Myristylpyridinium Bromide: A Close Look at a Modern Surfactant

Historical Development

Chemists set out searching for more effective surfactants as the industrial revolution ramped up chemical use in every corner of manufacturing and personal care. Myristylpyridinium bromide first popped up on the radar thanks to innovations in quaternary ammonium compounds, a class discovered for their ability to disrupt microbial membranes. In the decades following World War II, as synthetic detergents boomed and the pharmaceutical industry grew hungry for new antiseptics, researchers turned their attention to long-chain pyridinium salts like myristylpyridinium bromide. They realized this compound didn’t just offer impressive cleaning action, but also proved tough against bacteria, making it stand out from some short-chain analogs.

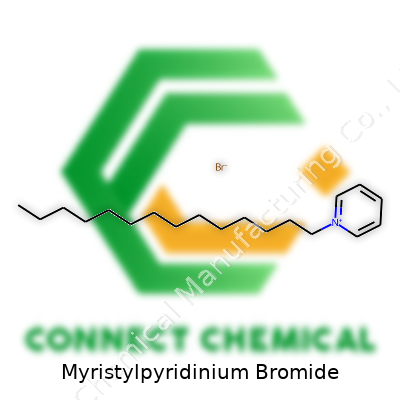

Product Overview

Folks find myristylpyridinium bromide most often in the form of a white crystalline powder or sometimes as a solid lump. It appeals to those blending personal care products for its ability to boost foaming and act as a germ-fighting agent. Many oral hygiene products, surface sanitizers, and industrial cleaning formulas rely on this compound for both performance and safety—in controlled amounts. Looking at the chemical makeup, it’s formally called 1-Myristylpyridinium bromide, or N-tetradecylpyridinium bromide. Its reputation goes beyond cleaning, since formulators prize its power to tackle bacterial contamination.

Physical & Chemical Properties

Myristylpyridinium bromide sticks out thanks to its soluble nature in both water and alcohol. The melting point runs between 180–185°C, and the molecular formula reads C19H34BrN. That lengthy hydrocarbon chain gives it a nearly waxy texture, which contributes to its ability to sweep up oils and dirt. In the lab, folks note its stability under standard conditions, but exposure to heat or strong oxidizers can trigger decomposition or side reactions. The bromide counterion makes it easy to combine with other ingredients, especially those that need a cationic surfactant.

Technical Specifications & Labeling

Labeling for myristylpyridinium bromide reflects the need for clarity in manufacturing. Pharma and cosmetic suppliers mark purity—often over 98%—and list its CAS Number (143-27-1) to avoid confusion among close analogs. Packaging comes sealed tight to prevent moisture, and hazard statements detail the need for protection from skin and eye contact. Regulations require suppliers to list concentration limits, storage guidance, and batch records, because quality issues in antimicrobial agents could spell trouble for downstream users.

Preparation Method

Large-scale synthesis uses a quaternization reaction, where myristyl chloride reacts with pyridine in the presence of sodium bromide or another bromide source. The mixture stirs under heat, yielding the pyridinium salt and releasing HCl, which needs neutralizing or venting off. Purification follows, involving washing and recrystallization with ethanol or isopropanol, producing the white solid used as the end product. Some labs opt for greener solvents or tweak the chain length, but the base chemistry stays consistent across continents.

Chemical Reactions & Modifications

The pyridinium ring tolerates mild conditions, opening the door for substitution or extension reactions. Chemists can shift the chain length, swap halide counterions, or add functional groups for broader spectrum killing power or altered solubility. For instance, swapping the bromide for chloride drops cost and sometimes improves compatibility with specific excipients, though each modification means retesting antimicrobial activity. Myristylpyridinium’s cationic nature lets it bind to anionic molecules, creating opportunities for drug delivery, biofilm disruption, or enhanced emulsification.

Synonyms & Product Names

On packaging and technical sheets, this compound might show up as N-Tetradecylpyridinium bromide, Pyridinium, 1-tetradecyl-, bromide, or even just MPB. This list of names helps researchers avoid confusion, since the market contains shorter and longer chain analogs—each with its quirks and applications. In the dental care industry, it slips into formulas under identity codes set by international regulators, keeping naming consistent from one region to another.

Safety & Operational Standards

Working with myristylpyridinium bromide carries more than a few precautions. It irritates eyes and skin, so gloves and splash-proof goggles become mandatory in any lab or plant. Airborne dust creates a respiratory hazard. Safety advisories direct users to work in well-ventilated environments or under a fume hood. Spills call for immediate cleanup, since water can spread it further. Waste disposal follows strict protocols, because surface-active compounds don’t break down quickly in landfills or water treatment plants. Plant safety teams need to review each new application, as overexposure—or accidental mixing with incompatible chemicals—can cause severe reactions.

Application Area

Pharmaceutical labs turn to myristylpyridinium bromide as a topical antiseptic and oral rinse ingredient, often in low concentrations where bacterial inhibition matters most. Personal care manufacturers blend it into mouthwashes, throat sprays, and even some deodorants for both antimicrobial and surfactant properties. Hard-surface cleaners for hospitals, schools, or public spaces take advantage of its germ-killing strength. It sometimes crops up as a preservative in ophthalmic and nasal products, though final concentrations sit under tight regulatory limits. Attention shifts to industrial water treatment, where long-chain pyridinium salts break down biofilms and combat microbial fouling in pipes and cooling towers.

Research & Development

Academic researchers continue studying new derivatives for everything from improved microbial selectivity to less skin irritation. Drug delivery opens another research avenue, with some groups building nano-vesicles using myristylpyridinium’s amphiphilic character. R&D labs examine structure-activity relationships, tweaking chain length and the aromatic ring to tackle resistant strains. Environmental impact studies also play a growing role, as universities and private labs track the persistence of pyridinium salts in wastewater, and hunt for enzymatic routes to break them down more efficiently after use.

Toxicity Research

Most toxicity work reveals that myristylpyridinium bromide causes cell membrane disruption in bacteria, but similar mechanisms irritate human tissues, especially in higher concentrations. Animal studies point to moderate toxicity when ingested or inhaled, and long-term exposure runs the risk of impacting aquatic ecosystems if wastewater treatment doesn’t catch it. Regulatory groups watch for cumulative effects, urging more research before new applications hit the shelves. Researchers in toxicology dig into the balance between antimicrobial efficacy and harm to non-target species, which shapes how product developers approach formulation craft.

Future Prospects

The landscape for myristylpyridinium bromide keeps shifting as legislation tightens around persistent environmental contaminants and as antibiotic resistance climbs. Companies pour resources into new forms that are as tough on germs but quicker to break down in the environment. Health-conscious shoppers and industrial clients alike demand transparency, pressuring everyone along the supply chain to deliver safety data, environmental impact reports, and green chemistry innovations. Collaborative projects between academia and industry fast-track discovery of more sustainable cationic surfactants, drawing on everything from plant chemistry to next-gen bioprocessing methods. The drive for better performance and lower ecological impact shapes product pipelines and training, making it clear that the days of careless surfactant use have passed. As research grows more robust, and more voices join the debate on toxicity and biodegradability, brands putting myristylpyridinium bromide to work face the challenge—and opportunity—of proving both safety and effectiveness on a broader stage.

Everyday Chemistry at Work

I remember growing up with bottles of mouthwash lined up next to the bathroom sink. Back then, I never thought twice about what made those blue and green liquids so effective. Years later, I realize compounds like myristylpyridinium bromide do a lot of heavy lifting in products people use without much thought. Unlike some of the classic ingredients, this one doesn’t often get a spotlight. Yet, its presence in certain formulations becomes clear once you look into it.

How This Compound Enters Our Lives

This quaternary ammonium compound shows up in both personal care products and some cleaning agents. It serves as an antimicrobial agent—meaning it tackles bacteria, viruses, and fungi on surfaces, skin, and even in the mouth. There’s something practical about how a single compound works across both household and personal areas. Companies put it to work in mouthwashes, throat sprays, surface disinfectants, and handwashes. It gives these products an edge when it comes to stopping the spread of germs and keeping spaces safer for families.

Trust and Safety: What Science Tells Us

People care about what goes on or in their bodies, and so do I. Safety data always matters before welcoming any new ingredient into routines. Over the years, reviews published in journals and summaries from regulatory agencies have examined quaternary compounds like myristylpyridinium bromide. Studies point out that, when used at concentrations typical for handwash or oral care, this compound works against a variety of bacteria and yeast. That action can cut down on bad breath and reduce infection risk.

Regulators such as the Food and Drug Administration and the European Chemicals Agency set clear limits on how much of these compounds get used in each application. Research shows that skin and mucous membrane irritation possible at higher concentrations leads brands to use amounts much lower than that threshold. With that guidance in place, people benefit from the germ-fighting powers without having to worry so much about side effects.

Environmental Questions

This is where experience as a parent and eco-conscious shopper comes in. Surfactants and disinfectants flow down the drain, traveling into waterways that support wildlife and community water reserves. Research published by environmental groups and government labs keeps a close eye on these substances. Myristylpyridinium bromide doesn’t accumulate in soil and breaks down in treatment plants, but it still needs checking to make sure it doesn't create bigger problems as demand grows. Cleaning up after ourselves, as a society, means keeping an eye on substances we take for granted.

Toward More Responsible Chemistry

Manufacturers know people value products that do the job but also fit a safer and more responsible lifestyle. Transparency helps. Sharing results of long-term safety studies and offering options that use lower-impact ingredients go a long way. There’s also pressure from consumers like me, who want the company behind their mouthwash or cleaner to share how raw materials are sourced and how possible risks to the environment are managed.

Putting value on informed choice means giving customers real knowledge, not just big promises on a label. It’s on all of us—from ingredient suppliers to formulators to users—to ask questions, learn from science, and never stop pushing for safer, cleaner, trusted products.

Understanding Myristylpyridinium Bromide

Myristylpyridinium bromide pops up in places where people least expect it—cleaners, personal care products, some specialized sanitizers. It acts as a quaternary ammonium compound, which means it’s designed to kill bacteria and viruses by disrupting their membranes. This makes it handy, especially in environments where hygiene is a top priority. But around the world, more folks want to know: is it actually okay to have this kind of chemical on your skin?

Breaking Down the Risks

Most quaternary ammonium compounds don’t have a warm reputation among dermatologists. If anyone remembers that stinging after using certain disinfectant wipes, that’s a clue your skin isn’t on friendly terms with these substances. Myristylpyridinium bromide, tested in lab settings, shows that it acts as an irritant at higher concentrations. Reports in toxicology journals and regulatory summaries—such as those published by the European Chemicals Agency—point out that repeated or prolonged skin contact can cause redness, dryness, and itchiness.

Conversations with pharmacists and past hours spent squinting at ingredient labels always push the same idea: sensitive skin types react more quickly, but long exposure is a problem for almost everyone. I remember a week spent using a strong germicidal cleaner with bare hands—my skin felt tight and flaky within days. Myristylpyridinium bromide won’t eat through skin on contact, but you won’t want it sticking around for long.

Reviewing the Research

Research teams find that concentration is the main concern. Low doses, such as those found in some rinse-off hair products or diluted surface sprays, might only bother people with pre-existing eczema or chemical sensitivities. Still, studies from peer-reviewed journals like the Contact Dermatitis series suggest even mild formulas may trigger allergic reactions with enough use.

Government agencies set safe exposure limits, yet those numbers come from controlled studies with fixed dosages. Real world use rarely matches lab conditions. The safety data sheets warn about accidental splashes, and recommend immediate washing, which matches advice from skin specialists. Nobody has seen confirmed reports of cancer or birth defects connected to myristylpyridinium bromide, but chronic irritation and potential for dermatitis are well documented.

Thoughts on Responsible Use

A couple of common sense rules have always worked for me. If a label lists myristylpyridinium bromide, don’t use that product as a hand cream. Rinse off any residue, and use gloves when handling concentrated cleaning solutions. Companies should phase out these compounds from products designed for frequent skin contact, especially with so many alternatives available—plant-based surfactants, milder disinfectants, even alcohol-based hand rubs made the leap in hospitals for a reason.

For anyone who needs to use products with myristylpyridinium bromide, using protective equipment and limiting exposure keeps skin healthier. Dermatologists suggest fragrance-free and hypoallergenic skin care after any potential exposure. The science shows its job well in cleaning, but human skin simply doesn’t call for strong ammonium compounds. If a product causes irritation, drop it from your routine. Health matters more than a theoretical extra percentage point in germ kill rate.

Storing Chemicals: Lessons Learned in Real Labs

Myristylpyridinium bromide might sound like a niche compound, but it’s a regular visitor in many research labs. Storage sounds simple on paper—just keep things safe, right? But anyone who’s worked in a real lab knows hazards multiply when chemical names get longer. Mistakes raise risks, and safety culture can suffer from little oversights.

Last year in my former university’s chemistry department, a single missed step in storage led to multiple hours of wasted research and a fire marshal’s unwelcome visit. The lesson stuck: always respect the specifics, especially for surfactant salts like Myristylpyridinium bromide. Research runs not just on creativity, but on discipline.

The Reality of Myristylpyridinium Bromide Storage

This white, waxy chemical brings a mix of organic and saltlike properties. Don’t judge by appearance. It can irritate skin, corrode eyes, and ruin a shelf of samples with a single spill. Moisture and heat aren’t just enemies; they almost guarantee headaches.

Store it tightly sealed in original containers or ones made of chemically-resistant plastic. Staff in charge of chemicals in my lab always checked seals right after deliveries—and again on every inventory day—because a cracked cap means more than just a ruined batch; it signals danger.

Humidity control lands high on the list. This surfactant soaks up water from air and clumps quickly. Lab air conditioning doesn’t count for much, since local humidity spikes in the summer can sneak in. We added desiccators as insurance. Not everyone enjoys restocking silica gel, but it beats scraping out soggy, useless powder.

Heat kills more value than most think. Anything above room temperature shortens shelf life and bumps up risks. All too often, crowded storage spaces force shortcuts, with boxes stacked too close to radiators or heat vents. In my experience, a digital thermometer in chemical storage outperforms guesswork. Most labs carve out a specific corner at 15–25ºC to avoid surprise reactions.

Incompatible storage is where I’ve seen the worst accidents. Mixing bases, oxidizers, and surfactants such as Myristylpyridinium bromide can start chemical drama even the best cleanup crews may struggle to contain. Our team posted big, clear signs and color-coded bins. New staff who ignored this step rarely lasted long. Peer review in chemical storage isn’t just best practice; it’s basic survival.

Supporting Good Storage Practices in Every Setting

Some argue regulations are enough, but the best labs make safety a tradition. The American Chemical Society and European Chemical Agency both highlight dry, cool, clearly labeled storage away from incompatible groups as fundamentals for this compound. Reading the safety data sheet isn’t busywork; it’s part of the process.

Hazard training can feel repetitive, but anyone in charge of a storeroom knows new eyes miss things veterans catch. At my last industrial contract, we had monthly walk-throughs and invited interns to spot risks. Management listened, and that openness paid off—accidents dropped year after year.

Waste handling also matters. Old or spilled Myristylpyridinium bromide doesn’t go down a drain. Our protocol involved airtight collection jars and clear reporting. Monitoring inventory cuts down expired stock, and scheduled disposal keeps the workspace manageable.

Why Getting Storage Right Protects Everyone

Paying attention to chemical standards hasn’t failed me yet. Simple routines—dry storage, sealed containers, clear labeling, proper waste—make science safer and smarter. Whether you work in a world-class institute or a high school classroom, keeping Myristylpyridinium bromide under control means looking out for each other. It’s not just about avoiding fines; it’s about making sure every researcher gets home safe.

Understanding What’s at Stake

Protecting people’s health and preventing harm to the environment comes first during any chemical spill. Myristylpyridinium bromide, used in surfactants and as an antiseptic, doesn’t belong on the floor or down the drain. I once saw a mild spill set off hours of cleaning and paperwork in a university lab. Looking back, I wish we had better training. Quick thinking can save a lot of trouble, but good practices make the real difference.

What Actually Works in an Emergency

Simple steps matter most. Never let panic take over. Evaluate the area for exposure risk. At the first sign of a spill, send a quick word to a supervisor, then move people away from the scene. Anyone who touches the substance should step aside and wash up, with a lab partner making sure nothing goes unreported.

Personal protective equipment isn’t just for show. Gloves, goggles, and lab coats keep the material off your hands, face, and skin. If ventilation seems poor or dust forms, use a half-mask respirator with the correct filter. I learned from a chemical hygiene officer that wearing basic nitrile gloves, not latex, offers better resistance. It’s easier to switch them out regularly than to regret a careless shortcut.

Cleaning Up: No Shortcuts Allowed

No one welcomes hours of cleaning, but every chemical deserves respect. Don’t ever try to sweep up powder with a dry broom or a vacuum without HEPA filtration—dust just hangs in the air and makes things worse. Instead, grab absorbent pads or damp paper towels and gently sweep the area. I picked up one lesson after seeing powder cloud rise by careless sweeping: slow movements prevent more mess.

Collect the soaked material right into sealable plastic bags or a chemical waste container. Heavy-duty zip bags work fine for small spills. For large spills, line a bucket with a waste bag and use a dustpan and scraper. Seal up everything, label it with the chemical’s name, and mark for hazardous waste pickup. Watch out for residues, especially near baseboards or electrical outlets—those need a second check and sometimes alcohol wipes.

Ventilation Can’t Be Ignored

Never try to mop up in a stuffy room. Even if the chemical doesn’t smell strong, fine particles can linger. I’ve felt the sting of chemical dust in a stuffy room before. Windows open, fans running, or even portable fume hoods all help get stray particles out. If no options exist, the spill may need trained hazmat response.

Why Reporting and Training Matter

Mistakes happen fast, especially for newcomers. Regular spill drills and updated chemical inventories make cleanups smoother and less stressful. Strong reporting habits, with logs of date, time, amount, and responders, keep everyone honest and prepared for audits. Correction flows into prevention; I’ve seen teams learn from honest slip-ups and tighten their routines because someone bothered to write it down.

Preparedness: Building Safer Habits

Designated spill kits equipped with absorbents, gloves, and labeled waste bags help everyone respond faster. Keeping these kits in plain sight removes panic from the picture. I always encourage people to practice with sample spills—muscle memory builds confidence. Rushed cleanups rarely end well, so patience and procedure save the day.

Understanding Myristylpyridinium Bromide

Myristylpyridinium bromide finds its way into a variety of products as a surfactant and antimicrobial agent. Daily life only rarely brings this chemical into the spotlight, but those involved in manufacturing, laboratories, or certain cleaning jobs might come into more frequent contact.

Challenges from Chemical Contact

Personal health matters a lot, and sometimes folks working with surfactants might notice effects right away. Myristylpyridinium bromide's irritant properties top the list of concerns. Skin that brushes against it can sting, itch, or show redness. Eyes don’t take kindly to direct splashes—it’s not unheard of for people to feel burning, watering, or blurry vision immediately afterwards. Repeated exposure over weeks or months can dry or crack the skin, possibly leading to dermatitis.

People sometimes shrug off protective gear, thinking a little contact won’t hurt. That’s not the sort of risk most would casually take if they knew even brief exposure might cause discomfort. For folks with pre-existing allergies or chemical sensitivities, such exposures can trigger stronger reactions—think swelling, rashes, or worsening eczema. Even a study from the National Institutes of Health highlighted how quaternary ammonium compounds (Myristylpyridinium bromide belongs to this group) often irritate the skin and airways of exposed workers.

Airborne Exposure and Breathing Issues

For those working with powders or spraying solutions, inhaling tiny droplets is possible. People with asthma or similar lung problems may experience wheezing, coughing, or shortness of breath. Repeated inhalation sometimes raises the risk for occupational asthma, something that can affect workers for years. Chronic exposure in poorly ventilated spaces only multiplies these risks.

Broader Health Concerns

There’s a lingering question about long-term damage. A handful of animal studies suggest quaternary ammonium compounds can have toxic effects on specific organs after long exposure, especially in higher concentrations than most people would ordinarily face. The World Health Organization and the Environmental Protection Agency leave safety margins in their recommendations, because there’s still a gap in human trials. Unanswered questions remain about chronic toxicity or links to bigger health worries, like reproductive problems, though current evidence hasn’t established a direct connection for Myristylpyridinium bromide.

Solutions for Safer Workplaces

Knowledge and preparation always beat regret. Routine skin checks and prompt reporting of rashes, coughing, or watery eyes make a real difference. Gloves and eye protection serve as cheap insurance—no one’s regretted pulling on nitrile gloves or a pair of goggles before handling unknown chemicals. Training on safe handling keeps the next person informed, and it builds a culture where looking out for each other is second nature. Good ventilation, like open windows or working under a fume hood, helps clear the air in spaces where fumes or splashes happen.

For regular users, reading safety data sheets isn’t bureaucratic box-ticking. Those sheets explain how to store, use, and dispose of Myristylpyridinium bromide with the respect it deserves. Washing hands after work and avoiding touching the face during use never goes out of style. For folks running businesses or labs, offering full access to safety equipment and clearly labeling chemicals cements trust and stops accidental mixes or risky shortcuts before they start.

Staying Informed

Science doesn’t stand still. New research, government studies, and workplace reports help update safety standards over time. For now, a healthy dose of caution, awareness, and common sense keeps chemical risks in check.