Methyl 3-Bromopropanoate: Science, Application, and the Path Forward

Historical Development

Chemistry runs on building blocks, and methyl 3-bromopropanoate earned its place in laboratories decades ago as the need grew for efficient alkylating agents. Long before the digital age, researchers tinkered in glassware, noticing that simple substitution on a propanoate backbone could open new synthetic routes. At first, methyl 3-bromopropanoate found modest use in academic research, helping chemists build complex molecules for pharmaceuticals. The molecule stayed relatively niche until the rise of organometallic chemistry in the late 1900s, when demand for specialty intermediates spiked in both industry and academia. Today, it sits on chemical supplier lists worldwide, a testament to the persistent need for adaptable halogenated esters in fine chemical synthesis.

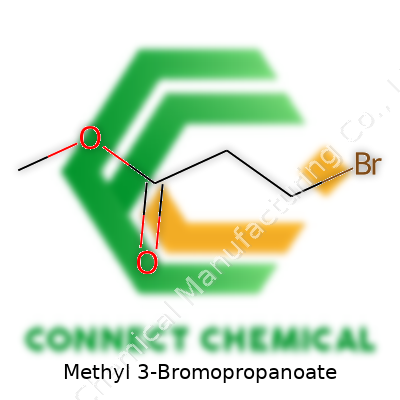

Product Overview

Methyl 3-bromopropanoate stands out for its versatility. Chemists use it as a starting point for synthesizing active pharmaceutical ingredients, agrochemicals, or specialty polymers. It offers a bromine leaving group two carbons away from a carboxylate ester, which means it can undergo a wide variety of reactions. Its molecular structure—C4H7BrO2—balances reactivity and manageability, giving researchers a reliable means for carbon extension and functionalization. Real-world demand for tailored, small-molecule synthesis gives methyl 3-bromopropanoate a steady foothold in research and pilot-scale manufacturing facilities.

Physical & Chemical Properties

This compound appears as a colorless to pale yellow liquid at room temperature. Odor reminds me of simple esters—slightly sharp and sweet—though the bromine atom gives it a heavier note. It boils at roughly 68–73°C at 20 mmHg, typical for mid-weight esters bearing halogens. The molecular weight clocks in at 167.01 g/mol. Its density sits at about 1.49 g/cm³, which feels heavy on the hand compared to many non-halogenated ethers. Limited water solubility keeps it mostly in organic phases during extractions and reactions, though it does dissolve easily in most polar aprotic solvents. Reaction conditions need careful attention—the bromine atom on the propanoate chain brings about reactivity under basic or nucleophilic conditions, and thermal stability can drop if exposed to open flames or oxidants.

Technical Specifications & Labeling

I once spent half a day sorting through a shipment with barely legible labeling—accuracy matters. High-grade methyl 3-bromopropanoate carries clear specifications: purity exceeds 98% by GC, water content remains under 0.5%, and minimal byproducts ensure the main peak dominates HPLC or NMR spectra. Labels from reputable suppliers show clear lot numbers, batch information, and hazard pictograms for corrosivity and flammability, following GHS or REACH guidelines. Packaging in amber glass bottles (usually 25 g, 100 g, or 500 g) protects the compound from light and moisture, underscoring its light sensitivity and volatility. This level of detail supports traceability and safe lab practice.

Preparation Method

Preparation of methyl 3-bromopropanoate takes me back to old organic lab sessions. Typically, one starts from 3-bromopropanoic acid, which can be made from propanoic acid with NBS (N-bromosuccinimide) under radical conditions. For esterification, the acid reacts with methanol in the presence of a strong acid catalyst, such as sulfuric acid or p-toluenesulfonic acid, under reflux. Water is removed to drive the reaction forward, then the product gets washed, separated, and dry-distilled. Some labs prefer reacting methyl 3-hydroxypropionate with phosphorus tribromide (PBr3), a process that swaps the hydroxyl group for bromine with high efficiency, albeit under stricter control due to exothermicity and toxic byproducts. Both methods require careful temperature and pH adjustments to avoid hydrolysis or over-bromination, reminding me how essential hands-on lab skills are for clean yields.

Chemical Reactions & Modifications

In the real world, methyl 3-bromopropanoate serves as a flexible intermediate. The bromine atom makes it ideal for nucleophilic substitution, where amines, thiols, or other nucleophiles can displace the bromide to form new carbon-nitrogen, carbon-sulfur, or carbon-oxygen bonds. That backbone lets it participate in Michael-type additions or build up carbon chains through alkylation. I’ve watched researchers use it in malonate or enolate alkylations, tweaking pH and solvent to direct product distribution. Under strong base, elimination can take place, forming methyl acrylate by removing HBr—a reaction that highlights the balance between substitution and elimination. This dynamic chemistry lies at the core of many medicinal and materials projects, where quick modifications are valued for speeding up optimization.

Synonyms & Product Names

People working with methyl 3-bromopropanoate might know it by other names: 3-Bromopropanoic acid methyl ester, methyl β-bromopropionate, or methyl 3-bromopropionate. Some catalogs list it under CAS No. 5960-72-3. Synonyms can cause confusion, especially across languages or supplier catalogs, so it pays to double-check purity, structure, and labeling before buying stocks or preparing internal reference materials.

Safety & Operational Standards

Handling this compound in the lab means not cutting corners on safety. Contact with skin or eyes can cause irritation or burns, and inhaling vapors—especially if heated—brings real health risks, including respiratory tract effects. Methyl esters tend to sneak past poorly fitted gloves, so I stick with thick nitrile and make sure all reactions run in ventilated hoods. Storage demands sealed, light-protected containers, far from oxidizers or ignition sources. Regulatory bodies like OSHA and ECHA set firm exposure limits: spill kits and eye wash stations stand by in my own lab routine, underscoring a strong respect for even familiar reagents. Consistent documentation and staff training go a long way toward preventing incidents before they happen.

Application Area

Pharmaceutical chemists and agrochemical developers pull methyl 3-bromopropanoate off the shelf for its unique capacity to introduce functional groups or extend chains. In my own experience, it played a pivotal role in synthesizing small-molecule drugs targeting neurological disorders, where the subtle tweak of a chain length or side group can define bioactivity. Polymer chemists appreciate it for grafting side-chains onto base polymers, building specialty plastics with select properties or surface reactivity. Environmental labs sometimes take interest in the molecule’s behavior, studying breakdown products and transformation pathways in simulated soils. This spread of applications speaks to the compound’s adaptability and the repeated need for reliable halogenated intermediates in many research and commercial sectors.

Research & Development

Current research takes methyl 3-bromopropanoate well beyond its initial uses. I’ve seen journals report its use in asymmetric synthesis, helping generate chiral centers for new drug scaffolds. Chemists push for greener, safer reaction protocols, aiming to swap out hazardous conditions for milder alternatives using phase transfer catalysis or microwave-assisted methods. In materials science, functionalization of nanomaterials often begins with small esters like this, feeding into the design of drug delivery vehicles or responsive coatings. Synthesizing analogues or isotopically labeled versions also opens doors for tracer studies in metabolic research, an area that underscores the molecule’s continuing relevance to advanced investigation and clinical translation.

Toxicity Research

It’s critical not to gloss over toxicity, especially in environments with students or new researchers. Esters containing bromine show greater reactivity toward biological molecules, posing a risk of cellular or genetic damage during mishandling. Methyl 3-bromopropanoate can cause moderate to severe acute toxicity in animal studies—skin corrosion, inflammation, and in severe cases, systemic organ effects. Regulatory reviews by agencies like ECHA flag the need for strict exposure monitoring and specific disposal protocols, since byproducts may have persistent environmental impacts. I keep updated SDS sheets on hand and advise colleagues to work with small quantities, noting that incident reports drive home the importance of vigilance with organobromines, even at bench scale.

Future Prospects

Advances in green chemistry, automation, and computational molecular design all point toward a changing landscape for chemical intermediates. Methyl 3-bromopropanoate will likely remain a go-to building block, but I see a push for more sustainable synthesis routes—less toxic brominating agents, solvent recycling, continuous-flow production. Polymer scientists experiment with alternatives for bromine-based modifications to curb environmental persistence. Policy developments may place tighter restrictions on emissions or handling, spurring innovation in safety and detection technology. My hope is new generations of chemists will inherit both the knowledge and the motivation to combine discovery with responsibility, ensuring methyl 3-bromopropanoate and similar reagents continue to unlock advances in life sciences without leaving safety behind.

The Structure at a Glance

Methyl 3-bromopropanoate catches attention in organic chemistry, especially when you spot the formula: C4H7BrO2. This isn’t just a number shuffle; every letter and number tells a story. The compound packs four carbons, seven hydrogens, a single bromine, and two oxygens. Its structure, CH2BrCH2COOCH3, means more than just chemistry jargon. It marks out each atom’s place in the molecule’s backbone, laying out a three-carbon chain with a bromine tagging onto carbon number three and a methyl group hanging off an ester end. This layout means something for both safety and reactivity.

The Importance of Getting the Formula Right

In my work as a lab technician, precision matters with chemicals like this one. Mixing up a bromine with a chlorine, or misplacing a carbon, affects more than a textbook answer. You risk reaction failure or, worse, safety incidents. The human eye sometimes skips small details, but in chemical synthesis, the wrong atom changes the final product. Imagine working up a synthesis for pharmaceuticals and missing a bromine—suddenly, your reaction doesn't behave, or your results make no sense. Double-checking with a formula like C4H7BrO2 keeps experiments on track.

Why Methyl 3-Bromopropanoate Gets Used

Methyl 3-bromopropanoate serves as a powerful building block in organic labs around the world. Chemists pick it when looking to add a three-carbon linker with a good leaving group (the bromine atom). I’ve seen colleagues turn to it when constructing more complex molecules, whether they’re working in synthesis of flavors, agrochemicals, or even flavors that give foods distinct zest. Sometimes, just swapping out this methyl ester for another creates a big shift in biological activity or aroma.

The Risks Tied to Handling

Lab safety instructors drilled into me: don’t trust any chemical until you check its formula and structure. With methyl 3-bromopropanoate, risks come from both the bromine atom and the ester group. Brominated compounds can irritate skin and lungs, or even be toxic if mishandled. Undergraduates sometimes breeze past safety sheets, but clear labeling of C4H7BrO2 on bottles stops accidental mixing and prevents exposure incidents. Good habits matter more than speed. I’ve seen gloves save hands from burns, and vapors cause headaches when fume hoods sat unused.

Potential Solutions for Safer and More Effective Use

Clear chemical labeling and updated digital records prevent confusion between similar reagents. Using a database like PubChem or SciFinder, I quickly spot that C4H7BrO2 means methyl 3-bromopropanoate, not some other brominated ester. This step takes minutes but keeps everyone safe and projects running smoothly. Rounding out the approach, strong training for new lab members builds a team that recognizes hazards and values accurate formulas. Collaboration’s smoother when there’s no debate about what each bottle contains.

Looking Forward

Greater awareness of chemical formulas like C4H7BrO2 gives scientists, industry workers, and even students better control over their work. Reliable results grow from solid basics—label reading, genuine understanding of molecular structure, and open communication. I’ve found that investing time up front saves weeks of troubleshooting later. With a strong grasp on the fundamentals and good habits in the lab, whether you're making new molecules or teaching chemistry, you get safer, faster, better outcomes every time.

The Backbone of Lab Work

Methyl 3-bromopropanoate belongs in every serious chemist's toolkit. In my grad school days, shelves lined with small, clear bottles filled with compounds much like this one were a familiar sight. This particular molecule gets its main reputation in reaction development. It’s a strong building block for synthesizing other chemicals. Researchers like the way its bromine atom offers a reliable anchor for different chemical reactions, especially those where adding something new to a basic skeleton is the entire point of the exercise.

Key Ingredient in Drug Research

Medicine doesn’t appear out of thin air—it starts on a chemist's bench with substances just like methyl 3-bromopropanoate. Drug discovery teams often lean on this compound to design and screen possible medicines. The main reason comes from its “bromo” group, which makes connecting and rearranging carbon chains more direct. The aspirin we take or the antibiotics that beat infections often begin as structures involving these switching games with carbons and bromines. For cancer and infection research, the diversity it brings to the table helps scientists search for that one winning combination.

Expanding Materials Science

This compound holds special value in materials chemistry. Polymers—think plastics, specialty coatings, or membranes—rely on specific starting units. Methyl 3-bromopropanoate helps chemists prepare these building blocks called monomers. Through simple chemical tricks, the small molecule morphs into a larger, repeatable unit with just the right attachment points. Researchers trying to make surfaces that resist water or carry medication straight to a target often use it. The results show up in things like stronger batteries and smarter packaging that keep food fresh.

A Role in Creating Flavors and Scents

Chemistry’s reach shows up in some surprising places, even in the bottle on your kitchen shelf. Methyl 3-bromopropanoate brings its own flexibility to the world of fragrances and food flavors. It helps create the backbone for more complex molecules that smell sweet or fruit-like, although the chemical itself never lands in finished products. By letting perfumers and food scientists develop molecules that mimic nature, it gives flavor that green apple note or that subtle floral backbone you notice in a good perfume.

The Safety Piece

Every lab worker gets drilled on safety. Handling methyl 3-bromopropanoate follows the same rules as most reactive lab chemicals—gloves, goggles, and fume hoods. My old advisor told endless stories of what happened when someone overlooked those details. It’s a strong reminder that whether a chemical gets used on a university bench or in a company’s pilot plant, training counts just as much as technical skill. The compound’s hazards, like skin and eye irritation or the risk of harmful vapors, make a case for treating basic safety as a core job, not just a legal requirement.

Finding Sustainable Paths Forward

The chemical industry shoulders a big responsibility. Methyl 3-bromopropanoate’s production takes careful planning—bromine chemistry isn’t exactly kind to rivers or air. Plants using greener technologies, like solvent recycling and smart waste handling, point the way forward. Some companies already report new ways to make it with less mess at the back end. From what I’ve seen, partnerships between research teams, industry experts, and regulators dig deeper than quick fixes; they encourage thinking that reduces harm and keeps progress honest.

Why Respecting Chemicals Matters

Anyone who’s worked around chemicals understands just how quickly small oversights can snowball into big problems. I remember once in a university lab, someone stored a halogenated ester right next to an oxidizer—luckily, a teaching assistant caught it before things went sideways. Methyl 3-Bromopropanoate may sound unassuming, yet it doesn’t forgive casual mistakes. Respecting its storage and handling makes all the difference.

What Makes Methyl 3-Bromopropanoate Special

Methyl 3-Bromopropanoate sits among the group of organic esters considered both reactive and volatile. It releases strong fumes, and direct contact stings. Facts back this up: The compound causes burns on skin, eyes, or if inhaled. That’s why anyone around it should regard it as more than just another bottle on the shelf.

Simple Rules for Storage

A dry, well-ventilated enclosure becomes the first line of defense. I always prefer chemical storage cabinets that keep vapors locked in and out of the main workspace. Methyl 3-Bromopropanoate shouldn’t cozy up to acids, bases, or strong oxidizing agents. Even small leaks or cross-contamination can trigger chemical reactions that release toxic gases or heat. Temperatures matter, too—keeping it at cool, steady conditions means less pressure builds up inside the bottle. Direct sunlight and sources of ignition raise the risk, so the darkest, coolest spot, far away from heat, always wins.

Handling Without Guesswork

Every exposure brings real risk, so full PPE stands as the minimum. Nitrile gloves stand up better than latex. Chemical splash goggles keep vapor away from eyes, and a lab coat guards arms and torso. I always make sure there’s a fume hood nearby—open bottles under open air, and you risk inhaling something harsh. Small spills get absorbed with sand or a spill kit; nobody wants to wipe up with paper towels, since wiping can spread fumes and splashes.

Immediate Response to Spills

Quick cleanup limits damage. A spill kit with inert material absorbs the liquid without encouraging chemical reactions. Once absorbed, scooping it up with tools reserved for toxic waste keeps cross-contamination out of the trash or sink. Old-timers in the lab know the value of labeling every container—one misread label, and the wrong person grabs the wrong thing, opening the door to accidents.

Waste Disposal and Environmental Awareness

Chemical waste doesn’t belong down the drain or in general trash bins. Local hazardous waste rules help prevent environmental contamination. A responsible lab separates halogenated waste from non-halogenated, following disposal procedures that keep groundwater and soil safe.

Training and Vigilance Pay Off

Open communication lines in a workplace keep everyone safer. Regular reminders about proper storage—posted right by the storage cabinet—help prevent lazy shortcuts. In my experience, most accidents happen when routine dulls respect for the risks. Bringing new staff into the loop early and sharing experiences, both good and bad, creates a culture where vigilance becomes second nature.

Common Sense Wins

Smart storage, careful handling, and solid waste management form the backbone of chemical safety. Methyl 3-Bromopropanoate rewards attention to detail and punishes complacency. Anyone with it on hand shouldn’t settle for less than thorough preparation.

Looking Closer at a Common Lab Chemical

The name methyl 3-bromopropanoate might sound like something you only hear in a research lab, but the risks this chemical brings go far past the boundaries of any classroom or university. Handling this clear, colorless liquid, I remember the tight smack of the smell — sharp, nothing pleasant about it, a sure hint to grab gloves and a lab coat fast.

What Science Actually Tells Us

Every chemical form brings a story of risk or reward, and methyl 3-bromopropanoate tips the scale toward caution. Science journals and safety data sheets point to skin irritation, eye burns, and lung distress if you breathe in the fumes for too long. Testing in labs shows this liquid reacts with moisture and forms acids that harm tissue. None of this is wild speculation — real people have reported dizziness and tightness in the chest after accidents with leaky bottles or broken flasks.

There isn’t much widespread public data on how this chemical acts once inside the body, but studies with other brominated esters suggest that the liver has a hard time breaking them down. Stubborn molecules linger and pile up in organs, which causes a threat if safety measures slip. That alone should convince anyone to treat this chemical with healthy respect. The long-winded toxicology charts can be hard to read, but one fact surfaces: methyl 3-bromopropanoate can be absorbed through the skin, inhaled, or even swallowed if food and work surfaces mix. Anyone who has ever labored in an older lab knows forgotten spills hide everywhere.

The Real Cost of Neglect

Small labs sometimes let their guard down if the chemical list looks “ordinary” enough. I have seen younger technicians rinse glassware without gloves, trust a whiff of the air as “just chemical smell,” and pay the price with red skin or worse. Safety should never fade into background noise. Even in low doses, repeated exposure adds up — slow, hard to track, but significant.

Waste disposal raises another problem. Pouring leftovers down the drain lets this brominated compound slip into water systems. Water treatment plants struggle with these types of synthetic molecules, so every shortcut can ripple farther than intended. Municipal safety boards have noted low but worrying levels of similar chemicals in water downstream from labs.

Simple Steps to Stay Safe

Protection always begins with real information. Lab workers and researchers need updated safety sheets taped right in sight. Gloves, splash-proof goggles, and good ventilation — sometimes just opening more windows in the room — make more difference than any rulebook. Cleaning spills right away and sealing bottles every time help everyone in the work area, not just the person using the chemical.

Leaders in industry and education can push for better awareness, not more bureaucracy. Safety training using honest stories — the kind that make you think twice before working sloppy — delivers lessons people remember. As for storage, locked chemical cabinets and spill trays offer simple insurance.

Methyl 3-bromopropanoate has its uses in making other chemicals, but safety is never just a list of requirements. Every person in a lab, from intern to professor, shapes the safety culture. Respect the real risks behind every bottle, not just the label outside.

Understanding the Numbers Behind a Simple Compound

In the world of chemistry, knowing the molar mass of a compound like methyl 3-bromopropanoate feels almost routine. Yet, the number—166.03 grams per mole—actually shapes decisions in labs, classrooms, and even in commercial manufacturing. I remember trying to perfect a synthesis in graduate school, and getting a reaction to balance meant more than just good math; it meant efficiency and safety.

Breaking Down the Formula

Methyl 3-bromopropanoate packs carbon, hydrogen, bromine, and oxygen into a small package: C4H7BrO2. Start counting: carbon brings 12.01, hydrogen 1.008, bromine 79.90, and oxygen 16.00 (all taken from the latest IUPAC recommendations). Let’s do the tally:

- Carbon: 4 atoms x 12.01 = 48.04

- Hydrogen: 7 atoms x 1.008 = 7.056

- Bromine: 1 atom x 79.90 = 79.90

- Oxygen: 2 atoms x 16.00 = 32.00

Add those up and you land right on 166.996—after rounding, textbooks and labs go with 166.03 grams per mole. This exactness matters. I’ve watched a group of students fail a yield calculation by a wide margin, just because someone rounded oxygen’s weight too early in the process.

Why Accuracy Has Real Consequences

Margins in lab work run skinny. Choose a slightly off molar mass, and your final product’s purity or quantity can slip. It’s not about being a perfectionist; it’s about cost. Extra grams of starting material waste money, and in an industry setting, even small errors multiply into real financial losses. Regulatory bodies like the FDA demand precision—one miscalculation and you face failed quality assurance tests. I’ve met chemists whose careers took a nosedive because of such mistakes.

Finding the Right Numbers: Sourcing Data

The periodic table updates make for more than wall art. The best chemists consult the latest values—published by IUPAC—because suppliers sometimes cut corners with old data. Using the wrong table means your work may not match results in reputable journals, which can have real consequences for publication or patents. At one startup, management learned the hard way. A team relied on outdated atomic weights and lost weeks recalibrating expensive equipment and justifying losses to investors. The lesson still sticks with me: keep your data fresh, just like your reagents.

Getting Consistent Results: A Chemist’s Shortlist

Strong labs build checklists. Confirm batch certificates from suppliers. Audit calculations. Invest in digital scales with the right calibration. Compare with reference standards. Instead of waiting to fix things after a mistake, proactive labs catch errors before they reach the next stage. Large-scale producers set up double-verification for all mass-based measurements. At home or at work, my own routine involves referencing digital composition calculators and cross-checking against primary sources. Peer review in calculation, just as you would in publication, can save a whole week of troubleshooting.

Simple Numbers, Big Impact

The number on the balance sheet—166.03—carries weight far beyond its decimals. It shapes safety, regulatory compliance, product yield, and even a lab’s reputation. Experience shows that respecting basic calculations pays off, no matter how small the molecule or how big the batch.