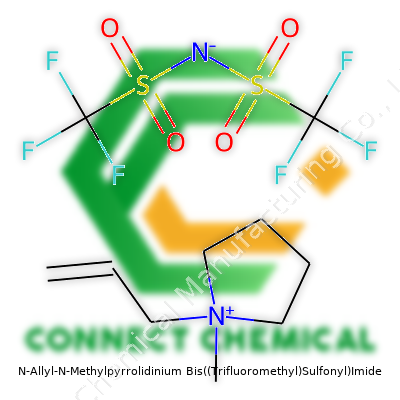

N-Allyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide: Commentary and Insights

Historical Development

Chemists didn’t land on N-Allyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide overnight. The journey of this compound started with the push for safer, more robust electrolytes during the lithium battery era of the late 20th century. Organic salts with non-flammable characteristics became a high priority after countless fire mishaps. Researchers moved from classic ionic liquids like EMI-TFSI and started incorporating functional groups, like the allyl and methyl moieties here, to create more tunable liquid salts. These tweaks didn’t just help in temperature stability; they responded to the demand for specific reactivity, lower viscosity, and environmental resilience. N-Allyl-N-Methylpyrrolidinium-based salts surfaced in journals on battery and supercapacitor chemistry as new options with enticing properties, granting chemists broader playgrounds to push the limits of both green chemistry and high-tech applications.

Product Overview

This salt steps into the ionic liquid conversation with a unique blend of stability and versatility. It’s typically supplied as a clear, faintly viscous oil unless stored cold. Energy labs and chemical manufacturers value it for its non-volatility and reliable ionic conductivity. Electrochemists know it’s not limited to any one arena; researchers have mixed it in batteries, solar cells, and new-age actuators, chasing performance and safety. Its structural features, especially the presence of the pyrrolidinium core and bis(trifluoromethyl)sulfonylimide (TFSI) anion, set it apart as it tends to keep a wide electrochemical window and maintain chemical inertia, two aspects that frequently cause trouble in older, more reactive salts.

Physical & Chemical Properties

The physical side of this compound matters to anyone handling it daily. It behaves like other room-temperature ionic liquids but often beats them in low viscosity and handling ease. You’ll see a melting point below -20°C and a decomposition temperature past 350°C, making it viable for broad temperature processes. It absorbs little water from air, a plus when controlling humidity is tricky. Its conductivity, routinely checked by engineers, surpasses 7 mS/cm at 25°C in many setups, a property battery researchers pay close attention to. The strong C–N and S–N bonds in its structure mean it doesn’t easily break down, even against strong oxidizers or under extended electrical cycling, supporting its use across long product lifetimes.

Technical Specifications & Labeling

Detail matters, especially at procurement and regulatory review stages. The technical datasheet usually highlights a purity of 99% or higher. Manufacturers often stress low water content (below 0.1% by Karl Fischer titration) and minimal halide or metal ions, guaranteeing the compound’s suitability for sensitive electronics. Labels double down on the need for moisture control, safe handling, and fire safety guidance. UN numbers and GHS pictograms signal its position in chemical storage protocols, aiming for responsible handling from the lab to production floor.

Preparation Method

The classical route uses a quaternization reaction between N-methylpyrrolidine and allyl bromide, followed by anion exchange with lithium bis(trifluoromethanesulfonyl)imide. This fairly robust process relies on keeping the water out and managing precise temperatures to avoid side reactions. Organic chemists often scale only with rigid glovebox practice or Schlenk techniques, emphasizing the need for controlled environments. Yields vary (65-85%), hinging on reagent freshness and meticulous purification steps, especially rotary evaporation and multi-stage washing with organic solvents.

Chemical Reactions & Modifications

It holds up well in the face of nucleophiles and electrophiles because of its sturdy ionic framework. That makes direct modifications somewhat rare, though researchers have succeeded in tweaking the alkyl side chains or introducing functional groups for fine-tuned solubility or catalytic properties. The pyrrolidinium ring offers a foundation for more elaborate cationic scaffolds, supporting new derivatives for energy storage and carbon dioxide absorption. The TFSI anion stays popular for its size and charge delocalization, keeping the reactivity low and the stability high. Labs sometimes swap out the TFSI for other bulky anions, shifting viscosity and polarity for niche applications.

Synonyms & Product Names

Depending on the catalog or publication, you might see it called N-allyl-N-methylpyrrolidinium TFSI, or by the shorthand [AMPyr][TFSI]. Names like 1-Allyl-1-methylpyrrolidinium bis(trifluoromethylsulfonyl)imide pop up on chemical supply sites, along with variations on the IUPAC standard. Large manufacturers (Sigma-Aldrich, Tokyo Chemical Industry) catalog it under product numbers that highlight the cation-anion pair for clarity in cross-checking data sheets.

Safety & Operational Standards

Lab safety officers view this compound with cautious respect. It has a favorable profile versus volatile organic solvents, but it still calls for eye protection, gloves, and chemical fume hoods. Large spills, especially on hot surfaces, can release toxic byproducts, so training focuses on quick cleanup and containment. Automated microdosing systems and sealed transfer lines often keep human contact to a minimum. Safety data sheets cite oral and dermal LD50s that leave room for confidence, and unlike classic chlorinated or fluorinated solvents, the environmental persistence stays moderate when industrial waste is treated according to standards. Industrial sites keep detailed logs for storage locations and employ secondary containment wherever possible.

Application Area

Battery researchers have tested its limits in next-gen lithium and sodium systems, benefiting from its high electrochemical window. Supercapacitor labs see consistent gains in charge/discharge cycling. The photovoltaic industry looks to this molecule for dye-sensitized solar cell prototypes absorbing high levels of solar radiation without erratic breakdown. Newer fronts include its use as a medium for electrochemical CO2 reduction and in organic synthesis, offering mild but versatile solvation. As an antistatic agent in polymers, it doubles as both a process aid and a functional performance enhancer. Some teams have even investigated its value in pharmaceutical frameworks for ionic drug delivery vehicles.

Research & Development

Academic groups chase lower cost synthesis methods, evaluating everything from microwave heating to continuous flow systems to cut down waste and speed up production. Partnerships with industry giants explore its utility in solid-state electrolytes, mixed-matrix membranes, and redox-active organic electrolytes to push up energy density. I’ve seen specialized groups probe the effect of custom-tailored side chains, swapping allyl for benzyl or longer alkyl groups to match new polymer composites and device architectures. Journals often highlight its strong showing under thermal and oxidative stress, driving its adoption in demanding electronics or aerospace components.

Toxicity Research

Toxicologists study breakdown pathways for both the pyrrolidinium cation and TFSI anion, paying close attention to possible fluorinated side products in municipal water supplies or soils around disposal sites. Rodent models and aquatic invertebrate studies frame most environmental risk assessments, building a picture of acute and chronic impacts. For now, evidence ranks its toxicity well below older, more mobile ionic liquids, suggesting a promising safety margin for industrial applications. Still, researchers push for better assays on metabolite effects and chronic exposures in both worker populations and end-of-life water streams, keeping human and environmental safety in check as its use rises.

Future Prospects

This compound claims an expanding seat at the table as energy technologies evolve. More labs gear up to optimize synthesis costs, minimize environmental fallout, and improve biodegradability. The next leap might come from pairing its cation with even greener anions, or integrating it into nanocomposite backgrounds for advanced flexible devices. With regulators demanding transparency across chemical life cycles, developers lean heavier on full-spectrum toxicity and lifecycle studies. Looking forward, fields like quantum computing, biodegradable plastics, and next-generation medical devices may set the pace for new derivatives or smarter, circular uses of this stalwart ionic liquid. As the energy transition continues, the push for performance, safety, and sustainability will keep driving innovation—and scrutiny—in salts like N-Allyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide.

Pushing Boundaries in Battery Design

Batteries usually come to mind with lithium or classic electrolytes, but materials like N-Allyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide have sparked changes behind the scenes. I’ve spent a good chunk of time talking with engineers and researchers who keep one foot in the lab and one in manufacturing. They all mention safety as one of their bigger headaches. Most old-school liquid electrolytes in batteries catch fire if you stare at them wrong. This ionic liquid barely catches at all, even at high voltages. Engineers switch to it in high-power and next-gen lithium metal batteries that need a strong, non-flammable backbone. Phone batteries and grid-scale storage both benefit from this safety layer.

Rechargeable Devices and Greener Labs

Chemists dealing with electrochemical sensors, supercapacitors, and advanced rechargeable devices started pulling this compound from the shelf. I remember seeing a side-by-side performance test at a university demo. Devices running this ionic liquid delivered higher voltage windows and let designers crank up energy density. Unlike some niche materials, this one isn’t locked up by licensing or regulatory nightmares, which makes experimenters love it. Folks aiming for reduced carbon footprints and less hazardous waste have been using it in prototype rechargeable cells or as an electrolyte additive, since it cuts out a chunk of solvent waste and dodges petrochemicals.

Tough Industrial Conditions

A buddy working in a specialty coatings plant mentioned the challenge of doing chemical separations where heat levels soar and acids eat through normal equipment. N-Allyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide stands up to brutal industrial settings—they toss it into ionic liquid-based extraction or separation processes, such as isolating metals from complex ores. Plants handling high-value or tough-to-purify elements enjoy fewer shutdowns. Instead of swapping equipment or risking leaks, they cook up solutions using this ionic liquid thanks to its stability and low volatility.

Green Chemistry and Cleaner Production

The push for greener solvents doesn’t come from regulatory handwringing alone—scientists want to handle chemicals that stink less and don’t eat your gloves. N-Allyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide emerged as a solvent for challenging reactions that regular solvents failed. I’ve seen research labs using it to pull off tricky organic syntheses, since it often lets them ditch volatile organics and keep reaction waste to a minimum. Some groups explore its use in biotransformations because it gives enzymes a stable home, pushing reactions that barely limped along in other solvents.

Future Outlook and Possible Roadblocks

One hitch: getting this ionic liquid in bulk isn’t as cheap as mainstream solvents like acetone or methanol. Costs and supply chain wrinkles will stop some smaller outfits from switching right away. If larger production scales up, prices should come down, opening more doors for next-gen battery makers, green labs, and industrial sites trying to clean up their act. It’s promising to see something as tough and flexible as this in the hands of innovators, tackling safety, sustainability, and performance at the same time.

The Real Risks Behind Storage Decisions

Chemical stability doesn’t always look dramatic, but small changes can mean big trouble down the line. I’ve seen scientists shrug off a bottle’s seal or push a reagent back onto a warm shelf, only to regret it later. Moisture, heat, and light constantly threaten those neat rows of labeled vials. It’s not about a product’s expiration date stamped on the bottle. The hidden story unfolds in the lab’s humidity and the careless habits during late-night experiments.

Some colleagues remember one rotten sample destroying a whole week’s work, but stories fade fast. Study after study links decomposition to excess water vapor, sunlight creeping through thin glass, or temperatures drifting just a few degrees too high. For organic compounds, oxidation and hydrolysis tuck themselves out of sight until it’s too late. Inorganics can clump, discolor, or even start to fume if left exposed. Reagents that seem inert—once they turn or degrade—can ruin reactions or trigger dangerous releases, sometimes without warning.

Experience Brings Caution

In my own work, seeing a crystalline powder cake into a sticky lump reminded me: not every change is easy to spot. Even a faint odor or subtle color shift can signal something has gone wrong. Some folks take fresh bottles for granted, but I store everything based on hard-earned habit—tight lids, desiccators, far from direct sun. Chemicals with active groups like aldehydes or acids always call for an extra cold spot in the fridge, never a busy open bench.

Why the Right Storage Keeps Labs Running Safely

Over the years, poor storage has caused more headaches than outright mistakes. According to the US Chemical Safety Board, improper chemical storage leads to hundreds of near-misses each year, sometimes with explosions or harmful vapors seconds away. Labs that skip regular checks or allow clutter open the door to contamination and accidents. The right habits also protect expensive reagents—shaking the last few milligrams from a spoiled bottle wastes time and budget.

Minding Conditions as a Habit, Not a Rule

Standard recommendations—store in a cool, dry place, away from light—remain. I never trust room temperature to mean the same thing on a summer afternoon as it does in February. Digital thermometers and humidity gauges don’t lie. Even a box-in-a-box setup can add an extra barrier against moisture and temperature swings. Those using volatile compounds know: vents and extractor fans, not closed spaces, save lives and equipment.

Label dates make tracking easy. I jot down my initials, date opened, and the first sign of any change. Tossing out a suspicious powder always feels wasteful, but nothing compares to the disaster of running an entire batch only to find contamination. Peer-reviewed work on pharmaceutical degradation shows: storage slips often cost far more than the price of a new container.

Tools and Teamwork Strengthen Stability

Even the best containers can’t fix a forgetful staff or a cluttered shelf. Posting clear guidelines, running regular checks, and sharing stories about near-misses with colleagues goes further than any label or datasheet. Buying smaller amounts, keeping logs, and decontaminating shelves and fridges keep the whole lab safer. No degree of chemical expertise replaces vigilance. A tight lid and a quick glance make the difference between a reliable experiment and a ruined day.

What This Chemical Means For Lab Work

N-Allyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide—try saying that five times fast—has made a name for itself in battery research and electrochemical labs. You’ll usually run into it as an ionic liquid, which often enjoys praise for being less volatile than old-school organic solvents. The reduced vapor has drawn some to call these liquids “green solvents.” It sounds reassuring, almost like handling nothing more dangerous than briny water.

The Real Story on Safety

Once you dig into the material safety data, things start to look less warm and fuzzy. For years, I worked next to grad students swapping stories about glove tears, weird-smelling spills, and old labels half worn away. This particular compound has a mouthful of a name, but don’t let that distract from what it really does. Just because something isn’t flammable or boiling over at room temperature doesn’t mean you can treat it like baking soda. Absorption through the skin remains a key risk, an uncomfortable truth I’ve learned more than once helping clean up bench tops. Eye irritation and possible harm to aquatic life come up in hazard documentation time and again.

Why Regular Handling Routines Fall Short

I remember a time a colleague skipped eye protection during a quick clean-up, thinking an “ionic liquid” just sounds relatively harmless. Within minutes, he regretted that gamble. Once a chemical like this gets in contact with your eyes, the burning tells you everything you need about lab safety. I’ve never met a solvent—even a so-called green one—worth risking permanent damage. Acid-resistant gloves, splash goggles, and working with proper ventilation count as the basics, not as extra steps.

Environmental Hazards Can't Stay off the Table

Those “green” claims should face scrutiny. Ionic liquids often persist in water and soil. Research from places like the University of York found potential toxicity to aquatic organisms at surprisingly low concentrations. I've seen environmental engineers raise an eyebrow when people casually rinse glassware with the stuff down the drain.

How To Actually Stay Safe

Trusting gloves or fume hoods won’t save you if no one checks for chemical compatibility. Not every nitrile glove keeps these solvents out. Years spent in chemical storerooms teach you to look up glove guides before grabbing whatever is nearby. For sodium compounds, you might reach for one glove type, but for this, thicker and more resistant materials often win out. Double-gloving or checking gloves for pinholes goes from “student paranoia” to common sense.

Disposal matters, too. Store waste in tightly sealed, clearly labeled containers. Labs that treat chemical disposal as an afterthought end up with headaches later—from regulatory fines to accidents. Telling yourself you’ll “deal with it tomorrow” works until someone else tries to clean up an ambiguous bottle months later.

Making Informed Choices

No amount of tech jargon can cover real safety practices. Whether you’re developing new electrolytes or testing new batteries, experience teaches that a calm, cautious approach works best. If you walk into a lab handling N-Allyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide expecting an “inert” modern wonder, you end up surprised. Think twice, gear up, ask around for best practices, and always check the latest Material Safety Data Sheet. A little extra effort upfront saves a lot of pain—sometimes literally—down the line.

Digging Deeper than the Label

A purity specification isn’t just a number. It can be the difference between a successful experiment and a wasted day in the lab. Scientists, manufacturers, and even artists who rely on chemical supplies expect transparency about what’s in the bottle. When the label says “99.9% pure,” it seems straightforward—yet that 0.1% can mean unwanted metals, water, or organic byproducts hiding among the granules.

Over the past decade, stories from across labs and factories have made it clear: trace impurities—copper in solvents, chloride in acids, or even a few percent of “other” elements—can derail sensitive processes. As an example, researchers working on lithium-ion batteries care deeply about sodium impurities. These tiny amounts can cut battery life in half. Powdered chemicals grab moisture from the air, clump up, and lose reliability. Some impurities, such as heavy metals or certain organic residues, even risk health and safety.

The Real-World Impact of Purity

Buying chemicals isn’t about checking boxes. I once tried using off-the-shelf acetone for cleaning microscope slides. The slides were left with a cloudy residue. After switching to a higher-purity batch, the haze vanished and the experiments worked again. Here’s the core issue: downstream failures cost time and money far beyond the sticker price of the product itself. Even experienced hands get caught off guard by hidden contaminants.

Purity has real regulatory consequences, too. Pharmaceutical firms document every trace impurity. Food processors worry about allergen contamination measured in parts per million. In environmental labs, water standards can rest on whether a pollutant slips above a detection limit. So, chemical quality becomes everybody’s concern, not just a detail for the supplier’s catalog.

Forms Shape Results: More Than Just Powder or Liquid

People often overlook how the physical form changes the quality of a product. Fine powders dissolve faster, but can compact or spill easily. Granules pour better, but may leave particles behind. Liquids might seem convenient, but chemical stability can drop depending on the solvent or packaging. I learned this lesson in a project where a “dust-free” granular phosphate sounded ideal for mixing—and plugged up every piece of equipment we used.

The story repeats across industries. Engineers mixing plastics choose pellets for easy feeding. Labs making solutions seek crystalline forms that handle storage and humidity. Someone planning pesticide sprays checks for emulsifiable versus wettable powder, based on application. Purity and form are linked: liquid forms may hold stabilizers that affect both performance and shelf life; powders pick up contaminants or moisture in the wrong packaging.

Building Trust Starts with Clarity

Experience shows that clear documentation and open answers from suppliers save headaches every time. Certificates of analysis (COA), batch numbers, and full specifications let buyers make informed decisions. For those dealing with customs, shipping, or compliance, transparency prevents delays or legal trouble. A supplier able to specify the analytical method—ICP for metals, GC for solvents—signals accountability.

In the end, careful attention to purity and the right form supports every stage of research, development, and production. Demanding detail, asking questions, and reviewing data builds a foundation for safe and successful outcomes. The small print on a label can carry the weight of an entire project.

Change Drives Curiosity

Every time a lab bench lights up with a new compound, the mood changes. Promises of higher energy density or lower toxicity push curiosity even farther. My interest in battery materials comes from spending years watching how ingredients play out in real-world conditions—shake well in a vial, press into electrodes, repeat the tests. The makeup of a compound shapes more than just data on a chart. It changes how a cell gets built, charged, or recycled.

What Counts Under the Microscope

The basics matter. Let’s say we look at a newly proposed salt, oxide, or organic hybrid. Stability stands out early. If it breaks down in air or water, nobody wants to spend late nights chasing after vanished samples. Labs race for compounds that hold up, shipping value straight from bench to patent filings.

Performance grows from structure. The way atoms stack in a lattice, how ions travel through pores or defect sites—these little differences add up. Transition metals, phosphate groups, long-chain polymers each cast their own shadows on energy storage. Some combinations handle cycling for hundreds of times; others struggle once the pouch gets squeezed or heated.

Killer Apps and Red Flags

I often think back to early trials with lithium iron phosphate. Years ago, skepticism hovered since its voltage numbers trailed bigger-metal cousins. Still, cost and safety won out. A promising compound has to deliver real improvements: more charge per gram, safer fail modes, or cheaper manufacturing. If a compound contains rare or toxic elements—think cobalt, some nickel salts, heavy organics—the supply chain grows brittle. Cleanup gets expensive, politics climb into the story, and long-term investment slows down.

Cycle life grabs attention fast. A candidate can’t just work at the start. It should keep most of its punch after hundreds of discharges. Reports of fading capacity or sudden breakdowns usually send researchers hunting for fresh alternatives. If solvents in the process damage the material, or if byproducts build up on electrodes, nobody sees much future in scaling up.

Chasing Data, Not Vibes

Data from reputable sources sets the stage. Peer-reviewed journals prevent wasted effort; duplicate studies add muscle to breakthrough claims. Battery chemistry thrives on honest skepticism. Microsoft Academic, Nature, and Journal of Power Sources show trends, but numbers from these places stick if the methods hold up to repeat testing. Distributors and synthesis notes add helpful footnotes, like melting points or safe handling steps.

My lab time taught me to rely on impedance charts and scanning electron microscope images as much as sales sheets. Only real-world numbers, not wish lists, decide if a compound deserves a next-gen label. Energy density, voltage thresholds, safety in overcharge events—these numbers bear out across teams before commercial cash flows in.

Practical Paths Forward

Many labs cross-check possible battery candidates side by side. They swap out cathodes, tinker with binders, recalibrate cycling protocols, and compare trace impurities. Environmental regulations tighten year by year, so compostable or low-waste formulas often get extra funding. If a compound slides through these hurdles—robustness, performance, cost, and clean disposal—companies pick it up for more aggressive field tests.

Energy storage will always outpace theory alone. Ideas on paper run fast; benchwork walks behind, testing every bold claim. Real progress comes from compounds that meet the handshake moment: a cell built, charged up, and run thousands of times under uneven, imperfect conditions—then still hold charge by the end.