Lithium Bis(Trifluoromethane Sulfonimide): A Critical Chemical of the Modern Age

Historical Development

Lithium bis(trifluoromethane sulfonimide), or LiTFSI, made its appearance as the energy world started turning away from older, less stable salts for next-generation batteries. Once, folks used perchlorate and PF6^− based salts in lithium-ion battery electrolytes, but new research exposed how unsafe and reactive those were, raising eyebrows in labs and boardrooms. In the 1990s, as safer, more conductive, and chemically stable salts were needed for modern electronics, scientists developed LiTFSI. This compound didn't just offer greater ionic conductivity; it gave battery makers a ticket to more robust, longer-lasting devices. Only a few decades have passed since its discovery, yet LiTFSI is already considered a workhorse across advanced electrolyte systems, supporting research from portable electronics to electric vehicles and grid storage.

Product Overview

LiTFSI appears as a white to off-white powder, sparking little curiosity in its natural state unless one knows its potential. This salt dissolves readily in organic solvents, making it one of the easiest to work with for battery electrolyte formulators. Suppliers focus on purity levels exceeding 99.9%, since even trace impurities can trip up a sensitive electrochemical cell. Given its demand in energy, pharmaceutical, and specialty chemical industries, major producers provide LiTFSI with precise batch documentation and supply chain transparency.

Physical & Chemical Properties

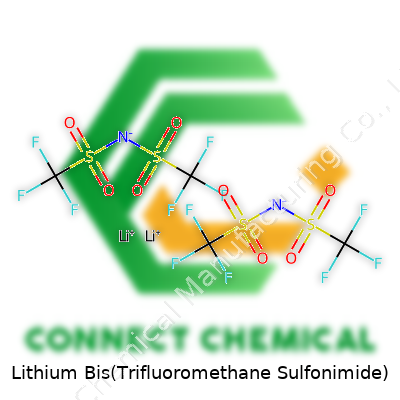

LiTFSI falls into the family of non-coordinating anions, built with two sulfonyl imide groups and three fluorine atoms glued to a methane core. The result: a salt that easily splits into ions but resists breakdown even at high voltages. Its melting point lines up around 236°C, and it doesn’t start decomposing until the thermometer passes 360°C. The compound thrives in a wide range of organic carbonates and ethers, from ethylene carbonate to dimethoxyethane. Water solubility is limited, but that’s what makes it so suitable for non-aqueous applications. In terms of hygroscopicity, LiTFSI will soak up moisture but not as aggressively as some early lithium salts, giving it an edge in storage and handling.

Technical Specifications & Labeling

Industry demand calls for clear documentation with every lot of LiTFSI—batch number, date of production, purity, moisture levels, ICP analysis for heavy metals, and, for high-end uses, the complete breakdown of residual solvents. Specifications run tighter than those for most industrial salts, as even small deviations can impact battery cycle life or pharmaceutical stability. Labels list both the IUPAC name—Lithium bis(trifluoromethanesulfonyl)imide—and the CAS number, along with hazard codes per the latest GHS conventions. Many suppliers go further by flagging country of origin and recommended storage conditions so buyers know exactly what to expect.

Preparation Method

The most reliable route to LiTFSI starts with trifluoromethanesulfonic anhydride and lithium nitride or lithium carbonate. Manufacturers first build the bis(trifluoromethane sulfonimide) acid in precise stoichiometric conditions before neutralizing it with a lithium base. Meticulous purification follows, involving multiple crystallizations and desalting to chase away any unreacted starting material. Any moisture or by-product can interfere with electrochemical behavior, so production matches pharmaceutical rigor rather than standard industrial norms. State-of-the-art facilities push for greener synthesis routes now, favoring improved atom efficiency and solvent recovery, but cost and scalability still control the conversation in most factories.

Chemical Reactions & Modifications

LiTFSI plays the steady partner in reactions, rarely interfering and seldom introducing side reactions in battery electrolytes. That stability owes to its non-coordinating anionic structure; lithium ions stay mobile, and unwanted complexes don’t form as they did with early salts. Chemists have explored TFSI derivatives, swapping lithium for sodium or potassium, and even tailoring the organic backbone for specialty uses in ionic liquids or supercapacitors. Some research labs work on tethering the TFSI group to polymers or frameworks, hoping to combine stability with new mechanical properties. Through these tweaks, they pursue faster ion movement, broader voltage ranges, and safer chemical environments.

Synonyms & Product Names

LiTFSI goes by several aliases—lithium bis(trifluoromethane)sulfonimide, lithium bis(trifluoromethylsulfonyl)imide, lithium trifluoromethanesulfonimide, or lithium TFSI. Commercial suppliers add branding flare, calling it by catalog numbers, special suffixes for purity levels (battery grade, research grade), or simply referencing its performance traits. The many names reflect innovation all over the chemical and battery industries, with specialty versions tailored for electronics, pharmaceuticals, or research programs.

Safety & Operational Standards

Lab safety with LiTFSI resembles that of other high-purity lithium salts. Prolonged exposure can irritate mucous membranes, so good practice calls for gloves, goggles, and, if working with dust, a face mask. Unlike some lithium salts, LiTFSI avoids explosive or toxic breakdown even under battery overcharge conditions. Industry applies strict protocols: dry handling, sealed storage under inert gas, and trained personnel, especially at scale. Safety data sheets summarize these standards, and organizations like OSHA and the European Chemicals Agency offer clear guidance for use, transport, and disposal. That diligence helps avoid contamination, exposure, and downstream system failures.

Application Area

Lithium-ion battery makers turn to LiTFSI for its unmatched electrochemical window and thermal stability. It sits at the core of advanced battery projects aiming to extend energy storage and support fast-charging electronics. Grid energy storage systems use LiTFSI to push cycle life farther than with older salts. Supercapacitors benefit from the same properties—stable charge cycles and low resistance. In pharmaceuticals, LiTFSI occasionally plays a role crafting organometallic catalysts or specialty intermediates, though most volume heads to batteries. Some research points to future uses in all-solid-state batteries and ionic liquids, where stability and low side reactivity win big margins.

Research & Development

Academics continue probing LiTFSI, since every incremental gain means better battery life, faster charging, or improved safety for electronic devices. Recent studies have mapped how LiTFSI interacts with new solvents and additives, seeking to squeeze out extra performance in high-voltage cathode chemistries. Researchers are keen to unlock safer solid electrolytes for solid-state batteries, using LiTFSI to suppress dendrite growth or boost lithium transport. Some have explored using radio-labeling or isotopic tracing to pin down lithium movement at the molecular level, opening doors to smarter, longer-lasting designs. Environmental research tracks LiTFSI breakdown products and their pathways, keeping a wary eye on long-term sustainability.

Toxicity Research

People working on lithium salts can’t ignore toxicity. LiTFSI isn’t the most hazardous in its class, but inhalation of dust causes mild irritation, and repeated handling without gloves eventually dries skin or causes rash. Animal studies suggest limited acute toxicity, though long-term impacts remain under research. Water solubility—though quite low—matters, as persistent fluorinated anions may show up in waste streams if disposal gets sloppy. Regulatory agencies keep reviewing findings and might introduce new discharge limits or tighter exposure thresholds, especially if large-scale use edges out older lithium compounds.

Future Prospects

LiTFSI’s story is far from over. Battery research never sleeps, especially with the global switch to cleaner transportation and smarter grid storage. Electrolyte experts keep pushing LiTFSI’s window, coupling it with new solvents and nanostructured additives to pull ahead of traditional PF6^− salts. Solid-state battery makers see LiTFSI as a building block to end runaround dendrite issues that kill battery life. Environmental concerns spark new discussions: can chemists build greener TFSI analogs with less environmental baggage, or engineer recycling systems that recover lithium quickly and safely? The next decade will test not just the performance of LiTFSI, but whether an industry built on rare elements can clean up behind itself and deliver both breakthroughs and responsibility.

What’s Behind the Name?

Few people outside chemistry circles give lithium bis(trifluoromethane sulfonimide), or LiTFSI, much thought. The chemical formula may trip up a casual reader, but LiTFSI plays an outsized role wherever advanced batteries and electronics are at work. I remember seeing stacks of battery prototypes in a research lab, all loaded with exotic salts. Out of the bunch, LiTFSI kept popping up, backed by a reputation for keeping high-tech equipment running safely and reliably.

How LiTFSI Shapes Modern Batteries

Smartphones and electric vehicles have become routine parts of daily life, and this salt shows up in the lithium-ion batteries powering them. Not every lithium salt fits the bill for battery use. Many break down too easily, lead to flaky battery performance, or even catch fire if a cell gets punctured or charged too fast. LiTFSI holds up to abuse far better than most older salts. It shrugs off moisture, temperature swings, and even electrical missteps.

Most lithium battery electrolytes use lithium hexafluorophosphate (LiPF6), which struggles with moisture and tends to fall apart too soon. I once watched a battery cell puff up and vent after a humidity test ruined its LiPF6 base. By swapping in LiTFSI, researchers kept the battery stable. Instantly, corrosion and breakdown nearly vanished. That effect changes how car companies and electronics makers can design safer batteries that last longer—no small matter with millions of devices shipping every month.

Why It Makes a Difference in Technology and Safety

Energy density and safety compete in battery design. Push for more power and fire risk climbs, keep things safe and performance stalls. LiTFSI bends these old rules by giving engineers a salt that resists forming the gases and byproducts known to spark trouble. It helps to block out water and doesn't spit out toxic hydrofluoric acid if things go wrong.

Analysts expect the market for high-performance batteries to triple within the next decade, led by EV growth. The demand for reliable salts that work in extremes without breaking down will follow. Researchers tested LiTFSI in dozens of lab setups—solid, liquid, and even polymer-based batteries. Each time, the chemical did better than expected. Its ability to keep batteries cycling longer without degradation stands out among its kind.

Environmental and Economic Hurdles

Big advances in materials often provoke new questions. LiTFSI shines in the lab, but it brings higher costs in real-world production. Heavy use of rare elements and a complicated synthesis bump up the price. Manufacturers face a puzzle: deliver safer, longer-lasting batteries or keep things affordable for consumers. In my conversations with battery engineers, most say that costs drop over time as processes improve and volume rises, so waiting out the initial premium holds promise.

Recycling remains another sticking point. No battery chemical delivers perfection after the first run. Governments and industry groups need to invest more in recycling programs that recover materials like LiTFSI. Right now, too much ends up in waste streams that can't be recaptured. Simpler recovery techniques could shift the equation, making these advanced salts more sustainable and cutting reliance on continuous mining.

Looking Ahead

Keeping up with evolving technology means leading-edge solutions, not just tired recipes. LiTFSI’s resilience is helping create electronics, cars, and even power grids that can actually keep up with our expectations. This salt keeps popping up in patents and conference talks, proving its impact stretches further than most realize. Until something better comes along, LiTFSI has claimed a front row seat in the next wave of safer and more powerful batteries.

Why Chemists Value LiTFSI

Anyone who pays attention to the nuts and bolts of battery chemistry will notice Lithium Bis(Trifluoromethane Sulfonimide) popping up more often in research papers and commercial battery discussions. Its chemical formula – LiN(SO2CF3)2 – does a lot more than decorate textbooks and journals. The arrangement inside this formula spells out the reasons for its adoption in high-performance batteries. A lithium cation pairs with a hefty, flexible anion loaded with fluorine, sulfur, and nitrogen—these atoms build a molecule that dissolves better in many organic solvents than traditional lithium salts like LiPF6.

The Push Behind LiTFSI’s Popularity

Battery makers don’t just chase the latest chemistry for bragging rights. Stability matters. LiTFSI delivers stronger thermal stability than some older salts. The compound resists breaking down under heat, keeping side reactions in check, and extending the life of lithium-ion cells. Fire risk also drops, which gives peace of mind to everyone from electric car drivers to grid storage techs watching over massive battery banks.

Poor moisture tolerance has always chased lithium salt chemistries. LiTFSI handles trace water far better than LiPF6. That resilience translates directly to longer battery life, fewer failures, and safer handling during cell assembly. Lab techs and production engineers, often juggling deadlines and safety standards, can breathe easier because the chemistry doesn’t leave them walking a tightrope. If you’ve ever worked with battery cell assembly, you know mistakes and tiny leaks happen more than anyone likes to admit.

Complications with Growth and Environmental Fate

Scaling up brings new puzzles. Synthesizing the trifluoromethanesulfonyl imide anion packs environmental concerns that don’t disappear just because the chemistry behaves better in a lab flask. Fluorinated compounds tend to linger in soil and water because most natural processes don’t break those bonds easily. People who live near chemical plants or battery recycling centers deserve cleaner operations and robust waste management.

If you’ve followed stories about PFAS (“forever chemicals”) polluting drinking water, you’ve seen how a fluorine-rich chemistry, left unchecked, can outlive its utility and create headaches that span decades. LiTFSI falls into this club of persistent molecules, so ramping up its production ought to go hand-in-hand with tougher oversight. That means not just optimizing the salt itself, but tightening control on effluent, developing real recycling approaches, and keeping a tight grip on byproducts. Honest, clear reporting from manufacturers counts here—workers and surrounding communities need it to feel safe.

Building Solutions, Not Just Supplies

If battery makers want to lean on LiTFSI for the next generation of electric cars or storage, the only responsible way forward mixes more than chemistry. Factories can design closed-loop systems to catch and process waste before it hits streams. Research labs are starting to explore greener routes to assemble the TFSI anion, including milder reactants and recyclable catalysts. Transparent partnerships with environmental watchdogs and academic chemists allow for independent audits.

Choosing a “better” lithium salt carries a duty to treat the entire supply chain like a living system. People expect cleaner power and longer battery life but can’t trade that for invisible toxins in water or air. With smart design and real accountability, LiN(SO2CF3)2 has a shot to raise performance standards without cutting corners on community safety or sustainability.

Why Attention to Chemical Safety Matters

Working with chemicals like Lithium Bis(Trifluoromethane Sulfonimide, LiTFSI) brings up safety concerns, especially as it becomes more popular in battery labs and manufacturing lines. In my own time around research spaces, especially where high-performance, next-gen materials show up, I’ve seen how one slip turns an experiment into an emergency. Trust sometimes grows around familiarity, and that confidence often leads to shortcuts. But a routine can mislead, and LiTFSI proves the point: even materials that don’t explode or catch fire immediately can cause harm in sneaky ways.

What Makes LiTFSI Stand Out

LiTFSI offers good solubility in organic solvents, high thermal stability, and outperforms old-school lithium salts in electrolytes. This level of performance drives research and, increasingly, commercial interest. Years ago, I remember seeing LiTFSI as a premium—a niche lab supply. Now, startups and established battery makers order in bulk. Some read the label, see “not flammable” and “low reactivity” and relax. The risk comes not from big events, but from cumulative exposure and careless handling.

The Main Risks in Handling

The most obvious risk comes from powder handling. LiTFSI clings to surfaces and hangs in the air. Inhalation or skin contact cause irritation—and in one case I saw, powder tracked into a break room led to rashes on several hands. Hydrolysis creates trifluoromethanesulfonic acid, a corrosive agent. Moist air in the lab speeds this up, so humidity control and keeping containers sealed become basic habits, not luxuries.

Eye exposure burns; missing goggles means trouble. Even with gloves on, carelessness leads to transfer. Gloves need regular changing. Nitrile works, but once wet with solvent, breakthrough times drop. I always double-check gloves and avoid cross-contamination, especially after hearing about a researcher who wiped sweat off his forehead without removing his gloves—an easy mistake, and he spent the next day at urgent care.

Environmental Considerations

Modern safety isn’t just about personal health. Regulations have started tightening because lithium salts in general don’t break down easily. Accidental release—dust going down the drain or disposal in regular trash—leads to wider pollution. I’ve seen teams build fume hood protocols just for weighing or dissolving LiTFSI, and implement rigorous waste capture. This takes effort and slows down work, but the price of ignoring it piles up. Water sources, soil, and even local wildlife can end up carrying chemical traces long-term.

Building a Culture of Responsibility

No chemical offers zero risk. The attitude matters as much as the product label. LiTFSI needs gloves, goggles, and a habit of washing up. People working with it should know what to do in case of accidental exposure; first-aid kits must be stocked, and emergency eyewash stations need regular checks. Safety data sheets are helpful, but experience fills the gaps—mentors remind new lab members to respect the material.

Teams that manage accountability—rotating safety checks, reviewing incidents, and encouraging a climate where speaking up is welcome—avoid preventable accidents. LiTFSI may not explode on contact, but hidden dangers build up over time without vigilance. The real danger lies not in the bottle but in forgetting that respect for chemicals keeps everyone safe.

Why Storage Choices Really Count

Anyone who’s ever handled advanced battery chemicals has probably heard about Lithium Bis(Trifluoromethane Sulfonimide)—many call it LiTFSI for short. This compound plays a vital role in lithium-ion batteries, supercapacitors, and other high-tech applications. It comes with unique properties but also asks for respect in handling and storage. Jobs in R&D labs or production lines often put people close to such materials, so there’s no room for mistakes. I’ve seen what happens when storage guidelines get brushed aside. The cost can be ruined product, lost hours, or worse, a chemical incident. Storing specialty salts like this isn’t just about following directions; it’s about keeping science safe, reliable, and progressive.

Understanding LiTFSI’s Personality

LiTFSI absorbs water straight from the air. The technical term is “hygroscopic.” If anyone leaves it open to humidity—say, on a benchtop or by a window—the salt will clump and sometimes even dissolve into a sticky goo. That’s not just a nuisance; it actually changes the chemistry. Impurities creep in, and the product loses its worth for precise research or battery manufacturing.

Heat does no favors, either. LiTFSI might seem stable, but temperature swings can speed up unwanted side reactions and speed up decomposition over time. More importantly, trace moisture can trigger hydrolysis, leaving behind toxic or hard-to-handle byproducts. An overheated or damp storeroom can trash a full drum of expensive material very quickly.

Smart Steps for Safe, Long-Lasting Storage

Putting these facts together, the best storage spot always stays cool and dry. In my lab days, desiccators never felt like an optional extra—they meant the difference between robust data and a failed week. Silica gel or molecular sieves inside the container pull any moisture out of the air, so the salt stays crisp and free-flowing. Sealed containers, equipped with either screw caps or even tamper-proof seals, mean less chance of a humidity leak. I always check containers for cracks or ill-fitting lids at delivery, too, since even a hairline gap lets in moisture.

Light doesn’t do much harm to most LiTFSI, but direct sun can ramp up temperature and threaten purity. Most pros stash their supply in the dark, or at least tuck it away from sunlit shelves. Regular inventory checks help me spot condensation or signs of clumping early, so no surprises turn up at crunch time. A dry, shaded storage space lets a small supply last far longer, and anyone can inspect it without hauling out the chemical safety kit.

Personal Responsibility Pays Off

Skimping on storage—leaving a jar open overnight, or not screwing the lid on fully—almost always brings regret. The clean-up is ugly and stock replacements cause budget headaches. Responsible storage is more than a set of rules. It’s an attitude to treat both material and coworkers with the respect high-stakes chemicals deserve. In the world of battery and energy tech, that level of care pays off through fewer failures and cleaner data.

Anyone who ever worried about wasted hours or cross-contaminated experiments will understand why taking these extra steps feels natural. Careful storage doesn’t just protect the company’s investment; it builds a solid reputation for reliability, safety, and quality. And in any lab or industrial space, that reputation matters much more than convenience.

What Purity Really Means for Lithium Bis(Trifluoromethane Sulfonimide

In today’s world of batteries, research, and advanced manufacturing, even one decimal point in a purity number can separate breakthrough performance from an underwhelming result. I spent several years working in a battery materials lab, and every time we ordered Lithium Bis(Trifluoromethane Sulfonimide (LiTFSI), that fine print listing purity shaped everything that followed, from how deeply we trusted our results to whether an experiment had to be repeated from scratch.

Purity Grades: What Actually Shows Up in Labs and Production

LiTFSI comes in a handful of common grades on the global market. Reagent grade LiTFSI typically clocks in above 98% purity. Researchers working in organic synthesis or preliminary battery work often settle for this threshold—it keeps costs down, and early results can still highlight trends. Once the focus shifts to high-performance lithium-ion electrolytes or sensitive research, expectations move higher. Electrochemical grade and battery grade LiTFSI generally push upwards of 99.9% purity, even stretching to 99.99% for top-shelf batches. I’ve seen certificates listing 99.995%. It can become almost comical, how those extra threes and nines draw attention and dollars.

Why Minor Impurities Hurt More Than They Seem

Anyone who has loaded a salt into a battery cell knows that impurities don’t just sit quietly. Trace metals, water, or even organic residues—these sneak in at levels below 100 parts per million in commercial-grade powders. They can wreck test results. Water in particular will trigger hydrolysis with lithium and eat away at electrolyte performance. Fluorine-containing byproducts, sometimes left over from incomplete manufacturing, can foul separators or throw off conductivity. The more sensitive the application, the less tolerance for these hitchhikers.

Trusted suppliers like Sigma-Aldrich, TCI, and Solvay publish detailed impurity breakdowns along with their batches. In practice, this helps end-users weigh risk. Do I test every lot, or trust their numbers? In a research setting, most groups run Karl Fischer titrations and extra analysis themselves anyway. It’s often a matter of budget versus risk tolerance. On the industrial floor, defects or a failed QC batch can carry six-figure consequences.

What Pushes Purity Higher, and Who Pays the Price

Ultra-high purity LiTFSI doesn’t come by accident. It means more careful raw materials, repeated recrystallization, rigorous filtration, and constant moisture monitoring. Each extra decimal point increases production costs. For gigafactories and ambitious EV startups, those pennies per gram add up quickly. Sometimes, project managers look at 99.9% and wonder if it’s truly worth going higher. In my experience, labs that spend weeks troubleshooting mysterious failures often discover a cheaper salt at the root of their headaches. The market keeps drifting toward higher purities as technologies demand more from electrolytes, with supply chains stretching from China and Europe to final assembly lines in the US and Japan.

Making Purity Real: Steps Toward Reliable Supply

For long-term progress, buyers and end-users need more transparent data on impurity profiles, not just a number on a datasheet. Pushing suppliers to certify with analytical documentation helps cut out unwelcome surprises. Labs benefit from joining consortia that standardize materials testing, creating pressure for consistent quality. On the production side, gradual ramp-up in purity requirements—paired with ongoing internal spot-checks—keeps costs under control without blind trust in vendors. It doesn’t guarantee perfection, but it saves time and money in the trenches.

In the race for cutting-edge energy storage, even tiny uncertainties about what’s inside that LiTFSI bottle can decide success or failure. Purity isn’t just a technical detail—it helps decide breakthroughs, budgets, and scientific reputations, one decimal place at a time.