Methyl 6-Bromohexanoate: Insights into Its Use, Development, and Future

Historical Development

Chemical synthesis took a giant leap forward in the mid-1900s. Methyl 6-bromohexanoate came out of practical needs—pharmaceutical labs and agricultural research required precise building blocks for new compounds. Chemists searching for efficient routes to amide linkages or complex lipid structures gravitated toward this compound. Its creation and continual use signal an ongoing story. The demand for advanced esters, particularly brominated ones, shaped its development, driven by research in universities and growth in specialty chemicals. Experienced researchers can recall the early days of open reflux flasks, tall glass columns, and days spent troubleshooting esterification yields. Now, improvements in purification, safety protocols, and environmental practices reflect its evolution.

Product Overview

Today, methyl 6-bromohexanoate holds a spot on the shelf in chemical storerooms around the world. Labs working on medical chemistry or polymer studies use it as a brominated ester, known for its ability to introduce a six-carbon backbone into longer molecules. A pale to colorless liquid, its moderate volatility means it stays put during handling, and experienced technicians value a reagent that doesn't complicate synthesis steps. Having worked with countless intermediates, I can recognize why seasoned chemists still reach for it; it bridges the gap between simple esters and more functionalized brominated chains needed in modern synthesis.

Physical & Chemical Properties

Methyl 6-bromohexanoate stands out for its moisture sensitivity and its reliable boiling point, usually hovering between 100–110°C at reduced pressure. By comparison, its density and refractive index make identification straightforward, sparing younger chemists a few headaches. Solubility leans toward organic solvents, best mixed with such agents in fume hoods. Its bromo-group supports nucleophilic substitution, a feature sought after for downstream functionalization. That sort of reactivity doesn’t require elaborate apparatus, reducing the barrier for entry into complex synthesis. The faint sweet odor signals purity—contamination skews this, a fact that any experienced lab hand can confirm.

Technical Specifications & Labeling

Accurate labeling matters, especially for a compound used in regulated environments. Typical vials display the CAS number, proper storage instructions (sealed, away from light), and purity, usually reported above 96%. Regulatory sheets include incompatibility warnings—strong bases and oxidizers pose risks. Weight, batch number, and expiration date appear on every bottle; slip-ups in this area have led to more than a few regretful hours in the lab. Clear indication of hazards, including GHS pictograms, signals both respect for chemical safety and regulatory compliance. Avoiding mislabeling and ensuring every bottle meets purity standards becomes routine for those familiar with Good Laboratory Practices.

Preparation Method

Making methyl 6-bromohexanoate commonly begins with 6-bromohexanoic acid, a compound more familiar to organic chemists. Reaction with methanol, usually in the presence of acid catalysts such as sulfuric or p-toluenesulfonic acid, yields the desired ester. This Fischer esterification method still dominates. Controlled heating and careful removal of water are keys to maximizing yield and purity. Completing several batches myself, I learned that patience and precise temperature control win out over any shortcut—overheating scorches the product, cutting into yield. Post-reaction washes with brine and thorough drying help remove residual acid and byproducts. Columns or distillation finish the job, delivering a product worthy of analytical scrutiny.

Chemical Reactions & Modifications

The bromo group embedded in methyl 6-bromohexanoate opens doors for all sorts of nucleophilic substitutions. Grignard reagents, amines, or thiols replace the bromide, creating new molecules used in drug development or agrochemical research. The ester group stands up to a range of conditions, though strong base hydrolysis reverts it to the parent acid. Advanced users modify it with reduction or coupling reactions, adding complexity or introducing fluorescent tags in biochemical assays. Over the years, these modifications found their place in graduate research, enabling faster development of analogs with medical or material applications. A well-documented reaction pathway means even less experienced chemists can work with confidence, provided they respect the risks.

Synonyms & Product Names

Methyl 6-bromohexanoate carries several names, reflecting conventions in chemical nomenclature and global commerce. You’ll spot it as methyl 6-bromohexanoate, methyl 6-bromohexanoic acid ester, or methyl caproate, 6-bromo-. Material Safety Data Sheets (MSDS) and chemical catalogs repeat these variants. Local suppliers may list translation-specific names—working internationally, I’ve seen labels in German, Japanese, and Mandarin. Cross-referencing with the CAS number (4596-42-9) avoids misidentification, a lesson I picked up managing multi-site research projects. Trading companies, often less familiar with technical nuance, sometimes over-simplify this labeling, so cross-verification stays critical.

Safety & Operational Standards

Safe handling practices don’t spring from thin air—they arise from hard-learned lessons. Methyl 6-bromohexanoate, with its reactive bromine atom, eggs on skin and eye irritation, and inhaling vapors risks respiratory issues. Years in busy facilities have taught me to respect the PPE rules: gloves, goggles, lab coat. Proper ventilation goes beyond compliance, since accidental release leaves a sting in the throat and memory. Waste handling sticks to hazardous organics protocols—spent solutions collected in labeled drums, disposal handled only by certified teams. Regular training and review of incident reports help avoid routine errors, a practice I’ve seen transform laboratory culture from complacency to responsibility.

Application Area

Chemists and biochemists use methyl 6-bromohexanoate to create new pharmaceutical intermediates, particularly as a precursor for amino acid derivatives, lipid analogs, and tailored building blocks for antibiotics. In agricultural research, the compound helps design novel pesticides and growth regulators. Materials scientists explore its utility in polymer modification, adding flexibility or introducing halogen-rich segments for specialty plastics. Medicinal chemistry sees renewed interest in brominated esters, and demand extends to industrial research looking to optimize surfactants and specialty lubricants. Product portfolios in the chemical industry keep growing as new applications for six-carbon esters are uncovered through funded collaborations with academia.

Research & Development

Strong research ties between universities and chemical manufacturers maintain progress in synthesis efficiency and application scope. Recent trends focus on greener esterification reactions, cutting down on hazardous solvents and shrinking waste streams—lessons hammered home during the push for sustainability in early 2020s. High-throughput screening in drug development leans on library compounds derived from methyl 6-bromohexanoate, a story repeated in countless patent filings. Analytical advances allow better tracking of purity, toxicity, and environmental breakdown products, feeding data into AI-assisted modeling. Having worked across industry and academia, I see the cycle where each improvement prompts new application ideas, drawing in multidisciplinary teams and wider funding.

Toxicity Research

Toxicologists approach methyl 6-bromohexanoate with caution. Animal studies reveal skin and mucous membrane irritation and trace levels promote enzyme disruption in hepatic cells. Acute exposure creates short-term symptoms; chronic dosing in rodents prompts longer-term research, with some data pointing toward mild neurotoxic effects. Readily absorbed through biological membranes, the ester’s brominated nature rings alarm bells for persistent effects, and regulators pay close attention. Having participated in toxicology review panels, I see how journals and regulatory agencies use this information to guide workplace limits and exposure controls. Safer alternatives or modifications often stem from robust dialogue between industrial hygienists, policymakers, and synthetic chemists.

Future Prospects

Looking ahead, methyl 6-bromohexanoate stands poised for a supporting role in big strides toward more efficient drug discovery, biodegradable surfactants, and safer agricultural chemicals. The synthetic routes might shift toward enzymatic catalysis or solvent-free methods, growing out of mounting pressure for sustainable chemistry. Advances in toxicology could prompt design tweaks, swapping out bromine or modulating the ester’s reactivity to tip the balance between function and safety. The next generation of chemists—more fluent in digital prediction and automation—will tap its potential in areas like precision medicine and bio-based materials. Shared lessons, investment in R&D, and trust in data integrity provide fertile ground for its continued relevance across a constantly changing scientific landscape.

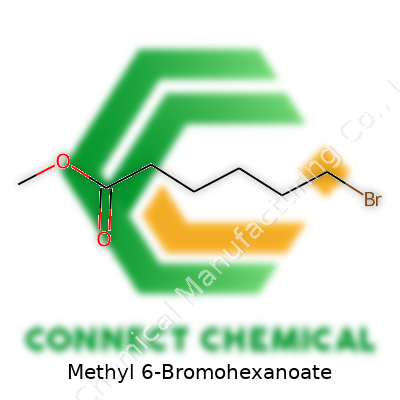

The Make-Up of Methyl 6-Bromohexanoate

Getting into the nuts and bolts of a compound like Methyl 6-Bromohexanoate means taking a closer look at its chemical skeleton. The name alone spells out the parts. You’ve got a methyl ester group, a six-carbon chain, and a bromine atom hanging off the sixth carbon. Chemists write it as C7H13BrO2. If you picture it, there’s a long chain—hexanoate—and methyl is at one end, bromine at the other. The structure basically traces out a couple of tried-and-true principles in organic chemistry. You get a chain that’s capped by an ester group on one end and by a more reactive site—bromine—on the other.

Where Science and Industry Meet

Putting structure to use, Methyl 6-Bromohexanoate steps into a lot of research labs and manufacturing processes. The reason sits in that bromine atom. Slapping a halogen onto an otherwise ordinary chain lets companies and labs build out more complicated molecules. That bromine site acts like a docking point for all kinds of changes—nucleophilic substitutions, coupling reactions, you name it. You’ve got a molecule that bridges the basics of organic structure and the tailored needs of pharmaceuticals or advanced materials.

I remember the patience involved in working with bromoalkanoates in grad school. Tinkering with their chains meant we could shape properties of new polymers. That bromine stood out in the NMR spectra like a beacon, showing whether our synthesis gave us what we wanted. By the time you finish functionalizing the chain, you’ve added in entirely new traits—flexibility, solubility, and sometimes even biological activity. It’s a reminder how deliberate chemical structure translates to tangible improvements.

Health, Safety, and Environmental Factors

You can’t talk about fine chemicals like Methyl 6-Bromohexanoate without bringing up safety. Esters like this are usually liquids or low-melting solids, often with modest volatility and recognizable odors. The bromine in their structure points to reactivity—good for synthesis, but potentially hazardous. Skin contact or inhalation can irritate; chronic exposure draws concern in the chemical community. In my own lab days, we focused on gloves, fume hoods, and careful inventory management to keep trouble away. Regulations from agencies like OSHA and the EPA nudge researchers and manufacturers to limit environmental impacts and occupational risks.

Safe use links right back to training. Knowing the structure, you grasp why certain precautions fit. That carbon-bromine bond means extra gloves and eye protection, because reagents and products featuring bromine don’t play nice if they spill on skin or hit the water table. Waste handling becomes part of the daily routine, not just an afterthought.

Pushing Forward with Responsible Chemistry

Making something useful from Methyl 6-Bromohexanoate relies on both chemistry and responsibility. Companies have started moving toward greener synthesis routes, swapping out hazardous reagents for milder ones, and designing methods that reduce waste. In academic settings, students learn that smart chemical design draws on both practical knowledge of structure and responsible management of risk. Each new approach can support safer labs, reduce pollutant loads, and foster innovation in making medicines or materials.

Breaking down the structure of a compound like this reveals how even simple changes at the molecular level can offer wide-reaching potential. Every addition on the chain, every tweak in the lab, echoes in the products we build and the safety of the people handling them.

Key Uses in Pharmaceutical Intermediates

Methyl 6-Bromohexanoate plays a key part in the pharmaceutical world, especially as a building block for creating more complex molecules. With a bromo group tethered to its carbon chain, chemists often reach for this compound when they want to introduce a longer alkyl chain into a drug candidate. For example, research teams use it to build molecules that can become active pharmaceutical ingredients, including those with antiviral and anticancer properties. Its structure gives medicinal chemists the flexibility to tweak side chains and shape new medicines. According to recent studies, modifying the length and flexibility of a molecule's chain can often determine how well it binds to biological targets or how it moves within the body. From my own graduate lab days, I recall how a seemingly minor change—like substituting a methyl group for a longer bromohexanoate—opened new avenues in synthesis projects. That flexibility still draws attention from drug discovery groups today.

Contributions to Material Science and Polymers

This compound pops up in material science labs too. The bromo group offers an easy handle for further reactions, letting researchers extend the carbon chain or attach other functional groups. In the world of specialty polymers, it gets used for creating custom monomers. These monomers then form tough, flexible polymers for coatings, adhesives, and advanced composites. Several patent filings describe routes where methyl 6-bromohexanoate acts as an intermediate for making monomers with unique properties like chemical resistance or softness. I remember collaborating on a polymer adhesion project where adding a bromohexanoate-derived segment boosted sticking power without wrecking flexibility. That sort of practical benefit stands out for industrial chemists looking to tailor new material properties without a lot of trial and error.

Role in Agrochemical Synthesis

Agrochemical companies also rely on methyl 6-bromohexanoate for its synthetic flexibility. Agrochemicals, such as herbicides and pesticides, require many different building blocks to target plant and insect biology without harming crops. The bromohexanoate structure is valuable in this sphere because it’s easy to modify, allowing for fast iteration. For example, chemical teams use it to attach new functional groups that target specific pest enzymes, all without going back to square one in their synthesis plans. In one published industry process, use of this compound cut several steps from the synthesis of a new herbicide, helping get that product through development and approval more efficiently. Time savings like that translate directly into more affordable solutions for growers and fewer delays in addressing agricultural challenges.

Environmental and Safety Factors

Working with organobromine compounds sometimes sparks debate about safety and environmental impact. While methyl 6-bromohexanoate offers lots of chemistry options, it also brings questions about handling and disposal. Having spent years in chemistry labs, I saw how important it is to manage brominated waste carefully. Regulatory agencies pay close attention to emissions and waste streams, so companies constantly seek greener synthesis routes and tighter containment. Some groups have been developing milder reaction conditions to minimize side products and hazards, taking genuine steps to shrink the environmental footprint. Chemists, both in industry and academia, share responsibility for making smarter, safer choices that protect people and communities.

Looking Ahead

The versatility of methyl 6-bromohexanoate keeps driving research in pharmaceuticals, materials, and agriculture. Its wide adoption underscores ongoing demand for adaptable building blocks that can streamline synthesis and open new doors for innovation. With continued efforts to make production more sustainable, the compound’s importance is likely to grow, especially where efficiency and responsible chemistry meet.

Why Proper Storage Matters

Methyl 6-bromohexanoate isn’t a household name, but it shows up in labs and manufacturing lines that demand reliable raw materials. This compound can be unforgiving if ignored, so treating it right avoids wasted product and unnecessary headaches. Poor storage leads to spoilage and spills, and for a substance with both reactivity and a little volatility, that risk isn’t just inconvenience — it becomes a safety conversation. Many folks working in chemical environments know what it's like to cut corners only to regret it later.

Temperature Control

People often overlook just how much ambient heat messes with chemicals. With methyl 6-bromohexanoate, cool conditions make all the difference for long-term stability. I’ve seen more than one case where a bottle stored near heat sinks or windows broke down, producing discoloration and loss of potency faster than anyone expected. Most guidance suggests keeping this compound under 25°C, far from any source of direct sunlight. A well-ventilated, dedicated chemical storage room—nothing fancy, just consistent and cool—offers the practical answer.

Dealing with Moisture and Air

Anyone who's handled methyl esters for more than a week likely knows moisture isn’t a minor threat. Exposure to high humidity or open air encourages hydrolysis and unwanted reactions. I’ve ruined small batches through sloppy capping and found myself cleaning sticky residues off shelving. For this reason, always return liquids to their original tightly-sealed amber glass bottles, and never transfer to a poorly fitted cap "just until tomorrow." Desiccators or cabinets with silica packs add a layer of insurance, especially in labs prone to damp air. Protecting contents from moisture and oxidation helps ensure you work with material that performs the way it should.

Safe Lab Practices: Physical Storage

No matter how sterile or laid-back your workspace, dangerous shortcuts with methyl 6-bromohexanoate cause problems. Spills from careless stacking or jammed shelving crowd more serious hazards into shared workspaces. Storing the bottle in a sturdy, labeled secondary container cuts down the chance of leaks reaching benchtops or floors. Wherever possible, avoid storing above head height. After an old coworker took a splash from a broken container falling off an overhead shelf, I keep these materials at waist-level or lower. Goggles, gloves, and a simple lab coat round out the basics—no one plans on accidents, but preparation minimizes outcomes.

Fire Hazards and Incompatible Chemicals

While methyl 6-bromohexanoate won’t ignite as easily as some lab solvents, it's still flammable, which ups the risk during unexpected flare-ups or heat exposure. Keeping it away from ignition sources like hot plates, open flames, or even strong oxidizers is plain common sense. Segregating it from acids, bases, and reactive metals lowers the chances of trouble. I've seen too many close calls in shared spaces from half-empty containers stored together for the sake of convenience—it rarely pays off.

Disposal and Emergency Procedures

Even with diligent care, spills happen. Having spill kits, eye wash stations, and emergency ventilation nearby means small mistakes won’t escalate. For leftovers or old stock, following local hazardous waste procedures matters more than ever. Pouring unwanted chemicals down the drain creates long-term harm, even if it seems easy in the moment. Regularly reviewing disposal steps with team members helps catch lapses before they snowball into real problems.

Moving Forward with Safer Practices

Understanding why methyl 6-bromohexanoate demands respect isn't about fear—it's about responsibility. Storing it in cool, dry, well-marked spaces, keeping incompatible chemicals apart, and following safety routines create a better environment for science and business alike. Doing these things every day turns good intentions into strong habits.

What Purity Means for Real-World Work

In labs and in industry, the purity of a chemical can set the tone for every step of a process. Methyl 6-Bromohexanoate, with uses ranging from pharmaceuticals to fragrances, is no stranger to this rule. Over the years, I’ve seen what minor differences in chemical quality can do. Even a tiny trace of contaminant may cause headaches down the line, from unreliable yields to regulatory snags.

For most reputable suppliers, Methyl 6-Bromohexanoate comes at a purity level of at least 98%. Often, you’ll spot “≥98%” or “≥99%” on the label, showing confidence in the product’s cleanliness. At this level, the impurity profile stays low enough for most lab research, pilot studies, and commercial synthesis runs. Every synthetic chemist I’ve worked with wants that certainty—less room for error and fewer surprises.

Testing and Proof in the Details

Reputable suppliers back up that purity with batch-specific data. Expect things like the certificate of analysis (COA), showing results from methods like GC-MS or NMR. These checks matter because slight differences in composition might not be obvious just by looking at a bottle. Certain syntheses, especially where chirality matters or by-products can interfere, really benefit from this level of trust. No one has time for a failed reaction just because raw material quality was taken for granted.

Packaging Shapes the Workflow

Suppliers rarely overlook how shipment and storage can affect a sensitive compound. For Methyl 6-Bromohexanoate, the packaging you’ll find usually fits the scale and purpose of your project. Small glass bottles, anywhere from 5 grams to 250 grams, work for bench-scale projects or R&D work. I remember the relief of opening a sealed amber glass vial after a long customs delay—the material stayed clean and stable, with no sign of degradations.

Bigger jobs need bulk packaging. Factories often order in plastic or metal drums, from a few kilograms to 25 kilograms or even 50 kilograms per drum. Secure seals and resistance to leaks give peace of mind during transport. For hazardous materials, UN-rated packaging keeps everyone on the right side of the law, as well as safer on the job.

The right packaging isn’t just about scale. Moisture, light, heat—these wreck chemical stocks if overlooked. Suppliers shipping this compound use opaque or amber containers that cut down on light exposure. Heat-sealed liners fight off moisture intrusion. A poorly chosen container leads to hydrolysis or slow breakdown, and I’ve seen more than one lab eat the cost for not checking how their chemicals traveled.

Solutions and Choices for Buyers

Seeing your chemical’s COA before signing anything can save a lot of frustration. Don’t hesitate to ask about batch numbers and test data. For large purchases, negotiating packaging type and volume isn’t just possible—it’s smart. Sometimes splitting a large drum into several smaller drums keeps spoilage low, especially when storage conditions aren’t perfect. For long-term projects, tracking the shelf life and rotating stock avoids trouble with degraded reagents down the road.

Methyl 6-Bromohexanoate, at high purity and in the right format, becomes a dependable building block rather than a stumbling block. Choosing carefully, and demanding solid information, helps buyers get the most out of every gram.

Understanding the Risks

People working in labs or chemical manufacturing often run across unfamiliar names on safety data sheets. Methyl 6-bromohexanoate fits that bill. Toss out the fancy jargon—what really matters is whether this stuff puts people, animals, or the environment in harm's way. Chemical hazards don’t announce themselves with flashing alarms. The real danger hides in how some compounds sneak through gloves or evaporate into the air, and this molecule lands squarely in the “handle with care” bucket.

Looking at Real Hazards

Take a hard look at the facts. Methyl 6-bromohexanoate comes with skin and eye irritation warnings. Even brief contact may leave skin red or cause a stinging sensation. Eyes deal even worse; an accidental splash feels a lot like chopping too many onions, except the burning sticks around a lot longer. Breathing in its vapors or mists can lead to lung irritation, headaches, or nausea. Some evidence also points to harmful long-term effects if someone gets too relaxed about exposure.

This stuff doesn’t break down quickly. Waterways contaminated with it can cause problems for fish and other wildlife, and runoff puts whole ecosystems at risk. Regulations around disposing and handling this molecule don’t exist just to annoy workers—they matter in keeping people and surroundings safe.

Safety Isn’t Optional

Every time I set foot in a lab, I see the same rush to “just get it done.” But cutting corners piles up trouble. For methyl 6-bromohexanoate, eye protection comes first—goggles do what squinting never could. Gloves made from nitrile or a similar material stand up well against this compound. Basic latex gloves can’t hold up, and skin left bare gets burned or, worse, lets this chemical slip right in.

Spills happen, even if someone thinks they’ve seen it all. Small spill kits, absorbent pads, and plenty of fresh air in the workspace help turn a near-miss into just another story. Fume hoods earn their keep here; chemical vapors float on air quickly, threatening everyone nearby. Ventilation can’t fix a spill, but it gives valuable time to clean up and get out.

Choosing the Right Precautions

Decent habits last longer than regulations. Washing hands with soap and water—not just sanitizer—makes a big difference. Storing the chemical in tightly sealed containers, away from heat sources and sunlight, prevents slow leaks and dangerous surprises. Labels should show the hazard, not get lost in translation. Training newcomers (and reminders for veterans) builds habits that have kept me, and many coworkers, healthy over the years.

Disposing of leftover material isn’t about tossing it in the trash. Local hazardous waste programs, clear protocols, and never dumping into a drain can prevent accidental poisoning or expensive fines. Respect for the rules springs from knowing someone else will drink the water downstream.

Finding Balanced Solutions

At the end of the day, methyl 6-bromohexanoate serves its purpose as a tool in chemical processes. Smart labs and thoughtful managers don’t treat it as some evil villain, but they don’t ignore the risks either. Taking a few extra seconds to suit up, check labels, and check the ventilation puts everyone on track to earn another safe shift. That’s what experience has taught me—don’t trust luck, trust good preparation.