Methyl 10-Bromodecanoate: An Exploration of Science, Industry, and Safety

Historical Development

Organic synthesis keeps moving forward because of building block molecules like Methyl 10-Bromodecanoate. Its story stretches back to mid-twentieth-century industrial chemistry, when demand for versatile intermediates rose across pharmaceuticals and polymers. At first, the industry leaned heavily on simple bromoalkanes, but lengthening the carbon chain and adding new functional groups pushed research into broader territory. By the 1970s, advances in selective bromination and esterification let chemists prepare compounds such as Methyl 10-Bromodecanoate at scale. Over time, tweaks to production methods improved purity and yield, making it easier for researchers and manufacturers to rely on this compound in everything from synthesis to specialty surfactants. My own time in an academic organic lab showed the importance of consistent access to reagents like these—not just for large companies but also small operations where reliability means fewer surprises.

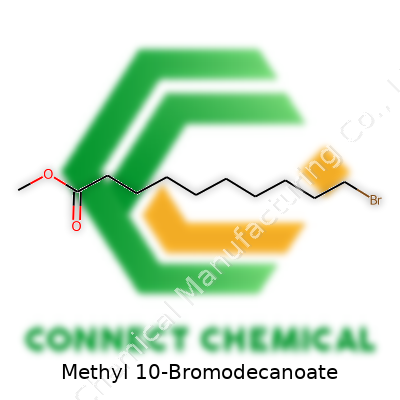

Product Overview

Methyl 10-Bromodecanoate lands in the catalog of organobromine esters. The molecule brings a ten-carbon backbone with a methyl ester at one end and a bromine atom at carbon ten. This simple-sounding structure carries weight because it bridges fatty acid chemistry and reactive halides. Researchers value its twin handles for further modification. The methyl ester resists mild hydrolysis, making storage and shipping safer, while the bromine atom stays reactive enough for substitution reactions. Commercial demand grows in labs working with complex lipids, surfactants, and new materials. In my experience, specialty suppliers never had trouble moving this compound to those needing to extend fatty acid chains or introduce new functional groups in fewer steps.

Physical & Chemical Properties

Methyl 10-Bromodecanoate typically shows up as a colorless to pale yellow liquid, sometimes forming a low-melting solid at cool room temperature. With a molecular weight sitting around 271.15 g/mol and a density just above that of water, it flows thickly but pours easily in the lab. This molecule does not carry the pungent odor of shorter chain bromo esters, so it’s easier to handle for longer synthesis sessions. Solubility leans toward organic solvents—dissolving smoothly in ether, chloroform, and dichloromethane. Water stays out of the picture, limiting loss during aqueous workups. The bromine makes the molecule heavy and reactive, but it also raises the boiling point closer to 125°C at reduced pressure. Experience says always double-check your glassware’s compatibility with organobromines, since they can etch and stain with rough handling.

Technical Specifications & Labeling

Labs and production companies track key markers for each batch. Purity sits above 97% for most research applications. Impurities rarely exceed half a percent by gas chromatography. Most labels carry core details: chemical formula (C11H21BrO2), CAS number, manufacturer’s name, batch code, and storage instructions. This molecule keeps best at cool temperatures, away from sunlight and open flames. Storage in amber glass bottles helps control unwanted side reactions and keeps the shelf life in the range of two years or longer. From practical experience, a detailed certificate of analysis matters for reproducibility, especially in regulated applications like pharmaceutical development.

Preparation Method

Synthesis of Methyl 10-Bromodecanoate follows a straightforward path but rewards careful process control. Typically, one starts with decanoic acid or methyl decanoate. Bromination happens through free radical addition, with N-bromosuccinimide (NBS) and a suitable initiator under controlled light or heat. Another route uses phosphorus tribromide with direct esterification for one-pot synthesis, bypassing the need for isolation of the intermediate. Reaction times, solvent choices, and temperatures all play big roles in yield and selectivity. A well-tuned protocol reaches 80–90% yield after workup. Washing, drying, and careful distillation or chromatography give the high-purity product labs want. Over my career, I’ve seen shortcuts produce by-products no one enjoys removing—full control gives better, purer yields but takes time and skill.

Chemical Reactions & Modifications

This molecule serves as a launching pad for many reactions. The terminal bromine reacts easily with nucleophiles, enabling substitution to amines, thiols, or azides for further derivatization. Strong bases swap the bromine for an alkene via elimination. The methyl ester lets the fatty chain extend without unwanted hydrolysis until a strong acid or base steps in. Using Grignard conditions, researchers add new carbon groups at the bromo position, expanding into branched or cyclic derivatives. Applications benefit from this flexibility—complex surfactants, modified lipids, and bioactive molecules all result from people pushing Methyl 10-Bromodecanoate through new or classic transformations. Every time a reaction goes smoothly, credit belongs as much to these well-designed starting materials as to the chemists running the benches.

Synonyms & Product Names

Supplier catalogs keep things simple or technical, depending on the target audience. Some common synonyms include Methyl decanoyl-10-bromide, 10-Bromodecanoic acid methyl ester, and Decanoic acid, 10-bromo-, methyl ester. Trading partners and regulatory bodies recognize these names alongside standardized ones. The CAS number anchors every label, preventing costly mix-ups. My work ordering chemicals taught me to cross-reference every name—one mislabeled bottle could halt a week’s worth of synthesis or skew analytic results.

Safety & Operational Standards

Safety matters as much at industrial scale as behind university benches. Methyl 10-Bromodecanoate demands careful respect: skin and eye contact triggers irritation, and vapors from heating or spills can cause respiratory harm if ventilation runs low. Material safety data sheets recommend heavy gloves, splash goggles, and a fume hood for every transfer, even small ones. Local exhaust ventilation catches stray vapors before people notice them. Good labeling and segregation from strong acids, bases, and oxidizers cut accident risks. Clean-up protocols require inert absorbents—water and soap lack the strength to neutralize heavy organobromines. Over decades, better personal protective equipment and real-time air monitors reduced risks, but safety drills and routine checks kept every scientist in the habit of treating these chemicals with the respect they deserve.

Application Area

Pharmaceutical discovery and specialty chemicals benefit most from Methyl 10-Bromodecanoate’s unique structure. The bromine atom’s reactivity lets drug designers add functional groups to long-chain molecules targeted at lipid membranes, while the fatty ester scaffold fits naturally into surfactant engineering. Some medical imaging agents and antimicrobial molecules also begin with this intermediate. Beyond biomedicine, researchers value its chain structure for producing lubricants, corrosion inhibitors, or molecular probes. I recall one computational chemist designing new amphiphiles—every promising candidate started with this molecule’s reliable platform as the backbone for further creativity. Scale matters, too: while gram quantities fuel R&D, kilogram batches keep pilot production lines running smoothly.

Research & Development

Academic labs and industrial innovation teams both rely on this molecule for pushing boundaries. As lipid chemistry advances, so does the demand for novel building blocks that handle functional group compatibility, regulatory approval, and process efficiency. Researchers explore greener bromination techniques—using photochemistry or alternative reagents to cut unwanted side-products and waste. Some aim for continuous-flow synthesis to deliver custom compounds with tighter quality control. Others look for non-brominated analogs to reduce environmental impact, recognizing regulators’ calls for safer, less persistent chemicals. In my work supporting graduate projects, success often depended on getting this molecule reliably and tweaking conditions to unlock new, patentable molecules.

Toxicity Research

Existing data shows potential hazards for workers and downstream users. Acute exposure leads to skin and eye irritation, with animal studies revealing mild toxicity at high doses. Regulatory agencies track environmental persistence and breakdown products, knowing that organobromines can linger longer in groundwater or sediments than shorter-chain relatives. Chronic toxicity studies remain underway, but evidence warrants strict handling on the job and responsible waste management at the end of a product’s life. Regulations limit occupational exposure, emphasizing engineering controls and personal protection. In my own fieldwork, audit teams always checked storage records and disposal logs to confirm no shortcuts put people or the environment at risk.

Future Prospects

Interest in Methyl 10-Bromodecanoate keeps rising as industries shift toward custom-fatty-acid derivatives, novel surfactants, and greener chemistry routes. Researchers look for ways to optimize synthesis while slashing waste and energy costs. Advances in catalysis or enzymatic approaches might provide new preparation routes, trimming side-product formation and improving atom economy. At the same time, materials science continues to push for new building blocks that carry both reactivity and biocompatibility. With growing regulatory scrutiny on persistent organic pollutants, R&D may well deliver analogs that balance performance with environmental safety. This molecule’s dual nature—as a sturdy platform for synthesis and a chemical that demands careful management—illustrates both the promise and the challenge facing modern chemistry.

Walking Into the World of Fine Chemicals

Years ago, a seasoned colleague slid over a sample of methyl 10-bromodecanoate and asked me to find its purpose outside simple catalog entries. At first glance, this compound might sound obscure, even to the chemically curious. Its main use connects directly to the world of specialty synthesis—making molecules that can’t be picked off a shelf.

Key Role in Organic Synthesis

Methyl 10-bromodecanoate holds a special position in organic chemistry because its structure makes it both a target and a tool for building things. The bromine atom attached to the carbon chain acts like a handle for chemists. They use it to swap in different atoms, a bit like switching a Lego brick in a much larger build. This swapping drives the creation of new compounds that lead downstream to fragrances, insect pheromones, or even drugs.

Several years back, I worked on a project aimed at mimicking a pheromone produced by a type of moth whose larvae attacked stored grains. Though the bug itself stays hidden, its chemical signal can be spotted in the tiniest concentrations. We built our replica molecule step-by-step, and right in the middle sat methyl 10-bromodecanoate. The chain length matters: too short or too long and the end product simply doesn’t work. The bromine made it possible to connect just the right piece, giving the team control over the final shape.

Building Blocks for Bioactive Compounds

Major pharmaceutical companies pay close attention to fine chemicals like this. The reason runs deeper than supply: they crave control in their synthetic routes. Methyl 10-bromodecanoate shows up in routes toward drugs that need a specific carbon chain or functional group in a precise position. A few research articles, including one published by the American Chemical Society, detail ways to hook together bigger, bioactive molecules using intermediates based on this compound.

Everyday Impacts

Even if few people know it by name, the compound impacts regular lives. Creating safer pest control methods for warehouses or farms sometimes depends on analogs built from this molecule. Some manufacturers use it as a step toward emollient components that end up in skin creams or specialty shampoos catering to allergies or scent sensitivities.

Consumers seeking fewer synthetic fragrances in products still rely, knowingly or not, on molecules crafted with intermediates similar to methyl 10-bromodecanoate. This demand pushes chemical manufacturers to improve how they handle, store, and dispose of such materials, as the bromine atom brings environmental management challenges. Strict regulations in Europe and North America have shaped cleaner production methods and better waste handling, which matters to both workers and surrounding communities.

The Push for Greener Chemistry

Not every producer uses older bromination techniques anymore. I’ve watched smaller labs and larger factories move toward methods that cut down on hazardous by-products. Switching away from harsh solvents, reusing reaction media, and better recovery technology now define industry best practices. These steps make chemical operations safer, while customers can shop with more confidence that companies take environmental responsibilities seriously.

Trust, Traceability, and the Road Ahead

Whether supporting research or appearing in the development of new household goods, methyl 10-bromodecanoate proves how a single step in a supply chain can ripple outward. For me, learning about such chemicals—how they evolve from lab curiosity to regular utility—underscores the value of transparency and safety in both research and manufacturing. Trust in consumer products often depends on small details in places few people think to look.

What Safe Storage Actually Means

Methyl 10-Bromodecanoate isn’t something most people keep in a garage, but in the world of specialty chemicals, it matters a lot how this material is stored. Storing a chemical like this well directly shapes its quality, safety, and the kind of results researchers or manufacturers get out of it. There’s more to it than tossing the bottle onto a shelf and calling it a day.

The Kind of Place Methyl 10-Bromodecanoate Needs

In my work with chemical supply, temperature often slips by in people’s setup—until a canister starts to sweat or labels fade. This compound prefers a spot out of the sun’s reach, way below 30°C, ideally at regular room temperature or a bit cooler. Heat doesn’t just threaten the shelf life; it pushes the risk of unstable compounds. Everyone wants a longer shelf life and a safer work setting.

There’s also the air. Humid conditions sneak up quickly, especially in older storerooms or in summer. Methyl 10-Bromodecanoate can react with water vapor over time; those little crystalline edges at the cap, small spots of mildew under the lid—those reveal leaks and lazy container habits. A dry area with good ventilation beats a lucky streak every time.

Containers and Compatibility

Glass bottles with tight, chemical-resistant seals serve this material best, based on years of lab rounds and more than a few supplier chats. Metal caps or loose plastic can give up after several openings, and it takes only a small crack for air or moisture to make trouble. Clear labels, with the opening date and hazard sign front and center, let every lab member know this bottle’s not regular stock.

I remember clients who stored their chemicals in shared cupboards with acids, bases, or solvents. That might sound efficient, but it’s a shortcut to cross-contamination. Even a trace of spilled ammonia or strong alkali eats into the purity. Chemicals with bromine content hold surprises you don’t want to release in a routine mishap.

Smarter Handling and Storage Solutions

So much depends on the little things—training every new tech to use gloves, clean tools, and keep the work benches clear after every job. Dust and dirt don’t just look bad; they help chemicals react in ways no one wants. Solid Standard Operating Procedures, written in plain language and kept up to date, build habits that protect the whole lab.

Safety cabinets dedicated to organics pay off ten times over, especially when paired with regular inventory checks. Keep incompatible stuff separate, post emergency spill guidelines, and inspect caps before and after every use. In our shop, a bit of colored tape shows a container’s last open date—easy, cheap, and surprisingly effective.

Minimizing Waste, Maximizing Safety

Larger containers seem cheaper on a purchase order, but small packed units keep each batch fresher and cut down on the amount tossed at the end of the year. Check expiration dates—waste disposal is never fun or cheap with a brominated compound. If a bottle sits open more than a year, it’s probably best recycled or professionally destroyed.

Shipping and storage always count as a single chain. If your supplier invests in cooled transport and proper labeling, you start off safer and stay that way longer. Every step focused on keeping the original material in top shape directly supports research goals and keeps everyone safer. Details matter, and they’re easier to get right than deal with a mess afterward.

Breaking Down Methyl 10-Bromodecanoate

Methyl 10-Bromodecanoate comes up in labs and chemical catalogs more often than you might expect. I first encountered it in the context of organic synthesis, especially in projects where tailored fatty acid derivatives mattered. The molecule’s backbone runs ten carbons long, with a bromine atom snagged onto the tenth carbon and a methyl ester making it more reactive than standard decanoates. Its chemical formula looks straightforward on paper: C11H21BrO2. Each piece serves a purpose—bromine for reactivity, a methyl group for solubility tweaks, and that decanoic chain for length and hydrophobicity.

Why Formula and Weight Matter in Real Applications

The molecular weight lands at 265.19 g/mol. That number takes on meaning fast in the lab. Accuracy in stoichiometry counts for more than just piling up correct reagents; it can mean the difference between a successful synthesis and a wasted afternoon. With a halogenated ester like this, missing a decimal point can throw off your reaction yields or throw impurities further down the workflow, haunting you during purification or spectral analysis.

I’ve worked in teams where small mistakes with chemical calculations snowballed, and nobody likes re-running a column because of one wrong molecular mass input. That weight—265.19—pins down how much substance actually enters the process and guides safe handling and disposal.

Importance for Research, Industry, and Safety

Researchers value the unique structure of Methyl 10-Bromodecanoate. Its long alkyl chain mimics natural fatty acids that pop up in biological membranes, while the bromine opens the door to more modifications via nucleophilic substitution. A team aiming to build more complex molecules can turn this ester into pharmaceuticals, surfactants, or tailored monomers, depending on the next steps. Knowing the exact formula and molecular weight builds confidence in the chosen pathway, gives reassurance in reporting data, and keeps the audit trail clean for regulatory filings.

In chemical manufacturing, precise identification cuts down on risks. A mix-up in formulas wastes money, resources, and sometimes even personnel safety. Regulatory agencies care not just that a compound does its job, but that every string of atoms fits the paperwork on file. The formula C11H21BrO2 becomes a shorthand for safety datasheets, transportation manifests, and disposal protocols. Following safety pointers on brominated organics prevents unnecessary exposures; a misplaced bottle or breach in protocol can lead to health issues or environmental trouble.

Room for Better Practices

Problems with errors in calculation or mishandling pop up all the time. Peer checks help, as does using well-built chemical inventory systems. Several times, technology saved my team from start-to-finish headaches. Barcode systems and software tracking stock formulas, weights, and CAS numbers build a safety net around manual calculation errors. Training remains the backbone—newcomers in chemistry often come under pressure in busy seasons, and reminders of the right steps matter. Experienced chemists pick up the slack here by encouraging double-checks and quiet walkthroughs of the math.

Methyl 10-Bromodecanoate might not show up in daily news, but for professionals dealing with organic synthesis, its details mean a great deal. The right formula and molecular weight anchor day-to-day reliability and bigger research progress.

What’s in a Chemical Name?

Methyl 10-bromodecanoate rarely features in casual conversation, but anyone working in the chemical, pharmaceutical, or research world will recognize this compound. It finds a place in specialty syntheses, and chemists rely on it to build more complex molecules. The question, though, goes beyond its uses. People want to know: is it hazardous or toxic? That’s the bigger concern for many, both at the lab bench and beyond.

Real Hazards in Everyday Labs

As someone who’s seen all sorts of substances run through a research lab, I’ve watched people underestimate the dangers based on a chemical’s obscurity. The issue isn’t just about acute toxicity, although that does matter. For methyl 10-bromodecanoate, safety data sheets consistently flag skin and eye irritation risks. Those who handle it without gloves or eye protection learn the hard way that this is not a benign oil. Inhaling its vapors can also irritate airways, and accidental ingestion leads to more severe problems—abdominal pain, nausea, and distress.

Deeper Down: Long-Term Risks

Longer exposure raises more questions. Brominated compounds as a class show some toxic features: some persist in the body, disrupt hormones, or cause organ damage after weeks or months. According to studies from the National Library of Medicine, there’s evidence that brominated chemicals like this one could damage liver cells or interfere with enzymes at relatively low doses. In my own experience, I’ve seen colleagues develop rashes after repeated skin contact, even at low concentrations.

Environmental Impact Isn’t Just an Afterthought

Speaking with colleagues in environmental chemistry, I’ve learned just how persistent halogenated compounds can be outside the lab. If methyl 10-bromodecanoate escapes into soil or water, it doesn’t break down quickly. Wildlife and aquatic organisms may absorb it, and then it works its way up the food chain. These impacts don’t always show themselves right away, but regulators and scientists have flagged persistent chemicals as threats to far more than just lab safety. A 2022 review in the journal Chemosphere put brominated organics on a list of “watch” chemicals due to bioaccumulation concerns.

Tackling the Real-World Dangers

Watching researchers become complacent about gloves and goggles—because the material isn’t a famous toxin—reminds me why basic protection matters. The answer isn’t to ban every chemical that stings the skin, but to keep proper handling and disposal as habits, not afterthoughts. Ventilated hoods, spill kits, and regular safety training cut down on accidents a lot more than warnings on bottles.

Regulators are starting to tighten the rules, urging sites to collect even small residues and use specialized waste disposal. I’ve seen this make a real impact, reducing run-off and stopping the habit of rinsing chemicals away. Wastewater checks and workplace air monitoring spot problems before they become lawsuits or headlines. Since alternative, less hazardous routes often exist for chemical syntheses, research teams and manufacturers can swap out riskier compounds like methyl 10-bromodecanoate without sacrificing progress.

Facts and Responsibility Lead the Way

Methyl 10-bromodecanoate doesn’t rank among the deadliest industrial chemicals, but ignoring its hazards can bring trouble. Personal vigilance, team habits, and up-to-date regulations shape safe and responsible labs and workplaces. As a scientist and as a citizen, I’ve learned that facts—backed by real experience—matter far more than a false sense of security.

Understanding Purity in Specialty Chemicals

Working in research labs and on custom synthesis projects, I’ve seen just how important purity grades can be. For Methyl 10-Bromodecanoate, the specificity of purity isn’t just a line on a certificate; it shapes both immediate outcomes and long-term safety. Laboratories and manufacturers who know their suppliers and product sources set themselves up for reliable, repeatable results. This holds true in pharmaceuticals, agricultural chemicals, and specialty intermediates.

Specification Details That Matter

The purity of Methyl 10-Bromodecanoate typically lands at or above 98 percent by GC (gas chromatography). Some batches boast assay levels closer to 99 percent. These numbers aren’t marketing fluff—they come from careful, transparent reporting, with full certificates outlining GC area percentages, water by Karl Fischer titration, and common impurity data. Trusted suppliers share full data summaries and batch-specific documentation.

For teams handling scale-up or anything related to human health and intricate chemical transformations, minor contaminants—like isomeric bromides, unreacted starting acids, or byproducts from esterification—present challenges. Even a fraction of a percent influences downstream synthesis, product color, or yields. I’ve watched projects grind to a halt because a raw material contained unexplained impurities, visible only at scale. Replacing a supplier over a small undetected contaminant means lost weeks and wasted investment.

Broader Impact of Purity on Results

Even for teams outside life sciences, technical grade and pharmaceutical grade aren’t just sales terms. Higher purity often means lower levels of moisture and heavy metals. Trace amounts of water prove disastrous in organometallic reactions; metals like iron or copper catalyze side reactions. I remember a batch of a brominated ester where the water content—a leftover from poorly dried methanol—ruined a Grignard reaction, costing a whole week’s work.

Reliability here isn’t about chasing perfection. It’s about consistency between batches and open line-of-sight from the certificate to the actual drum. Analytical traceability and supplier transparency shape downstream productivity. This is a theme I’ve heard echoed at conferences, in university labs, and in industry partnerships.

Improving Quality Assurance in the Supply Chain

It’s easy for buyers to chase bulk price breaks, yet each step removed from source introduces risk. A direct relationship with trusted manufacturers brings leverage: custom paperwork, extra impurity analysis, and transparent notifications about even trace-level changes. Every robust QA team I’ve worked with puts documentation at the forefront and keeps a direct line to their supplier’s technical specialists.

Routine batch-to-batch validation bridges the last mile gap. Running your own NMR or GC/MS spot checks, tracking changes over time, and sharing unexpected findings with the supplier creates a cycle of continuous improvement. Significant suppliers take feedback seriously—they want your repeat business more than your first order.

Choosing Wisely: The Real-World Importance of Purity

Purity grades for specialty chemicals like Methyl 10-Bromodecanoate steer business success, lab performance, and safety. Picking a supplier whose documentation matches what’s in the bottle pays dividends project after project. It’s about more than numbers on a page; it’s the difference between consistent results and expensive surprises.