Methyl 4-Bromobutyrate: Perspectives on a Key Chemical Reagent

Historical Development

Chemistry tells stories through the compounds that shape its discipline, and Methyl 4-Bromobutyrate stands as proof. Developed in the backdrop of rapid organic synthesis breakthroughs during the twentieth century, this ester carried the torch of functional molecule modification further. Before widespread availability, scientists relied on labor-intensive procedures to introduce bromine atoms into carbon chains. The introduction of streamlined halogenation paved the way for Methyl 4-Bromobutyrate synthesis by direct esterification and bromination routes. In those early days, reactions ran open to air and with little temperature control. As safety standards caught up, protocols improved. The wider industrial and academic embrace followed, supporting drug synthesis, agricultural research, and material development. This trajectory highlights how one reactive ester, conceived within decades of halide chemistry maturing, allowed researchers to imagine new molecule designs on a practical scale.

Product Overview

Methyl 4-Bromobutyrate delivers a four-carbon butyrate skeleton terminated by a methyl ester group and functionalized with a bromine at the gamma-carbon. This combination brings together electrophilicity and ester reactivity, offering a platform for alkylation, nucleophilic substitution, and more. Chemists who need to elongate carbon backbones or design prodrugs reach for this ester, valuing reliability in response and the predictable chemical profile. Laboratories and chemical suppliers package this compound, typically as a clear, mobile liquid, relying on consistent purity and strict handling to avoid cross-contamination. The compound not only underpins research projects on a bench scale but has also found a place as a building block for specialty chemicals and pharmaceutical intermediates.

Physical & Chemical Properties

Methyl 4-Bromobutyrate appears as a colorless to pale yellow liquid, with a mild odor that few forget after direct contact. Densities hover just above 1.4 g/cm³ at room temperature, with a boiling point around 210°C. The substance’s refractive index often registers near 1.450, which aids in quick laboratory identification during quality checks. Bromine’s presence at the gamma position makes this ester more reactive toward nucleophilic displacement compared to other butyrates. Its moderate hydrophobicity and solubility in common organic solvents like ether and dichloromethane simplify handling. Most chemists treat it as moisture-sensitive; even trace amounts of water can trigger unwanted side-reactions during storage or mixing.

Technical Specifications & Labeling

Product labels must reflect not only the compound name but also purity (typically ≥98%), batch number, lot records, and storage recommendations (often between 2°C and 8°C, in tightly sealed amber bottles). Statements about compliance with modern safety standards, such as REACH or local environmental agency guidelines, feature prominently on most containers. Transporting this ester across borders brings additional documentation, covering hazard classification, UN number (UN 3276), and emergency contact protocols. Detailed Certificates of Analysis list spectroscopic data, water content (Karl Fischer titration), GC trace, and occasionally residual bromide screening to assure users of batch consistency. This attention to detail reflects chemists’ reliance on trace-level predictability during syntheses.

Preparation Method

Standard laboratory preparation usually starts from 4-bromobutyric acid. Conversion to its corresponding acid chloride—via thionyl chloride or oxalyl chloride—enables straightforward methanolysis to yield the methyl ester. Careful control of temperature, moisture exclusion, and stoichiometry ensures high conversion rates and minimal byproducts. In industrial practice, direct Fischer esterification also serves as an attractive route under acid catalysis, but this method trades speed against higher risk of side-chain hydrolysis and self-condensation if not managed well. Analysts track final yield and impurity profiles by GC-MS and NMR, ensuring unwanted side-products—often halogen exchange species—do not creep into finished batches. Yields above 85% are common with meticulous progression, but the devil always sits in the details—glassware cleanliness, order of mixing, and the exclusion of atmospheric water make or break runs at scale.

Chemical Reactions & Modifications

The reactive bromine atom in Methyl 4-Bromobutyrate invites nucleophiles for substitution reactions, leading to a rich universe of derivatives: conversion to amines, thiols, and cyanides are common in synthetic campaigns. Reductive debromination creates chain-extended esters, particularly useful for prodrug design. The ester group also serves as a protecting handle during multistep organic syntheses, removable by hydrolysis or transesterification when needed. I have navigated multi-step syntheses that hinge on alkylation at this bromoester—each time, its performance has proven robust, so long as moisture and light are kept at bay. Chemists prize the well-defined reactivity, lending critical predictability for scale-up. In medicinal applications, these reactions help chemists introduce key moieties for bioactivity, such as in anticonvulsants and sedatives.

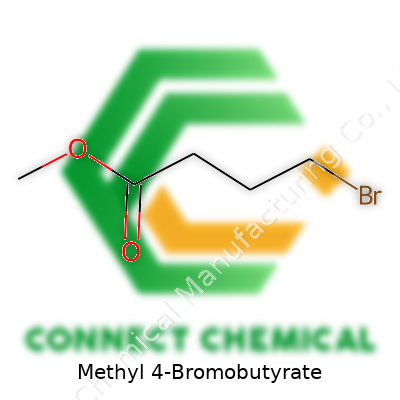

Synonyms & Product Names

Beyond its IUPAC designation, Methyl 4-Bromobutyrate goes by trade and laboratory aliases: γ-Bromobutyric acid methyl ester, Butyric acid, 4-bromo-, methyl ester, and Methyl γ-bromobutyrate. Some catalogs refer to it by less formal names, such as 4-Bromobutyric acid methyl ester, and certain regional suppliers append product codes with “MBBE” for shorthand. Chemical indexing agencies, such as ChemSpider and PubChem, correlate all such synonyms to a single molecular structure, smoothing the search for regulatory and purchasing staff. Diverse naming sometimes creates confusion during procurement, especially in multilingual contexts, so accurate structural diagrams and CAS Registry Numbers (such as 5112-26-9) become indispensable to prevent misorders.

Safety & Operational Standards

Laboratory and plant operators face real hazards while handling Methyl 4-Bromobutyrate. The compound’s volatility and lachrymatory effects demand strict ventilation and chemical splash protection. My own experience taught the value of double-gloving and using fume hoods after one minor exposure produced several days’ eye and respiratory discomfort. Safety data sheets (SDSs) outline significant hazards: acute toxicity if swallowed or inhaled, moderate skin and eye irritation, as well as longer-term exposure concerns that include brominated organic compounds’ debated links to endocrine disruption. Emergency protocols mandate ready access to eyewash stations; accidental spills require activated charcoal absorbents and ventilated containment. Safe disposal requires incineration or rigorous chemical neutralization to prevent environmental contamination. Companies regularly audit their procedures, updating with the latest workplace safety standards, reflecting a culture of proactive risk management.

Application Area

Methyl 4-Bromobutyrate underpins syntheses in pharmaceutical development, especially as a precursor for central nervous system agents, anticonvulsant drugs, and rare agrochemical active ingredients. Its ability to usher in tailored side chains or linkers proves central during lead optimization in medicinal chemistry, where every atom matters. In polymer and material science, the compound plays a quiet but significant role in creating functionalized monomers for specialty plastics and adhesives. Research groups value its modularity for probing metabolic pathways that feature butyric acid analogues—insights here sometimes spark new clinical approaches to neurology or cancer therapeutics. Having seen this reagent on procurement lists for both industrial and academic settings, I recognize its steady position in cross-disciplinary project pipelines.

Research & Development

Ongoing research explores expanded applications for Methyl 4-Bromobutyrate in medicinal chemistry, particularly as investigators design soft drugs that aim to limit systemic toxicity through metabolic lability. Teams working with radiolabeled analogues of the ester explore potential in diagnostic imaging: the ease of functional group modification shortens development timelines. In the realm of green chemistry and process intensification, teams search for less hazardous, lower-energy preparation routes that cut down hazardous byproducts and waste. Scholars reporting in journals such as the Journal of Organic Chemistry regularly propose new catalytic cycles that streamline the introduction of the bromoester functionality directly onto backbone molecules, consolidating steps and saving solvent. These efforts aim for cleaner, higher-yield pathways that reflect growing regulatory pressure and societal awareness about chemical footprints.

Toxicity Research

Research communities continuously assess bromine-containing esters for toxicity, driven by persistent uncertainty about their acute and chronic health impacts. Animal studies flag central nervous system depression and respiratory irritation as real risks following accidental ingestion or prolonged inhalation. Ex vivo studies find esterification might mitigate initial systemic effects, yet metabolic cleavage yields 4-bromobutyric acid, which can amplify toxicity. Broad literature surveys recorded episodes of organ-specific damage at high exposures—such as renal and hepatic effects—especially where compound storage or disposal fell short of best practices. Risk mitigation so often circles back to operator training, protective gear, and the implementation of rigorous fume management. My own habits changed drastically after reading near-miss reports and occupational safety data, underscoring real-world consequences of treating even familiar reagents with less respect than they deserve.

Future Prospects

As the chemical and pharmaceutical sectors shift toward sustainable manufacturing and safer molecules, Methyl 4-Bromobutyrate seems likely to benefit from innovation in both process and application. Automated synthesis platforms, leveraging in-line purification, hold promise for reducing human exposure and improving purity. Advances in continuous flow chemistry offer avenues for safer, more efficient bromination steps, which may unlock larger-scale adoption for even stricter regulatory regions. The push toward green chemistry will drive adoption of alternative brominating agents and renewable substrates, shrinking the footprint associated with each ton produced. Meanwhile, researchers continue hunting for therapeutic windows and pharmacological applications where the butyric acid backbone, enhanced by this reagent’s unique reactivity, could change the rules of molecular design. With global initiatives emphasizing occupational and environmental health, operational protocols and compound design will shape the way Methyl 4-Bromobutyrate works within both bench-top discovery and industrial production.

Understanding the Backbone

Methyl 4-bromobutyrate pulls together two well-known chemical groups. It takes a butyric acid chain, swaps out the fourth hydrogen for a bromine atom, and swaps the carboxylic acid hydrogen for a methyl group. This small adjustment gives a rather useful compound, especially in lab settings where small changes in structure mean a lot for reactivity and selectivity.

The Formula Explained

Let’s break this one down to its nuts and bolts. The core, butyric acid, looks like C4H8O2. Replace a hydrogen on the fourth carbon with bromine: now you’ve got C4H7BrO2. Adding a methyl ester drops one hydrogen and tacks on a methyl group (–CH3), so the final formula comes out to C5H9BrO2. This formula matches what routinely appears on chemical databases and bottles sitting on lab benches in synthetic organic labs.

Why Structure Matters

The distinct feature here is the placement of the bromine on the fourth carbon. That position makes it reactive in substitution and elimination reactions. For anyone spending hours in a lab, this usually means shorter synthetic routes to bigger targets. Pharmacologists and medicinal chemists look for these small changes in molecular structure. Even a single halogen, like bromine, can make a big difference in how molecules interact with enzymes or other drug targets.

Chemical safety demands respect any time a compound includes bromine. Skin contact and vapor inhalation become real concerns, and ignoring that risks health. Experience teaches anyone who’s handled methyl 4-bromobutyrate that good ventilation, nitrile gloves, and goggles carry more weight than a warning label or a printed MSDS sheet. I’ve known a few folks, including myself, who learned that lesson the hard way.

Applications

This compound finds its way into lots of syntheses. As a building block, methyl 4-bromobutyrate plays a part in making more complicated molecules including drugs, agrochemicals, and specialty materials. It gives chemists a tool for attaching other groups specifically at the fourth carbon, sometimes with surprising results in product yield and purity.

It’s tough to ignore how often these subtle changes in basic starting compounds drive innovation. In practice, finding a cleaner, safer, and cheaper way to make methyl 4-bromobutyrate remains a real research priority, both for academic labs and industrial outfits. Green chemistry principles urge everyone to look toward less waste, fewer toxic byproducts, and renewable raw materials. Swapping more efficient catalysts and milder solvents can cut costs and carbon footprints. Some researchers delve into biocatalysis, while others improve standard bromination methods by dialing in temperature, concentration, or stir speed.

Looking Forward

Just naming the formula—C5H9BrO2—barely scratches the surface. Its role spans far beyond textbook pages; it shapes work in labs, affects safety, and drives new science. My own time in the lab taught me that paying attention to these details is never wasted effort. Better understanding, improvement in synthetic methods, and heightened attention to safety all start with knowing exactly what you’re working with.

Chemists Value Simple Tools

Methyl 4-bromobutyrate sounds intimidating, but it’s just one building block that helps craft other, often much more complicated, chemicals. Its appeal comes from the fact that this molecule carries both a reactive “bromide” handle and an ester group—two features that make it remarkably adaptable in the lab. This combination means it slots easily into organic syntheses, and years spent behind a lab bench confirm you see this bottle pop up across a surprising range of projects.

Fuel for New Molecules

Most folks working in pharmaceuticals, biotech, or academia rely on intermediates like this to build up larger compounds piece by piece. Methyl 4-bromobutyrate often enters into these creative chains through something called an alkylation reaction—basically, it reacts with other chemicals to add new sections to a skeleton molecule. Drug discovery teams check hundreds or thousands of different variants while searching for new medicines, and flexible reagents like this let them modify chemical structures quickly without reinventing the wheel each time. The presence of that bromine makes it easy to swap for other groups, which streamlines the hunt for promising drug candidates.

Linking Fragments in Peptide Work

Peptide chemists—those designing mini-proteins for research or therapy—regularly face tricky challenges connecting small fragments to each other. Methyl 4-bromobutyrate provides one reliable way to form these bonds. In a packed research group, I’ve seen teams turn to this trusty molecule to “extend” amino acid chains by adding four-carbon spacers or tacking on functional arms that target specific tasks in the body. Even a small tweak to a peptide’s shape can transform how it behaves in a cell, so these precision changes carry outsized importance for new diagnostics, sensors, or even next-generation antibiotics.

A Platform for Material Science and Beyond

Chemists always keep an eye out for versatile starting points that can take their science in different directions. Methyl 4-bromobutyrate appears in the recipes for making specialty polymers—plastics with unique characteristics. For example, tweaking the backbone of a material with this compound can help researchers produce plastics that stretch more, resist solvents, or interact better with living tissue for biomedical devices. In my own experience, playing with building blocks like this leads to discoveries that aren't in a textbook—maybe a glue that works underwater or a plastic sensor for food safety.

Safe Handling and Environmental Considerations

Like most chemicals with an active halogen, this compound demands respect during use. Many research teams and manufacturers handle methyl 4-bromobutyrate in cowl hoods, strap on gloves, and use it in closed systems to prevent leaks or spills. Regulations keep a close eye on its movement, since improper disposal can lead to ecosystem harm. It’s common for labs to run risk assessments and work with specialists to recycle or safely neutralize leftovers. This attention to detail reflects a growing awareness in science—a commitment to both safety and sustainability, not just speed in discovery.

Challenges and Better Alternatives

Despite its strengths, methyl 4-bromobutyrate doesn’t fit every need. Brominated compounds sometimes hang around in the environment longer than anyone wants, raising worries about accumulation or toxicity. Researchers keep searching for greener substitutes, with some groups moving toward leaving out halogens entirely. These alternatives often lag behind in reactivity or cost more, but ongoing progress suggests future labs might rely on safer, cleaner cousins that don’t force a trade-off between performance and responsibility.

Real Life Lessons from the Lab

It never feels good to discover a bottle of Methyl 4-Bromobutyrate that’s gone murky, grown strange crystals, or worse, leaked its strong odor into the cabinet. For folks working in synthetic chemistry, this isn’t just wasteful—it's dangerous and expensive. Over the years, I’ve seen how skipping best practices for storage can spark safety hazards, slow down workflows, and even stall big projects. I always stress to new lab members that small oversights become big messes, especially with organic reagents.

Understanding What You’re Working With

Methyl 4-Bromobutyrate comes as a colorless to pale yellow oily liquid. It’s a handy intermediate for building more complex molecules. At the same time, it’s sensitive to light, moisture, and strong bases, and should be handled with a healthy respect. The material brings its own risks: it’s harmful if swallowed, may damage the nervous system with repeated exposure, and isn’t something you want to spill or inhale.

Practical Storage Guidance

I’ve found the best way to store this compound is in a tightly closed amber glass bottle. Clear glass lets in light, which speeds up decomposition. Keeping it tightly sealed prevents moisture from the air from sneaking in and starting unwanted reactions. Even a small drip on the threads of a bottle cap will make a sticky mess by your next experiment.

Chemical storage rooms aren’t all created equal. Use a ventilated, dedicated cabinet, preferably for organics. It shouldn’t be near acids, strong bases, or oxidizers. Spacing out incompatible chemicals should never be left for later. If you forget, you might find containers pressurizing, cracking, or even erupting in the worst case.

Temperature control matters. Room temperature works well, but this means a real 18–25°C range, not a shelf in a warehouse that swings with the seasons. Too hot, and you’ll see vapor pressure creep; too cold and you might find solid clumps. I’ve seen folks tuck everything into a cold room, but with Methyl 4-Bromobutyrate, this can pull water out of the humid air, which changes the chemistry and the safety profile.

Growing a Safety Culture

If your lab uses labels with “received” and “last opened” dates, you’re already ahead of the pack. Keeping good records means you spot trouble before it escalates. I keep a log and always check the smell, consistency, and color before measuring for a reaction.

Every reputable supplier prints recommendations right on the container. Their documentation matches what agencies like OSHA and the CDC say on chemical hygiene. Trust those sources more than internet shortcuts. It pays to stay current, since regulations and understanding do shift.

Responsible Disposal and Next Steps

If you spot something wrong—a change in appearance, a whiff of a new smell—quarantine the bottle and alert your safety officer. Don’t pour it down the drain or let it evaporate. Trained waste disposal teams have the right protocols.

To prevent incidents, train every new user hands-on with these chemicals, update your chemical inventory annually, and always keep the safety data sheet within reach. No shortcut replaces attention to detail and personal accountability. Routines built around responsibility create safer, more productive labs.

I’ve seen too many promising experiments derailed by careless storage. It only takes one overlooked step for a setback. Reliable storage shows respect for the work, for colleagues, and for yourself.

Understanding the Risks

Methyl 4-bromobutyrate tends to show up in labs focused on pharmaceutical synthesis and organic chemistry. It doesn’t have the household notoriety of bleach or ammonia, but it raises health and safety questions all the same. The presence of a bromine atom in this ester changes things quite a bit compared to common solvents or flavor esters. The chemical can irritate skin, eyes, and the human respiratory system if you handle it without proper barriers. Sometimes, people skip gloves, and those are the moments that end with stories of red, itchy hands or mild chemical burns.

Chemicals like this hang around in fume hoods for a reason. Vapors or accidental splashes bring risks that basic ventilation cannot always fix. There’s data from various safety sheets showing acute toxicity isn’t off the charts, but you don’t need catastrophic numbers to recognize a real hazard. The accidental dose you didn’t expect, the moment a drop gets on your skin, that’s all it takes to learn respect for a substance most people never notice.

Digging Into Toxicity

A quick dive into the literature tells another part of the story. Methyl 4-bromobutyrate doesn’t kill instantly, but it does throw warning signs: skin and eye corrosion, strong irritation, trouble for anyone with breathing issues. The trouble often starts with volatilization at room temperature—meaning you could breathe in more than you planned if the room is not well set up.

Animal studies, where available, show moderate toxicity levels. This chemical’s presence in the body causes problems that don’t always resolve overnight. Imagine the typical mishaps in chemical research—an accidental spill, a forgotten pipette with chemical residue. Those moments add up. Chronic exposure risks stand out as the reason places like mine enforce gloves, goggles, and full skin cover. The search for long-term effects hasn’t finished. People concerned about carcinogenic or mutagenic effects often avoid direct handling unless absolutely necessary.

Everyday Lab Lessons

The weight of responsibility falls on lab workers and supervisors. Universities and research companies run training that makes these risks clear—because a small error leads to an emergency room visit, not just a ruined experiment. I’ve seen corners cut with other chemicals, but not with anything containing bromine. The reaction is swift and unmistakable.

Disposal becomes a second battleground. Waste containing methyl 4-bromobutyrate never goes down the drain. Hazardous waste containers line the walls of well-managed labs. Getting rid of halogenated organic compounds demands a licensed company, not a do-it-yourself kit. The EPA and OSHA have clear advice, and the cost of proper disposal shows up in every lab’s budget.

Smart Steps Forward

Safer work practices make a difference. Ventilation systems with regular maintenance, chemical-resistant gloves, and goggles don’t cost much compared to medical bills. Training isn’t just for newcomers—refreshers catch even seasoned chemists before an accident. Some researchers try to replace such chemicals with alternatives, but in many synthesis pathways there’s no easy swap. Manufacturers and supply houses mark the packaging with bright hazard information for a reason.

Methyl 4-bromobutyrate reminds anyone in a lab that danger hides in small bottles, not just large drums. Preparation, vigilance, and respect for safety rules pay off for people who want to go home healthy every day.

Looking Past the Spec Sheet

People in labs or on production floors know that chemical purity shapes research results and quality outcomes. Methyl 4-Bromobutyrate, a standard in organic synthesis, seems simple on paper: a liquid, a familiar molecular structure, and a purity percentage. But a label reading “98% pure” doesn’t tell the whole story. Anyone who’s handled this ester knows, you want more than numbers from a certificate of analysis. You want to trust the process—and that means digging into transparency.

Why Purity Tells More Than Just Numbers

Working with this compound, purity isn’t a side note. In catalysis and multistep synthesis, even a trace impurity can wreck a yield or introduce off-target products. Spectroscopy reveals the truth—residual solvents, leftover reagents, and analogues lurk in lower-grade supplies. The presence of these extras affects not only lab safety but reliability, too. In one of my old grad school projects, our methyl ester sat at 97%. We brushed it off as "good enough," but the downstream reaction frothed with unexplainable byproducts. Weeks of troubleshooting later, impurities in our starting material were the root.

Interpreting the Data—Not Just Reading the Label

Manufacturers often use gas chromatography or NMR to report content, but the difference between “assay by GC” and real chemical purity runs deeper. Some data leaves questions unanswered. Was that missing 2% just water, or something reactive? Safety teams crave these details, especially since esters like this carry exposure risks and can form harmful compounds if mishandled.

Industry Benchmarks and Buyer Expectations

Pharmaceutical companies set a baseline: at least 98% purity for research-grade Methyl 4-Bromobutyrate, no exceptions. For high-end applications, some buyers want 99.5% or better, with the impurities listed explicitly, not hidden in footnotes. Academic researchers aiming for publications can't cut corners either. Reproducibility starts with clarity about what's in the flask. That’s how the science moves forward.

Improving Confidence—Testing and Traceability

Labs with decent budgets run their own analyses on each lot. Smaller teams rely on supplier data, yet both benefit when vendors offer raw chromatograms, not just summaries. Open data builds trust. The best suppliers provide batch certificates by default, with methods and detection limits clear. Those who offer to send detailed spectra or even real-time support stand out—you know they aren't just reselling anonymous stock.

Spotting Red Flags and Raising the Bar

Smart buyers check the basics: the product comes sealed, lot numbers match, and storage recommendations are specific. Any transparency gap—from vague wording about "typical" purity to unclear impurity limits—signals corners might be cut. Anyone burned by inconsistent lots learns to ask for full batch histories and ongoing quality audits.

Getting What Matters Right

Current demand for traceable production and environmental accountability means honest reporting is as valuable as the compound itself. Strong relationships form when buyers and suppliers talk openly about both needs and problems that come up. Expect more than a purity percentage—expect a shared stake in safe, predictable science.