancy

Over the years, I’ve noticed that double-checking storage rules avoids more trouble than relying on memory alone. A lot of the worst lab incidents I heard about started with a cluttered shelf and a missing label. If CTAC gets mistaken for something else, or a cracked lid goes unchecked, the clean-up isn’t just a hassle. Poison control calls get made. Workers land in the emergency room.

Facilities that take chemical inventories seriously have far fewer problems. Using logbooks or digital tracking stops chemicals from piling up and going out of date. This way, expired material gets removed before anyone has to deal with it spilling or turning unstable. Also, storing all safety data sheets close by helps everyone make the right choices fast, even on tough days.

Better Training, Fewer Bad Surprises

There’s no shortcut around good habits. Relying on new employees to remember verbal instructions doesn’t end well. I remember a training supervisor who put up simple checklists near storage rooms, with clear photos and step-by-step tasks. That single habit changed how confident staff felt in emergencies. Regular drills—just like in schools—help cement habits. Spills happen less often in places where people know the layout and which door leads to the emergency shower.

Strong personal protective gear, including goggles and gloves, makes just as much sense in storage rooms as it does in active labs. Despite that, I’ve seen people get lazy after a few quiet months. Bringing up recent incidents at monthly safety meetings keeps everyone alert. Using real-world examples, especially ones close to home, gets attention far better than reading off generic warnings.

Avoiding Trouble Means Thinking Ahead

Chemical storage deserves respect, not routine. CTAC has a place in everything from antistatic treatments to personal care products. That doesn’t mean it’s tame. A bit of planning—clear labels, right containers, regular checks, and steady training—saves injuries and stops costly accidents. Shortcuts make dangerous stories. Careful, thoughtful storage gives peace of mind, day in and day out.

What This Compound Does in Daily Products

Hexadecyltrimethylammonium chloride, often called CTAC, makes its mark in plenty of products you’ll find around the house and in industrial settings. The first place you’ll spot it is on the ingredient lists for many cleaning and disinfectant products. It belongs to a group of chemicals known as quaternary ammonium compounds. This group offers solid antimicrobial properties. At home, CTAC keeps kitchen counters, floors, and toilets cleaner by breaking down greasy residue and killing off bacteria, viruses, and fungi. That same action extends to hospitals, where cleanliness carries higher stakes. In healthcare settings, it helps disinfect surfaces touched by scores of people every day.

Personal Care Products Relying on CTAC

Walk into a pharmacy and run your hand along the shelves of conditioners, shampoos, and lotion bottles; there’s a good chance some of those products use CTAC. Its positive charge helps neutralize static and smooth down hair cuticles, so hair doesn’t puff up or tangle easily. CTAC also works in body lotions, helping other ingredients blend together while preserving the lotion’s shelf life by reducing microbial growth. Many times, people have no idea that something helping their hair look smooth and glossy began its life as a chemical with a name most folks can’t pronounce.

Industrial Processing Benefits

Step away from the kitchen sink or shower and CTAC keeps showing up, especially in industries where separating substances matters. In mining, CTAC plays a key part in mineral flotation, which means it helps lift valuable minerals away from the rest of the rock so they’re easier to harvest. In textile processing, the compound works as a softener, making fabrics feel less abrasive and more comfortable against the skin. Paint manufacturers put CTAC to use as an antistatic agent and dispersant, improving how pigments get spread out and stick to surfaces.

CTAC and Water Treatment

Municipalities and industry sites face regular challenges with water contamination. Algae, bacteria, and biofilms cause trouble in pipes and tanks. CTAC jumps in as a biocide, breaking up these unwanted growths before they clog pipes or taint water supplies. Water purification companies add doses of CTAC to kill microorganisms and prevent scale formation on membranes and filters.

Weighing Benefits Against Risks

While CTAC improves sanitation, hair care, and product performance, concerns linger about health and environmental impact. Studies show some quaternary ammonium compounds can cause skin irritation or trigger allergies in sensitive individuals. There are also worries about water runoff—when CTAC reaches rivers or groundwater, it can harm aquatic life by lingering in the environment and affecting fish and plants. Research published by the National Institutes of Health highlights long-term damage if these compounds accumulate.

Looking for Safer Alternatives

The simplicity and power of CTAC can’t be understated, yet researchers are pushing for greener alternatives. Plant-based surfactants and enzymes are being tested in cleaning products, aiming to deliver the same levels of cleanliness and product stability with a lighter environmental footprint. Industry leaders have started incorporating tighter controls and shifted toward safer disposal and recycling procedures to minimize chemical runoff.

CTAC’s presence in so many products stems from its versatility, but responsible handling remains just as important. People asking questions, reading product labels, and supporting companies focused on safety help steer the industry toward better practices that protect personal health and the environment alike.