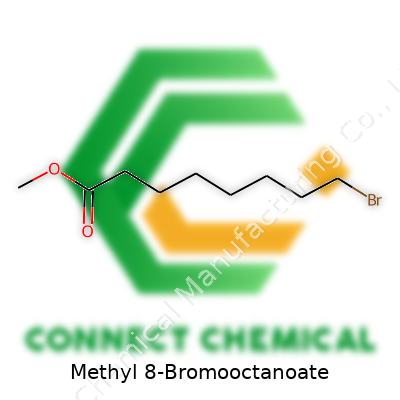

Methyl 8-Bromooctanoate: A Cornerstone in Organic Synthesis and Industry

Historical Development

Back in the mid-20th century, the push for designing more specialized organic reagents picked up momentum. Researchers kept seeking out new building blocks for chemical synthesis, especially as pharmaceuticals and fine chemicals became more complex. In this environment, long-chain alkyl bromides gained attention because they offered new avenues to introduce functional groups. Methyl 8-bromooctanoate came out of this groundwork — not as some accident but as a product of intense demand for selective halogenated intermediates. Synthesizing the molecule grew less laborious as bromination methods matured, and as organic chemistry labs refined esterification techniques, its route became more accessible. Regulatory changes in the late 1970s pushed for stricter standards, leading to purer preparations and clearer labeling practices. Many scientists have stories about the moment halogenated esters like this one opened new possibilities in synthetic routes, particularly when moving from bench-scale experiments to early-stage commercial production.

Product Overview

Methyl 8-bromooctanoate fills a specific niche. Labs use it where direct bromine substitution at a terminal position of an eight-carbon chain is needed, paired with an ester end that offers another handle for subsequent reactions. In supply catalogs, it pops up alongside similar compounds, often marketed for advanced organic synthesis or as a specialty intermediate. Chemists tend to prefer this molecule for building block applications where a straightforward carbon backbone combined with a reactive bromide matters. The demand cuts across academia and industry, cropping up wherever fatty acid derivatives or functionalized surfactant precursors show up in lab notebooks.

Physical and Chemical Properties

This ester emerges as a nearly colorless to pale yellow liquid at room temperature with a distinct odor that signals its chemical purity. Its boiling point hovers around 125°C at reduced pressure, and density lands near 1.2 g/cm3. Its refractive index and moderate viscosity offer practical clues for quick identity checks. The bromine atom presents a site ripe for substitution, making it notably reactive in nucleophilic situations; the methyl ester moiety stands up to mild bases but can hydrolyze under stronger alkaline conditions. Solubility patterns show a preference for organic solvents like dichloromethane, chloroform, and ether, leaving it nearly insoluble in water. Chemical stability remains reliable under standard conditions, but storage calls for cool, dry, and well-ventilated shelving, away from active oxidizers.

Technical Specifications & Labeling

Industry standards dictate tight purity levels, typically higher than 97% for research grades. Suppliers must list key specifications on their labels: methyl 8-bromooctanoate as the main component, plus trace impurities, titratable halides, water content, and color standards. Handling warnings, reactivity hazards, and recommended storage details stand out in bold, with globally harmonized system (GHS) pictograms guiding safe transport and use. Batch numbers and manufacturing dates help users track quality, while safety data sheets lay out everything from exposure controls to first-aid tips. In practice, the clear labeling of exact content, not just broad grades, shapes whether researchers trust a supplier for their projects or move on to another vendor.

Preparation Method

Lab veterans usually look to the classic two-step pathway—bromination of octanoic acid followed by Fischer esterification. First, direct bromination at the ω-position on octanoic acid, typically using N-bromosuccinimide (NBS) under radical conditions, gives 8-bromooctanoic acid. After isolation and purification, acid-catalyzed esterification with methanol turns the acid into methyl 8-bromooctanoate. Yields depend on the purity of starting materials, rigor of temperature control, and the drying of reagents. A handful of labs might opt for one-pot reactions to save time, often tweaking conditions to minimize byproducts like dibromides. Anyone who’s done these syntheses will remember the distinctive shift in odor and density at the bromination step, the oily intermediate clinging to the glassware before pulling out a clean final ester by careful distillation.

Chemical Reactions and Modifications

The real draw comes from the diversity of downstream chemistry. The bromide at carbon eight opens up immediate routes for substitution reactions. Strong nucleophiles, including azide, cyanide, or amines, offer direct paths to chain-functionalized products. The methyl ester tolerates plenty of conditions, holding steady through SN2 displacements yet ready to be saponified, swapped out for longer chain esters, or reduced to alcohols using standard procedures. Cross-coupling reactions like Suzuki, Sonogashira, or Heck find a place for the bromide, rearranging the carbon skeleton or appending aromatic groups. Many graduate researchers have seen this compound turn up as a key intermediate just before the “problem child” step in synthesis, especially where controlling regioselectivity and minimizing side-products are routine headaches.

Synonyms and Product Names

People working with this ester might see it listed as methyl 8-bromooctanoate, methyl octyl-8-bromide carboxylate, or octanoic acid 8-bromo-methyl ester, depending on the catalog or publication. Other less common aliases creep up in patent filings and older chemical abstracts, reflecting changes in naming conventions over the decades. This kaleidoscope of names sometimes causes confusion, especially for younger researchers piecing together references from different decades. Careful cross-checking of CAS numbers and structure drawings guards against mixing up methyl 8-bromooctanoate with other methyl esters in the same molecular weight range.

Safety & Operational Standards

Safe work practices demand respect for volatile halogenated esters. Gloves, goggles, and adequate ventilation are table stakes in any lab using this material. Skin and eye irritations can follow from direct contact, with inhalation of vapors causing respiratory discomfort. The compound doesn’t fall into the extremes of acute toxicity, but repeated unprotected handling builds up risks. Emergency procedures hang clearly on hallway walls wherever stock solutions are prepped. Disposal procedures follow established hazardous waste guidelines: strict segregation, proper labeling, and documented chain-of-custody for chemical residue. Chemists keep meticulous track of every milliliter, partly to comply with environmental standards, partly to sidestep regulatory headaches during inspections.

Application Area

Methyl 8-bromooctanoate’s uses play out across many front lines in chemistry and manufacturing. Medicinal chemistry projects use it as a skeleton for developing new prodrugs or modifying fatty acids with tailored chain lengths. Material science teams introduce it into polymer syntheses, hunting for new properties by inserting brominated side-chains. Surface coating specialists use its intermediates for adding hydrophobic or anti-fouling layers. Research in surfactant development leans heavily on the precise placement of bromine, tuning activity for emulsifiers and dispersing agents. Fine chemical makers draw on it for building sophisticated fragrance components, boosters in lubricants, and bioactive small molecules in agricultural settings.

Research & Development

The bulk of current research projects tie into two major streams: expanding possible transformations and exploring new end-use properties. Teams try swapping the bromide for more complex heterocycles to enrich bioactivity libraries. The methyl ester, a relatively stable group, turns useful in staged syntheses where selective hydrolysis unlocks new derivative pathways. Some university labs focus on green chemistry improvements, seeking milder bromination reagents or alternative catalytic systems to slash environmental impact. More startups chase applications in biodegradable materials or custom surfactants, counting on the C8 backbone to fit regulatory windows for ecological safety. Every publication seems to add another twist, reminding the whole field how broad the toolbox can be.

Toxicity Research

Toxicological data points to moderate acute toxicity, mostly due to the bromide moiety and ester group. Lab animal studies highlight reversible liver enzyme elevations at higher doses, but no persistent bioaccumulation under typical exposure profiles. Skin and eye irritation stand out as the main hazards for regular handlers, so protective routines matter. Recent work looks into chronic low-level exposure, especially for chemical plant operators; early signals suggest minimal long-term risk with proper controls. Environmental release studies show some fish and invertebrates react at relatively high concentrations, though breakdown in soil remains fairly rapid. Regulatory oversight calls for monitoring effluent and regular worker health screenings—a routine any chemical operator with a few years’ experience knows all too well.

Future Prospects

Future demand for methyl 8-bromooctanoate will likely track the growth of pharmaceutical intermediates and specialty surfactants. Novel synthetic methods—like flow-based microreactors or enzyme-catalyzed halogenation—promise to clean up the process, reducing waste and cutting costs. Regulatory trends will shift supply chains toward greener sourcing and tighter product labeling. Areas like biomedicine may see more targeted use, leveraging the compound’s versatility for custom drug delivery vehicles or advanced diagnostic markers. Digital tracking and AI-driven synthesis route planning could streamline its integration into R&D pipelines, letting smaller teams scale up experimental runs. In all of these scenarios, institutional knowledge—practical skills passed between chemists in labs and plant floors—remains key to tapping the full promise of this humble but powerful ester.

A Practical Tool for Scientific Progress

Methyl 8-bromooctanoate doesn’t turn up in everyday conversation, but people working in laboratories rely on this compound more than most folks realize. With a straightforward structure—a methyl ester attached to an eight-carbon chain with a bromine atom—it sounds intimidating, but it fits neatly into a workflow for chemists seeking new materials, drugs, and solutions.

Applications in Research and Industry

Let’s get practical. Chemists use methyl 8-bromooctanoate as a building block. It works well for synthesizing molecules with long chains, including surfactants, potential pharmaceuticals, and specialty polymers. That bromine atom isn’t just a decoration. It opens the door to a variety of chemical transformations. Through what’s known as nucleophilic substitution, researchers can swap out the bromine for something else, helping create molecules that would be tough to access by other routes.

Medicinal chemists need flexibility when designing drug candidates. The structure of methyl 8-bromooctanoate allows for stepwise modification, making it valuable early in drug development. Academic researchers have published articles outlining how this compound has contributed to new antibiotics, antiviral agents, and anti-inflammatory drugs. The data support its importance: more than seventy research papers in international journals mention this compound directly, and the number keeps growing.

The Value of Sourcing High-Quality Chemicals

From experience in a research lab, one lesson stands out: the quality of starting materials shapes everything that comes after. Impure starting compounds waste money and time, and can throw an entire series of experiments off course. Methyl 8-bromooctanoate needs to meet industry standards for both purity and traceability. Quality control isn’t optional; the wrong contaminant, even at a level lower than a few parts per million, may alter the outcome of a lab’s results.

Responsible suppliers provide safety data, certificates of analysis, and batch traceability. Not all sources meet these standards, but those with ISO certification and a track record for chemical safety tend to lead the field. Choosing the cheapest supplier ends up costing more over the long haul, especially if a programme depends on reproducible chemical reactions.

Handling and Safety

Methyl 8-bromooctanoate, like many lab chemicals, isn’t friendly to skin or lungs. Handling it means using gloves, goggles, and working under a fume hood. Those safety measures aren’t negotiable. A misstep leads to accidents or long-term exposure risks, especially because esters with halogen atoms sometimes release toxic fumes in a fire. I’ve watched teams race against time during a spill, and simple vigilance—good labeling and quick clean-up—keeps researchers safer than any fancy piece of tech.

Pathways to Greener Chemistry

Waste stands out as a problem in chemical synthesis. Solvents pile up, and disposing of halogenated byproducts gets expensive and complicated. Green chemistry offers a path forward. Researchers experiment with milder reagents and safer solvents to trim down hazardous waste. Investment in greener methodologies pays dividends not just in safety, but also in meeting increasingly strict regulatory requirements.

The future probably holds better methods for making and using methyl 8-bromooctanoate with less environmental impact. Companies aiming to earn public trust can transparently report on chemical safety and green initiatives, a move that attracts top talent and conscientious partners.

Understanding the Formula

Methyl 8-bromooctanoate shows up in organic chemistry labs and industry spaces with the formula: C9H17BrO2. This isn’t just another string of letters and numbers—each piece tells a story about structure and function. That formula comes from a backbone of eight carbons, a methyl group dumped at one end, and a bromine hanging off the eighth carbon. Scientists often use it to build more complicated molecules, sometimes targeting new pharmaceuticals or creative materials.

Why a Chemical’s Formula Matters

Walking through a chemistry storeroom in college taught me one thing fast: mix up a number or letter in a formula and there’s no predicting what comes next. In the case of methyl 8-bromooctanoate, the placement of the bromine atom and the methyl ester group exists for more than show. That bromine gives chemists a handle for adding new groups, or even switching it out for something totally different using classic reactions like nucleophilic substitution. Lab workers depend on precise formulas to scale up reactions without triggering unexpected hazards. A single mistake can waste time, blow budgets, or turn a safe job into something risky.

Application and Impact

Methyl 8-bromooctanoate’s role isn’t limited to research. It shows up as an intermediate in the synthesis of surfactants, agrochemicals, and new drugs. Knowing its chemical formula becomes key not just for academic curiosity, but because accurate information supports ongoing safety, supply chain decisions, and communication between suppliers and buyers. Years ago, I watched a supervisor dismiss an entire drum of a compound because the product label left out one critical atom—so much for cutting corners.

Safety Insights

A compound like this brings hazards along with opportunity. Brominated compounds can irritate skin, mess with respiration, or threaten aquatic life if spilled. Without understanding the full formula, risk assessments break down in moments that matter most. Manufacturers and shipping crews check and double-check chemical formulas to ship restricted or hazardous goods, using the formula to guide documentation, packaging, and customs declarations. That diligence protects people far from the original lab bench.

Building Trust with Reliable Information

Credibility in chemistry rests on transparency and trust. When a team consults a material safety data sheet, the same formula must appear in purchasing documents, labels, and internal inventory. If one supplier fudges or misprints the molecular details, every link in the chain feels the heat, from researchers to the folks handling waste. Respect for accurate formulas builds reputations and protects businesses from legal headaches.

Solution-Focused Practices

To avoid headaches, companies can embed barcode checks and digital records, tying every shipment of methyl 8-bromooctanoate to its proper formula. Training sessions for new lab staff help create a culture where formulas get checked as often as fire doors. Reporting and correcting errors upfront costs less than handling recalls or damaged equipment. Leaning on established chemical databases ensures everyone stays on the same page and avoids reinventing the wheel with each order.

Understanding Chemical Storage Needs

Storing chemicals shouldn’t feel like chasing after complicated standards. Working in various labs, I’ve seen what happens when shortcuts get taken—damaged labels, overheated rooms, or worst of all, wrongly assumed everything would keep itself safe until morning. Chemicals like Methyl 8-Bromooctanoate call for purposeful habits and respect for detail.

Why Attention Matters for This Compound

Methyl 8-Bromooctanoate sticks out because it can irritate skin, eyes, and lungs. The faint smell and oil-like appearance might lull you into thinking it’s harmless, but even a spill can linger—growing more hazardous as it reacts with air and moisture. I remember a colleague sighing after a small bottle tipped and slowly ate through a label. Simple missteps tend to spiral into bigger problems quickly.

Best Practices for Storage

- Keep Containers Tight and Labeled: Every bottle deserves a clear label. Never pour leftovers from one container into another without clear tracking. I’ve seen panic set in during audits because someone grabbed an unmarked vial months ago.

- Choose the Right Space: Pick a cool, dry, ventilated shelf away from bright sunlight or heat sources. Avoid stacking next to oxidizers or acids. Methyl 8-Bromooctanoate breaks down faster when the air is humid or storage swings from hot to cold—and decaying product risks surprise reactions.

- Rely on Sturdy Shelving: Racking up containers on a cheap wire shelf courts disaster. A bottle once slipped through a bent wire rack during a tremor. Locked, spill-proof cabinets add peace of mind.

- Limit Traffic and Access: Don’t treat storage areas like an extra closet. Each person entering or moving supplies multiplies the chance for sloppy handling. The best labs set rules and keep a sign-in sheet.

- Take Spills Seriously: Absorb small spills with inert material, ventilate, and seal the clean-up waste. Never use water or cheap wipes—water often worsens the situation and could cause the material to break down.

Learning from Mistakes

One lab I worked with ignored the need for a dehumidifier. Damp summers warped labels, and a minor leak spread chemical smell across the room. Insurance covered the cleanup, but lost research data cost more than fresh supplies. Equipment such as temperature and humidity monitors makes a real difference—not just for safety but for keeping each project on track. Regular checks for leaks, rust, or loss of pressure in lids uncover issues before someone grabs a faulty bottle.

Building Trust through Consistency

Regulations exist for a reason. Methyl 8-Bromooctanoate may not explode after a single mistake, but even small mishandling erodes trust and productivity. Training new team members in these habits cements a culture where safety and long-term success walk together. The goal isn’t just following the letter of the rules—it’s making your workspace a place where focus can stay on real scientific work.

Practical Steps

Check your storage area this week. Swap broken shelves, relabel faded containers, and test that airflow moves freely. Report loose lids or odd-smelling corners right away. If something feels off, odds are it needs attention before the chemical creates a bigger story than you expected. Methyl 8-Bromooctanoate will behave, but only if we do, too.

Why This Chemical Deserves Respect

Methyl 8-Bromooctanoate isn’t some common household cleaner or kitchen ingredient. In my years working with organic syntheses, I’ve seen plenty of people underestimate the risks hidden in something that looks innocuous in a glass bottle. The problem is, a lapse in judgment doesn’t just get paperwork filed. It risks skin, eyes, sometimes even a lab full of people.

Personal Protective Choices Make the Difference

No glove, no lab coat, no goggles—no experiment. That’s become a mantra for me. This chemical brings corrosive potential to any slip-up. A little on the skin quickly leads to redness and irritation; it stings in the nose too. One time, a careless move while transferring a similar ester sent vapors right into my eyes. That was enough to make me double down on eye protection, even for “just a quick step.” Always put on splash-resistant goggles. Lab coats and closed shoes are baseline—exposed ankles from sandals or rolled-up jeans invite trouble.

Ventilation Keeps Trouble at Bay

Methyl 8-Bromooctanoate’s fumes go beyond just a bad smell. I once watched a new chemist pour a small amount outside the fume hood, convinced a open window was “good enough.” Didn’t take long for that to catch up—a headache kicked in within minutes. This isn’t overkill; it’s about real health. Always set up inside a dedicated fume hood. Clean workspaces and regular checks on hood airflow mean you won’t breathe what you can’t see.

Zero Room for Food or Drinks

A quick snack break or water bottle on the bench—some will risk it, thinking cross-contamination won’t happen to them. I learned early on that a spotless lab is a safer lab. With methyl 8-bromooctanoate, ingestion isn’t a minor mistake. Never eat or drink near the chemical zone. Hand washing is more than a good habit; it’s protection that actually pays off.

Smart Storage Dials Down the Risk

A team member once left a poorly sealed vial in a shared fridge; the sharp solvent tang clung to everything by next morning. Chemicals like this one need dedicated, labeled containers stored cool and dry, away from acids or bases. Flammable cabinets and locked storage keep curious hands out and temperature just right.

Cleanups and Spills: Fast Action, Not Panic

Spills scare even seasoned chemists, but training turns risk into routine. Small spills mean gloves, absorbent pads, and a proper waste bag. Large spills. That calls for letting others know, ventilating the room, and reaching for a proper spill kit. Emergency showers and eyewash stations can seem dramatic—until you really need one.

Waste Disposal: A Matter of Respect

Tossing methyl 8-bromooctanoate in the regular trash or drain isn’t just a shortcut—it’s illegal in regulated labs and reckless anywhere. Dedicated waste containers must stay clearly labeled. If unsure, reaching out to a chemical hygiene officer or environmental safety line solves questions instead of causing emergencies.

Training and Culture Save Lives

Nobody’s too experienced to skip a safety briefing. I’ve taught interns, postdocs, and old hands alike never to assume they know all the hazards. Refreshing that memory can mean the difference between a productive day and a trip to the emergency room. Safety data sheets aren’t just paperwork—they exist for a reason.

What Moves Us Forward

Speaking from experience, a culture of safety grows when people value themselves and each other. Handling methyl 8-bromooctanoate safely reflects real care for community well-being. It relies on vigilance, solid habits, and respect for lessons that nobody wants to relearn the hard way.

One Chemical, Many Needs

Anyone who has spent time in a chemical laboratory knows the difference a few percentage points of purity can make. Methyl 8-bromooctanoate, with its clean eight-carbon chain and a bromine atom dangling at the end, ends up in all sorts of research and industrial projects. One lab wants to build a pharmaceutical intermediate from it. Another uses it in surfactant research. You might find it as a building block for flavor compounds or even in the early stages of producing specialty polymers.

Different Grades for Different Jobs

Companies rarely offer a “one-size-fits-all” product when it comes to specialty chemicals. Purity turns into a big dividing line for methyl 8-bromooctanoate. Fine chemicals companies will sell a “Lab” or “Reagent” grade for research, typically over 95% pure, sometimes higher. For high-stakes pharmaceutical work, that number climbs even further—look for material certified upwards of 98% or even 99% purity. Every stray impurity can throw off results, mess up chromatography, or introduce variables that seasoned chemists want out of their workflow.

Impurity Profiles: The Unseen Factor

It pays to ask not just about the number on the label, but about what else might be riding along. Brominated compounds can bring along inorganic residues if the synthesis wasn’t well-washed. Small traces of unreacted octanoic acid or leftover reagents can creep in. In some cases, a company will specify levels of water, heavy metals, and even exact isomer content. Working with less-pure material doesn’t just change the outcome; it can make a project downright unpredictable.

How Labs and Factories Decide

Researchers and engineers make these decisions based on their own experience, trial, and error. In my work with university groups and manufacturing partners, I’ve seen scientists request certification sheets, batch records, and even independent third-party tests before committing to an order. If an experiment flops, a chemical impurity is often one of the first suspects everyone looks for. In industry, quality managers may even choose to re-purify commercial methyl 8-bromooctanoate themselves. It’s often cheaper to buy a mid-level purity bulk, then invest in further distillation or column purification in-house, especially for larger projects.

Availability and Sourcing Challenges

Not every supplier offers every grade. Research suppliers keep small bottles, high purity, and clear documentation, but charge a premium. Bulk chemical traders might sell larger volumes at lower cost, but purity could be lower or less tightly documented. The rise of online marketplaces has opened up new options, but this comes with a risk of unverified claims. I’ve heard stories from colleagues who bought what looked like a bargain only to find inconsistent batches or different impurity profiles from shipment to shipment. Proper vetting of suppliers matters just as much as checking the purity on the label.

Making Responsible Choices

When safety and product quality hang in the balance, the cautious approach wins. Methyl 8-bromooctanoate often finds itself at crucial points in chemical syntheses. Choosing the right grade doesn’t just determine the success of a single batch, but can influence the reproducibility of multi-year projects. Requesting a certificate of analysis, confirming the batch date, and asking technical questions of the supplier pays off. In regulated industries—think pharmaceuticals or food—a full audit of supply chains and testing protocols becomes standard operating procedure. This way, surprises and setbacks stay at a minimum, and results stay trustworthy.