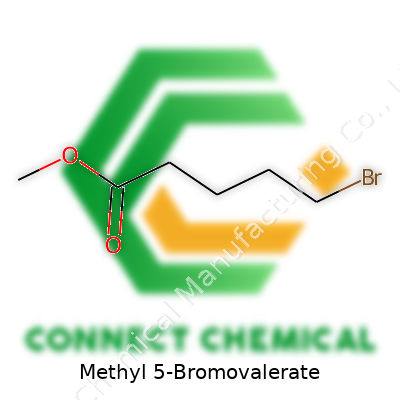

Methyl 5-Bromovalerate: Journey, Properties, Applications, and Beyond

Historical Development

Organic bromine compounds hold a special place in the toolkit of chemists, and methyl 5-bromovalerate comes from a deep-rooted lineage. Early organic synthesis explored the manipulation of valeric acid derivatives, pushing chemists to produce esters and halogenated compounds in the quest for new reactivity. Through the last century, bromination found increasing utility in the fields of pharmaceuticals and materials science. Laboratories once relied on cumbersome isolation methods, but today, streamlined syntheses and purification have made methyl 5-bromovalerate more accessible. In my own academic research years back, I traced the transformation of simple carboxylic acids to brominated esters, seeing both the ingenuity of past generations and the foundation they laid for present-day chemical innovation.

Product Overview

Methyl 5-bromovalerate, with its clear structure—a methyl ester group attached to a five-carbon chain terminating in a bromine atom—brings a blend of utility and reactivity. What stands out about this compound is the way it bridges restructuring hydrocarbon chains and introducing significant chemical functionality. As a specialty intermediate, it serves synthetic chemists in numerous ways, functioning as a precursor to more complex molecules. This compound shows up in fine chemical production, medicinal chemistry labs, and industrial synthesis routes, always helping unlock further transformations due to its accessible bromine group and its manageable reactivity profile.

Physical & Chemical Properties

Methyl 5-bromovalerate presents as a colorless to pale yellow liquid, typically with a moderate boiling point in the 200–210 °C range. I’ve handled similar haloesters—easy pour, modest viscosity, noticeable yet not overpowering odor. It loves most non-polar organic solvents, stays away from water, and its density signals the heavy bromine atom’s presence. The bromine atom on the terminal position gives it both good leaving group ability and susceptibility to nucleophilic attacks, which sets up a range of downstream chemistry. On the shelf, the compound stays stable under cool, dry conditions, but – like all brominated organics – it prefers glass containers with well-fitted lids to keep out excess moisture and light.

Technical Specifications & Labeling

Industry-grade methyl 5-bromovalerate arrives with strict purity benchmarks, usually upwards of 97% by GC or HPLC analysis, sometimes spiked with internal standards for quality monitoring. Labels and technical sheets need to declare CAS number 6306-32-1, batch number, weight, production date, and hazard statements. In my years around lab procurement, such transparency—down to impurity profiles like unreacted starting material or related esters—proves crucial for reproducibility. Given the sensitivity of many downstream reactions, knowing even minor contaminants can prevent frustrating surprises in the synthetic route. For shippers and warehouse staff, UN numbers and hazard pictograms warn of potential combustibility and environmental danger, so everyone knows how to handle, store, and dispose of the substance safely.

Preparation Method

The preparation of methyl 5-bromovalerate usually builds on the esterification and bromination of valeric acid derivatives. A common route starts by reacting valeric acid with methanol in the presence of an acid catalyst to form methyl valerate. After this, bromination targets the terminal carbon atom, often under radical conditions with N-bromosuccinimide in the presence of light or peroxides. From my memories of long hours at the bench, slow addition and careful control over temperature prevent runaway reactions or unwanted multi-bromination. Washing, extraction, and vacuum distillation round out the process, leaving a refined product that’s ready for downstream use. Improved methods now cut down on waste and streamline purification, showing how incremental improvements in methodology mean safer, cleaner, and more cost-effective production.

Chemical Reactions & Modifications

Chemists appreciate methyl 5-bromovalerate for its amenability to further transformations. The bromine atom acts as a versatile handle: it can be replaced by nucleophiles such as amines, thiols, or cyanide to form new amides, thioesters, or nitriles. Not too long ago, I tweaked alkylation reactions by swapping the bromide for azide, eventually reducing to the primary amine, a key building block in pharmaceutical research. Methyl 5-bromovalerate also participates in couplings and substitutions, giving rise to molecules with added aromaticity or increased chain length. Its structure supports Grignard and organolithium additions, broadening its reach in synthetic planning. Each transformation depends on the precise placement of the bromine and the resilience of the ester group to various reagents.

Synonyms & Product Names

Over the years, the nomenclature landscape has become more standardized, but older names still cycle through catalogs. Methyl 5-bromopentanoate, 5-bromovaleric acid methyl ester, and similar variants all refer to the same compound. On some datasheets, I’ve spotted trade names or abbreviated labels, especially in European or Asian supply chains. Consistent, well-communicated naming prevents mishaps—one mix-up between isomers once set a project of mine two weeks behind schedule. As research grows more global, precise chemical identity supports efficient collaboration and reliable handling across borders and laboratories.

Safety & Operational Standards

Methyl 5-bromovalerate brings several risks typical of halogenated organics. Skin and eye contact can cause irritation, and inhalation or ingestion pose serious health hazards. Safety data sheets require warnings about flammability and environmental impact since brominated compounds can persist in ecosystems. Good practice means lab coats, gloves, goggles, and well-ventilated hoods every time this chemical comes out. My time training new lab members reinforced just how crucial it is to keep these standards high—complacency leads to accidents, which are preventable with the right routine. Waste disposal typically involves collection in halogenated solvent waste streams, avoiding drains or open trash. Local and global regulations continue to evolve, demanding updated protocols and regular safety training.

Application Area

Methyl 5-bromovalerate serves as an important intermediate in pharmaceutical and agrochemical synthesis, particularly where selective substitution or further functionalization is needed. Research teams use it to construct molecules that target specific biological pathways, with the bromine atom making it easy to introduce diverse groups through substitution reactions. Its reach extends to flavors, fragrances, and specialty polymers as well, where tailored structure impacts end-product properties. From my experience in academia and industry, having a reactive ester like this speeds up exploratory work—once you master the safe handling, it can cut weeks off multi-step synthetic campaigns, helping get new candidates from the fume hood to biological assays with less delay.

Research & Development

Ongoing R&D focuses on improving reaction selectivity, reducing byproducts, and scaling up synthesis in greener ways—sometimes using biocatalysts or flow chemistry for greater control. The academic literature keeps turning out new derivatives based on the methyl 5-bromovalerate backbone, using it as a launching pad for novel drugs, catalysts, and specialty chemicals. Engaged researchers chase cleaner routes, such as using less toxic brominating agents or recyclable catalysts. In a project last year, collaboration between organic and process chemists led to a big reduction in solvent use while keeping yields high. This kind of progress, motivated by economic and environmental priorities, keeps methyl 5-bromovalerate at the frontline of synthetic organic chemistry.

Toxicity Research

Toxicity studies highlight both acute hazards and longer-term impacts on health and ecosystems. Like many alkyl bromides, methyl 5-bromovalerate can irritate mucous membranes and may be harmful if inhaled, ingested, or absorbed through the skin. Animal testing has documented effects ranging from mild sedation to organ toxicity at higher doses. Chronic exposure remains a concern, pushing companies and researchers to use personal protective equipment and engineering controls. Regulatory scrutiny pushes further; environmental persistence and potential for bioaccumulation spur calls for better waste management and treatment technologies. Advances in mechanistic toxicology support safer exposure limits, keeping human and environmental health at the center of industrial use.

Future Prospects

The outlook for methyl 5-bromovalerate tracks with trends toward greater demand for customized chemical building blocks, more sustainable production, and stricter regulatory expectations. Chemical engineers work to develop continuous flow processes that minimize waste and energy use, while analytical chemists refine detection methods for trace residues in products and the environment. The continued growth of pharmaceuticals, agrochemicals, and specialty materials guarantees its relevance for years to come. In my network, I see research groups tuning the reactivity of haloesters and testing greener substitutions that maintain synthetic flexibility. As customers seek safer, more sustainable compounds, methyl 5-bromovalerate will evolve—adapting to changing chemistry, regulation, and marketplace needs, continuing to power discovery across countless sectors.

Bringing Chemistry Into Focus

People sometimes look at a compound like Methyl 5-Bromovalerate and feel they’ve entered a different world. But it’s not just a string of complicated syllables. This compound—holding the chemical formula C6H11BrO2—plays a role in research labs and chemical processes that impact the products people use daily.

Understanding the Structure

Dig into the name, and you see how everything fits. The “methyl” piece means there’s a methyl ester group in play. “5-bromo” labels a bromine atom added to the fifth carbon on a straight five-carbon chain, the backbone of valeric acid. The final piece, “valerate,” reminds us of a five-carbon acid, so the structure looks like this: CH3OOC-(CH2)4-Br. That’s where every atom sits in the formula C6H11BrO2.

Why Exact Chemical Formulas Matter

In a lab, knowing this structure isn’t just about getting it right on paper. The placement of bromine changes how the molecule reacts with other chemicals. That single atom swap could mean the difference between an ingredient in a useful medicine and one that doesn’t work at all. Pharmaceutical researchers have known surprises can happen when a compound’s structure isn’t treated with care. I’ve seen researchers in organic chemistry focus for days just to make sure every synthetic step places atoms where they’re needed.

According to a 2022 article in Journal of Chemical Education, over 60% of retracted or reproducibility-challenged studies involve a misidentified or poorly understood compound. With Methyl 5-Bromovalerate, a simple slip—a misplaced methyl group, a mispositioned bromine—leads to outcomes nobody expected and sometimes years of wasted effort.

Downstream Applications That Depend on Clarity

Methyl 5-Bromovalerate doesn’t just sit around in flasks. Chemists use it as an intermediate on the path to bigger, more complex molecules—some that end up in fragrances, flavors, or drugs. People who work in synthetic chemistry use compounds like this one to build blocks for new ideas. Each added atom and functional group unlocks new options for creating molecules with specific effects.

For someone in chemical research, getting the formula right can mean a jump ahead. An incorrect formula or ambiguous labeling means other teams might face an unexpected mess—a test might fail, or even worse, contamination in downstream products can happen. Modern chemical supply companies already use strict quality checks, but every scientist shares responsibility for verifying the paper trail of each chemical batch.

Real-World Steps Toward Quality

Open sharing of verified chemical structures stands as one path forward. Using public chemical databases, like PubChem and ChemSpider, chemists verify both structure and formula before an experiment begins. Automated spectral verification—cross-checking using NMR or mass spectra—serves as a second layer of defense.

The bigger lesson goes beyond this one molecule. Asking about the chemical formula isn’t just for students or academics. In industry, regulatory standards—often guided by the FDA and European agencies—demand full clarity at every step. When people rely on chemistry in healthcare, food production, or environmental monitoring, knowing exactly what sits in the bottle matters. Small mistakes cause big trouble. Clear, careful attention—starting with something as simple as a formula—forms one of the cornerstones of good science.

The Chemical's Role in Organic Synthesis

Methyl 5-Bromovalerate stands out as more than another compound in a catalog. Chemists rely on it heavily for building blocks in organic synthesis. Its structure, featuring both an ester group and a bromine atom, means it can be a launching point for creating more complex molecules. Take my time in the lab: turning this compound into other valuable chemicals often happens through nucleophilic substitution, where the bromine atom gets replaced. This process forms new carbon-carbon or carbon-heteroatom bonds, which can then lead into the development of specialized fine chemicals.

Pharmaceutical Research Depends on Reliable Starting Materials

Drug discovery never slows down, and new molecules with biological action always remain in high demand. In my own work and in conversations with professionals at pharmaceutical companies, I’ve seen Methyl 5-Bromovalerate serve as a key starting material for small-molecule active ingredients. Its chemical structure makes it possible to introduce various functional groups that chemists want for testing or optimization. For instance, its backbone shows up in early-stage development of compounds aimed at treating neurological and metabolic disorders. Public studies record its use in synthesizing intermediates related to GABA analogs and other promising agents for the central nervous system.

Forging Links in the Fragrance and Flavor Industry

Esters often bring pleasant aromas. During my internship in a specialty chemicals facility, I learned just how valuable methyl esters become as platforms for new flavors and fragrances. Methyl 5-Bromovalerate can transform into alcohols, acids, or other esters through simple chemical tweaks. Researchers then test these molecules in panel studies to assess olfactory qualities. Though it’s not a finished product, this compound sits early in the chain for new scent creation, offering perfumers and flavorists a tool for expanding the range of notes available to them.

Agrochemical Synthesis and Crop Protection

Farmers rely on a steady flow of science-driven agrochemicals. Many herbicides and insecticides start with molecules that look a lot like methyl 5-bromovalerate. If you look through patent filings and agricultural chemistry literature, you’ll find references to this compound in pathways to produce modern crop protection agents. The reason tracks back to versatility: brominated esters such as this allow agrochemical manufacturers to diversify their pipeline. Companies can swap out the bromine for other groups that deliver targeted action against pests but with a safety profile growers demand.

Research and Academic Training

Walk through university chemistry departments and you’ll see researchers reaching for methyl 5-bromovalerate for teaching advanced reaction mechanisms. Its clear reactivity helps students grasp substitution, elimination, and reduction reactions. In my classes, professors constantly used examples involving this compound to help demystify lab protocols. Beyond its use in teaching, its predictable behavior means research projects can proceed with fewer surprises, saving time and resources for teams focused on innovation.

Responsible Handling Remains Key

Safety always comes first around chemicals like methyl 5-bromovalerate. Reading its safety data sheet, you notice the warnings about inhalation and skin contact. In my experience, double-checking fume hood airflow and protective gear feels less like a nuisance and more like a necessity. Proper disposal practices reduce the risk of environmental harm, and regulatory oversight helps keep everyone accountable.

Understanding the Risks

Methyl 5-Bromovalerate has a way of making itself known in the lab. Its sweet, somewhat pungent smell tells you right away that this stuff isn’t your everyday solvent. It might look harmless as a colorless liquid, but anyone working with organic reagents quickly learns not to trust appearances. Countless laboratories rely on esters like this for synthesis steps, so it makes sense to talk straight about what keeps people out of trouble with this compound.

Handling It Right

Wearing gloves, goggles, and a lab coat sounds obvious, yet I’ve seen folks stretch the rules. Maybe they’re in a hurry, or maybe they just figure nothing will ever spill or splash. Once, I bumped a beaker and got a drop on my glove. Good thing I remembered to change gloves right away. This ester can irritate the skin and eyes, and if it hits a cut, you’ll feel it. Staying under the fume hood isn’t a suggestion; that vapor sneaks up on you, and inhaling it can lead to headaches or nausea, sometimes worse. Not all vapors come with a warning whiff, so trust your equipment more than your nose.

Fire and Reactivity Hazards

Methyl 5-Bromovalerate ignites more easily than some materials in the cabinet. I’ve watched a careless wipe catch fire from a hot plate nearby, and it’s no fun explaining how that happens. The flash point is around 80°C, so anything warmer than a hot coffee mug gets risky. Keeping sources of ignition—heat, spark, even static electricity—far from the compound makes a world of difference. Mixing it with strong bases or acids, or exposing it to strong oxidizers, invites violent reactions. Over time, old bottles build up pressure, so check labels and storage dates before opening anything that’s been sitting around for a while.

Storage Practices

Esters don’t get along with moisture, heat, or direct sunlight. The best spot stays cool and dry, away from oxidizing agents and any acidic or basic materials. Keeping Methyl 5-Bromovalerate in a tightly sealed container slows down any decomposition and controls fumes. Using secondary containment—like a plastic tray—can save shelves from sticky messes and leaks. I once saw a tiny crack in a cap turn into a full-on spill after a weekend on the shelf, so even simple habits like checking for damage pay off.

Dealing with Spills and Waste

No matter how careful you are, accidents happen. If you knock over a flask or drop a pipette, having spill kits nearby cuts down risk. Absorbent pads, neutralizing agents, and gloves sit within arm’s reach for a reason. Cleaning up with paper towels does not cut it; fumes linger, and skin contact leaves a sting. All cleanup tools go into a labeled waste container, not regular trash. Disposal needs to follow chemical waste rules, not just a trip to the sink. Most university and company labs have strict protocols, and for good reason: improper disposal can ruin wastewater systems and hurt wildlife downstream.

Training and Common Sense

Before picking up any bottle, good lab workers double-check the label and safety data sheet. Sharing experiences with coworkers and calling out risky habits keeps standards high. I’ve seen training sessions prevent mishaps by teaching the difference between confidence and carelessness. Taking five seconds to suit up and check equipment is never wasted time. Real lab safety comes from treating every bottle with respect, not just the ones with danger symbols.

References:- PubChem, National Institutes of Health: Methyl 5-Bromovalerate Chemical Safety Data

- European Chemicals Agency: Recommendations for Handling Brominated Esters

Understanding the Needs of a Sensitive Chemical

Walking through a research lab or chemical storeroom, I’ve learned respect for substances that don’t ask for much but threaten a lot if ignored. Methyl 5-bromovalerate, a colorless to pale yellow liquid with a faint fruity odor, fits into this group. Small mistakes in storage for even relatively low-hazard chemicals catch you off guard after weeks or months. Chemists rely on simple rules: keep it dry, protect it from light, keep it cool, stay organized. Not every substance demands jewelry-level security, but there’s a baseline of care that protects people and data from avoidable accidents and product loss.

Temperature: Keeping It Cool and Stable

Methyl 5-bromovalerate asks for a storage temperature below 25°C. In many labs, this looks like a sturdy cabinet or a room with dedicated temperature control. Heat speeds up hydrolysis and over time degrades ester compounds, especially ones with an active bromine group. I’ve seen a bottle stored near a heating vent puff up and hiss come spring—nothing catastrophic, but a wasted purchase and a strong reminder. Temperature swings play worse tricks. Keeping bottles out of direct sunlight and away from obvious thermal sources matters more than most newcomers guess.

Humidity and Moisture: The Silent Threat

A lot of overlooked losses trace right back to slow moisture seepage. Methyl 5-bromovalerate reacts with water. The reaction isn’t dramatic at a glance, but over several weeks the substance breaks down into its acid and alcohol parts, leaving you with a bottle full of uncertainty. I make sure to seal every bottle tightly, using screw caps with PTFE liners when possible. If desiccators are available, anhydrous calcium chloride or silica gel work as solid options to keep the humidity away. Leaving bottles open just because you plan to use them again soon is a habit many regret. It’s easy to label a bottle “for disposal” and much harder to recapture wasted effort.

Safe Containers and Clear Labeling

Many undergraduates overlook the container. You want glass with a tight seal; methyl esters and plastics don’t always mix happily in storage, especially over a long period. Clear glass brings a risk of light exposure, so amber bottles make more sense if the storeroom sees regular lighting. Labeling, always in waterproof ink, guards against confusion later. Even a faded label or wrong cap can end a good experiment weeks before you realize something’s gone bad.

Storing Away from Incompatible Substances

Halogenated esters don’t react with quite as much as pure halogens or acids, but they don’t belong right next to strong bases, oxidizers, or reducing agents. If a spill occurs, things can spiral. In crowded settings, marking out zones for acids, organics, bases, and oxidizers stops small leaks from becoming bigger hazards. Chemical inventories work best when everyone logs what comes and goes, making it easier to track shelf life and avoid accidental mixing.

Building Good Habits: Safer Labs and Better Results

I’ve worked in groups where careful storage meant chemicals lasted through the semester, and in places where hasty decisions left shelves full of questionable compounds. The difference shows up both in safety and cost. A little extra care—checking caps, logging inspections, keeping bottles out of the sun—pays off over time. Teaching these habits to new students or colleagues creates a culture where accidents go down and results go up. Anyone handling methyl 5-bromovalerate benefits from keeping these storage lessons up front.

More Than a Chemical Formula

Methyl 5-bromovalerate isn’t something you pick up at the pharmacy or hardware store. It’s a specialty building block in the world of synthesis, especially in pharmaceuticals and research. What you get in a bottle or drum often shapes how far you can trust your experiment results.

Why Purity Grades Matter

Chemists have stories about batches of a compound that promised one grade and delivered another. One year, I worked on scaling up a lab synthesis involving a brominated ester. Even a tiny impurity changed the yield and the color of our final product. We traced the issue back to the source: a bottle labeled “tech grade” instead of “analytical.”

Purity grades generally begin around “technical,” suitable for process chemistry or industrial intermediates. This level fits non-sensitive reactions, where fussing over details isn’t worth the effort or cost. Analytical or “reagent” grade sits higher on the ladder. Reagent grade Methyl 5-bromovalerate goes through tighter controls and more testing—think 98% or higher, sometimes over 99%. That few percentage points can save days of trouble.

Pharmaceutical producers might demand “high purity” or “GMP” compliant batches, where every trace impurity gets listed and scrutinized. It comes at a price, but failure isn’t an option with regulatory standards at play. So when a researcher orders, the question—what’s the grade?—is more than a detail. It’s the difference between trust and throwing out a week’s work.

Different Tasks, Different Containers

On one of my first visits to a commercial supplier, shelf after shelf lined with glass bottles and steel drums showed how differently customers buy the same compound. Academic labs might not need 500 grams for a year’s research, so small amber glass bottles—100 grams or less—make sense. They protect its chemical stability and fit someone’s grant budget.

Turn the corner, and industrial clients grab ten-liter drums. They run continuous processes, so the smaller packing isn’t just wasteful; it’s expensive. Larger containers run the risk of contamination if opened too many times, so handling protocols take center stage.

I once saw a mishap where someone ordered a kilo in a single container. Turns out, their reactions ran at a tenth that scale, forcing them to crack the seal over and over. By the end, moisture snuck in and ruined what was left. If it had shipped in 100-gram bottles, the waste and stress would have been much lower.

Supplier Transparency and Buyer Awareness

It’s easy to assume a chemical comes one way, but making that call without checking a supplier’s technical data invites headaches. Some suppliers write clear specs on the label; others, buried three clicks away in a PDF. The best in the industry never hide what a buyer is paying for. Scrutinizing not just the percentage of purity, but also water content, stabilizer presence, and packaging scales often prevents future surprises.

Imagine a system where every order came with full testing results and real-time stock information for different pack sizes. It’d save mistakes and phone calls chasing clarity. Until then, buyers and researchers benefit from asking questions upfront, documenting needs, and keeping an eye on reputable distributors.

In chemical sourcing, detail pays off—sometimes with better yields, other times with the peace of mind that comes from knowing exactly what’s in the bottle.