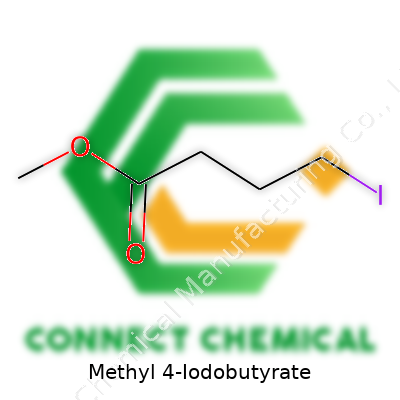

Methyl 4-Iodobutyrate: A Comprehensive Look

Historical Development

Decades ago, scientists searching for intermediates for pharmaceutical projects took a hard look at molecules with functional side chains. Methyl 4-iodobutyrate entered laboratories as a candidate for delivering synthetic iodoalkyl groups—a detail that matters when targeting complex drug blueprints or crafting novel agricultural chemicals. As organic synthesis matured in the 20th century, the appetite for tailored carbon frameworks grew. Researchers discovered that introducing iodine into short-chain esters produced versatile reagents and intermediates that could swap out the iodo group for all sorts of other functional groups. This flexibility laid the groundwork for a steady demand, and by the 1970s, methyl 4-iodobutyrate started appearing in chemical supply catalogs, supporting research from Europe to Asia and the US.

Product Overview

What sets methyl 4-iodobutyrate apart is the presence of both an ester and an iodine—a rare duo. Technicians hungry for halfway molecules that streamline big organic syntheses gravitated toward it. No big surprise to see it filling roles in creating medicines, pesticides, or just helping people explore new chemical territories for advanced polymers. As regulatory requirements got stricter, suppliers stepped up by providing detailed documentation, reassuring buyers about purity, contaminants, and handling. Methyl 4-iodobutyrate also carved out a niche in university and industrial research, popping up as a trusted component in thousands of reaction schemes.

Physical & Chemical Properties

Pouring methyl 4-iodobutyrate into a beaker reveals a colorless to pale-yellow liquid with a faint odor, similar to other low-molecular-weight esters. Its density sits higher than standard esters at roughly 1.7 g/cm³, thanks to the heavy iodine atom. This same feature drags down volatility; it boils at about 225°C. The ester effortlessly dissolves in most common organic solvents like ether, chloroform, and dichloromethane, making it easy to use in reactions that need quick mixing. Unlike many other organoiodide compounds, methyl 4-iodobutyrate doesn't break down with sunlight or typical storage, so it tolerates long shelf lives in properly sealed glass. Still, it reacts with strong nucleophiles, bases, and reducing agents, so storage guidelines warn about moisture and open flames for obvious reasons.

Technical Specifications & Labeling

Chemical manufacturers list methyl 4-iodobutyrate under several purities, most aiming for 97% or better for research and pilot plant use. The labeling points out its UN number and hazard pictograms, flagging it as a flammable and harmful substance under GHS classification. Labels go beyond generic warnings, giving details on storage temperature, expiration, batch codes, and recommended personal protective equipment. Detailed certificates of analysis are common for each batch, highlighting the water content, assay, major impurities such as methyl 3-iodobutyrate, and information about heavy metal residues. For those with regulatory needs, suppliers also attach REACH, TSCA, and other documentation to support the product for regulated sectors.

Preparation Method

Synthesis in the lab typically follows the route of reacting 4-iodobutyric acid with methanol in the presence of an acid catalyst, often sulfuric acid, driving esterification. For larger batches in industry, acid chloride activation sometimes speeds things up. Some clever routes start with methyl 4-chlorobutyrate and swap the chlorine for iodine using sodium iodide in acetone—a well-known Finkelstein reaction that lets chemists dial in conditions for higher yields and fewer byproducts. Scrubbing leftover acid and halides out calls for standard water washes and a careful distillation under reduced pressure. Each method produces a slightly different impurity profile, influencing suitability for extra-sensitive pharmaceutical applications.

Chemical Reactions & Modifications

Chemists count on methyl 4-iodobutyrate as a robust starting point for introducing other groups. The iodine atom acts like a loaded spring—easy to swap with nucleophiles or use in coupling reactions. Popular moves involve using palladium or nickel catalysis to build carbon-carbon links, stretching short backbones into long, branched, or even cyclic targets. Grignard reagents attack the ester function, creating new alcohols. In addition to substitutions, reductions with zinc or sodium give rise to methyl butyrate, stripping out the iodo group for studies involving hydrodehalogenation. These tweaks broaden the chemistry possible with a simple four-carbon skeleton, making it easier for researchers to explore new drug ingredients or specialty polymers.

Synonyms & Product Names

Depending on who’s writing the label, you might see methyl 4-iodobutyrate appear as methyl gamma-iodobutyrate or 4-iodobutyric acid methyl ester. Old catalogs sometimes use aliases like methyl iodidebutyrate, but most modern suppliers stick with the IUPAC name or CAS number to avoid mistakes. Academic literature usually cross-references the major names so that chemists can track protocols, product specifications, and regulatory filings with minimal confusion. As world trade ramps up, suppliers list synonyms in English, German, and other major languages to smooth cross-border transactions and compliance paperwork.

Safety & Operational Standards

Few people forget their first spill of methyl 4-iodobutyrate. Contact with skin or eyes brings stinging and redness, while inhaling its fumes in a closed fume hood feels uncomfortable. Safety data sheets underscore the need for gloves, goggles, and lab coats, and recommend adequate ventilation. Regulations enforce clear signage and storage in flammable-proof cabinets away from heat or moisture. Waste disposal rules treat the compound as hazardous, pushing labs to collect and neutralize waste streams instead of washing small quantities down the drain. Training for emergency cleanup addresses iodine salts and organic acid residues, which stubbornly stick to benches if not wiped up properly.

Application Area

Pharmaceutical researchers draw up plans for new anti-epileptic drugs or anti-inflammatory compounds and turn to methyl 4-iodobutyrate for adding or swapping out side chains. Agrochemical developers tweak the molecule to synthesize innovative herbicides or insecticides, counting on its ability to serve as a modular building block. Synthetic organic chemists explore new reaction pathways by exploiting the unique properties of the iodo group, allowing rapid screening with various transition metals or nucleophiles. Materials scientists treat it as a source for specialty esters with custom-tailored degradability, feeding into the biodegradable plastics industry. At the research bench, students and postdocs use it as a model substrate for teaching classic nucleophilic substitution and aromatic iodination protocols.

Research & Development

A glance at recent journals shows steady interest in methyl 4-iodobutyrate, with dozens of teams developing more efficient coupling partners or seeking greener synthesis routes. Some labs experiment with enzyme-catalyzed modifications, hoping to slash hazardous waste and improve selectivity. Medicinal chemistry groups list it in screening libraries, aiming for streamlined late-stage functionalization when hunting for new therapeutic leads. Collaboration between industry and academia pushes for safer alternatives to traditional solvents and activating agents, which could decrease the environmental impact of large-scale manufacturing. Patents pile up around specialized processes for transforming methyl 4-iodobutyrate into high-value intermediates, especially those linked to blockbuster drugs.

Toxicity Research

Long-term health risks of methyl 4-iodobutyrate haven’t filled up databases like more famous industrial chemicals, but early toxicity screens tell a cautionary tale. Rat and mouse studies suggest it irritates tissues at moderate doses. Unpublished reports in select pharmaceutical projects point to mild liver enzyme elevation after chronic exposure. The heavy iodine atom raises flags about thyroid disruption if mishandled or absorbed over long work periods. Regulatory agencies continue expanding lists of required toxicity tests, and some chemists are already substituting less hazardous alternatives in teaching environments. Thoughtful risk assessment drives safer protocols and nudges industry toward less toxic analogs, especially as green chemistry gains ground.

Future Prospects

Looking ahead, the demand for compact, multifunctional coupling reagents appears strong, with methyl 4-iodobutyrate still anchoring many synthetic plans. Pressure mounts to redesign production for lower-waste, more renewable sources—bio-based feedstocks and water-based esterification stand out in recent grant proposals. Researchers test catalysts with fewer heavy metals, aiming for cleaner final products. Pharmaceutical companies seek intermediates with a clearer environmental and safety profile, raising the bar on documentation and responsible disposal. Expect to see growth in specialty derivatives made from this core molecule and more collaboration between academic science and commercial enterprises to unlock new applications in medicine, plastics, and green chemistry.

Spotlight on Real-World Chemistry

Methyl 4-iodobutyrate doesn’t come up in dinner table chat, but this chemical draws plenty of interest among folks working in research labs. It’s not just another niche compound. Over the years, I've watched colleagues reach for it when standard building blocks won't cut it. Its value roots itself partly in the iodine atom sitting on a butyrate backbone, which lets synthetic chemists build up complex molecules from a small, versatile starting point.

Synthesis: Getting the Basics Done Faster

Chemists use methyl 4-iodobutyrate as a key piece in making longer, more complicated molecules. In my own lab work, I saw it used in the pursuit of new pharmaceuticals. You often want to attach unique “handles” to your main molecule — and that iodine atom lets you swap it out through a type of reaction called cross-coupling. This speeds up the search for drug candidates. Scientists often prefer compounds with iodine since the reactions usually end cleanly and don't take forever. Instead of slogging through less cooperative reactions, they rely on compounds like methyl 4-iodobutyrate to keep research moving.

Medicinal Chemistry: Opening New Avenues

Drug researchers have a habit of seeking out molecules that can branch in a dozen directions. Methyl 4-iodobutyrate delivers on that front. Its structure allows chemists to tack on pieces that tailor new compounds for treating disease. In cancer research, for instance, I watched teams design modified butyrates because these molecules can interact with enzymes that play roles in gene regulation. Some were chasing epigenetic therapies, banking on the fact that altering a chemical pathway might slow cancer growth. Methyl 4-iodobutyrate gave them a quick jumping-off point. That kind of efficiency matters when human health is on the line.

Specialty Chemicals and Beyond

This isn’t only about new drugs. The fine chemicals world, the folks making dyes, agrochemicals, or probes for biology research, lean into methyl 4-iodobutyrate too. I remember one agricultural project where it served as a connector to produce special esters for controlled-release fertilizers. It's about putting together something novel from reliable pieces. No one wants a process that uses too much energy or risks poor yields. Having an intermediate that works saves companies trouble and cost down the line.

Challenges and Responsible Practices

Not every story about methyl 4-iodobutyrate glows. The iodine atom is more reactive than it sounds from the outside, and this chunk of the molecule demands good handling practices. Exposure concerns come up, so lab workers rely on strong ventilation and personal safety gear. Waste containing organic iodine isn’t easy on the environment, so responsible disposal stays a top priority. Chemical companies have started to offer greener alternatives, finding ways to recover and recycle more iodine. From working in the lab, I know just cleaning up after synthesis can eat up time and resources, which shows why it matters to keep safety and sustainability front and center.

Looking Forward

Demand for compounds like methyl 4-iodobutyrate looks steady as new drugs and technologies keep researchers looking for strong, adaptable starting materials. With more labs adopting greener approaches and pushing for safer reagents, the chemistry community circles back to improved practices. My own experience has taught me that every new tool reshapes possibilities—yet the real payoff always comes from how responsibly we use old favorites like methyl 4-iodobutyrate.

The Nuts and Bolts: Formula and Weight

Methyl 4-iodobutyrate draws attention in organic labs for its simplicity and punchy reactivity. Its molecular formula looks straightforward: C5H9IO2. This translates to five carbons, nine hydrogens, one iodine atom, and two oxygens strung together. People tend to overlook just how much adding a single iodine to a molecule like this transforms its character.

Iodine isn’t a small atom. In fact, it’s heavy and brings the total molecular weight of methyl 4-iodobutyrate up to approximately 244.03 g/mol. Compare that to a halogen-free methyl butyrate—much lighter. Chemists pay attention to this number when they figure out dosing for reactions or ordering stock for a new synthesis project. Underestimating the impact of a halogen like iodine means wasted resources and missed yields.

Why the Structure Matters

Methyl 4-iodobutyrate’s structure might look plain: a methyl ester and an iodine atom at the end of a four-carbon chain. Still, the presence of iodine can make or break a synthesis strategy. Reactions involving nucleophilic substitution, like SN2 chemistry, fly when iodine’s in the mix. The C–I bond snaps with relative ease, making room for complex, high-value products.

In drug development or advanced polymer work, subtle changes like these shift a project from conceptual to practical. My own work with halogenated esters opened my eyes to their dual power—controllable reactivity and a gateway to countless downstream derivatives. Chemists lean on these molecules for more than just building blocks. The weight, formula, and functional groups play off each other in every reaction scheme.

Methyl 4-Iodobutyrate in Synthesis

Labs across the world use methyl 4-iodobutyrate because iodine’s presence provides a shortcut to complex molecules. Students in undergraduate labs learn to respect its volatility and high density, using precise scales to avoid mistakes from confusing its mass with similar but lighter compounds. In one medicinal chemistry lab, I saw colleagues choose this ester for alkyl chain extension because they could control the reaction outcome with minimal waste.

Data from suppliers confirm demand for methyl 4-iodobutyrate in pharmaceuticals, agrochemicals, and specialty chemicals, especially for introducing the butyrate chain into larger structures. This speaks volumes about the practical need for well-characterized, easy-to-handle intermediates. Handling safety cannot be ignored. Iodinated compounds often require proper ventilation and careful disposal, not just for regulatory compliance but for researcher health.

Improving Chemistry with Attention to Detail

R&D teams benefit from closely tracking basic facts like molecular formula and weight. Inaccurate calculations cause failed scale-ups and resource loss. Cross-checking supplier data against primary literature or trusted online databases—such as PubChem and ChemSpider—prevents setbacks. Even seasoned chemists can benefit from a few minutes’ confirmation before launching new syntheses.

Chemical education thrives when students know more than just how to draw the structure. Understanding why a lab chooses methyl 4-iodobutyrate over another ester, and exactly how its molecular attributes drive results, prepares the next generation for the dynamic challenges of research. The balance of practicality, careful calculation, and respect for fundamental chemistry keeps projects on track from small-scale reactions to commercial production.

Understanding Why Storage Matters

Methyl 4-iodobutyrate, as simple as the name sounds, shows up in research labs and chemical manufacturing, often as an intermediate for other chemicals. Safe storage saves more than a workday. It keeps health risks low, prevents accidents, and protects against costly chemical loss. Accidents involving organoiodine compounds don’t show much mercy and can make a work environment dangerous, especially if vapors or spills occur.

Temperature and Environmental Controls

From my experience in university chemical storerooms, chemicals disappear to waste drums much faster when temperature fluctuates. Methyl 4-iodobutyrate doesn’t belong in the sun, nor does it thrive near radiators or window ledges. Cold, dry stockrooms keep this compound in good shape. Aim for around 2–8°C. That’s a typical lab fridge, not a household freezer and never a warm shelf. Fridges designed for lab chemicals shield against temperature spikes better than domestic options, too.

Humidity brings trouble. Nobody enjoys opening a bottle only to find decomposed, cloudy liquid or solid residue caked on the sides. Keep the desiccator nearby or use silica packets if moisture sneaks into the storage area. Condensation turns a good bottle into hazardous waste very quickly.

Container Choice Matters

A careless cap on a solvent bottle never ends well. I’ve lost good supplies to evaporation or contamination. Methyl 4-iodobutyrate comes in tightly sealed amber bottles, often glass, for a reason. Iodinated esters react with light and air faster than you’d think. Pick screw-cap bottles, not corked or rubber-sealed jars. Glass outperforms plastic here, resisting leaching or chemical attack.

Label the container clearly. Handwritten scribbles fade or smudge with solvents and cleaning spray. Printed, chemical-resistant labels save everyone time and confusion. Double-check expiry dates before putting a bottle back on the shelf, because degraded stock can give nasty surprises in the next synthesis run.

Avoiding Dangerous Mixes

Storing all halogenated chemicals together might sound neat, but a spill makes an unpredictable mess. I learned from a minor incident involving chlorine compounds that isolation often pays off. Methyl 4-iodobutyrate releases harsh fumes on contact with strong bases, acids, or oxidizers. Keep acids elsewhere. Segregation prevents exothermic reactions and toxic vapor clouds. Lock away large suppliers’ bulk containers, away from warmth or humidity sources.

Don’t forget ventilation. Fumes build up easily even with small leaks, especially if your storage space lacks proper airflow. Local lab rules usually insist on storing volatile organics in ventilated cabinets. Signs for “Corrosive/Irritant Organics” help remind coworkers to check the right spot first.

Personal Protection and Spill Response

I always reach for gloves and goggles before moving a methyl 4-iodobutyrate bottle, no matter how light the flask. A single slip covers hands in a stinging, strong-smelling liquid. Disposable nitrile gloves and safety glasses keep exposure low. Splash risks mean face shields and full lab coats pay off in the long run.

Each storage area in my previous lab kept absorbent pads and a chemical spill kit close to the door. Don’t rely on paper towels—commercial spill kits absorb faster and deal with chemical toxicity better. If a spill happens, clean up immediately and ventilate well. If fumes or symptoms occur, leave the area and install fans or call the safety team.

It’s tempting to cut corners on storage when rushing between experiments. Over time, safe habits matter far more than a few lost minutes.

Understanding What We’re Handling

Methyl 4-iodobutyrate falls under a particular group of chemicals that chemists use for organic synthesis and drug development projects. Its structure gives it some versatile qualities in the lab, especially when building complex molecules. Most people outside the lab never come across it, but those who do must take safety seriously.

Exposure Risks in Everyday Practice

The first thing that comes to mind with methyl 4-iodobutyrate is its iodo- group. Chemicals with organoiodine groups often carry real hazards. Not all are deadly, but even trace contact with the skin can cause irritation, while breathing in vapors or fine mist can trigger headaches, nausea, and sometimes coughing or sore throat. A few unlucky folks may end up with more serious reactions, since iodo compounds can sometimes affect thyroid function or even cause rashes after repeated contact. Eyes are especially sensitive—one splash can set off burning and watering, enough to ruin any workday.

Toxicity: Real-World Evidence

Plenty of safety data revolves around methyl 4-iodobutyrate’s structure. It’s similar to other alkyl iodides, which often act as alkylating agents. These molecules can interfere with biological processes, even binding to DNA or essential proteins in cells. There’s not a stack of clinical case studies featuring this particular compound, but researchers put it in the same risk category as other iodo-based lab reagents due to its chemical activity. Some sources show it can cause skin and respiratory irritation at fairly low exposure levels. Animal models indicate that high doses may cause central nervous system depression, but this calls for far larger amounts than typical lab use.

Handling these sorts of chemicals as a chemist has always meant watching for sneaky exposure. Gloves, goggles, lab coats, and good ventilation aren’t optional, they’re essential tools in keeping a group safe. I’ve seen someone skip these basics and end up with burns from a single careless touch—that lesson sticks hard.

Why Safety Should Remain Front and Center

Methyl 4-iodobutyrate rarely ends up in consumer products or ordinary workplaces, yet stories from industrial settings prove that lax storage or disposal ramps up the risks for nearby workers and even the surrounding environment. The iodo- group makes the molecule persistent—it doesn’t break down so quickly, and improper down-the-drain disposal can create a mess for water treatment systems. Some iodine-based molecules convert into more persistent pollutants if conditions are right, raising further environmental health issues.

Practical Solutions and Safer Workflows

Chasing perfect safety might be unrealistic, but consistent habits go a long way. Storing methyl 4-iodobutyrate in sealed containers, logging each use, and keeping all containers labeled with clear hazard warnings helps prevent accidents. Fume hoods aren’t just a backup plan—they handle vapor that’s otherwise invisible until symptoms kick in. Spill kits and emergency eyewash stations cut down injury risk in seconds when accidents happen. Anyone working with these compounds should receive hands-on training, learn to spot early signs of exposure, and know the right steps after a spill or splash.

Pushing for safer alternatives sometimes pays off. Some research teams now swap alkyl iodides for less reactive halogens when possible, or test new methods that skip the need for these reagents altogether. These changes won’t fit every project, but the push for safer chemistry keeps moving forward as awareness grows.

Looking Ahead

Methyl 4-iodobutyrate won’t disappear from labs, but respecting its hazards should remain top priority. The facts point to a simple truth: informed chemists and tight lab practices reduce risk, protect health, and keep advances coming without unnecessary harm.

Direct Link to New Drug Development

Methyl 4-iodobutyrate rarely grabs headlines, but this chemical goes a long way in the lab. Take drug discovery as an example. Medicinal chemists prize it for its building block status. The iodo group makes it a prime candidate for carbon-carbon bond formation. In less technical terms: the stuff helps connect complicated fragments during early drug synthesis. Researchers often reach for it while assembling molecules designed to fight cancer, viral infections, or neurological disorders. There’s a reason it comes up in so many medicinal chemistry patents—its flexibility acts a bit like a Swiss army knife in synthetic chemistry.

Bringing Special Traits to Organic Synthesis

Chemical synthesis is as much about creativity as it is about rules. Methyl 4-iodobutyrate opens routes to chain elongation, which means it can extend a molecule’s backbone in a predictable way. Anyone working on synthesizing amino acids, peptides, or specialized polymers appreciates that kind of reliability. I’ve seen chemists light up after a successful coupling reaction with this compound—fewer side-products, higher yields, and robust performance under cross-coupling methods like Suzuki and Heck reactions.

Its versatility often shows in the production of building blocks for agricultural chemicals. Pesticide and herbicide researchers turn to this compound for the same reason drug developers do. The iodo group gives flexibility, but methyl ester makes it manageable and easy to handle in the lab. Most colleagues I know trust it for straightforward derivatization, reducing unnecessary steps and wasted time.

Fueling Academia's Curiosity

Academic labs often chase novel reactions. Methyl 4-iodobutyrate gets chosen because it shows clear, interpretable results in reaction development. You’ll spot it in journal articles about catalytic reactions, new ligands, and greener reaction pathways. My own grad school lab once picked this compound for a tough reaction optimization study. It gave us reproducible results and generous feedback during analysis—qualities that move academic research faster. Undergrad students get their hands on it early, thanks to its safety profile compared to less stable iodo compounds.

Shaping Future Polymers and Materials

The polymer world never stands still. Scientists who engineer specialty materials use methyl 4-iodobutyrate as a precursor. Attaching functional chains in a controlled fashion holds huge value in designing next-generation plastics and coatings. Some research teams even tailor responsive surfaces, smart packaging, or medical device coatings with this compound’s help. Whenever material scientists dream up monomers that bend or stretch with specific triggers, it often plays a part.

Eye Toward Sustainability and Safety

Chemistry’s green wave keeps rising. Regulatory pressure asks for safer, less toxic chemical routes. Methyl 4-iodobutyrate stands out, not because of zero risk, but because it plays well in reactions that minimize harsh reagents. Its track record lets process chemists create safer work environments and lower waste. Researchers find it easier to control reactions and handle cleanup with fewer headaches.

As chemical manufacturing looks for cleaner and smarter options, methyl 4-iodobutyrate’s continued presence suggests that flexible, well-behaved compounds still carry plenty of weight. Newer applications will likely build on its trust earned in the lab, translating those quiet strengths into safer and more responsible chemistry—whether for lifesaving drugs or new materials that make life better and cleaner.