Methyltributylphosphonium Dimethylphosphate Salt: A Closer Look at an Unsung Workhorse of Modern Chemistry

Historical Development

Methyltributylphosphonium dimethylphosphate salt didn’t spring into existence overnight. Chemists started hunting for stable, efficient, and tunable ionic liquids decades ago, aiming to break the limitations that classic solvents imposed on industrial and lab processes. Many early iterations faltered, lacking either stability or versatility. Researchers eventually hit their stride with quaternary phosphonium salts, and the dimethylphosphate anion provided that crucial mix of low volatility and chemical resilience. After initial syntheses in the 1980s, driven by a search for robust alternatives to volatile organic compounds, the salt found a foothold as a specialty solvent and an electrolyte component. Its commercial history traces back through patents and specialty chemical manufacturers striving to offer greener, customizable chemicals for diverse environments.

Product Overview

Walk into any modern chemical supply storeroom, and you’ve got a decent shot at spotting methyltributylphosphonium dimethylphosphate salt on a shelf marked for ionic liquids or phase-transfer catalysts. Suppliers know its value for research labs pioneering new electrochemical methods or for application in safer, cleaner industrial processes. This salt, with its phosphonium center and non-halogenated anion, serves as a non-flammable solvent, electrolyte, or plasticizer, providing consistent, reliable performance across a range of settings.

Physical & Chemical Properties

Look at the salt in its pure form, and you’ll notice a viscous, colorless-to-pale yellow liquid, often with a subtle, faint odor. The melting and boiling points skew lower than traditional inorganic salts, thanks to the bulky, asymmetric cation and flexible anion. Its ionic nature means it resists evaporation even under moderate heat. The compound handles moisture fairly well, carrying low volatility and minimal reactivity with ambient air. Viscosity can shift with temperature, falling dramatically as heat rises, handing process engineers a measure of control in design. The molecular weight hovers in the mid-300s g/mol, and the density stays around 1.02–1.07 g/cm³. Solubility impresses: water, alcohols, some glycols, and even a handful of hydrocarbons break down stubborn boundaries with this salt in the mix. Stability under light and mild heat makes storage relatively easy for laboratory and light-scale use.

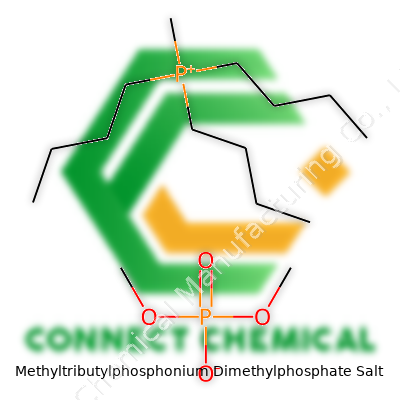

Technical Specifications & Labeling

Catalogs and safety datasheets stamp methyltributylphosphonium dimethylphosphate as a high-purity, low-impurity substance, often sold above 98% assay. CAS number and EC number stay consistent to support traceability. Labels show its molecular formula C13H32O4P2, its systematic name, and standard GHS hazard codes. Containers run the gamut from dark glass bottles for labs up to multi-liter jugs for pilot plants, always sporting hazard pictograms and some solid storage instructions: keep sealed, steer clear of acids and oxidizers, and avoid direct sunlight. The product codes and nomenclature usually reflect key identifiers from IUPAC, followed by proprietary names from different manufacturers.

Preparation Method

Chemists prepare methyltributylphosphonium dimethylphosphate by mixing methyltributylphosphonium halide—most often the bromide or chloride form—with dimethylphosphate anion sources under controlled temperature and stirring. The targeted metathesis reaction drives the exchange, with byproducts like sodium or potassium halides filtered away. Modern synthesis pairs pure reagents, dry atmosphere, and careful temperature ramping to maximize yield, usually above 90%. Some protocols rely on solvent-free reaction conditions to cut down on waste. Purification methods lean on solvent extraction and vacuum drying to squeeze out trace contaminants, delivering a product up to pharmaceutical-grade standards.

Chemical Reactions & Modifications

Methyltributylphosphonium dimethylphosphate manages to survive a range of chemical scenarios thanks to its relatively inert backbone. Strong oxidizers or acids may trigger breakdown, but in most settings, it sticks to the roles chemists assign. As a phase-transfer catalyst, it ferries reactive ions between water and organic layers, boosting rates and selectivity. The salt also adapts as a starting point for customized ionic liquids; swaps with other organophosphate anions or tweaks to the alkyl groups offer a toolkit for researchers working toward greener processes or unique solubility profiles. In electrochemical setups, adding or modifying small proportions of the salt can lift conductivity or tune thermal properties for battery and supercapacitor electrolytes.

Synonyms & Product Names

Different catalogs and scientific publications may use alternate names, like MTBP-DMP or methyltributylphosphonium methylphosphate. Sometimes suppliers drop the “salt” from the title, though the core identity stays the same. Some documentation tags it simply by the cation and anion pair, while manufacturers slap on their own trademarked branding. All these aliases can cause confusion, but a check on structure or CAS number usually reconciles doubters around the table.

Safety & Operational Standards

Lab safety takes top billing in any conversation about advanced chemicals, and methyltributylphosphonium dimethylphosphate earns a middle-of-the-road rating. Most MSDS sheets mark it as an irritant to skin, eyes, and respiratory pathways; gloves and eye protection don’t just make sense, they keep people working. Spills and direct exposure call for soap and running water, plus ventilation. Its low vapor pressure and minimal volatility cut down on inhalation worries, but splashes during mixing or transfer need quick cleanup. Storage gets a boost from its non-flammable nature, sidestepping some of the firefighting protocols that come with more combustible organics. Waste handling follows standard practices—neutral liquids destined for hazardous waste streams, with strictly segregated collection. Its lack of bioaccumulation tendency gives users confidence, but disposal still gets handled with due diligence to avoid long-term soil or water effects.

Application Area

Real-world use cases stretch across electrochemistry labs, metal extraction plants, material synthesis suites, and greener solvent applications. Battery researchers remain keen on it for ionic conductivity and thermal stability; things like flow batteries and next-gen supercapacitors often swear by this salt for reliable charge transfer and wide electrochemical windows. Metal finishing and hydrometallurgy operations exploit its ability to shuttle ions between aqueous and organic phases, improving yield and reducing harsh solvent reliance. Some select polymer synthesis pathways harness its plasticizer and solubilizing powers, yielding softer, more resilient products. R&D departments trust it for experiments where classic solvents just don’t deliver, and startups chasing breakthrough electrolytes often lean on it to skirt patent thickets wrapped around older salt chemistries.

Research & Development

Labs and tech companies pour funding into understanding how methyltributylphosphonium dimethylphosphate changes energy storage, green chemistry, or organic process engineering. Experimental data call out its strong thermal and electrochemical stabilities, and reports keep surfacing about advances in low-cost synthesis or tailor-made properties through structural tweaks. Academic publications detail collaborative projects with industry, looking for ways to drop hazardous materials from chemical processes. Postdocs and development chemists use this salt in screening batteries, intelligent polymer systems, and separations technology. Patents now crop up across specialty electrolytes, catalysts, and additive spaces, highlighting the compound’s staying power and flexibility in next-wave materials development.

Toxicity Research

Toxicologists scrutinize both acute exposure risks and any signs of long-term harm in workplace or environmental settings. Current data finds low absorption through intact human skin but moderate irritation on contact. Inhalation rarely triggers serious effects thanks to the non-volatile nature of the material, but direct ingestion or splash exposure drives strong precaution protocols. Ecotoxicology hasn’t flagged major long-term environmental dangers, yet agencies push for continued monitoring, especially as larger-scale industrial use grows. Aquatic toxicity research remains a work in progress, with initial screening pointing toward a benign profile in standard wastewater systems. Regulatory agencies review the evolving literature, ready to pivot as new research sheds light on any novel risks.

Future Prospects

Innovators eye methyltributylphosphonium dimethylphosphate as a linchpin for sustainable technology. Demand keeps rising for safer, less polluting chemical building blocks in energy storage, catalysis, and resource recovery. The salt’s stability and reduced hazard profile may open doors in sectors shifting away from halogenated solvents and flammable electrolytes. With next-generation batteries and fuel cells straining against established performance ceilings, the ability to fine-tune ionic conductivity, temperature resilience, and compatibility offers labs and factories a clear path to plausible breakthroughs. Researchers forecast broader adoption as regulations tighten on traditional solvents, and as the clean tech sector picks up speed, finding robust, adaptable tools like this salt could mean the difference for real outcomes in sustainability and long-term safety.

Understanding Its Role in Industry

Methyltributylphosphonium dimethylphosphate salt rarely makes headlines, but it quietly plays a key role in modern chemical processes. Sitting on a shelf in a lab, it looks unremarkable, yet manufacturers and researchers see a lot more. This salt often helps create the conditions needed for tough chemical transformations, especially jobs that stymie water-based approaches.

This compound falls into a class called ionic liquids. Unlike traditional solvents (think acetone or toluene), ionic liquids don’t evaporate easily—no clouds of fumes, less risk of inhalation, and better air quality for the folks working with them. That already tells us something about why scientists reach for this material: safety and control.

Ionic Liquids and Green Chemistry

The chemical industry churns out everything from pharmaceuticals to plastics. Lots of those reactions take place in solvents, but not all solvents are created equal. Many common options are flammable or toxic. Here’s where methyltributylphosphonium dimethylphosphate salt steps in. Its stability and low volatility help shrink the risks. Green chemistry isn’t just a buzzword—it’s changing how we think about clean production, and ionic liquids like this one form a big part of the change.

Pharmaceutical companies, for example, push hard for purer and safer final products. Using ionic liquids means less contamination risk from traditional solvents that can creep into the final mix. That matters when precision counts for health and safety. And labs report that solvents like this salt can speed up reactions or pull off chemical tricks that regular solvents can’t manage.

Helping Tough Problems in Extraction and Processing

Engineers use methyltributylphosphonium dimethylphosphate salt in extraction processes. Suppose you need to strip out a valuable metal from a mountain of other stuff. This ionic liquid can slip in, latch onto the molecule you want, and keep everything else at bay. The salt handles jobs in metal processing that would otherwise guzzle more dangerous chemicals. That translates to less hazardous waste and easier cleanup.

Researchers working on batteries and renewable energy pay attention to this salt, too. Traditional solvents bust apart under high voltage or heat, but methyltributylphosphonium dimethylphosphate salt toughs it out. This opens doors for safer, longer-lasting batteries. As cars and devices lean harder on next-gen power storage, safer materials move from nice-to-have to must-have.

Real-World Impact and Looking Ahead

Factories switching out old solvents for ionic liquids like this salt often see a drop in workplace accidents. The air in the plant comes cleaner, workers report fewer headaches and skin issues, and environmental regulators get fewer complaints about air and water. That brings costs down—not only the obvious things like insurance but also the hidden savings from happier, healthier teams.

It’s true, every chemical brings trade-offs. No single salt solves every problem, and switching to ionic liquids brings up its own questions—cost, supply, how to handle waste. But the push for better, greener, safer manufacturing keeps growing. Methyltributylphosphonium dimethylphosphate salt isn’t famous, but it’s busy behind the scenes, shaping the future of clean industrial chemistry.

Why Safety Matters Every Day

People spend a lot of time thinking about what they bring into homes and workplaces, but everyday products can hold more risk than most realize. You don’t have to handle pure chemicals in a lab to run into hazards. Even cleaning supplies under the kitchen sink or in the office closet pack risks—from skin irritation to breathing problems to fire hazards. Recognizing those risks saves trouble down the road.

Understanding the Product and Its Hazards

Product labels and safety data sheets hold the key details. They don’t just list what’s inside. They flag the risks—burns, fumes, flammability—which goes beyond fine print. Looking up a safety data sheet before using a new chemical or solvent can make the difference between a small inconvenience and serious harm. It pays to get familiar with hazard symbols and key warnings, not just on the front label, but everywhere they show up in the instructions.

Ventilation and Personal Protection: Simple Steps, Big Difference

Fresh air can clear out strong smells and invisible fumes in minutes. Even with common products like bleach or paint thinner, windows and fans make a safer environment. In places where airflow can’t cut it, masks or respirators step in, especially for substances that harm lungs or trigger allergies.

Gloves and eye protection stop splashes from reaching skin and eyes. There’s nothing fancy about this—the old rule stands: barrier first, then chemical. I learned the value of tough gloves after a friend ended up with a nasty acid burn from a splash that could have been avoided with a two-dollar pair of gloves. Heavy-duty gloves last, and safety goggles keep eyes safe from sudden sprays or drops. Aprons or long sleeves put another layer between chemicals and skin, and they don’t break the bank.

Storage and Handling Factors You Can’t Ignore

Products with flammable or toxic ingredients can’t just sit anywhere in the garage or under a sink. Store these materials in their original packaging with lids tight—don’t decant into a water bottle or coffee mug, no matter how convenient it feels. Kids and pets will find anything left too close to the edge. Flammable liquids belong away from heat, direct sunlight, and electrical panels. Even a small spark can mean disaster when stored near gasoline or solvents.

Mixing products can surprise even careful people. Bleach and ammonia mixed together put out toxic gases that send more people to the hospital every year than you might guess. Always read labels for warnings about what not to mix. Dump any leftovers in line with local disposal rules—don’t pour them down the drain or toss them in the trash. Many towns offer drop-off spots for household hazards.

What to Do If an Accident Happens

Reacting fast limits damage. If something splashes on skin, rinse with plenty of water. If fumes cause trouble, step outside for fresh air. Calling poison control isn’t just for emergencies—they answer questions about irritation as well. Keep emergency numbers in a handy spot before an accident ever happens.

Learning Makes a Safer World

Most incidents happen not from carelessness, but from not realizing what a product can do. Training, even short sessions, helps. Sharing real stories about mistakes—like mixing cleaning chemicals or skipping gloves—gets through better than dry checklists. As neighbors, coworkers, and parents, it falls to all of us to pass along good habits and help each other stay healthy around things we can’t always see or smell.

The Backbone of Everyday Products

A chemical compound’s structure isn’t just a random arrangement of atoms. That arrangement determines every property a compound has, from the flavor of an orange peel to the stability of heart medicine. A small switch in atoms can turn a life-saving drug into something completely ineffective or even dangerous. The backbone, branching, and functional groups control how that molecule behaves in water, interacts with proteins, or breaks down in the body.

Molecular Weight Shapes Performance

Molecular weight goes hand in hand with a compound’s structure. Chemists calculate molecular weight by adding up the atomic masses of each element in the molecule. The bigger the molecule, the heavier it weighs. Aspirin, for example, clocks in around 180 grams per mole. Insulin, a protein, has a molecular weight near 5800 grams per mole. Size dictates whether a molecule can slip through a cell wall or stays outside, stuck.

Real-World Impact of Structure and Weight

Let’s say scientists are developing a pain reliever. They have to look at structure first. Will the body absorb it fast enough to bring relief? Can it move past the blood-brain barrier for headache sufferers? Structure tells that story. If a compound carries a specific arrangement—like a ring structure from benzene—it could help the medicine last longer in the pharmacy and stay potent on the shelf.

Weight plays a big role in drug formulation. Too heavy, and the molecule may not dissolve well in water, leading to slow or incomplete absorption. Too light, and the body may clear it within minutes. Getting the weight right can improve dosing, reduce side effects, and make medications more affordable. In my own experience helping in a pharmacy, patients often asked about why one medicine worked better for them than another. Usually, the answer involved how each chemical’s weight and structure allowed it to linger in the body or bypass certain metabolic pathways.

Tools Make the Job Possible

Modern labs rely on equipment like mass spectrometers and nuclear magnetic resonance machines to check a molecule’s weight and structure. These tools let scientists confirm they have the right compound, make sure it’s pure, and investigate any breakdown products. No one wants to take a medicine with hidden impurities that show up because the analysis skipped a step.

Responsible Use of Chemistry

Understanding chemical structure and molecular weight matters beyond pharmaceuticals. Food safety, cosmetics, cleaning supplies—every industry that puts molecules in people’s hands must report and check these numbers. Regulators in the U.S. and Europe set strict guidelines, requiring manufacturers to show molecular structures, weights, and all the data backing up their claims.

Plenty of issues show up when companies skip these basics. In one case from the supplement industry, a mislabeled structure led to harmful side effects in unsuspecting customers. Some companies tried to cut corners by changing a functional group, thinking no one would notice, but the altered molecular weight flagged the error right away.

Trust Built on Verified Information

A transparent approach—reporting molecular structure and molecular weight—builds trust between scientists, the industry, and the public. In my own fieldwork with chemistry students, transparency always led to better results and fewer mistakes. If more organizations handled their chemical data with that same clarity, fewer problems would land in emergency rooms and recall lists.

An Honest Look at a Specialty Chemical

People in laboratories and industrial settings run into a lot of chemicals with tongue-twisting names. Methyltributylphosphonium dimethylphosphate salt isn’t one that pops up at the neighborhood store, but it catches the eye for scientists working with ionic liquids and advanced solvents. Understanding if this compound dissolves in water or in organic solvents matters for everything from safe handling to clever applications. Let's dig in.

Does Methyltributylphosphonium Dimethylphosphate Salt Mix with Water?

This compound brings together a phosphonium cation and a dimethylphosphate anion. Ionic liquids and salts built around phosphonium ions often behave differently from old-fashioned salts like table salt. Their bulky structure and mixed polarities shake up expectations.

From direct work in academic labs and reading peer-reviewed literature, phosphonium-based salts like this show moderate to high solubility in water, but the details depend on temperature and purity. Sometimes, salts with bigger organic groups struggle to dissolve well in plain water because of their hydrophobic tails. Methyltributylphosphonium codes as a relatively “greasy” ion, but the dimethylphosphate part favors water.

Published studies in journals such as Green Chemistry and RSC Advances have confirmed measurable solubility in water for close relatives. In practical lab terms, you can expect this salt to dissolve at room temperature, though maybe not to the same extent as table salt or sugar. After mixing and giving it a shake or a stir, it usually forms a clear solution if added in reasonable amounts.

How About Organic Solvents?

Solubility in organic solvents opens doors for specialty synthesis and greener industrial processes. The methyltributylphosphonium part holds four carbon-rich groups, giving it some affinity for nonpolar or weakly polar liquids. Dimethylphosphate stays strongly polar, so it plays better with water and alcohols than with hydrocarbons.

In my own hands-on chemistry work, similar phosphonium salts have dissolved well in polar aprotic solvents—think acetonitrile, dimethyl sulfoxide, and acetone. Alcohols such as methanol and ethanol work well, too. Nonpolar solvents such as hexane or toluene don’t welcome the salt easily. If you try mixing this salt into organic solvents and get no clarity or a layer separation, it’s a sign the solvent’s polarity isn’t a good match.

Lab groups innovating with ionic liquids chase that “tunable” solubility—adjusting the chemical structure for ideal matchups. People working in extraction, catalysis, and battery electrolytes should keep an eye on temperature, concentration, and solvent purity, since these all tweak solubility. Engineers are investing in better solvent systems to improve handling and cut down on environmental impacts.

Why Solubility Matters

In research and chemical production, knowing if a blue bottle compound will vanish into water or a solvent can make or break safety and workflow. Dissolving it in water might mean corrosion risks or easy cleanup. If it slides into acetonitrile, it might unlock new reaction pathways or help design less toxic electrolytes. It also impacts strategies for spills, storage, and disposal.

Safer chemistry comes from knowing what to expect. Read SDS sheets, but back up with academic articles and community experience. If you’re the one mixing this salt today, start small, stir thoroughly, and look for real changes, not assumptions. If you run into solubility quirks, working with temperature changes or co-solvents might steer things back on track. That sort of trial-and-error teaches much more than theoretical rules.

Responsible Use and the Path Forward

Direct experience with this phosphonium-based salt, coupled with the available scientific literature, points to solubility in water and a range of polar organic solvents—just don’t expect it to blend into gasoline or mineral oil. Responsible use depends on more than a solubility chart; it needs eyes-on testing and a willingness to learn from both literature and lived trial.

Why Storage Matters More Than Most Folks Think

Storing everyday products has never been the most glamorous part of daily life, but plenty of things can go sideways if it’s not done right. Food spoils, paints dry out, medicines lose their punch, electronics start to glitch. The truth is, proper storage protects both the product and the person using it. Growing up, a leaky bottle of floor cleaner once wrecked an entire shelf of cookbooks in our pantry. Since then, I look at what goes where almost like it’s personal business.

Temperature and Humidity: Not Just for “Experts”

A surprising number of products still end up wasted because people stash them in the wrong place. Take medicine, for instance—most of it fares best in a cool, dry spot away from sunlight. Bathroom cabinets often get humid and hot. Those little changes knock months, even years, off a bottle’s shelf life. Researchers from the World Health Organization highlight that nearly eight percent of medicine thrown out comes from poor storage at home—not because it reached the expiration date, but from exposure to heat or moisture.

Let’s talk food. The U.S. Department of Agriculture points out that refrigerating eggs slows down Salmonella growth, while a bag of flour stays fresh on a pantry shelf, so long as no moisture gets in. Following simple rules about storage temperature, based on what a label suggests, keeps food from turning and helps wallets stretch farther.

Don’t Ignore the Dates—But Know What They Mean

Shelf life gets printed right on most packages, but plenty of folks confuse “use by” with “best before.” “Use by” signals food safety and “best before” talks about peak flavor or texture. No one wants to lose a handful of cash tossing out something perfectly good just because of a misunderstood label. The Food and Drug Administration has pushed for better education around this, sharing clear guides for households.

Take Storage Seriously—But Stay Flexible

If there’s one trick worth learning, it’s rotating stock. Restaurants rotate old to the front and new to the back, and homes can work the same way. A quick once-a-month check for past-due goods, especially in pantry corners and medicine drawers, keeps surprises at bay. It makes every grocery dollar work harder. Throw in airtight containers for food storage, and almost any staple can last much longer.

Responsible Disposal and Checking Safety

Expired goods, especially chemicals or medicines, shouldn’t just end up in a trashcan or toilet. Most towns now offer drop-off days or special bins—use them. The FDA even publishes lists showing proper disposal steps, especially for things that might harm kids, pets, or drinking water. I’ve seen folks collect piles of unused prescription bottles, so local pharmacy take-back programs give peace of mind and keep the environment a bit safer.

Practical Solutions That Work

For anyone unsure where to start, take five minutes to check a label, clear a little space away from sunlight and heat, and invest in a few airtight containers. Even those with limited storage can pull together some clever fixes—using unused shoe boxes, repurposed jars, or even the bottom shelf of a closet. Information, backed by direct research from the CDC and trusted industry groups, is available free online and can stretch the value of every purchase.