Mercaptodimethylamine Oxide: A Closer Look at Its Journey and Impact

Historical Development

Tracing back several decades, the story of Mercaptodimethylamine Oxide tells more than just the tale of a chemical compound—it lines up with advances in both organic synthesis and growing industrial needs. In early chemical literature, researchers pushed boundaries to create new thiol-containing compounds, seeing possibilities in both stability and reactivity. By the 1980s and 90s, industrial applications called for precisely tuned molecules to meet demands in cleaning, chemical processing, and personal care. At the same time, scientists shared reports on alkylamine oxides, discovering how sulfhydryl modifications could open doors to unique functionalities. That’s how Mercaptodimethylamine Oxide found itself gradually entering common lab shelves and then making its way to plant production floors worldwide. The story isn’t just about invention—it’s about adapting new knowledge to real-world needs, often outpacing regulatory and toxicological study for years at a stretch.

Product Overview

Today, Mercaptodimethylamine Oxide stands out in catalogs as a multi-purpose intermediate and an ingredient that brings more than basic performance to specialty formulations. Synthetic chemists and product formulators favor it for its ready-to-modify chemical structure and predictable solubility profile. Some still see it as a niche offering, but supply chains have grown to keep pace with demand for compounds equipped to tackle tough sulfur-based transformations, surface modification, and even select biochemical applications. From a research bench to specialty surfactants or biocide precursors, this compound thrives where other amine oxides struggle with reactivity or long-term storage.

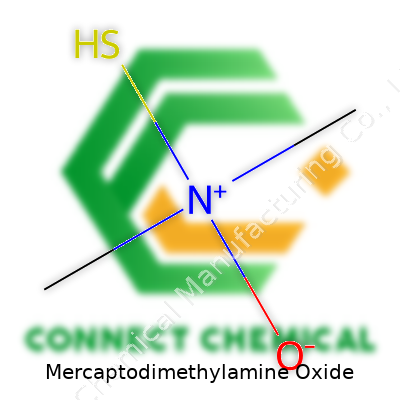

Physical & Chemical Properties

Mercaptodimethylamine Oxide often appears as a pale yellow to light brown liquid or low melting solid, depending on the hydration state and nature of counter ions in its commercial form. It often carries a faint but sharp odor, typical for thiols, and dissolves well in both water and polar organic solvents. Its aqueous solubility allows for flexibility in formulating blends, while its melting point and boiling point fit comfortably in the mid-range that synthetic chemists seek for easy handling and storage. In solution, it maintains good stability, unless exposed to strong oxidizers or acids, where both the thiol and amine oxide groups react readily. The dual-functionality brings a richness to its reactivity—rare among similar compounds.

Technical Specifications & Labeling

Labels mark Mercaptodimethylamine Oxide with tight technical specifications. Purity usually reaches above 98%, with stringent controls on water content, related thiol impurities, residual chlorides, and color index. In terms of packaging, suppliers recommend HDPE drums or amber glass bottles to block UV and slow down oxidation processes. Technical datasheets supply key values: specific gravity, refractive index, and pH (1% solution). SDS documents call out reactivity with common acids and oxidants, safe storage temperature ranges, and spill containment advice. Product names sometimes reflect supplier branding, batch information, or grade distinctions—such as “laboratory grade” for analytical use or “industrial grade” for bulk buyers.

Preparation Method

The current commercial route usually builds from dimethylamine precursors and employs a controlled oxidation in the presence of a mercaptan source. Catalytic oxidants turn the amine into an amine oxide with mild heating, where timing and concentration play a huge role in product yield and side-product suppression. Alternative lab-scale protocols sometimes substitute hydrogen peroxide as a gentler oxidant, improving selectivity at the expense of longer reaction times. Post-synthesis, operators employ vacuum stripping and fractional distillation to drive out residual solvents and low-boiling impurities. Modern improvements focus on minimizing energy use and creating safe, scalable processes with minimal waste, both for economic and regulatory reasons.

Chemical Reactions & Modifications

One thing that sets Mercaptodimethylamine Oxide apart is its versatility in chemical transformations. The thiol group allows for facile coupling with alkyl halides and activated esters—making it ideal for building more complex, sulfur-containing molecules, catalysts, or enzymes mimics. The amine oxide brings a layer of mild oxidizing potential, useful both in organic synthesis and in cleaning or disinfection processes. Researchers often tweak the molecule’s backbone, driving efforts to customize reactivity for specific tasks—such as tailoring hydrophobicity or enhancing binding to metals for chelation workflows. These modifications rely on the compound’s stability, making it a reliable platform for innovation.

Synonyms & Product Names

Known in literature and industry under a handful of names, Mercaptodimethylamine Oxide goes by names like N,N-Dimethylthiohydroxylamine oxide or simply as its short acronym, MDAO. Some suppliers register trademarked versions, pairing the generic scientific designation with a proprietary code or custom grade number. Regulatory listings track synonyms to ensure safety and compliance, especially across international shipments where customs may flag unknown derivatives. For research papers and patents, accurate naming matters—a practice that keeps discovery records consistent and easy to follow for everyone from bench scientists to product managers.

Safety & Operational Standards

Working safely with Mercaptodimethylamine Oxide requires more than basic lab rules. The thiol group easily releases gas on contact with acidic or oxidizing contaminants, so proper ventilation matters—a lesson learned firsthand in the crowded fume hoods of academic labs. Many users wear double gloves and check cartridge respirators, especially for scale-up or open transfer operations. Safety training covers not just spill cleanup but the importance of storing the chemical away from incompatible classes. Eye protection and face shields aren’t optional, as splashes can cause lasting irritation or, in rare exposures, more severe effects. Emergency protocols call for swift neutralization of spills, regular monitoring for vapor build-up, and labeled backup containers in case of storage container failure. These experiences, shared across both research and industry settings, highlight the need for every operator to take safety documentation seriously, recognizing that overly casual approaches can bring long-term health risks and facility downtime.

Application Area

The spectrum of uses for Mercaptodimethylamine Oxide continues to expand. Detergent manufacturers appreciate the balance of cleaning power and low-foaming action, as the compound helps solubilize tough organic residues without overwhelming formulas with unwanted byproducts. In industrial water treatment, it plays a supporting role in corrosion inhibition and metal scavenging, especially in recovery systems where residues could otherwise foul heat exchangers. Research laboratories use it for structural modifications, peptide synthesis, and design of sulfur-labeled radiotracers. The pharmaceutical industry eyes it as a route for drug candidate optimization, partly because its reactivity supports the insertion of “handles” for further functionalization. Each use case tells a story of evolving chemistry, trial and error, and the determination to turn unique functional groups into real-world solutions.

Research & Development

As research teams continue exploring the boundaries of chemical synthesis, Mercaptodimethylamine Oxide finds itself in the middle of innovation. Academic teams lean on it to try out new catalyst designs, metal-organic assemblies, or to probe the basics of redox-driven coupling reactions. Industry-sponsored projects look for cost savings by substituting traditional agents with easier-to-handle intermediates like MDAO, banking on stability and tunable reactivity. Recent years have brought a renewed push for “green chemistry” routes to make or use this compound, focusing on safer solvents, renewable feedstocks, and closed-loop processing to limit workplace exposure and environmental impact. Every time a new derivative or application surfaces, it drives demand for more thoughtful toxicological and long-term stability research, making this a hot topic at both specialty conferences and regulatory roundtables.

Toxicity Research

The unique blend of thiol and amine oxide groups brings both promise and responsibility. Early toxicology screens flagged skin and eye irritation potential, leading to stricter label warnings and increased adoption of personal protective equipment. Chronic exposure outcomes remain under review, with longer-term studies focusing on both inhalation routes and biodegradation byproducts. Environmental toxicologists warn that improper disposal compounds the risk to aquatic systems, since breakdown can yield small amounts of persistent organosulfurs. Those in the field need to press for transparent reporting of both short-term hazard data and public disclosure of long-term chronic studies. That means not just waiting for regulators, but pushing for comprehensive workplace monitoring and robust exposure minimization once risks show up.

Future Prospects

As the demand for precision chemical solutions grows, Mercaptodimethylamine Oxide looks set for a bigger role. Ongoing advances in catalysis, electronics, and green chemistry open fresh opportunities to harness the molecule’s twin reactivity. At the same time, the industry faces challenges around regulatory compliance, waste management, and the cost of meeting advanced safety infrastructure. The outlook depends on honest collaboration between researchers, suppliers, and regulatory agencies to chase both performance and responsible stewardship. With sharper analytical tools and a renewed focus on safe-by-design molecules, the path forward aims to secure the benefits of Mercaptodimethylamine Oxide while guarding against known and unknown risks—a balance learned over decades of real-world use and adaptation.

Everyday Uses and Real-World Stakes

Mercaptodimethylamine oxide might sound like trouble, but in truth, many people rely on what it can do—often without realizing it. This compound pops up in settings ranging from factories to cleaning aisles. It finds its way into some household products because of how well it breaks down grease and binds up certain metal ions. There’s plenty of chemistry behind it, but the results touch practical, daily concerns.

How It Works on Grease and Stains

Some years back, I volunteered at a community kitchen. Grease from daily cooking clung to steel counters and tile floors. Over time, I noticed certain degreasers never quite cleared things up, while others made everything shine. Digging into the labels, ingredients like mercaptodimethylamine oxide came up. The compound works by grabbing oil and grime at the molecular level, helping water carry it away. This power in cutting grease explains why cleaning product companies keep reaching for it.

Industrial Connections

Factories and processing plants often struggle with contamination. Metals in water lead to buildup and corrosion. Mercaptodimethylamine oxide helps control these problems because it can “hold on” to those metal ions and stabilize harsh environments. Back in my college lab days, we’d watch solutions stay clear when this compound stepped in, protecting valuable equipment and saving headaches on maintenance.

Health and Environment: Points to Watch

Not every chemical used in cleaning or industry makes for a safe guest in the home or outdoors. Research from the National Institutes of Health and EPA outlines concerns about the buildup of related compounds in waterways and soil. Side effects get even more attention when people work with the concentrated raw form or breathe in fumes accidentally. On personal experience, a neighbor once suffered skin irritation after using a cleaner meant for commercial settings at home. Stories like his make it clear—labels and guidance matter.

Transparency and Testing

The story of mercaptodimethylamine oxide reflects a larger problem with chemicals in daily life. Many products include it without offering much explanation about long-term health or environmental impact. Leading tech and chemical firms spend big money testing for toxicity and environmental drift. Groups like the Environmental Working Group call for stronger oversight, urging companies to prove safety before pushing new substances out to market. My own conversations with environmental scientists tell me testing remains slow, but pressure keeps mounting for answers.

Steps Forward for Safety

If a product pitches superior grease-busting powers, users deserve honest details on what’s inside. Manufacturers should lean into full ingredient disclosure. Even better, they’d do well to invest in safer alternatives and greener chemistries. As someone who deals with allergies, I pay close attention to what goes into my house—more transparency would let all of us make smarter choices. And on a larger scale, government regulators must set higher benchmarks. Proper training on handling concentrated versions can help workers, while strong policies guide waste-management and keep waterways clear.

Finding Middle Ground

Mercaptodimethylamine oxide does some heavy lifting in industry and at home, but it doesn’t come free of risk. With clearer research, tighter rules, and honest labeling, companies and individuals can bring out the best traits without stumbling into preventable hazards. Both industry players and watchdogs need to keep pushing for answers, because the stakes play out far beyond a single product on a shelf. Choices made today shape safer homes and healthier ecosystems down the line.

Understanding the Real Hazards on the Ground

Standing in a lab coat, goggles slipping down the nose, the word "Mercaptodimethylamine Oxide" looks harmless on a shipping drum. My first encounter with it sounded much less threatening than the long, chemical name on the label. Many compounds share such innocent beginnings. This one, though, often shows up in labs and specialty industrial settings, and the risks it carries deserve more attention than the name suggests.

Known Properties and Potential Threats

Mercaptodimethylamine Oxide, with its sulfur, amine, and oxygen-containing groups, isn’t the sort of substance you want splashed on your skin or wafting through the air. Breathing in fumes can irritate the eyes and respiratory tract—a lesson learned the hard way during a hurried spill in a university prep room. Even diluted, this stuff produces a sharp, unpleasant odor, a warning signal that you shouldn’t ignore.

The Material Safety Data Sheet (MSDS), a staple of responsible lab work, lists skin and eye irritation and possible respiratory sensitivity. Researchers at the National Institutes of Health track chemical impacts carefully, and this one stands out for the number of reported accidents linked to poor ventilation and lax glove use. Direct exposure often leads to redness and itching on contact, sometimes more if left untreated. Ingestion? Unlikely by accident, but effects range from stomach pain to far more severe symptoms.

Practical Experience: Why Safety Measures Matter

Handling Mercaptodimethylamine Oxide goes beyond “wear gloves” and “keep away from eyes.” During one summer internship, a careless colleague brushed his unwashed hand across his mouth after working with this stuff. He landed in the hospital with swelling and difficulty breathing. His experience drove home a lesson: this compound rewards carelessness with consequences. Every lab has stories like these. Experience tells me to treat every step—fitting masks, checking fume hoods, double-bagging containers for disposal—as nonnegotiable. Many overlook smaller risks until small problems spiral.

Looking Upstream: Better Practices for Every User

While this chemical crops up in specialized manufacturing and research, the core lessons fit almost any environment with hazardous compounds. Awareness starts with training. Rushed instructions and outdated posters do no real good. Clear, practical guidance on what to do if a spill happens or a glove tears reduces injuries. Reliable PPE—nitrile gloves, safety goggles, long sleeves—shields users if the right protocols get followed. Regular practice runs through emergency procedures (not just drills for show) boost confidence, making panic less likely if something actually goes wrong.

Companies sometimes skimp on engineering controls. Ventilation should fit actual use, not simply tick a compliance box. Proper fume hoods, adequate airflow, and sensors for leaks prevent small mistakes from growing. Providing accessible hand-washing stations and easy-to-reach eye wash bottles aren’t luxuries in modern labs or chemical plants—they’re essentials for anyone handling risky materials.

Transparency: Why Clear Information Protects Everyone

New staff, seasoned researchers, and cleaning crew all deserve access to honest safety data. Labels with vague warnings or inconsistent hazard signs put people at risk. Open discussion of “worst-case” incidents encourages self-reporting and early response.

From personal experience and documented cases, Mercaptodimethylamine Oxide isn’t “the most dangerous” substance out there, but ignoring its hazards creates problems that pile up fast. Posting clear guides, scheduling regular inspections, and offering health check-ins for those exposed during accidents could reduce harm in any facility.

Understanding the Chemistry

Mercaptodimethylamine oxide isn’t a household name, but anyone who’s handled specialty chemicals knows how much trouble improper storage can bring. This compound contains both sulfur and amine groups, making it reactive with certain environmental elements. Moisture and high temperatures transform safe storage into a risky guessing game. It doesn’t belong anywhere near food or everyday use products. Strict chemical management isn’t just for comfort—it’s about real-life safety.

What Experience Teaches About Storage

Many years working in labs and warehouse spaces taught me that the shelf life of chemicals hinges on routine choices. Mercaptodimethylamine oxide reacts with oxidizing agents and acids, prompting dangerous byproducts or odors if stored carelessly. Even accidental mixing through shared airflow or dust can trigger problems. I once saw a minor leak in a storage cabinet spread a rotten smell into a whole room, leading to an expensive cleanup. That experience hammered home the need for ventilation and segregated storage for sulfur compounds. Safety data sheets help, but lived experience shows that one misstep can cost dearly.

Physical Environment Matters

Mercaptodimethylamine oxide stays stable in a dry, cool spot, out of direct sunlight. Fluctuating temperatures or high humidity allow caking, decomposition, or releases of fumes. Standard HVAC doesn’t cut it; specialized climate control provides steady air and humidity levels, which prove critical during hot summers or damp seasons. Even closed containers sweat in bad conditions, and that slow trickle finds ways to disrupt the integrity of your stock. Double-walled containment offers another layer of assurance, thinking ahead to spills and accidental bumps.

Container Selection and Handling

A lot rides on which containers hold the chemical. People often choose glass or HDPE (high-density polyethylene) for storage, as both types resist corrosion and maintain structural integrity. Sealed lids and secure locking rings prevent vapor loss and contamination from other materials. Labels need to stay clean and legible, so rotating containers to face outward speeds up inspections. I always keep a change log at eye level, helping coworkers spot how long a batch has sat in storage and when it’s time to review or discard old stock. Chemical-resistant gloves, goggles, and an emergency eyewash station nearby keep accidents from turning into injuries.

Regulatory Rules and Environmental Impact

Legal codes require clear documentation and emergency procedures for hazardous materials. Regular training keeps teams sharp about what’s in each cabinet, and sets up clear routines for deliveries, inventory checks, and rollouts. Too many labs skip the paperwork, but that leads to expensive violations or real threats to health. Responsible disposal processes for leftover mercaptodimethylamine oxide protect groundwater and landfill safety, and sticking with local and federal disposal rules keeps communities safer. Inspectors respond well to transparent records and labeled containers.

Practical Steps Toward Improvement

Easy solutions make a difference. Temperature alarms, silica gel packs under pallet shelving, and secondary spill trays help stop small leaks from turning into emergencies. Dry, secure locations away from main walkways reduce physical accidents. Inclusion of training refreshers in quarterly meetings prevents storage knowledge from slipping. Using digital inventory tools improves traceability and response in case of problems. Everyone from lab tech to warehouse manager benefits when safety and practical habits become routine, not an afterthought.

Digging into the Chemistry

In scientific circles, people often toss around names that trip up most non-chemists. Mercaptodimethylamine oxide is one of those mouthfuls. Strip away the jargon, and at its core, this chemical brings together some familiar atoms in an unusual way. Its chemical formula is C2H7NOS. This breaks down to two carbon atoms, seven hydrogens, one nitrogen, one oxygen, and one sulfur.

Why This Structure Matters

Anyone who’s mixed a kitchen cleaner or scrubbed out a stain knows that small changes in chemical makeup turn something benign into something powerful. The arrangement of sulfur and nitrogen in mercaptodimethylamine oxide gives it unique reactivity. The sulfur pulls in certain metals, making this chemical handy in a range of industries, from wastewater treatment to specialty manufacturing. This specific combination also means it can latch onto heavy metals, forming stable bonds that don’t break apart easily.

Practical Use and Real-World Impact

During my time volunteering in a municipal lab, I saw firsthand how chemicals like mercaptodimethylamine oxide shape water quality. Municipal facilities juggle tons of complex compounds. Cleaning up industrial runoff takes more than bulk filters — it often relies on targeted chemicals. The oxygen in the molecule helps combat foul odors, while the “mercapto” or thiol group targets metal ions. In a real sense, workers count on these molecules to fish lead and mercury out of our rivers and lakes.

Potential Health and Environmental Risks

Working with substances like mercaptodimethylamine oxide takes respect and caution. The presence of both a thiol group and an amine means both sharp odors and the chance of toxicity if safety lapses. Any chemical that grabs onto metals can wind up causing issues if it escapes into the environment unmonitored. Researchers have warned about the risk of build-up in wastewater sludge. From there, it might slip into soil or crops. There’s an ongoing push for more transparent labeling and tougher disposal rules around specialty amine oxides. Nobody really wants legacy contaminants showing up years down the line, especially not in agricultural land.

Toward Safer Chemistry

More companies have started switching from chemicals with difficult residues to ones that either break down fast or bind up tightly enough that they’re easy to recover. This is especially relevant because evolving regulations now demand proof of safety for human and ecological health. High-throughput screening gives scientists a way to catch red flags before problems crop up, and safer process design means less risk for workers while still getting the job done. Government agencies like the EPA monitor these improvements and often work closely with manufacturers when updating material safety data sheets.

What to Consider Next

The conversation about mercaptodimethylamine oxide should always factor in both its usefulness and its risks. Innovative chemistry walks that line, giving industry what it needs while watching out for the broader community. As we adopt greener practices, the ultimate goal should revolve around designing chemicals from the start to minimize surprises downstream. Everyone from researchers to plant operators plays a role in managing these compounds, keeping both health and environment front and center.

Danger Lurks with Improper Handling

A bottle of Mercaptodimethylamine Oxide rarely attracts attention on a storeroom shelf, yet every chemist knows it can become a real headache outside proper handling. I remember an instance during a routine chemistry lab session, that unmistakable rotten-cabbage scent warned us of a tiny spill. Noxious smells aside, there’s a bigger issue: environmental and human health risks mount when chemicals find their way to the wrong places.

The Science: Not Just Another Amine

Direct contact with Mercaptodimethylamine Oxide may cause skin or respiratory irritation. Waterways face even greater danger, as this compound can harm aquatic life. The EPA and local jurisdictions classify it as hazardous waste for a reason. Pouring excess down the drain, outside of strict dilution and neutralization procedures, may well invite trouble. Local treatment plants are not designed to remove every trace, and environmental residues persist far beyond what we immediately see or smell.

Documentation, Not Guesswork

Chemical waste piles up over months, so a sound documentation system ensures no container gets lost or misidentified. Before opening a bottle, check the SDS for specific dangers and necessary steps. Clear labeling helps everyone around you, including custodians or emergency responders, handle things correctly—even years later. Skipping this step leads to confusion and, in my experience, more frequent accidents in shared lab spaces.

What the Experts Actually Do

Labs with seasoned staff don’t improvise—they collect excessive Mercaptodimethylamine Oxide in dedicated waste containers labeled for organosulfur compounds, then store these in ventilated chemical waste cabinets. Outsourcing to licensed hazardous waste handlers removes the risk from amateur hands. National programs like Clean Harbors or Veolia offer proven disposal chains, traceable manifests, and trained staff equipped for every scenario.

Shortcuts Invite Backlash

Down-the-drain disposal surfaces as a lazy temptation, especially where plumbing and dilution seem to hide small quantities. A spill I once saw declared “nothing to worry about” promptly turned into a backroom clean-up measured in hours, not minutes, due to pipe corrosion and local water warnings. Administrative costs soared when inspectors flagged outdated disposal logs during surprise audits.

Training Pays Off

Empowering everyone—from graduate students to full-time lab techs—with real training, not just online modules, keeps surprises to a minimum. Many labs run annual “disposal days” where experienced folks walk new staff through best practices. This hands-on approach weeds out myths and complacency that spread in busy facilities.

Practical Steps for Every Facility

A small operation should consult local environmental agencies and avoid off-the-shelf drain disposal. Capture every milliliter in a sealed container, never mix with incompatible substances, and double-check local guidelines for transport and submission. Facilities far from major urban centers sometimes leverage regional waste co-ops, pooling small generators' waste for more efficient removal.

Innovation Knocks: Future Prospects

Green chemistry teams now eye safer substitutes for Mercaptodimethylamine Oxide in research and industrial synthesis. Some universities trial real-time breakdown units using oxidation or biodegradation, aiming for in-lab neutralization before disposal even begins. While promising, adoption takes time, teamwork, and ongoing monitoring.

Taking Ownership at Every Step

No shortcuts or quick fixes compare to personal responsibility. Each worker in a lab or industrial facility plays a part: double-check those waste streams, foster open dialogue with environmental health teams, and keep safety ahead of convenience. That approach keeps chemical mishaps rare—and water, air, and people a lot safer.