Methyltributylammonium Chloride: A Comprehensive Commentary

Historical Development

Chemistry often tells stories few expect to find in a laboratory bottle. Methyltributylammonium chloride did not make headlines in early quaternary ammonium compound research, but the development of phase-transfer catalysis and the need for efficient organic synthesis routes pushed it into the spotlight. Scientists in the 1970s started seeing the advantages of ammonium salts that shifted reactions from stubborn solvents into milder, more manageable conditions. Academic curiosity and industrial necessity fueled interest, so demand grew for simpler, scalable, and more environmentally aware processes. Personal experience in teaching organic chemistry confirms that students grasp chemical potential faster when learning about solutions driven by efficiency, not just theory. The journey of Methyltributylammonium chloride shows how minor changes in a molecule’s structure influence the effectiveness of a whole process, hinting that the best chemical is often one that carries a history of problem-solving behind its name.

Product Overview

Ask a synthetic chemist about workhorse reagents, and they often mention compounds that make life easier in the lab. Methyltributylammonium chloride stands out as a phase-transfer catalyst, helping ionic substances react in organic layers where they otherwise wouldn’t. It helps replace harsher conditions with milder ones, making some transformations quicker and safer. Chemical supply catalogs offer graded options, catering to industries needing both bench-top reliability and large-scale performance. From simple alkylation reactions to intricate multistep syntheses, its role stretches far past specialty fields, breaking free from academic journals to solve real-world problems.

Physical & Chemical Properties

This compound shows up as a white, crystalline solid at room temperature. It dissolves well in water but shows keen solubility in several organic solvents, opening doors for mixed-phase chemistry. Boiling and melting points don’t shift with each new batch, giving labs the consistency they count on week to week. The molecular structure—three butyl groups and a methyl group surrounding a central nitrogen—sets the frame for its chemical personality. These characteristics allow it to ferry ions between phases, vital in reactions where organic and aqueous components otherwise keep their distance. That property lies at the heart of greener, more efficient synthetic routes, and it brings value to processes ranging from pharmaceuticals to advanced materials research.

Technical Specifications & Labeling

Commercial suppliers often provide detailed sheets spelling out purity, moisture content, and trace impurities. Labels must reflect the exact batch, grade, and storage recommendations. This transparency goes beyond regulatory compliance; it cuts down on mistakes in sensitive reactions. My own lab work has underscored that cutting corners with reagent quality often costs more time fixing problems downstream. Customers in regulated industries expect certainties about content and contaminants. Exact details on packaging, weight, and recommended storage—often cool and dry, away from light—make sense only when consistently delivered, lest process engineers wind up with months of sludge or failed synthesis.

Preparation Method

Manufacturers synthesize this compound by alkylating tributylamine with methyl chloride, usually in controlled conditions that combine heat, solvent, and pressure to drive the reaction toward completion. Purification steps follow, relying on careful solvent extraction and, occasionally, recrystallization. Waste handling during this process demands responsible disposal, especially since chloroalkanes and residual amines can harm workspace and environment alike. The practical chemistry of its preparation reflects broader industrial moves toward safer, more sustainable chemical synthesis. Working with students in a teaching lab, the lesson holds clear: every step in making these salts points to choices that favor safety and sound chemical stewardship.

Chemical Reactions & Modifications

A standout feature is its unwavering performance as a phase-transfer catalyst. It shuttles anions across otherwise impenetrable barriers, making it possible to run nucleophilic substitutions and other transformations much more efficiently. Chemists sometimes tweak the structure, swapping out butyl for other alkyl groups, aiming for greater solubility or thermal stability depending on the final application. Methyltributylammonium chloride finds use in halide exchange reactions, and it also sees modification into other ammonium salts that address specific niche challenges in industry and research.

Synonyms & Product Names

Known in industry and academic circles by an array of synonyms—including Tributylmethylammonium chloride and MBTAC—this compound often appears under several product codes in chemical supply catalogs. Such variety can lead to confusion, especially for new researchers scanning product listings. Consistent use of IUPAC names and CAS registry numbers cuts through the clutter, making procurement and regulatory filings more straightforward. Ensuring clear identity staves off accidental substitution, which often leads to costly setbacks in multi-step syntheses.

Safety & Operational Standards

Labs and production floors expect thorough safety data, and for good reason. Direct contact with the skin may cause irritation, while inhalation of dust or exposure to large amounts can affect respiratory health. Proper personal protective equipment (PPE)—lab coats, gloves, and fume hoods—should come standard. Emergency protocols need periodic review as part of daily operational discipline, and waste streams should get neutralized ahead of disposal to meet both company policy and local environmental law. Training new staff on these points pays dividends in safety records and process reliability, a lesson driven home after seeing costly shutdowns triggered by preventable errors.

Application Area

Industrial syntheses benefit from the catalyst’s ability to accelerate substitution reactions, particularly those involving halides or other leaving groups. Methyltributylammonium chloride holds value in drug manufacturing, polymer modification, dyes, agrochemicals, and specialty chemical sectors. It can reduce reliance on more hazardous solvents or conditions, aiding companies trying to modernize their processes for both safety and environmental compliance. From personal experience watching green chemistry initiatives roll out in factories, adaptability ranks high when companies seek ways to meet stricter standards without sacrificing productivity.

Research & Development

Driven by growing attention to efficiency and sustainability, research teams explore new modifications of methyltributylammonium chloride aimed at further cutting waste and reducing environmental impact. The compound serves as a benchmark for testing emerging phase transfer catalysts, helping scientists measure the benefits of each tweak or new entry. Partnerships between academic groups and industry keep data and innovation flowing in both directions—students benefit from fresh challenges, and companies rely on real-world testing away from the publishing treadmill.

Toxicity Research

Toxicity profiles of quaternary ammonium compounds spark much debate, and existing data points to a need for careful handling and judicious disposal of methyltributylammonium chloride. Acute exposure may lead to irritation of the skin and eyes, while repeated inhalation could prompt more severe symptoms. Several jurisdictions track environmental release to prevent persistent contamination of waterways and soil. In one project, improper disposal led to elevated levels in local groundwater, prompting a costly remediation effort. Toxicology research continues to search for ways to establish clear exposure thresholds, shape best practice protocols, and anticipate long-term impacts. Evidence-based guidance remains essential for anyone working along the chemical supply chain.

Future Prospects

Regulators, investors, and operators all seek out chemicals that promise both flexibility and safety. Looking ahead, researchers and chemical producers aim to redesign methyltributylammonium chloride for even better environmental performance—less toxic byproducts, higher efficiency, and easier recycling from waste streams. Ongoing collaboration between discipline experts and policy makers sparks hope that future generations of phase-transfer catalysts will shrink both cost and carbon footprint even further, all without giving up the versatility demanded by fast-moving markets. My observation: the future belongs to chemicals with a proven track record, yet shaped by lessons learned at the intersection of innovation and responsible stewardship.

A Closer Look at the Chemical

Methyltributylammonium chloride might sound like something you’d only spot in a dense chemistry journal, but it plays a role in products and processes that reach into daily life. This compound belongs to a family called quaternary ammonium salts. Lab scientists know it as a phase-transfer catalyst, a helper that makes tough reactions go forward by getting ingredients that usually ignore each other to work together. In practice, this means it helps move ions from one place to another, which can change how reactions happen in water or oil-based settings. It’s like convincing oil and vinegar to finally blend, when left to themselves, they’d stay separate.

Industry Leans In

Chemical plants and research labs don’t just use methyltributylammonium chloride for its fancy name. This compound makes processes more efficient, often trimming costs and cutting down waste. Manufacturers use it for organic syntheses, helping form things like pharmaceuticals, agrochemicals, and specialty plastics. Patients who take certain medications, or farmers who rely on crop protection, can trace some of their safety and success back to this role in the supply chain. Each batch matters—if the chemistry behind those reactions fails, quality drops, and the end users pay the price.

Hidden in Everyday Products

Outside the lab, methyltributylammonium chloride sneaks into the creation of dyes, pigments, and detergents. Ever wondered why some modern fabrics resist stains or keep their color longer? Persistent performance often starts with clean, tightly controlled chemistry. This compound steps in to help in the early stages, laying down a foundation before the final polished product lands on store shelves.

What’s at Stake?

With its benefits come questions, especially about health and environmental risks. The chemical industry faces pressure to balance progress with safety. I’ve seen strict scrutiny applied to every stage—from shipping raw materials to handling lab spills. Methyltributylammonium chloride could irritate skin or eyes and needs careful use, much like other quaternary ammonium compounds. Regulators keep track of disposal rules to prevent contamination of water and soil. In my experience working with industrial chemists, I’ve watched seasoned professionals rely on material safety data sheets and rigorous training just to open the canister. Responsible handling never takes a back seat.

Better Ways Forward

The push for sustainable chemistry grows each year. Methyltributylammonium chloride plays a role now, but researchers look for cleaner, greener alternatives that do the same work with less risk. Green chemistry labs test biodegradable phase-transfer catalysts, aiming to keep efficiency high and hazards low. Chemical companies invest in waste reduction strategies and updated recycling routes. Progress comes from both sides—new substances and new methods. Innovations that cut down on toxicity and make processes more eco-friendly benefit everyone—from the worker stirring the batch to those who live near production sites.

Final Thoughts

Methyltributylammonium chloride shows how chemistry touches everything—healthcare, clothing, food, and more. Its presence might stay in the background, but the choices around how it’s made, handled, and replaced make lasting marks. With smart science and strict safety, better solutions rise and communities share the rewards.

Respect the Substance, Cut Down on Risks

People working with chemicals like Methyltributylammonium Chloride often tell stories about minor mistakes that led to big headaches. Once, I watched a lab tech clean up a leak, and just as they finished, they admitted they only skimmed the storage instructions—never a comforting moment for anyone on shift. With chemicals like this, shortcuts turn small tasks into expensive or dangerous problems. Respecting the specifics pays off over time.

Moisture and Air: The Hidden Enemies

If a compound pulls in water from the air, you can expect lumps in the container, annoying clumping, or even altered performance in experiments and processes. This chloride has a knack for attracting moisture. Even in what seems like a dry storeroom, humidity creeps in, leads to caking, or can set off slow chemical change. A well-sealed container, preferably with a desiccant in a secondary container, helps fight this. Simple habits—like closing caps right after pouring and never leaving jars open—go further than fancy gear in day-to-day use.

Containers, Compatibility, and Cleanliness

Some solvents or chemicals chew through common plastics. Polyethylene, polycarbonate, or even some glass with loose-fitting lids all have stories of failed seals or vapor leaks. Taking time to check compatible containers and inspecting new shipments avoids surprises later. Contaminated lids or dried crystals left on threads can create false readings or introduce impurities. Scooping a little out for direct use, without returning the leftover to the main jar, keeps supplies cleaner and reduces possible cross-contamination.

Temperature and Light

Leaving the compound on a sunny bench or next to a heat source ruins shelf life. Most labs store Methyltributylammonium Chloride under moderate, steady temperatures. Direct sunlight can degrade some compounds, or just prompt condensation inside. Even a simple cupboard or drawer, away from radiators or windows, works. If cold conditions matter—a rare concern for this specific salt—there’s no harm checking the manufacturer’s notes. I remember once trying to cut corners during a busy semester, storing a similar salt in an equipment closet. The temperature swung hot and cold, which ended up costing two weeks in failed tests. With busy schedules, retracing steps to source those errors wastes more time than simply sticking to stable storage rules.

Labeling and Emergency Planning

Nobody wants guesswork during a spill or fire. Big, bold labeling with hazards (like “Corrosive” or “Irritant”) and clear dates for opening or transfer helps everyone—from the seasoned chemist to the new assistant—work safely. A nearby, up-to-date material safety data sheet offers quick answers when something unexpected happens. I always make it a point to print new sheets and tape them right near the main supply in any shared lab.

Safe Handling Habits Make a Difference

Gloves, good ventilation, and eye protection sound obvious until you see someone hurry through without them. Methyltributylammonium Chloride may seem benign compared to some chemicals, but skin irritation, accidental inhalation, or splashes in the eye still turn regular days upside-down. Waste goes in dedicated containers—never in the drain or with regular trash. Even if disposal costs a little extra, making mistakes in this area never ends well. Training new folks personally, instead of just handing them a printout, creates better habits and stronger teamwork.

Understanding Where Concerns Begin

Methyltributylammonium chloride doesn’t often grab headlines, but this chemical finds its way into more labs and factories than people think. Used mainly as a phase transfer catalyst, it helps reactions go faster and smoother, particularly where water and organic liquids need some encouragement to mix. Here’s the thing: any chemical with power to speed reactions raises a flag when it comes to exposure, whether in the workplace or out in the wild.

What Happens in the Lab Doesn’t Always Stay There

Having worked in chemical labs, proper storage and handling echo through your daily tasks—gloves, safety goggles, ventilation fans roaring in the background. Yet, human nature and systems make mistakes. Even one containment breach can put methyltributylammonium chloride on surfaces, on skin, sometimes in the air. Inhalation and skin absorption—those are your classic occupational risks. Agencies like the European Chemicals Agency flag it for being toxic if swallowed and irritating to the eyes and skin. The Material Safety Data Sheet backs this up, warning of respiratory tract irritation. So it’s not just paperwork, but a living threat within poorly managed settings.

Taking a Closer Look at Environmental Footprints

Few chemicals stay contained forever. Drains see more action than people might think—rinsed glassware, splashes, spills. Once methyltributylammonium chloride enters water systems, trouble brews. Studies suggest release into waterways may harm aquatic life, as quaternary ammonium compounds can damage cell membranes of fish and invertebrates. The European Union pays attention to such substances, not just for toxicity, but for how long they stick around. Early evidence shows methyltributylammonium chloride doesn’t break down easily in natural environments, so it lingers and moves up the food chain.

Why the Health Conversation Goes Beyond the Lab

Not every community lives within sight of a chemical plant, but waste streams flow far. Down the line, contaminated water can end up in crops or drinking sources. Families near disposal sites shoulder higher risks, and once these compounds show up in groundwater, options for removing them run thin. Hospitals and clinics meeting unexplained skin rashes or respiratory distress might not connect the dots unless someone connects environmental records and patient symptoms.

Building Smarter Barriers Against Hazard

Experience shows the weakest link often turns out to be training. Employees, contractors, and custodians, each needs clear reminders—not once a year, but as habits. Spill response kits and emergency wash stations, yes, but regular checks make the real difference. Companies sometimes focus on production goals and miss near-misses and leaks, so third-party audits should be the rule, not the occasional box-tick.

Governing Use and Disposal—Not Just Trusting Labels

Manufacturers hold responsibility, but government regulations must catch up. Tracking disposal and penalizing illegal dumping gives communities teeth to protect themselves. Local governments should ask for evidence, not promises. Wastewater treatment plants may need upgraded systems to catch persistent chemicals like methyltributylammonium chloride.

Moving Toward Substitutes

Some manufacturers already research safer alternatives. Incentives for switching, plus support for industries willing to test new routes, matter more than ever as more evidence piles up about bioaccumulation and ecosystem risk. Open data sharing about accidental releases and environmental monitoring helps researchers and residents stay ahead.

Everyday Choices, Cumulative Outcomes

Methyltributylammonium chloride flew under the radar for a while, but facts get clearer with more study: ongoing release, long-term health problems, and ecosystem threats stack up. Informed choices today—by policymakers, facilities, and individuals—will mean less risk for future generations.

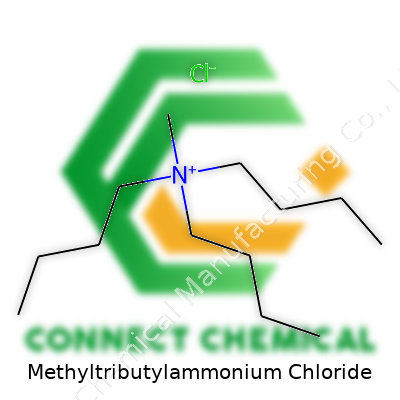

Chemical Formula and Molecular Weight

Methyltributylammonium chloride, a quaternary ammonium compound, features the chemical formula C13H30ClN. Its structure includes one methyl group and three butyl groups attached to a central nitrogen atom, with chloride acting as the counterion. The molecular weight comes out to 251.84 g/mol. This isn’t some exotic figure used only in textbooks—chemists, researchers, and industrial workers alike pay attention to it when considering just how much of this compound they need for their work or if shipping calculations need doing.

Why the Molecular Details Matter

Many see chemical formulas and molecular weights as pure numbers, but missing out on their significance does a real disservice to the topic. In my own experience, nothing causes bigger headaches in a laboratory than a simple error in molecular weight calculations. Even tiny mistakes can throw off experiments, impact product yields, or lead to waste—sometimes more than budget allows. Knowing that methyltributylammonium chloride weighs in at 251.84 g/mol sets the baseline for accurate measurement, reducing wasted resources and helping everyone down the line do their job better.

Industry professionals rely on molecular details for safe handling. Methyltributylammonium chloride acts as a phase transfer catalyst, breaking down the barrier between organic and aqueous phases. This unlocks reactions that wouldn’t happen otherwise. These processes show up in the production of medicines, specialty chemicals, or even in environmental cleanups. Ignoring its specific formula can seriously complicate quality control or lead to costly stoppages.

Real-World Uses and Safe Handling

This compound shows up in phase transfer catalysis, where it helps move ions from an aqueous solution to an organic phase or vice versa. These moves make reactions more efficient, which matters to small operations and larger industries in equal measure. Workers in these spaces need to know what they’re handling. The formula offers more than trivia—it informs how much to use, how strong storage needs to be, and what happens when heat, moisture, or incompatible chemicals come near.

Methyltributylammonium chloride’s molecular details also influence discussions about environmental impact and safety. The chloride ion presents no mystery, but not all quaternary ammonium compounds break down easily in nature. Careful calculation based on actual molecular weight supports responsible disposal methods. By applying accurate data, companies stay compliant with environmental regulations, prevent costly fines, and avoid harming local communities.

Education and Broader Impact

In chemistry classrooms, methyltributylammonium chloride demonstrates why students should care about formulas and molecular weight. Teaching students early to use these numbers not only reinforces basic math skills but also prepares them to make smart decisions in laboratories or industry settings. Every teacher who insists on double-checking the molecular weight isn’t just being fussy—this habit keeps future errors at bay, promoting a culture of accountability.

Open sharing of accurate data prevents problems before they start. Government regulations, shipping paperwork, even procurement orders all depend on having the correct chemical formula and weight. As standards become stricter and the world grows more interconnected, relying on best practices for sharing such details supports not just efficiency but also safety and public trust.

Paths Toward Better Outcomes

Reducing risk and preventing waste means paying attention to details, starting with the formula and molecular weight. Lab professionals and educators alike benefit by fostering habits that treat these numbers as essentials, not afterthoughts. Digital systems and up-to-date databases make it easier to access these details, though each user still carries responsibility for double-checking numbers before use.

Sharing knowledge about structure and weight levels the field for innovation and safety. In my own work, every well-run lab or plant has made it standard to post formulas and weights near storage areas and protocols, so mistakes become less common and training newcomers gets far easier. Putting careful attention upfront saves headaches later and supports the kind of responsible work the whole field depends on.

Understanding the Chemical's Risks

Methyltributylammonium chloride pops up in many labs and industrial processes. It helps reactions run more smoothly, especially in organic synthesis. Despite its usefulness, this compound does not belong in the sink or tossed out with regular trash. Experience reminds anyone working with chemicals that cutting corners on disposal leads to far-reaching consequences—polluted water, sick wildlife, and public health headaches. Story after story tells us accidental releases don’t disappear; they compound into bigger, costlier issues. News reports on contaminated rivers teach us the fallout lands on communities, not just scientists or manufacturers.

Why Safe Disposal Matters

This chemical can irritate skin, eyes, and lungs. Water systems can’t filter out every synthetic substance, especially ones they weren’t designed to handle. The more these compounds slip into soil and groundwater, the more hazardous our environments become. Agricultural workers, plant operators, and even school kids walking by storm drains feel the impact.

Waste handlers deal firsthand with the fallout if a lab or company dumps materials the wrong way. Dumps overflow with toxins, burn piles release hazardous fumes, groundwater picks up what the ground can’t hold. Once a chemical enters these systems, stopping the spread becomes a near-impossible task.

Best Practices from the Field

Clear protocols save headaches and lawsuits. The smart approach starts by collecting spent methyltributylammonium chloride in tightly sealed, clearly labeled containers. Every responsible user checks containers for cracks, double-bags liners if leaks pose a risk, and keeps incompatible substances apart.

Facilities who work with this compound train staff not to cut any corners. Labels get checked, manifests reviewed, disposal plans re-read every time a new worker steps on site. I've seen firsthand how a little attention to these steps pays off: plants running smoothly, audits flying by, no emergency calls.

Partnering with Certified Waste Handlers

Specialized waste companies pick up hazardous chemicals for a reason. Their teams know exactly which chemicals can mix, which need isolated, and how to process everything so nothing leaks into the broader world. They follow government rules that protect everyone’s health. Labs should call these pros long before barrels start piling up.

I’ve watched companies try to save a quick buck by skipping this step, only to face stoppages and fines once the state finds out. Those extra phone calls and fees save so much trouble in the long run. Documentation, which may seem tedious, becomes invaluable if regulators ever ask questions.

The Path Forward—Taking Responsibility

Industry and researchers already have plenty on their plates, but safe disposal of chemicals like methyltributylammonium chloride isn’t optional. Holding each other accountable, sharing disposal resources, and training every new hire create a culture of stewardship that protects more than just the company’s bottom line. State and federal agencies offer programs, training, and even grants to set up safer disposal systems. Seeking that support bolsters community health.

Responsibility for chemical disposal stretches beyond a single lab or plant. The next time a drum fills up, remember the folks downstream. Spend the time. Call the experts. Choose the long-term view, and help make sure hazardous compounds don’t turn up where nobody wants them—least of all, in our drinking water.