Methyltriphenylphosphonium Bromide: A Deep Dive into Its Role and Impact

Historical Development

Back in the 1960s, chemical synthesis landscapes began to change as researchers started using quaternary phosphonium salts. Methyltriphenylphosphonium bromide emerged as a key player because it helped organic chemists push the boundaries of carbon-carbon bond formation. Its development came out of necessity — as research teams worldwide needed stable yet reactive intermediates, particularly for ylide generation in Wittig reactions. I’ve seen old textbooks describing how this compound simplified access to alkenes, a breakthrough that led to countless advances in pharmaceuticals and materials science.

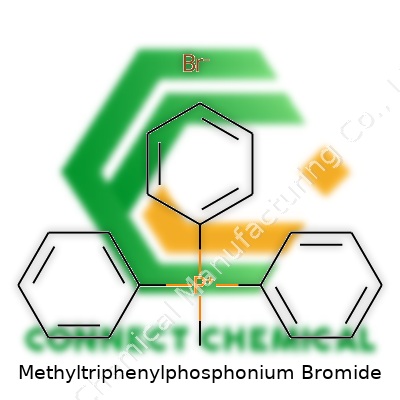

Product Overview

Methyltriphenylphosphonium bromide, often called MTPB, lands on most chemist’s benches as white, crystalline powder. Its formula, C19H18PBr, gives a nod to its bulky triphenylphosphine roots. Labs stock it because it helps turn carbonyl compounds into double bonds—a practical tool. Chemical suppliers and catalogues list it as a reagent with good shelf life, a reasonable cost, and manageable handling requirements. Standard packaging ranges from a few grams for research to multi-kilo containers for scale-up. Names sometimes change: it appears as Methytrifenylphosphonium bromide, or just as a Wittig salt, but its chemistry remains consistent.

Physical and Chemical Properties

Sitting on the bench, MTPB appears as needles or fine powder, bright white and not hygroscopic, which keeps weighing accurate. Its melting range sits between 250-260°C, which I’ve found useful during recrystallizations—less charring, more product recovery. The compound dissolves best in polar solvents; dimethyl sulfoxide, acetonitrile, and even methanol work, but water brings limited solubility due to the bulky phenyl rings. Its phosphonium core shields it from rapid degradation under light or air, offering consistent reactivity batch-to-batch. Infrared and NMR data provide clear confirmation of its structure, which streamlines quality control in synthetic labs.

Technical Specifications & Labeling

Suppliers mark bottles with purity specs, usually >98%, and regularly provide spectroscopic data (NMR, IR) for each lot. Labels always feature the CAS number, 1779-49-3, hazard warnings, and guidance on storage: dry, cool conditions work best. Packaging rarely allows light or humidity exposure, which keeps the material stable. Labs organizing long syntheses appreciate tight traceability, and barcode inventory systems now track everything from delivery to disposal. I value clear expiry dates, which support reproducible synthetic work across many batches. Safety data sheets often accompany the product, outlining essential response steps for spills or exposure.

Preparation Method

MTPB synthesis takes place in two steps: reaction of triphenylphosphine with methyl bromide yields the phosphonium salt. Triphenylphosphine dissolves in non-polar solvents, followed by a slow addition of methyl bromide, sometimes under chilled conditions to manage exotherms. Stirring for hours brings the salt crashing out, filtered and washed to yield the pure product. I remember pilot batches needing clean glassware and careful stoichiometry; leftover methyl bromide can irritate the nose, which reminds me always to keep fume hoods running. Yields regularly exceed 90% if solvents are anhydrous and temperatures controlled.

Chemical Reactions & Modifications

MTPB draws attention for its role in making methylene ylides—essential for the Wittig reaction. Chemists add a strong base (like sodium hydride or n-butyllithium) to a MTPB solution, pulling off the methyl proton and creating the reactive ylide. That intermediate attacks aldehydes or ketones, converting them to alkenes with remarkable selectivity. My colleagues and I have tailored reaction conditions to manipulate E/Z selectivity in double bond construction, and MTPB always responded predictably to changes in solvent and temperature. Modifications using other alkylating agents lead to related phosphonium salts, expanding the toolkit for different synthetic challenges.

Synonyms & Product Names

While most call it methyltriphenylphosphonium bromide, catalogs and research papers swap synonyms: MTPB, methyltpp-Br, or triphenylphosphine methyl bromide. Always double-checking lot numbers and supplier codes prevents confusion, especially given lookalike salts in the same chemical families. Some suppliers highlight its application in the Wittig reaction, bundling it under broader product categories.

Safety & Operational Standards

MTPB doesn’t escape regulatory oversight. Work settings follow strict glove and goggle rules, as the compound can irritate the skin and eyes. Inhalation risks push labs to operate under chemical fume hoods, which I’ve found keep air clean even during long runs. Waste streams containing phosphine derivatives travel as hazardous waste for incineration. Spillage means prompt cleanup with inert absorbents to cut exposure. Labs posting up-to-date signage and keeping SDS on hand reduce accident rates.

Application Area

I’ve seen MTPB used across pharmaceuticals, polymers, and fine chemicals. Its main claim remains the Wittig reaction, transforming aldehydes into terminal alkenes—a cornerstone for steroid synthesis, vitamin creation, and fragrances. It shines where selective C=C bond formation counts, bypassing problematic side reactions that plague older techniques. Researchers designing small molecules turn to MTPB to streamline syntheses, especially in high-throughput environments. Material scientists create specialty coatings and advanced materials, harnessing the stability and reactivity of phosphonium ylides.

Research & Development

Innovation circles around new ylides and reaction pathways, using the reliable platform MTPB provides. Some teams look at greener base choices, swapping out pyrophoric n-butyllithium for milder, safer alternatives. Academic groups test modifications on the phenyl rings to fine-tune the reactivity, while others tweak process scale-up for industrial batch sizes to support drug manufacturing. I’ve followed papers showing MTPB as a starting point for new ligands in catalysis, building more complex functional molecules with greater efficiency. Collaborative research between industry and universities pushes the performance envelope and uncovers new uses, especially in bioconjugation and advanced polymer synthesis.

Toxicity Research

Toxicological studies highlight moderate hazard for acute exposure—human data remain sparse, but animal models flag potential impacts on respiratory, mucosal, and dermal tissues. Long-term exposure data are limited, driving efforts to improve local exhaust and minimize dust. Many chemists, myself included, appreciate ready access to PPE and comprehensive training before handling. Some labs implement environmental monitoring to check for phosphine derivatives in air, aligning with regulatory trends toward proactive health and safety. Suggested exposure limits from guidelines keep risk in check for both researchers and the environment.

Future Prospects

The road ahead looks promising: MTPB has earned its place in synthetic playbooks, yet new demands continue to surface. Push for greener chemistry prompts development of safer bases and closed-system reactors to cut emissions. Researchers test immobilized phosphonium salts for easier recycling, lowering waste and manufacturing costs. Health-conscious labs lean toward digital tracking of handling and disposal, meeting tighter safety requirements. In my view, the compound’s fundamental stability and straightforward synthesis ensure it remains relevant, even as new technologies shape the landscape of molecular construction.

The Building Block Nobody Talks About

Methyltriphenylphosphonium bromide sounds intimidating, but for many chemists, it’s a go-to tool. This white, slightly chunky powder pops up in labs around the world, mostly because it's essential for making something called a Wittig reagent. That might sound like obscure shop talk. In truth, anyone working on new medicines, smart materials, or even dyes uses this compound—directly or indirectly.

Why Scientists Reach for It

Researchers use methyltriphenylphosphonium bromide because it helps them swap certain atoms in big molecules for fresh ones. Say you want to turn a sticky oil into a solid. Or maybe you need a zigzag shape in your drug molecule so it fits a protein target better. The chemical itself won’t do the transformation. Instead, scientists mix it with a strong base to make a ylide—think of this as a reactive little player, always on the hunt to join forces with another molecule. Most of the time, these efforts focus on the Wittig reaction. That process creates new carbon-carbon double bonds, which show up everywhere in life sciences, agriculture, and materials chemistry.

The Everyday Impact: Medicines and Materials

Anyone curious about the final products might spot methyltriphenylphosphonium bromide’s influence without ever knowing it. The Wittig reaction, powered by this reagent, helps chemists put together parts of antibiotics, antiviral pills, anti-inflammatory drugs, and cancer medicines. It also shows up in stories about plant protection—crop scientists working on better pesticides and herbicides often assemble their new products through these reactions. The beauty comes from its flexibility. Just by changing the bits attached to the phosphonium, labs can design chemicals for very different jobs, whether it’s breaking down pollution or building solar cells.

Why Purity and Supply Matter

Nobody wants dirty reagents. In my own grad school days, I watched experiments flop when the phosphonium salt picked up water from the air or sat too long on a shelf. The result: unexpected byproducts and plenty of wasted time. High-purity methyltriphenylphosphonium bromide keeps the work moving. Supply chain hiccups force chemists to improvise or pause important projects. Tighter sourcing standards and smarter storage—think desiccators and fresh packaging—reduce these headaches.

Keeping Safety Front and Center

Like a lot of lab chemicals, methyltriphenylphosphonium bromide demands respect. Nobody should breathe in its dust or let it touch bare skin. It can irritate eyes and lungs, so gloves, goggles, and good ventilation matter way more than the average person expects. Years ago, in a crowded student lab, I saw someone brush a hand across a face without thinking. Personal protection saved that student from a bad chemical burn. Good habits and honest safety discussions set professionals apart from dabblers.

Looking Down the Road

Green chemistry keeps growing, and so does scrutiny on what ends up in waste streams. Some worry about phosphonium byproducts, asking if they pollute water or soil. Smart chemists now test biodegradable or recyclable variants. More sustainable bases for the Wittig reaction promise to trim hazardous waste even further. Open collaboration and reliable information about environmental impact help push the field in a cleaner direction.

Final Thoughts

Methyltriphenylphosphonium bromide helps make breakthroughs in healthcare, materials, and agriculture possible. It’s not flashy, and you won’t find it on supermarket shelves, but it keeps chemical innovators moving forward. Prioritizing quality, safety, and sustainability sets apart the best in the business.

A Closer Look at What Goes Into Storing Chemicals Safely

If you’ve ever worked in a chemistry lab, you know strict storage guidelines stand between a functional workplace and a whole lot of wasted time—and sometimes, ruined experiments. I’ve watched researchers scramble more than once because a container wasn’t shut tight or a bottle sat too close to a sunny window. With methyltriphenylphosphonium bromide, skipping the basics can cost batches of precious material and sometimes more. Knowing how to store this compound comes down to a respect for both safety and science.

Why Stability and Safety Rely on the Right Environment

Methyltriphenylphosphonium bromide has proven itself crucial for synthetic organic chemistry, especially in Wittig reactions. You want this compound dry, cool, and protected from light. Moisture draws trouble—methyltriphenylphosphonium bromide will slowly decompose if left in a damp spot. It turns sticky or may even clump, throwing your weigh-outs off and making future reactions unpredictable. If you ever opened a jar and found a damp mess inside, you realize just how much humidity shortens the shelf life of even the highest-purity batch.

Heat becomes the next big enemy. A simple lab shelf near radiators or warm equipment can push the temperature up, chipping away at the chemical’s quality. Cooler, steady temperatures do a better job at holding methyltriphenylphosphonium bromide steady month after month. I once watched a shipment left near a sunny window turn yellowish by the end of summer—classic sign of light or heat exposure taking its toll.

The Right Container Makes a Difference

Glass bottles with tight, chemical-resistant seals usually work best. Plastic might not always hold up, especially if there’s any question about compatibility. Chemicals that attract moisture need solid defense—desiccators loaded with fresh drying agents give methyltriphenylphosphonium bromide its best shot at lasting as long as possible. Lab techs who skip this step usually pay for it in the quality of their final product.

Labeling can’t be overlooked: I’ve seen researchers waste good batches because the last person never dated the bottle. Tracking receipt dates helps with rotating stock before small amounts turn useless. No fancy system required—just a roll of tape, a Sharpie, and the discipline to jot down the essentials each time a fresh batch arrives.

Keeping Hazards in Perspective

Mishandling chemically active compounds brings risk. Accidental contact or dust from a degraded sample could irritate skin, eyes, or lungs. Gloves and goggles keep those risks low. That said, methyltriphenylphosphonium bromide hasn’t earned a reputation as one of the more dangerous reagents—unless folks get lazy about those basic protections. Staying alert means cleaning up spills, closing lids after every use, and knowing the emergency contacts if something goes wrong.

What Can Improve Chemical Storage Now

On a practical level, storage standards often slip when labs get cluttered or long-term goals get lost in day-to-day pressures. Regular inventory checks help, and so does building a habit of quick spot-inspections each week. Training new lab members to respect storage conditions gives everyone a stake in protecting what they work with. Automated temperature and humidity monitors keep the environment honest—and no one has to guess if a shelf runs too warm or a desiccator loses its punch.

Methyltriphenylphosphonium bromide rewards the careful and organized. Give it a cool, dry, dark home, and it will do its job in your reactions without fuss. Safe, reliable chemical work depends less on luck and more on consistent, practical habits built up over time.

Getting Real About Chemical Safety in the Lab

Methyltriphenylphosphonium bromide shows up on plenty of chemical inventory sheets, especially for students and researchers interested in organic synthesis. It pops up in key reactions, like the Wittig reaction, helping shape carbon-carbon bonds in the process of building more complex molecules. The excitement of watching new compounds come together overshadowed the risk sometimes, especially early on in student labs. Handling it felt routine. That's when missteps with chemicals happen most often.

Breaking Down the Risks

Methyltriphenylphosphonium bromide isn't just another white crystalline solid. It brings real risks. Skin and eye irritation can follow brief exposure, according to Sigma-Aldrich’s safety datasheets. Prolonged inhalation exposure could leave anyone with coughing, headaches, or even more serious respiratory issues. It's classified as harmful if swallowed and may cause long-term environmental damage if not disposed of properly. People often overlook these risks because it's not as notorious as bigger names like benzene or mercury.

Much of chemical work in research comes down to routine. Rushing, skipping gloves during a transfer, or assuming a bit of exposure doesn't matter—the outcome is sometimes a ruined experiment or worse, a trip to the health clinic. Some chemical safety incidents aren't about catastrophic explosions. They're about years of chronic, low-level exposure that lead to bigger health problems down the road.

Practices That Matter

Every time I pull out the jar, I ask myself: gloves on, goggles tight, lab coat buttoned? Boston University published a helpful study tracking minor accidents in chemistry departments, and the number one cause—improper personal protective equipment. Fume hoods aren't just for the smelliest chemicals; they're the best way to avoid inhaling dust from reagents like methyltriphenylphosphonium bromide. It can produce fine particles. Just opening a jar in a drafty room can carry particles right to the nose.

It’s easy to forget the journey from chemical container to waste stream. Any leftover methyltriphenylphosphonium bromide shouldn't go down the drain. Proper hazardous waste disposal matters. This isn’t just regulatory red tape. Reports out of the EPA show compounds like this persisting in water systems and accumulating in aquatic life. It’s a small role in a bigger ecosystem problem.

Solutions in Real Life

Building a safety mindset takes more than signs on the wall. Stories from senior lab workers stick with me far more than any rulebook. A grad student once shared getting a splash of methyltriphenylphosphonium bromide on his wrist and shrugging it off, only to end up with a rash and hours at occupational health. Universities that encourage open discussion of near-misses seem to train the safest chemists.

Labs with straightforward spill protocols, easily accessible material safety data, and a “watch out for each other” attitude build habits that last. Practice makes the procedures familiar, not just something checked off before the first experiment. It isn’t just about individual health, either—proper handling protects coworkers, the environment, and research results.

Why It Stays Important

Chemistry fuels innovation in everything from medicine to energy. Responsibility doesn’t stop at the bench. My experience says that treating hazardous reagents with respect—like methyltriphenylphosphonium bromide—keeps the focus on discovery without risking health or the future of the lab.

Understanding Methyltriphenylphosphonium Bromide

Methyltriphenylphosphonium bromide carries a chemical formula of C19H18PBr. The structure isn’t just a jumble of letters and numbers—it represents a core backbone for some creative chemistry. The molecule comes together from triphenylphosphine, methyl bromide, and a spark of curiosity. The phosphorus atom, holding three phenyl groups and one methyl, binds up with a bromide ion. This union creates a salt that pops up in organic synthesis circles more often than most people might think.

Why This Formula Matters in Real Labs

Chemists don’t memorize these formulas for show. Knowing C19H18PBr by heart makes a big difference in reaction planning. Picture sitting in a slightly cluttered lab, marker in hand, sketching out the Wittig reaction. The methyltriphenylphosphonium ion delivers the methyl group so the reaction works its magic, transforming aldehydes and ketones into alkenes. A missing hydrogen or a stray atom can throw results way off, so accuracy matters for safety and for spending less money on do-overs.

Diving Into the Science: How the Structure Works

The methyltriphenylphosphonium part packs a punch because phosphorus holds that positive charge well when paired with three large phenyl rings. The bromide sits nearby, keeping the charge balanced. This set-up turns out useful beyond just the Wittig reaction. Some folks reach for it when making designer alkenes—outcomes that might run from pharmaceutical ingredients to custom materials for niche electronics.

Keeping Labs Safe and Smart

Safety deserves a spotlight here. Methyltriphenylphosphonium bromide is less volatile than many reagents, but it doesn’t mean gloves are optional. Spills aren’t just a mess; they signal mistakes that could’ve been avoided by knowing the material's composition and handling needs. A missed detail can put a whole team at risk, and the formula C19H18PBr provides a roadmap for what personal protective gear and ventilation setups make sense.

Common Challenges and Fixes in Synthesis

Even with directions in hand, making methyltriphenylphosphonium bromide in the lab can throw curveballs. Impure reagents, water sneaking into containers, equipment that hasn’t seen a good scrub—the recipe for a failed experiment. Consistent record-keeping and double-checking formulas keep things running smoother. Good habits help cut down on surprises and teach junior chemists that the right formula is more than trivia—it helps science move forward without unnecessary hiccups.

Looking Ahead: New Uses and Responsible Handling

Research points to expanded uses for this compound as chemists explore greener and more efficient reactions. More sustainable lab setups rely on knowing each ingredient in detail, which means C19H18PBr is part of a puzzle that stretches from undergraduate benches to R&D pipelines. Ideas around responsible sourcing and safe disposal become part of the conversation, reflecting a bigger shift in science: knowledge and care go hand in hand.

Understanding the Chemical

Methyltriphenylphosphonium bromide isn’t found on a store shelf. Most people working with it are chemists or lab techs, not folks handling daily cleaning jobs. This chemical pops up in organic synthesis, and it’s got a reputation for being a bit tricky to deal with. We’re not talking about a harmless ingredient—this compound packs both a phosphorus atom bonded to three hefty phenyl groups, and it tacks a methyl group on top of that. The bromide part just helps make it a solid and more manageable, compared to its chloride or iodide cousins.

Because it’s an organophosphorus salt, it can leave a lasting impression on the environment if tossed out the wrong way. The presence of phenyl groups and bromine means traditional routes like dumping down the drain don’t cut it, and burning isn’t on the table. Since most people only cross paths with this chemical in serious research or industrial environments, thinking about proper disposal isn’t just good lab practice—it lines up with regulations from groups like the EPA and local authorities.

The Right Way to Handle Waste

Every person in a lab hears this one rule early: never just throw chemical waste in the trash, and definitely don’t pour it in the sink. You collect it, label it, and pass it off to professionals who know what to do. For methyltriphenylphosphonium bromide, that means designating a separate, clearly marked waste container. Don’t mix it with other waste, since mixing different chemicals can spark dangerous reactions or make things even harder on the people trying to dispose of it later.

Once you gather enough waste or finish up your experiment, hand over the container to a hazardous waste disposal contractor. They have the gear, permits, and training to keep people and the environment safe. Many labs keep a paper trail of each handoff, so nothing gets lost. States like California publish strict rules for handling stuff like this, and following them just makes sense for legal and ethical reasons.

Risks We Can’t Ignore

People who cut corners with chemical waste have made the news more than once. I’ve seen labs pay hefty fines, and I’ve read stories of workers dealing with unexpected exposures years after a slip-up. Organophosphorus compounds sometimes show toxicity in aquatic life, and heavy metals like bromine can linger if they leak into water systems. Burning the waste releases toxic gases. Landfills can’t handle it because of potential leaching as barrels break down. In short, every shortcut comes with a real cost.

Room for Better Solutions

Big waste companies process hazardous chemicals using methods such as high-temperature incineration in facilities designed to trap and scrub out toxic byproducts. Some labs explore neutralization steps before disposal, but this only works with full knowledge of the reaction—and even then, the byproducts might still demand professional handling. Sharing chemical inventories and using only what’s needed limits leftovers. Training and regular audits help labs catch mistakes early.

Some countries set up centralized drop-off days or use government-supported disposal programs. Munich offers a city-wide chemical collection program for small users, which helps avoid illegal dumping. In the United States, colleges often run “chemical return” drives at semester’s end.

Final Thoughts Born From Experience

Over the years, my time in academic labs made it clear: Nothing replaces the role of serious oversight and a strong culture of safety. Disposing of methyltriphenylphosphonium bromide looks complicated, but it’s really about respect—for people, law, and the planet. Anyone who works with this compound or something like it should know the rules and take pride in getting disposal right. Mistakes leave scars on more than just the ecosystem—they tear through trust and safety in the workplace, too.