Methyl 4-Chlorobutyrate: A Close Look at Its Path, Properties, and Future

Historical Development

Decades ago, chemists hunting for ways to transform raw hydrocarbons landed on a handful of esters with the potential to unlock new pathways in organic synthesis. Methyl 4-chlorobutyrate emerged from this era, building on the basic workhorse reactions that shaped the golden age of synthetic chemistry. Early methods often relied on rudimentary distillation and crude phase separation, a far cry from the technical finesse reached today. This compound’s traceable evolution mirrors the shift from laboratory curiosity to backbone intermediate in pharmaceuticals, crop protection, and materials science. As labs pressed for shorter syntheses and higher selectivity, the methods for making and handling methyl 4-chlorobutyrate kept pace, improving yield and purity, and pushing past old limitations in both academic and production settings.

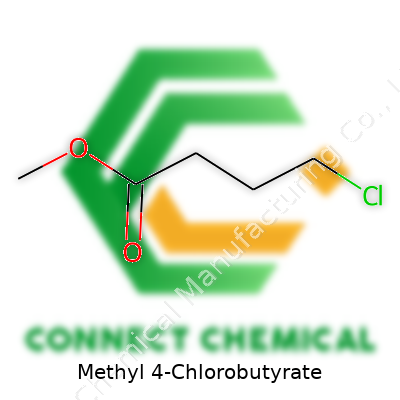

Product Overview

Methyl 4-chlorobutyrate often shows up as a colorless to pale yellow liquid that integrates into a broad swath of synthetic routes. Across industrial settings, its profile attracts both large manufacturers and specialty researchers. Several suppliers target it for bulk delivery, offering customized grades and packaging. In catalogues dedicated to small-scale R&D, scientists treat it as both a fundamental building block and a gateway to more complex molecules. Its role in making fine chemicals shows up both in literature citations and in the stories from chemical engineers who have wrestled with its quirks on the production floor.

Physical and Chemical Properties

Bringing a molecular weight near 150 g/mol and a boiling point near 210°C, methyl 4-chlorobutyrate introduces a manageable volatility profile at typical laboratory temperatures. Its density falls just above that of water, with a moderate refractive index and a characteristic sweet odor unmistakable on the bench. The chlorine substituent at the terminal position plays a key role, giving the compound both distinct reactivity and direct synthetic utility. Its solubility skews toward organic solvents like ether, dichloromethane, and alcohols, but it shows only limited mixing with water, keeping its handling options flexible for chemists familiar with ester chemistry. This combination of attributes ensures that it sits comfortably in the toolkit, offering both reactivity and usability.

Technical Specifications and Labeling

Suppliers mark containers using international conventions, including product name, chemical structure, and batch number, supporting traceability and regulatory compliance. Purity levels typically exceed 97% for both research and industrial applications, a threshold that balances cost against downstream synthesis needs. Labels carry hazard pictograms in line with the Globally Harmonized System; users count on these for safe handling, storage, and disposal. In facilities handling kilogram quantities, technical sheets attach specific warnings about inhalation risks, eye and skin irritation, and the proper types of ventilation and personal protective equipment. These aren’t mere legalese; most people who’ve spent time in synthesis learn to take these guidelines seriously after seeing what even a small slip-up can cause.

Preparation Method

The route heading most directly to methyl 4-chlorobutyrate starts with 4-chlorobutyric acid, itself formed from chlorination of butyric acid or via the Michael addition on unsaturated precursors. Esterification follows using methanol in the presence of sulfuric acid or other suitable catalysts, where good technique pays off in improved yields. For scale-up, continuous flow setups and azeotropic water removal improve throughput and avoid the frequent bottlenecks found in batch reactors. In smaller, teaching or research labs, the simplicity and reliability of this classic Fischer esterification still ranks as the go-to method. Quality finishing steps, like fractional distillation under reduced pressure, strip away side products and dampen the risks posed by unreacted acid and residual chlorine.

Chemical Reactions and Modifications

With its exposed chloro group and nucleophilic ester tail, methyl 4-chlorobutyrate anchors a broad family of transformations. Nucleophilic substitution at the chlorine opens direct routes to amines, ethers, and thioethers, forming half of the story in medicinal chemistry scaffolding. Reduction conditions can gently convert the ester to the corresponding alcohol or, with stronger treatment, to the fully reduced hydrocarbon. Grignard reagents, organolithiums, and other carbon-centered nucleophiles snap up the chlorinated carbon to yield longer chains and ring-closed products, typical for agrochemical and pharmaceutical pipelines. Modifications targeting the ester—hydrolysis, transesterification, amidation—support a whole branch of combinatorial chemistry. These practical handles broaden out into a technical universe most chemists find rich with possibilities and full of learning moments, both triumphant and humbling.

Synonyms and Product Names

Methyl 4-chlorobutyrate appears under various labels, depending on the supplier and application. Shortened names, such as MCB, or systematics like methyl gamma-chlorobutyrate, often show up in technical bulletins and patent files. Other trade monikers might blend reference numbers with brand identities, a familiar sight on invoices and safety sheets across the chemical industry. Chemists swapping stories about process challenges use these names interchangeably, keeping the conversation focused on actual working experience and results, rather than fancy branding.

Safety and Operational Standards

A safe working environment depends on solid respect for chemicals like this. Vapors tickle the nose and can irritate airways, even in a well-ventilated room. Spills on skin prompt prompt washing; stories circulate about the discomfort that can follow delayed action. Gloves, goggles, and well-fitted lab coats cut down on both frequency and severity of minor accidents. Fire risks run moderate—esters can ignite under the right conditions, but with a bit of sense and good housekeeping, the likelihood shrinks. In production settings, closed systems and vapor controls serve both the operators and the environment, honoring the lessons passed down from one shift to another. Training never stops, because the complacency born of routine can bring more trouble than ignorance ever did.

Application Area

Methyl 4-chlorobutyrate claims a spot as a mainstay intermediate in the synthesis of anticonvulsants, local anesthetics, and specialty solvents. Agrochemicals also spring from its framework, transforming the simple ester into the backbone of selective herbicides and growth regulators. Polymer scientists draw on its reactivity to tailor side chains, sometimes tweaking mechanical and adhesive properties. Within fragrance research, derivatization transforms this compound into macrocyclic musks and stabilizers, while material engineers check its performance in barrier and packaging applications. It also supports education, introducing students to key transformations seen in the industrial world without the cost or risk tied to more exotic reagents.

Research and Development

Teams seeking greener chemistry routes run fresh tests on solvent swaps, biocatalytic options, and improved reactor designs. The push to lower waste and cut down hazardous byproducts keeps methyl 4-chlorobutyrate at the center of ongoing process improvement. Research groups report on new asymmetric approaches, aiming at specialty enantiomers that unlock better pharmaceutical and agricultural tools. Analytical chemists optimize detection and quantification, recognizing regulatory calls for tighter trace analysis in both workplace environments and product quality control. Interdisciplinary collaboration brings fresh eyes and creative shortcuts, reminding everyone that old chemistry can hold new tricks when tackled with the right mix of curiosity and tenacity.

Toxicity Research

Safety data from both animal and in vitro studies guide industry attitudes toward methyl 4-chlorobutyrate. Acute exposure leads to moderate irritation of eyes and lungs, prompting conservative exposure limits in many countries. Chronic effects remain a topic for further study, especially as workers encounter the compound in higher-throughput settings. Environmental fate studies point to moderate persistence, raising concerns about proper containment and solvent recycling. Poison control resources track accidental ingestion cases, which prompt supportive, symptomatic care. Chemists and managers alike watch for changes in regulatory guidelines and invest in better detection and response plans to limit both acute risks and possible long-haul effects—work that matters for both personal and environmental health.

Future Prospects

Research into more sustainable synthesis draws ongoing attention, especially as the industry pivots from petrochemical feedstocks toward renewable sources. Advances in flow chemistry and process automation promise safer, cleaner, and cheaper supply. Academic and industrial collaboration can uncover new roles for this compound, such as tailored drug delivery vehicles, next-generation polymers, and eco-friendlier pesticides. Regulators and technologists work to define safer handling practices and lower emissions, keeping the entire lifecycle of methyl 4-chlorobutyrate in focus. Every improvement reflects cumulative experience, much of it shared informally between bench chemists and engineers who measure progress in both technical achievement and personal stories told in the break room.

Methyl 4-Chlorobutyrate and Its Uses

Methyl 4-chlorobutyrate, with the chemical formula C5H9ClO2, shows up in a surprising number of industry labs and research benches. You might not see it headlining science news, yet this molecule plays a part in creating pharmaceuticals, fragrances, and specialty chemicals that affect daily life. The molecule’s backbone comes from butyric acid, and the "methyl" refers to its ester group—so there’s no mystery here. The chlorine atom attached at the fourth carbon tweaks its reactivity, turning it into a useful building block for more complex substances.

The Chemistry Behind the Formula

Looking at C5H9ClO2, you find five carbons, nine hydrogens, one chlorine, and two oxygens. Picture a chain of four carbons, one of them carrying a chlorine atom, ending in a carboxylic acid group, which then gets converted into a methyl ester. This pattern shapes the chemical’s properties. The molecule’s structure lets chemists make targeted changes to create different products, from nerve agents in defense research to less controversial compounds like certain flavors and scents.

Health, Safety, and Environmental Considerations

Methyl 4-chlorobutyrate has some hazards. Direct skin contact irritates, and inhaling vapors causes respiratory irritation. Labs using it rely on gloves and strong ventilation. The chlorine atom hints at environmental challenges. Chlorinated organic compounds stick around longer in water and soil, sometimes breaking down slower than people expect. Strict waste protocols keep the compound from finding its way outside the lab, protecting drinking water and river habitats.

How the Formula Shapes Regulations

Governments and safety boards keep close tabs on chlorinated solvents and esters. C5H9ClO2 joins other halogenated compounds on lists that require reporting, proper labeling, and secure storage. These rules don’t exist just for paperwork. They protect workers, neighbors, and the environment from potential mishaps. Responsible chemical handling goes a long way to avoid spill stories in the news.

Alternatives and Greener Practices

Every year, manufacturers and researchers look for safer options. Green chemistry pushes for non-halogenated alternatives where possible. Some labs swap out chlorine for less persistent groups, or improve waste treatment so nothing lingers outdoors. Sharing data on safer substitutes helps. Besides regulatory pressure, there’s a strong business case: customers in pharmaceuticals and food flavorings increasingly demand cleaner manufacturing footprints. Cleaner production reduces disposal costs and lowers long-term liability, so it pays off beyond the balance sheet.

Supporting Future Chemistry

Essential knowledge of the chemical structure, like C5H9ClO2, lets chemists make better choices as they design new drugs or environmentally friendly materials. Real progress comes from understanding both the power and pitfalls of molecules. As curiosity, market shifts, and social responsibility intersect, people keep finding ways to use science with care. There’s always a need for sharp eyes, respect for safety sheets, and some ingenuity to get results without setbacks—for people and the planet alike.

Bridging the Gap in Pharmaceutical Chemistry

Methyl 4-chlorobutyrate shows up in labs that chase after life-saving drugs. It’s not the finished pill or vial you see at the pharmacy. Instead, this compound plays an unsung but crucial role as a building block. Medications—from muscle relaxants to drugs dealing with seizures—might trace some of their origins back to this molecule. Working in a chemistry lab myself, I saw firsthand the scramble to find intermediates that wouldn’t set your experiment back days or weeks. This one ticks the boxes for stability and reliability. It’s added early and torn apart halfway through a synthesis, often helping shape the core structure of new drug candidates.

Core Ingredient in Organic Synthesis

Research doesn’t stop at medicine. University labs and chemical manufacturers often synthesize specialty chemicals starting from methyl 4-chlorobutyrate. Its reactive chlorine group opens doors for straightforward modifications. For someone who has tried to make custom amino acids or tweak the backbone of small molecules, this compound saves time. Many who work on new agrochemicals, specialty monomers, or advanced materials turn to it for its simplicity. It serves up a reliable backbone to attach other functions—making it easier to sketch out new molecular blueprints.

Supporting New Materials

Polymers don’t just appear on their own. Companies crafting novel plastics and coatings sometimes need additives or sensitive monomers that start with methyl 4-chlorobutyrate. This compound steps in during the synthesis of specialty polyesters or certain copolymers, helping tune flexibility, strength, or even response to light or heat. Having talked with folks testing new biodegradable plastics, I know how important it is to control every aspect of a polymer’s structure. Introducing this molecule at the right stage gives control over the final product’s characteristics.

Pesticide Development and Agrochemical Research

Farmers may not know it, but some pesticides rely on this compound during their manufacture. Agrochemical research teams often modify methyl 4-chlorobutyrate as they chase new insecticides or weed killers. The chlorine group turns out to be handy in attaching components that make a compound effective in the field. Because regulatory demands keep rising, there’s a strong push to find active ingredients that break down safely. Here’s where the simplicity and reliability of methyl 4-chlorobutyrate shines again, allowing for quick testing and modification.

Challenges and Safer Approaches

One concern is safe handling. As someone who’s mixed and measured this compound, I can say its volatility and reactivity require careful storage and good ventilation. Methyl 4-chlorobutyrate isn’t something you want spilling or evaporating around you. Regulations call for containment and labeling, and the best-run labs put a focus on personal protective equipment. Learning from safety drills, I saw how responsible use keeps accidents out of the headlines.

Companies that want to protect workers and the environment have started shifting toward greener chemistry. Supplier audits and on-site training now form part of the standard playbook. There’s growing interest in sourcing chemicals from producers with solid records on emissions and waste management. While methyl 4-chlorobutyrate won't disappear soon, researchers keep pushing for routes that generate less hazardous waste or cut reliance on chlorinated intermediates.

The Bigger Picture

Behind every finished product in medicine, agriculture, or materials science, builders like methyl 4-chlorobutyrate help push boundaries. The right tools in experienced hands—combined with ethical sourcing and safe practices—can move industries forward without leaving safety or sustainability behind.

Understanding the Substance

Methyl 4-Chlorobutyrate serves as a useful building block in chemical synthesis, popping up in research labs and industry alike. Like with many reactive chemicals, it calls for respect. My own years working in a university organic chemistry lab taught me that even straightforward liquids can trip up experienced folks if they get too comfortable.

Real Dangers of Poor Storage

Leaving a reactive chemical uncapped, or settling for any old shelf, isn’t just sloppy—it can put people’s health on the line. Methyl 4-Chlorobutyrate releases vapors that can irritate the eyes, nose, and skin. If you’ve ever caught a whiff of an irritant in a tight lab, you know that coughing fit and burn in your throat stick with you. Shortcuts have no place here.

Flammable liquids need real containment. Any spark, day-to-day static, or broken light fixture transforms an innocent bottle into an accident. Too many lab mishaps hinge on a bottle stored near a heat source or carelessly set under sunlight. Even a sunny corner can lead to chemical decomposition. And nobody wants unknown byproducts when safety is at stake.

Lab-Proven Steps for Safe Storage

A solid metal flammable storage cabinet, placed away from direct sunlight and designed for volatile chemicals, pays for itself many times over. Heat and moisture speed up chemical breakdown and raise risks. A dry, cool spot with steady temperature does most of the hard work. My department wrote it into every protocol to lock up any container right after use, no matter how rushed the experiment. This basic habit avoided more scares than anything else.

The right kind of container matters. Glass or specialty plastics, tightly sealed, beat makeshift bottles hands down. Clearly labeling bottles—bold, legible, and with hazard details—helps anyone working the next shift dodge costly mistakes.

Handling You Can Trust

Working with volatile esters never feels routine, even after years. Gloves and lab coats typically block out brief splashes, but face shields protect against fumes better than goggles alone. I remember a student ignoring this advice, and even short exposure led to a hospital visit. That one mistake changed our onboarding instructions forever.

Lab hoods aren’t just space hogs—they pull fumes away from anyone mixing, pouring, or even just uncapping a bottle. Fume exposure creeps up on those who think quick pours won’t matter. In shared environments, consistently using a hood cuts down on chronic health issues years down the road. Ventilation keeps shared air safe for everyone.

Accident Planning: Not Just for Bureaucrats

Preparedness stems from real-world experience. Eyewash stations and spill kits belong right next to chemical workspaces. In labs I’ve worked at, these tools sat within arm’s reach for fast response. Quick thinking helps, but knowing exactly where to grab a neutralizer can make the difference between a scare and a disaster.

Disposal isn’t an afterthought either. Pouring waste down a drain invites EPA violations and local water supply contamination. Marking dedicated waste bins and teaching everyone how to neutralize hazardous chemicals turns sustainability from a slogan into daily practice.

The Bottom Line

Safe handling and storage of chemicals like Methyl 4-Chlorobutyrate boils down to mutual trust. If one person gets complacent, everyone shares the risk. Consistent habits, proper equipment, and shared responsibility build safer labs and industries, no shortcuts allowed.

The Real Risk Behind Methyl 4-Chlorobutyrate

Methyl 4-chlorobutyrate pops up in chemical supply catalogs for research and has some use in making other chemicals in the lab. Most people never see it outside a laboratory, but that doesn't always mean the public can tune out its dangers. I’ve worked in research labs around all kinds of low-boiling ester and halide compounds, and one lesson stands out: respect for even the small bottles of liquid. Methyl 4-chlorobutyrate isn’t as famous as chloroform or acetone, yet the risks deserve attention from handling to storage and disposal.

Health Impacts and Toxicity

Let's talk straight: this stuff isn’t harmless. Just a whiff packs a punch. Inhaling enough vapor can trigger coughing, dizziness, or a sore throat. Direct skin contact feels uncomfortable—think stinging, redness, lasting irritation. Authorities classify it as hazardous because it acts as an irritant and may cause more serious symptoms with repeated or higher exposure. Accidental splashing in my days on the bench led to a scramble to the safety shower, not a casual rinse at the sink. That tells you all you need to know about how it interacts with skin and eyes.

Data from animal studies point to signs of acute toxicity, with significant effects on respiratory function at higher doses. NIOSH and similar groups suggest keeping air levels really low—no more than a few parts per million—to stay in safe territory. Mistakes in labeling, lax storage, or poor ventilation ramp up the danger for everyone in the room. Experience working with esters like this shows the odor sometimes comes before irritation, but that’s no reason to rely on your nose as a safe indicator.

Environmental and Workplace Safety Concerns

Once this type of compound leaks, it can run into drains and streams, causing issues for aquatic life. We're not talking outright catastrophe, but spills threaten small organisms in lab water baths and beyond. Methyl 4-chlorobutyrate breaks down slowly, and its chlorine atom means more attention during disposal—standard protocols require collection, not wash-down-the-drain shortcuts.

NIOSH and the EU’s chemical safety databases stress protective gear for a reason. Nitrile gloves, lab coats, and eye shields are hardly overkill. Some labs install local exhausts or even full fume hoods for mixing or decanting, especially in research settings. That forms a consistent habit—never treat the liquid like an ordinary bottle of rubbing alcohol.

Reducing Hazard Where Possible

What can labs do to reduce toxicity risk? From my end, regular training and stricter supervision help a lot. Newcomers sometimes shrug off the warning labels, so older hands must walk them through best practices. Proper labeling saves long-term trouble. Anyone storing methyl 4-chlorobutyrate should use certified containers, away from incompatible chemicals—never near bases or acids, since unexpected reactions spark off toxic fumes.

Working with supply teams offers chances to substitute less hazardous alternatives if the chemistry allows. In cases where no substitute cuts it, up-to-date safety data sheets spell out step-by-step responses for spills, exposure, or fire. Sticking to small batch work, especially with no ventilation, also shrinks the odds of harm. Even today, hearing about careless mishaps elsewhere pushes me to double-check procedures and storage.

The Takeaway

Methyl 4-chlorobutyrate isn’t notorious, but any worker or lab student who’s handled it remembers the sting and the smell. Treating it with care, embracing strong training, and staying alert to changing safety information keeps its risks in check. In chemistry, the devil sits in the details—and with this compound, those details absolutely matter.

A Look at Its Physical Nature

Methyl 4-chlorobutyrate shows up as a clear, colorless liquid, which tells you a lot about its purity and common uses in the lab. You’d catch a sharp, sometimes sweet odor if you popped open a bottle—like sniffing lingering glue in a workshop. With a boiling point around 196°C and a melting point well below freezing, this chemical doesn’t mind staying liquid except in frigid environments. Experienced hands know its density runs close to 1.13 grams per cubic centimeter at room temperature, a hint it packs a bit more punch than plain water.

In my own time handling this compound during synthesis work, gloves became non-negotiable. It slips through latex pretty fast, so nitrile often ends up the glove of choice. You won’t see this liquid mixing easily with water, either. It floats or sinks past, barely dissolving—much of its work happens in organic solvents. Ether, chloroform, and alcohols treat methyl 4-chlorobutyrate as an old friend, blending right in.

Chemical Behavior You Can Count On

This molecule keeps things simple: it has a methyl ester group hooked up to a four-carbon chain, and there’s a chlorine atom sitting on the fourth carbon. That chlorine gives the molecule bite, making it ready to undergo substitutions that form more reactive products. Back in my graduate days, I saw methyl 4-chlorobutyrate swap out that chlorine for all kinds of chemical guests in nucleophilic substitution reactions—essential for making building blocks for pharmaceuticals.

The ester group at the other end doesn’t sit idle either. Chemists count on it for easy hydrolysis, giving either the acid or returning an alcohol, depending on which direction you run the reaction. Because of that, research teams build custom molecules by swapping, reducing, or expanding the chain at this spot. In the right hands, it transforms into more valuable intermediates.

Safety Needs and Real-World Impacts

Take it from someone who’s had to clean up after spills—methyl 4-chlorobutyrate enters the body through skin, lungs, or the digestive tract if you’re not careful. It carries nasty risks, irritating the eyes, nose, and lungs right away. Given enough exposure, it may cause dizziness or stomach troubles. Chemically, it tends not to explode, but it can catch fire if a flame or spark comes close. Good fume hoods and personal protection keep problems away.

The world relies on methyl 4-chlorobutyrate beyond the bench. Drug researchers, agrochemical companies, and polymer scientists each take advantage of its reactive groups. It’s a key player in making compounds that block diseases in crops or unlock cancer therapies. These are real needs—problems that demand swift, tested solutions.

Safer handling shows up as a shared responsibility. Manufacturers work to improve packaging to avoid leaks, while chemical policies set limits for storage and disposal. Training counts more than protocols; I’ve seen seasoned chemists pause and double-check labels instead of cutting corners. Quick cleanup kits and reliable ventilation stop most incidents before they turn into emergencies. In the end, teamwork drives safe, efficient use.

Moving Toward Smarter Solutions

Tackling the risks of methyl 4-chlorobutyrate pushes us to learn from mistakes and design ways to avoid exposure. Substituting it with less hazardous compounds in certain processes saves time and health. Collaboration between chemists, health experts, and regulators works best. Better labeling, stricter workplace standards, and regular safety audits all help ensure every person who touches these chemicals goes home as healthy as they started.