Methyl 6-Chlorohexanoate: Context, Characteristics, and Contribution

Historical Development

Years before methyl 6-chlorohexanoate made its way into laboratories and industrial facilities, chemists recognized the need for versatile building blocks. Early research into aliphatic esters highlighted their use as intermediates, and as new organic synthesis routes came up in the mid-twentieth century, the methyl ester of 6-chlorohexanoic acid started showing up in patent literature and synthesis schemes. Industrial laboratories, especially in Europe and East Asia, turned these compounds into go-to substrates. Practical interest in derivatives like methyl 6-chlorohexanoate rose because of their ability to deliver reliable reactivity and manageable toxicity compared to more volatile or aromatic options.

Product Overview

For those unfamiliar, methyl 6-chlorohexanoate is an esterified version of 6-chlorohexanoic acid. It brings together a straightforward chemical backbone with a reactive chloro group on the terminal position. You find this compound in a transparent liquid form, carrying a faint sweet odor. Chemists tend to appreciate its moderate boiling point, clear color, and its straightforward use as an intermediate. The product’s popularity comes from its balance of versatility and ease of storage.

Physical & Chemical Properties

A closer look at the physical and chemical makeup of methyl 6-chlorohexanoate shows it wears many hats. As a colorless to pale yellow liquid, it comes with a boiling point around 220-225°C at atmospheric pressure. With a density around 1.02 g/cm³ at room temperature, it fits comfortably in the boat with similar aliphatic esters. It dissolves best in common organic solvents like ethanol, ether, and acetone, but won’t blend in with water. That makes it easy to isolate or purify, which is a real bonus during large-scale prep. The chloro group on the terminal end packs a punch in nucleophilic substitution reactions, leaving options open for chain extension or new functionalization.

Technical Specifications & Labeling

Suppliers pin down specifications with high detail: purity usually lands above 98% by GC, acid value and water content requirements keep in step with typical industry needs. Labels must include hazard information per GHS standards, especially because the ester can irritate skin and eyes, and it’s flammable. UN shipping numbers and country-specific regulatory details go right on the drums and bottles. Batch numbers stay visible for traceability, which can make a big difference if there’s any recall or quality check.

Preparation Method

Production stays pretty direct—start with 6-chlorohexanoic acid and react it with methanol, using an acid catalyst like sulfuric acid or p-toluenesulfonic acid. After refluxing the mix, chemists typically separate out water and excess methanol through distillation, then purify the ester from remaining acid with aqueous washings. This core esterification mirrors classical methods described in the org chem canon. Scale-ups in the factory lab lean on stainless steel reactors and in-line azeotropic distillation to handle larger volumes.

Chemical Reactions & Modifications

Lab teams embrace methyl 6-chlorohexanoate for the chloro leaving group and the flexible ester moiety. The compound works well in nucleophilic displacement, giving access to 6-substituted hexanoates when replaced by amines, alkoxides, or thiols. Reduction with LiAlH4 or borohydride sources turns the ester into 6-chlorohexanol, an upstream chemical for surfactants or fragrances. If you want to swap the chlorine, base-mediated elimination or metal-catalyzed cross-coupling opens the door to more elaborate chains. The methyl ester resists hydrolysis in neutral or slightly acidic aqueous environments but flips over with strong bases or acids for conversion to the parent acid or related derivatives.

Synonyms & Product Names

Depending on geography or supplier, methyl 6-chlorohexanoate often appears as methyl caproate, 6-chloro-, or 6-chlorocaproic acid methyl ester. Chemical abstracts generally catalog it as M6CH, and catalogue numbers vary between Sigma-Aldrich, TCI, or local producers. These synonyms help laboratories and purchasing departments track down the right bottle among inventories, especially when regulations or languages differ across borders.

Safety & Operational Standards

Handling guidelines make a real difference. Operators wear goggles, gloves, and lab coats—no exceptions. Good ventilation and fume hoods remove vapors, while storage away from heat and ignition sources avoids accidents. SDS sheets spell out first-aid, spills, and firefighting guidance, reflecting years of lab safety feedback and regulatory cycles. Fire risk calls for foam or CO₂ extinguishers, and emergency plans need to cover accidental exposure. Workers regularly review updated local and international standards since enforcement audits keep rising in frequency.

Application Area

The biggest names in specialty chemicals use methyl 6-chlorohexanoate as an intermediate. Agrochemical firms snap it up for halogenated herbicides or growth regulators. In the pharma sector, it slides into multi-step routes, setting up the backbone for prodrugs or active metabolites, especially if you want to get creative with lipophilicity or metabolic stability. Polymer labs view it as a monomer or modifier, sometimes as a way to test surface reactivity before upscaling custom plastics. Perfume and flavor companies might look at its alcohol derivatives, since the chain length lines up with notes found in natural scents. Contract manufacturers worth their salt keep some on shelves for quick access.

Research & Development

R&D labs see methyl 6-chlorohexanoate as a way to explore new synthesis pathways for surfactants, biodegradable plastics, and even advanced lubricants. Structure-activity relationship investigations lean on it when testing longer-chain substitutions or targeting slow-release functionalities. Green chemistry teams keep working on alternative catalysts and recycling pathways, hoping to trim waste from esterification runs or swap out strong acids for less corrosive alternatives. High-throughput synthesis robots can churn through variant reactions in a day, giving solid data on which modifications pay the biggest dividends downstream.

Toxicity Research

Safety researchers rarely leave toxicity questions to chance. Animal and cell studies check for acute effects, and most results show low to moderate irritancy, mainly from the chloro group. Chronic exposure studies in rats or mice point to liver or enzyme changes only at high doses, but real-world use stays far from those thresholds. Toxicologists write up thorough reports that circulate with regulatory submissions, and new computational tools now help flag long-term or low-level risks well before any incidents surface. Industrial hygienists use these findings to structure workplace monitoring and establish safety margins.

Future Prospects

With regulations pushing the chemical industry toward safer and more sustainable intermediates, methyl 6-chlorohexanoate now faces regular review. Companies look at bio-based synthesis routes, aiming to lessen reliance on petroleum-derived inputs or hazardous waste. Academic groups keep testing catalyst innovations, hoping to slice energy costs and CO₂ output. Pharma continues to probe its chain modifications for potential oral drugs, and coatings engineers experiment with it for specialty surface treatments offering durability and flexibility. Progress moves with practical demand, pushing research and production to do more with less. The next decade will likely see greener protocols, expanded use in functional materials, and data-driven safety improvements sticking closer to end-user and environmental health.

Understanding Its Place in Chemical Manufacturing

Methyl 6-chlorohexanoate shows up in chemical plants more often than most realize. Labs use it as a building block for bigger molecules. The structure—a six-carbon chain with a methyl group at one end and a chlorine atom tucked further down—lets researchers build all sorts of things off it. Turning to real-world experience, it’s clear that this compound keeps popping up in the synthesis of pharmaceuticals, agrochemicals, and specialty polymers.

Gateway to Pharmaceuticals and Agrochemicals

Making certain medicines gets easier with methyl 6-chlorohexanoate. Chemists often pick derivatives of hexanoic acid as starting points because they bring stability and easy modification. The methyl ester protects one end of the molecule. The chlorine atom hangs there like a handle, practically begging another molecule to replace it—an obvious target for making more complicated compounds.

I remember a project in grad school involving nerve agent antidotes. Our first step involved swapping out chlorine and tacking on a new functional group. Yields climbed and cleanup took less time because the compound behaved predictably. Friends still working in agricultural research mention a similar story—building blocks like this one cut down on costs and accelerate product development cycles. Patent records for crop protection products show methyl 6-chlorohexanoate’s name comes up in routes to new herbicides and plant growth regulators.

Polymer and Material Science

Beyond medicine and farming, this molecule paves the way for specialty polymers. Its structure allows chemists to introduce side chains or crosslinks where needed. Some high-performance plastics rely on finely-tuned monomers for flexibility or resistance to harsh chemicals. Intermediates like methyl 6-chlorohexanoate help keep these supply chains alive.

Environmental and Safety Concerns

While working with any chlorinated compound, safety and environmental responsibility require attention. Chlorinated intermediates sometimes resist breaking down in nature. Runoff and improper disposal introduce risks to soil and water. From my own time on safety committees, I learned regulators want tighter documentation of these chemicals. The industry response has leaned toward better containment systems, traceability, and even recycling efforts where possible. Sustainable chemistry isn’t just a buzzword anymore; companies face growing pressure to limit environmental impacts at every step, starting from core ingredients.

Room for Practical Solutions

Reducing any downside begins with process efficiency. Manufacturers benefit from reactors engineered to minimize waste. Swapping in greener reagents cuts down on side products that linger in wastewater. Education also plays a role. Workers in factories get hands-on training to keep leaks in check and avoid accidents. Community outreach helps local residents understand what’s happening next door and how risks get managed.

Sourcing greener feedstocks remains tough for some specialty chemicals. Still, research pushes ahead, looking for chlorine-free routes or biodegradable substitutes. Industry partnerships with universities make a real difference here, as new discoveries take shape faster when scientists and manufacturers pull in the same direction.

Why Attention Matters

Methyl 6-chlorohexanoate may not attract daily headlines, but people who rely on safe medicines, clean food, and resilient materials end up depending on it. The story of this one chemical speaks to the broader web of responsibility, innovation, and real-world impact threading through today’s chemical sector. Progress follows when everyone—chemists, regulators, and community leaders alike—stays engaged and committed to safer, smarter use of critical intermediates.

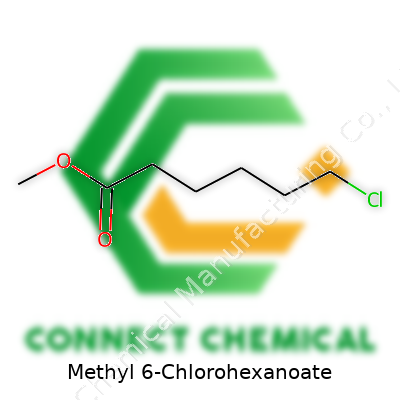

Chemical Formula: C7H13ClO2

Methyl 6-Chlorohexanoate stands out as a compound not just for its formula, C7H13ClO2, but for the impact this molecule has on industrial and research settings. The molecular structure places a chlorine atom at the sixth carbon of the hexanoic acid backbone, with a methyl ester functional group. For people getting their hands dirty in organic synthesis, the placement of even a single chlorine atom changes everything—from reactivity to safety measures.

I remember a graduate student struggling to get a reaction to work, only to discover that a simple misplacement of a chlorine atom threw off the entire synthesis route. In the case of this compound, a methyl ester makes it more volatile than its acid relative, and the chlorine atom pushes the reactivity up another notch. This means labs must pay close attention to not only the chemicals themselves but also the storage, waste, and possible byproducts.

Why C7H13ClO2 Matters in Research

Researchers often use molecules like Methyl 6-Chlorohexanoate as intermediates—stepping stones to more complex pharmaceuticals or specialty chemicals. Halogenated esters show up all over synthetic routes because their structure lets chemists swap or build new bonds with a bit more control. Each atom in the formula serves a purpose: seven carbons for backbone flexibility, thirteen hydrogens for stability, chlorine for targeted reactivity, and the two oxygens to anchor the ester functionality.

According to the National Center for Biotechnology Information, halogenated esters sometimes find roles as flavors, fragrances, or even as markers in biochemical experiments. There’s a safety trade-off, though: compounds containing both chlorine and ester groups can be harmful if not handled with care. Toxicity studies have shown possible irritation risks. Researchers need gloves and eye protection, and it’s wise to handle this compound under a fume hood.

Challenges and Safety Concerns

Problems can pop up if attention slips. The formula points to a molecule that’s both lipophilic and reactive. I know a chemist who learned the hard way that a single drop can linger in a glove if not washed off right away. Chlorinated organics, including this ester, resist breakdown and sometimes stick around in wastewater if not monitored. Factories and universities keep records of their use, both because of workplace safety and environmental rules.

Pollution risk links back to the chemical’s structure. Halogenated byproducts sometimes work their way into natural water supplies. Some researchers recommend more rigorous waste treatment systems in labs and industry. One solution involves activated carbon filters and controlled incineration, both proven over years of handling similar compounds. Others call for using less toxic alternatives whenever possible. It takes commitment from every lab and facility to put health and environmental impact front and center.

Looking Beyond the Formula

Understanding the chemical formula, C7H13ClO2, does more than check a box on a test. For chemists, environmental specialists, and even the communities near production sites, this knowledge helps keep people safe and encourages smarter choices. People handling chemicals day in and day out know the responsibility that comes with each flask or bottle with a complicated name and number. Methyl 6-Chlorohexanoate sums up how even a simple formula can spark important conversations and shape decisions in the real world.

A Closer Look at the Chemical

Methyl 6-Chlorohexanoate has a reputation in the chemical world: it’s a colorless liquid, known for both its usefulness and its demanding nature. It plays a part in creating pharmaceuticals and specialty chemicals. Anyone who’s worked in a lab, even doing something as simple as cat litter experiments in college, will recall how a single missed safety step leads to a headache, or worse.

Keeping It Stable Starts with Temperature and Air

Let’s be honest. Too many chemicals end up wasted or hazardous because someone ignores the basics. Methyl 6-Chlorohexanoate sits on that list. Store it tight and dry, away from any stray sunlight or heat. Heat does more than just evaporate liquids—it can trigger unwanted chemical changes, and with chloro-compounds, that risk sits even higher. Leave a container open or in a humid, warm spot, and the chances of contamination multiply.

In practice, this means picking a space with consistent air conditioning, where the thermometer rarely drifts from room temp, usually around 20-25°C (68-77°F). Storage near ovens, radiators, or under intense lights invites trouble. Even in warehouses, sunlight sneaking through a high window can wreak havoc over a few weeks.

Containers Matter for purity and Safety

Glass often works best, but some thick, well-sealed plastic bottles also do the job. It’s tempting to reuse random jars; I’ve seen enough labs where Tupperware pops up next to properly labeled reagent bottles. These shortcuts always come with risks: certain plastics can break down, leaching unexpected things into your stored liquid. Make sure containers show clear chemical-resistance and sealing. Labels should be waterproof, legible, and right side up—no half-torn masking tape.

Keep Water and Oxygen Out

The moment moisture or air finds its way in, Methyl 6-Chlorohexanoate can shift. Hydrolysis brings unwanted byproducts and can harm both experiments and health. Busy environments make slips easy. A simple solution: stick with tight seals and only open what’s actually needed. In my experience, prepping ahead and drawing up measured samples saves time and cuts down on exposure.

Avoiding Accidents and Emergencies

Every lab disaster starts with a small act—a forgotten cap, a spill, or a misplaced bottle. Chemistry textbooks always say, “keep incompatible chemicals apart,” but real-life slips often come from a crowded shelf, not carelessness. This chemical reacts with strong oxidizers and acids, so keep it apart from cleaners, bleach, and strong acids. Never stack it near eye-level—spills and splashes move downward fast. Even short exposure can irritate skin and eyes, so gloves and goggles become a daily habit, not a chore.

Old Stock and Responsible Disposal

The longer a bottle sits, the greater the chance of decomposition or contamination. Review dates on all chemicals monthly and rotate through older stock before opening new bottles. Any weird smells, discoloration, or crystals on a cap signal the need for safe disposal. Local regulations often require special handling for halogenated chemicals. Find out the process, train staff well, and keep the emergency spill kit stocked and easy to reach.

Building a Culture Around Chemical Care

Respect for chemicals, even those handled daily, runs deeper than rules and stickers. Safe storage of Methyl 6-Chlorohexanoate reflects habits formed from good training and vigilance. Every safe, clean storage area in a lab or warehouse comes down to people who look out for one another and fix small problems before they grow. Experience—my own and that of those before me—shows that attention to these basics keeps both people and products out of trouble.

Understanding the Substance

Methyl 6-chlorohexanoate shows up as a clear liquid, often used in organic synthesis and specialty chemical production. Factories and labs work with it for various experiments or as a building block for more complex molecules. On the surface, it does its job discreetly, but the safety information tucked in the fine print is worth a real look.

Human Health Considerations

Chemical safety isn’t just about catastrophic risks; sometimes small exposures matter. For methyl 6-chlorohexanoate, the Material Safety Data Sheets flag irritation as a main concern. Splash some on your skin or eyes, and you’ll get redness, discomfort, maybe even burns if it lingers. Accidental inhalation causes coughing, headache, and irritation in the throat and airways. Swallow it and nausea might follow—this isn’t something that should ever end up near food or drink.

Long-term studies on methyl 6-chlorohexanoate in people stay limited. That’s not a green light for casual handling, it’s an indicator to stay cautious and assume the risks extend further than we know. Similar ester compounds break down in the body into alcohol and acid byproducts. Some cases show chronic exposure to comparable chemicals leading to nervous system effects or liver stress. Personal experience and the experience of chemists I know: Going without gloves or goggles, even for a couple of minutes, ends with regret. Eyes sting, skin itches—simple mistakes, immediate reminders that safe handling isn’t optional.

Flammability and Storage Risks

This compound is flammable. Spills near ignition sources quickly spiral out of control. Storage next to acids, oxidizers, or open flames can bring dangerous reactions. Flammable liquid cabinets, proper ventilation, spill trays, and clear protocols make a difference. I’ve seen labs lose thousands in equipment from small fires that grew because a flammable liquid went unchecked. No experiment needs that level of risk for the price of a secure bottle top or a working fume hood.

Environmental Fate

Toxicity stretches beyond direct health impact. Methyl 6-chlorohexanoate gets into water, it doesn’t just vanish. The chlorine atom means aquatic organisms likely face higher consequences than with similar non-halogenated esters. Fish or invertebrates exposed can suffer from toxic buildup, with effects on reproduction, growth, and survival. Fact: Lower concentrations harm small aquatic life before big animals ever register a change.

Practical Steps Forward

Reducing risks starts with solid training. Everyone working with this compound should have real information, not just paperwork. Clear labeling, glove policies, and working fume hoods matter. Using less hazardous chemicals for routine work—where possible—cuts down overall risk. Waste containers stay locked when not in use and get labeled with every detail, not just a name. Regular safety audits catch problems early, long before exposure climbs or accidents break out.

Ultimately, methyl 6-chlorohexanoate deserves respect—not alarm, not dismissal. It’s a useful compound with real dangers, both obvious and hidden. Through better practices, honest conversations, and clear eyes on the risks, people and the environment gain more protection than any label or warning alone could offer.

What Methyl 6-Chlorohexanoate Looks and Feels Like

Methyl 6-Chlorohexanoate draws some interest from chemists working with specialty esters. This chemical appears as a colorless to pale yellow liquid, which often gives a clue about its chemical purity and handling. Chemicals of this structure don't solidify at room temperature, making liquid storage and transport more straightforward compared to powders or solids.

With a molecular formula of C7H13ClO2, the substance sits in the category of medium-chain esters. The “methyl” part of the name points to a methyl group attached to the carboxyl end, and the “6-chlorohexanoate” rolls off the tongue as a six-carbon chain with a chlorine atom on the sixth carbon. The chain length and the ester functional group push the boiling point much higher than simple short-chain esters, providing some stability during chemical reactions and storage.

Boiling and Melting Points

If you hold a flask of Methyl 6-Chlorohexanoate, you will not notice it turning solid in the freezer or at room temperature. Its melting point sits far below normal room temperatures, making it a liquid for most lab applications. For boiling, this ester does not vaporize easily in an open room. Its boiling point hovers around 230°C, which is a helpful property for chemists who need a solvent or reactant that doesn't vaporize and escape at moderate temperatures. Lab experience tells me that unusually volatile esters are a headache, so this property cuts down on chemical loss and reduces inhalation risks around the lab bench.

Density and Solubility

The density of Methyl 6-Chlorohexanoate falls between 1.04 to 1.06 g/cm3. That's a bit higher than water, but it means if you pour this into water, it will mostly sink. This density difference often comes with halogen-containing organics. Speaking personally, handling chemicals of this density often makes precise liquid measuring easier compared to lighter solvents.

Pour a bit of this ester into a beaker of water, and they separate rapidly. Methyl 6-Chlorohexanoate doesn’t mix with water; its hydrophobic chain and only a single ester functional group mean limited hydrogen bonding. This keeps it out of water-based solutions but makes it perfect for organic extractions. In practice, it dissolves well in organic solvents like ether, acetone, or dichloromethane—chemicals you reach for in synthesis work or purification steps.

Odor, Stability, and Handling

Some esters hit your nose with fruity or floral scents, though this one leans toward a faint, sweetish odor—hardly overpowering. In the lab, a strong smell often signals volatility, but here, the subtlety means vapors stay low unless the stuff is heated up. Storage stays worry-free if you keep it away from strong oxidizers and sources of ignition. Based on hands-on lab routines, keeping organochlorine esters in tightly sealed containers prevents evaporation and contamination.

Why These Properties Matter in the Real World

Chemicals used in industry and labs prove their value through physical properties. The high boiling point cuts down on accidental losses in heated processes. Low solubility in water fits extraction work or when you need separation from water-based mixtures. In chemical research, I look for these characteristics to decide if a molecule suits a given reaction or process. Workers and researchers benefit from handling stable liquids over fumes or unstable solids.

Improving safety means respecting the substance’s density and vapor pressure, using appropriate gloves, glasses, and ventilation. If clients seek greener chemistry, sourcing esters with lower protein and DNA reactivity offers fewer risks in health and safety. Training techs to understand these basic properties pays off, whether handling five grams or five hundred liters.