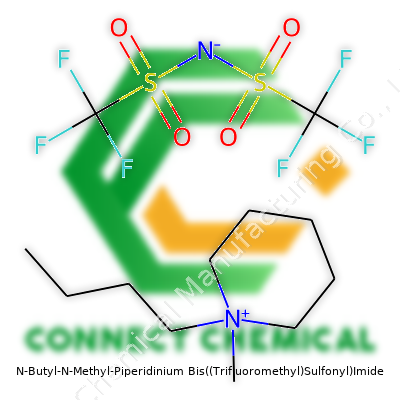

N-Butyl-N-Methyl-Piperidinium Bis((Trifluoromethyl)Sulfonyl)Imide: A Deep Dive into Its Journey, Properties, and Impact

Historical Development

Chemistry journals didn’t always buzz about ionic liquids like N-Butyl-N-Methyl-Piperidinium Bis((Trifluoromethyl)Sulfonyl)Imide. In the late 20th century, ionic liquids barely registered outside small research labs. As environmental regulations started pinching the chemical industry, scientists scoured for cleaner alternatives to volatile organic solvents. This compound’s birth followed that wave. Researchers at the intersection of green chemistry and high-performance engineering channeled years of exploration into developing ionic liquids based on piperidinium cations and bis(trifluoromethylsulfonyl)imide anions. Their discoveries weren’t just about molecules. They carved out a space for safe, efficient solvents in labs and industries. This family of salts matured as the backbone for electrolyte innovation, energy storage research, and specialty synthesis techniques that pushed boundaries throughout the early 2000s.

Product Overview

N-Butyl-N-Methyl-Piperidinium Bis((Trifluoromethyl)Sulfonyl)Imide doesn’t blend into the crowd of industrial chemicals. With a piperidinium core, one methyl, and one butyl side chain, it forms a cation that interacts tightly with the bis(trifluoromethylsulfonyl)imide anion. This combo yields an ionic liquid—basically a salt that remains liquid at room temperature. Such compounds don’t give off toxic vapors, a key edge over traditional organic solvents. Researchers chase after this liquid for its unique mix of chemical stability, negligible vapor pressure, thermal robustness, and unusual electrochemical behavior. In a world where chemical spillages, environmental fines, and vapor hazards can slam budgets, materials like this deliver practical value alongside laboratory curiosity.

Physical & Chemical Properties

Pour this ionic liquid into a beaker, and it’ll form a nearly colorless, sometimes faintly yellow, viscous liquid. Density lands close to 1.32 g/cm³, sticking heavier than water but flowing with surprising smoothness. Most brands offer the product at purities exceeding 99%, with rigorous controls on water and halide content. The melting point sits low enough to keep it liquid at standard lab temperatures. The real asset lies in its wide liquid range—freezing temperature around -9°C, decomposition above 350°C, resisting most attempts at evaporation in open air. It handles exposure to common acids and bases with nonchalance, won’t combust like many hydrocarbons, and dissolves a spectrum of polar or semi-polar compounds. The bis(trifluoromethylsulfonyl)imide anion, loaded with electron-withdrawing groups, delivers significant hydrophobicity, so this liquid often shuns water, preferring organic company.

Technical Specifications & Labeling

Bottles in industry and academia arrive with international shipping designations, capped in chemical-resistant containers. Researchers and operators check for purity markers, measured water content, batch identification, and recommended storage temperatures—usually below 30°C to preserve shelf life. High-voltage battery manufacturers and electrochemical labs prize lots that post detailed electrochemical window readings; commonly, technicians look for stable performance up to 5 volts, even in presence of reactive metal electrodes. Safety Data Sheets spell out regulatory identifiers, including CAS numbers—105886-57-7 for those tracking international databases. For environmentally sensitive projects, suppliers often provide evidence of heavy metal analysis and compliance with RoHS or REACH standards.

Preparation Method

Years in the lab taught me that scaling up the synthesis of advanced ionic liquids turns routine chemistry into an exercise in patience and precision. This product usually starts with N-methylpiperidine, which undergoes butylation with a butyl halide in a solvent like acetonitrile. Controlled heating, vigorous stirring, and real-time monitoring of phase separation help chemists wrangle high yields of N-butyl-N-methylpiperidinium halide. That intermediate then meets lithium bis(trifluoromethanesulfonyl)imide in water or acetonitrile. Anion exchange triggers precipitation of lithium halide, leaving the target ionic liquid in solution. Chemists rely on repeated extractions, vacuum drying, and filtration, aiming to remove trace halides—since leftover chlorine or bromine can sabotage stability. The process, while labor-intensive, scales up consistently for bulk supply once optimized. Every bench chemist knows the relief of testing the final product by NMR, only to see clean peaks and a sharp absence of contamination.

Chemical Reactions & Modifications

This ionic liquid often joins reactions as a solvent, but also as a reactant. It resists breakdown under most standard reaction conditions, though prolonged exposure to strong bases or nucleophiles may trigger subtle decomposition—especially at higher temperatures. The piperidinium core allows for functionalization on nitrogen or ring carbons, offering creative chemists a handle to tweak solubility or tune ionic conductivity. In electrolytes for lithium batteries, scientists modify the alkyl chains—sometimes swapping butyl for hexyl or ethyl, hunting marginal gains in conductivity or viscosity that can improve cell lifespan and performance. I recall struggling with high-viscosity issues during an electrode surface study. A small switch on the piperidinium structure dropped viscosity by a third, showing how minor chemical changes transform application potential.

Synonyms & Product Names

N-Butyl-N-Methyl-Piperidinium Bis((Trifluoromethyl)Sulfonyl)Imide pops up in catalogs as BMPy-TFSI, BMP-TFSI, or even [BMPip][TFSI]. Some suppliers refer to it as 1-Butyl-1-methylpiperidinium bis(trifluoromethanesulfonyl)imide. Each synonym signals the same core compound, but knowing the difference prevents crossed wires when ordering or searching through literature. Global procurement often hits snags on slight naming mismatches, so researchers keep a sharp eye on chemical synonyms to dodge delays and miscommunications.

Safety & Operational Standards

Most chemists never forget early lab days, learning to respect every bottle's hazard label. This ionic liquid changes the routine: no explosive vapors, minimal fire risk, but persistent warnings about long-term handling. Gloves, goggles, and lab coats stand as the first defense—standard practice, regardless of low volatility. Inhalation risks drop compared to volatile solvents, but splash or skin exposure brings discomfort and potential irritation. Researchers check for proper ventilation during weighing or sample preparation, since low volatility still doesn't mean risk-free. Waste disposal channels into the same containers as other organic chemical residues, never down the drain. Detailed record-keeping helps manage compliance with environmental guidelines; no one relishes a surprise audit or spill. Regular training, clear written protocols, and readiness for accidental exposure build a safer, more confident laboratory culture.

Application Area

Electrochemical engineers and battery startups often chase after new ionic liquids to push lithium-ion performance. This product’s popularity exploded alongside wider adoption of high-reliability batteries in consumer devices, electric vehicles, and backup grids. The non-flammable nature and standing tolerance for high voltages enable safe operation where traditional carbonates catch fire under stress. Supercapacitor designers, fuel cell researchers, and industrial lubricant developers thread this compound into prototypes for energy storage and transfer. Its near-zero volatility keeps sensitive reactions contained, helping photochemical and catalytic experiments run cleanly with fewer byproducts. I’ve consulted on projects exploring solar cell manufacturing and advanced separations. In every case, the shift to this type of solvent unlocked simpler, safer workups and cleanup, especially when compared to toxic hydrocarbons or chlorinated solvents.

Research & Development

Universities and startups run headlong into each other in the race to invent new materials for a low-carbon future. Researchers continue chasing novel ionic liquid modifications, looking for improvements in conductivity, viscosity, and environmental compatibility. The piperidinium family offers promising ground for tuning structure and performance, so grant proposals and research papers pile up every year. Industry partnerships focus on scaling up synthesis, cutting material costs, and evaluating compatibility with rare-earth elements or alternative electrode materials. The conversations I’ve had with academics often center on the need for practical, scalable routes from bench to industrial pilot plants. The gaps between small-scale synthesis and real-world manufacturing remain one of the biggest sticking points in commercial adoption—but ongoing collaboration edges the technology forward.

Toxicity Research

Initial excitement over ionic liquids sometimes glossed over their long-term environmental and health effects. Toxicologists quickly caught up, finding that even compounds with low immediate toxicity can accumulate in ecosystems or disrupt wastewater treatment. This compound resists rapid breakdown in soil or water, prompting deeper studies into its potential bioaccumulation and endocrine disruption. Short-term tests in rats and fish often show moderate toxic thresholds, though well below the risk posed by classic solvents like benzene or toluene. Labs now run ecotoxicity screens as a routine part of product approval, reviewing not just acute effects but also the potential for slow leaching or long-term harms. Data from the past decade recommends careful containment and waste management, echoing what many chemists have learned through direct experience—nothing used at industrial scale comes without consequences that ripple far beyond the lab.

Future Prospects

Electrification of transportation and the march toward safer, greener chemistry propel this compound into a bright, but complex, future. Battery innovation needs stable, high-voltage electrolytes, and materials built around piperidinium and TFSI anions deliver the precise properties demanded by next-gen systems. Yet regulatory pressure around persistent chemicals pushes scientists to re-examine environmental and toxicological footprints. I’ve watched manufacturers pivot quickly, racing to adapt process chemistry or seek greener alternatives as data and guidelines evolve. Collaboration between academic groups, startup labs, and established chemical giants continues to drive incremental gains—whether through better purification strategies, new functional group tweaks, or improved recyclability. Enthusiasm remains grounded by the reality that every advancement carries a responsibility to public health and the earth. Success isn’t just about engineering molecules; it’s about building materials that meet urgent demands without mortgaging tomorrow’s resources.

Powering the Future of Batteries

Most people have never heard of N-Butyl-N-Methyl-Piperidinium Bis((Trifluoromethyl)Sulfonyl)Imide, often shortened for the sanity of chemists as BMP-TFSI or similar. In the world of battery innovation, this ionic liquid keeps showing up in research for lithium-ion batteries, pushing technology past old limits. Working with batteries means chasing better performance—higher safety, more stability, and much longer life. BMP-TFSI steps in where regular electrolytes won’t cut it.

Understanding the Buzz

Ionic liquids like BMP-TFSI refuse to evaporate easily. They barely burn, even under stress. Ask anyone who has worked with flammable solvents in a battery lab—pouring a volatile electrolyte brings risk. Mixing BMP-TFSI into batteries pulls a lot of that danger away. It still lets ions zip back and forth, powering phones, cars, and solar backups, but brings down the risk of a meltdown or explosion.

Researchers lean on this unique chemical structure when they need electrolytes that don’t freeze, even in real cold, or break down when pushed past normal voltage. It handles heat and cold without blinking. Devices built for electric cars, grid-scale storage, or even satellites benefit when the chemistry inside the battery won’t quit.

Supporting the Transition Away From Fossil Fuels

We need new solutions to store energy when the sun goes down or the wind stops blowing. Large batteries lined up in banks keep whole neighborhoods running between gusts, but older lithium-ion designs carry real risk and keep firefighters on edge. Swapping in robust electrolytes such as BMP-TFSI offers a straightforward upgrade. This switch cuts down on fire risk and helps systems last longer. That means less waste, fewer dead packs to recycle, and a smaller footprint for every watt stored.

Potential for Beyond Battery Tech

Besides batteries, BMP-TFSI gets attention for its role as a solvent. Companies working with advanced chemical processes, such as making pharmaceuticals or processing rare metals, face tight controls on emissions and safety. The push toward greener, less toxic industrial solvents points right at ionic liquids. BMP-TFSI doesn't let off clouds of toxic vapor. It stands up under pressure and cycles of reuse. From my time in a lab wrestling with messy, evaporative solvents, using a stable, almost odorless ionic liquid makes cleanup and safety rules far easier to respect.

Scientists keep pushing the boundaries, mixing BMP-TFSI into new battery recipes, advanced supercapacitors, and next-generation devices. Each breakthrough buys a little more time off the grid and builds tech a bit more resilient to misuse, heat waves, and crashes. Old-style electrolytes brought compromise. This newer breed removes some of those problems. BMP-TFSI, with its baked-in safety and flexibility, helps real-world applications catch up to lab promises—and that keeps us moving forward, one cycle at a time.

Getting a Real Feel for What This Compound Is

Most people probably don’t think about things like melting point or solubility when they think about what makes a substance tick. It’s easy to overlook the nuts and bolts, but physical properties give us a way to know how a compound will behave before anyone tries to use it. Take its melting point, for example. A substance that melts at a high temperature often shows stability—you can heat it, move it, mix it in manufacturing, and it won’t break down or ooze out all over the place. If you think about how table salt keeps its form in a hot kitchen, you start to see the value of stability. Boiling point brings similar practical strengths. A compound with a high boiling point won’t turn into a gas and vanish when things heat up, so storage and safety plans can be made around that quality.

How a compound looks—crystalline, powdery or oily—tells a lot about what it’ll be doing once it hits your hand or a mixing tank. The look, the density, even the color let you spot contamination or mishandling before big problems start. Chemists in food, cosmetics and medicine need reliable consistency and purity.

Breaking Down Chemical Properties

Chemical properties deal with how stubborn or reactive a substance acts. Flammability counts big in industry. Take acetone—many nail salons keep it around, but its high flammability means every bottle needs careful handling. A less flammable compound makes for a quieter day and just easier storage.

Reactivity tells whether something will play nice with others or throw a fit during mixing. For cleaners or agricultural chemicals, that kind of knowledge prevents dangerous surprises. Some substances react with air or water, giving off heat, gas, or even acid. These reactions aren’t just academic—they shape how you store things and what gear you must wear.

Another thing we check is pH. A compound that leans acidic or basic can damage skin, metal storage tanks or even the environment. Folk wisdom says to keep vinegar and bleach apart for a good reason—mixing the wrong substances can create problems for people and property.

What’s at Stake?

Different industries have different needs, but most face the same risks: safety, cost, and effectiveness. I’ve seen a soap maker get a shipment of the wrong grade of sodium hydroxide—that batch not only cost money, the harshness caused real skin burns. Knowing what you’re handling isn’t just following a rulebook; it’s the difference between safe habits and an accident.

How to Make It Better

There’s a lot of power in transparency and education. People handling chemicals—whether at home, in a lab, or in a factory—really need details about what’s in their hands. Clear labeling and access to data sheets matter, but I’ve learned it takes straight talk and training as well. Employers and regulators ought to invest more in plain-language guides and real-world examples.

Better testing in key industries, even at a small scale, pays for itself when it catches a hazard early. Anyone can grab gloves and goggles, but a person who understands how a compound acts will be safer and work smarter. Industry-wide sharing of real mishaps and fixes can keep others out of trouble, and fosters a culture of responsibility in every field.

Understanding the Risks

N-Butyl-N-Methyl-Piperidinium Bis((Trifluoromethyl)Sulfonyl)Imide doesn’t turn up on household shopping lists. Its name alone feels daunting—chemical safety feels even more important with tongue-twisters like this. This ionic liquid draws attention for its use in advanced batteries, electrochemical devices, and specialty manufacturing. Laboratories and factories keep it because its properties help achieve things typical materials can’t pull off. But anyone opening a bottle or barrel of this stuff faces a reality: this chemical brings real risks to health and safety.

Hazards Worth Knowing

Stories pass between researchers about skin irritation after spills, headaches from poor ventilation, and gloves changed more than once in a shift. Most ionic liquids, including this one, don’t smell or look dangerous. That leads to tricky moments—someone skips goggles, thinking, "It’s just a salt, right?" but trifluoromethyl sulfonyl imide anions carry toxicity. Published studies show these substances can cause skin and eye burns, respiratory discomfort, and sometimes more severe effects if people don’t take care.

Direct evidence remains limited for chronic human health effects, but experts lean toward caution because the fluorinated groups raise environmental flags. Animals exposed to similar compounds often develop liver and kidney trouble, and these chemicals break down very slightly if at all—once they exist, they’re tough to remove from water or soil. One 2022 toxicology review called out the need for better environmental tracking. Exposure at work brings the biggest risk for people, but factories using ionic liquids can also add to broader chemical pollution if they don’t manage waste properly.

Smart Precautions Matter

Over the years, I’ve seen how much good habits can shield us in the lab. Splash goggles and nitrile gloves stop splatter and keep hands protected. Chemists use lab coats, fume hoods, and chemical-resistant pads on benches. A few minutes of setup becomes the difference between a harmless task and a painful chemical burn. Ventilation stands out as vital. If vapors get trapped in a small room, it’s easy to develop headaches or chest tightness in an afternoon. Simple rules like "never work alone" and “read the SDS before handling anything new” slow folks down, but they keep accidents from turning serious.

Clean-up deserves attention, too. Any chemical spilled on benches or floors requires a dedicated spill kit. That means absorbents, neutralizers, and a way to label and bag waste for disposal. Rags or regular paper towels just spread risk around and add confusion if something gets thrown in a regular trash can by mistake.

Tackling Long-Term Concerns

Labs and businesses can’t treat this stuff as just another bottle on the shelf. Responsible handling routines must include worker training days, updated safety datasheets, and time set aside to review near-misses and improve protocols. From where I stand, group learning and clear instructions save more fingers and eyes than expensive safety gear.

Regulation matters. Some countries now require tracking ionic liquid wastes. Company leadership builds trust when they invest in high-quality wastewater treatment, air filtration, and regular environmental checks. These moves protect everyone, from lab workers breathing the air to the communities downstream.

N-Butyl-N-Methyl-Piperidinium Bis((Trifluoromethyl)Sulfonyl)Imide belongs in careful hands. With proper planning, respect for potential harm, and a culture of safety, this powerful tool doesn’t have to bring along regret.

Getting Storage Right: Why It Matters

Anyone who’s spent time working in a chemical lab knows how easy it is to overlook storage protocols, especially when unfamiliar compounds show up on the bench. You remember the dramatic stories that prove ignoring these protocols can cost both time and safety—sometimes more. With certain ionic liquids like N-Butyl-N-Methyl-Piperidinium Bis((Trifluoromethyl)Sulfonyl)Imide, mistakes come from underestimating subtle things such as moisture creeping into containers and temperature shifts.

What’s Really at Stake: Keeping Quality and Safety Top of Mind

This compound, often called BMPyTFSI, stands out for its thermal stability and nonvolatility. People use it in battery research, electrochemistry, and materials science because of these properties. But throw it in a regular cabinet and you risk water contamination. Exposing BMPyTFSI to humid air leads to changes in viscosity and ionic conductivity, making your sample unreliable for future experiments. I’ve watched projects stall because what seemed like a minor bump in numbers actually traced back to moisture uptake in ionic liquids.

Beyond quality, storage ties directly into health concerns. Although BMPyTFSI doesn’t vaporize quickly, any compound with bis(trifluoromethyl)sulfonyl imide in its name carries the risk of chemical burns and potential toxicity. Nobody wants to open a container only to find hydrolysis products, or worse, an unidentified sticky mess that demands cleanup.

Clear Steps: Proper Storage from Experience

BMPyTFSI fares best in airtight glass bottles with Teflon-lined caps. Plastic containers won’t do the job, as some polymers leach or deform over time. I always double-check seals after seeing otherwise fine samples slowly go off due to unnoticed cap warping.

This is a hygroscopic compound—meaning it’s thirsty for water in the air. Never store it on open shelves, no matter how dry the room seems. Instead, place the container inside a desiccator with fresh silica gel or another proven drying agent. If you’re handling large quantities in industry, walk-in dry rooms or nitrogen-filled glove boxes keep the air moisture-free and prevent awkward results in downstream processing.

Heat speeds up unwanted reactions. Even if BMPyTFSI stays stable at higher temperatures, keeping it cool extends its shelf life and prevents discoloration. In my own lab, the sample bottles sit in a dedicated fridge alongside other sensitive liquids—far away from acids and oxidizers. Guidance from chemical suppliers usually recommends 2 to 8°C, which fits with what I’ve seen in practice.

BMPyTFSI needs to stay away from light too. UV exposure might trigger subtle degradation, especially over months. Amber glass provides a smart and easy barrier.

Practical Moves: Building Good Habits

Simple steps make long-term sense: Label containers with date and source, replace drying agents often, and track how long each batch sits in storage. If I forget to do this, I risk repeating mistakes or wasting money on ruined chemicals.

Training new staff matters. So many accidents come down to not knowing the quirks of each compound. Taking twenty minutes to walk someone through these steps has saved hundreds of hours in lost research and mitigated unexpected cleanup.

Reliable Sourcing and Ongoing Review

Get BMPyTFSI from reputable suppliers that provide detailed certificates of analysis. Documentation about purity, residual solvents, and water content helps you confirm that the storage process supports, rather than undermines, your experiments. That’s the difference between meaningful results and wasted time chasing down contamination.

Regularly inspect storage spaces and review protocols as new information comes out. What worked fine a decade ago might fall short by today’s safety and consistency standards.

Looking Ahead

BMPyTFSI has earned a spot in serious research and tech labs because of the value it brings. Keeping storage rock solid lets that value come through without interruption or unnecessary risks. Good practice keeps discovery on track and people safe.

Purity: Not Just a Number on a Label

Most people glance at the purity percentage and move on. There’s a lot more behind that figure. High purity often means better performance. I’ve worked in an industrial lab where the raw materials made or broke the experiments. We checked for impurities that might seem insignificant to someone scanning a data sheet. Some impurities ruin batch consistency, or worse, damage equipment. High-purity products come with a higher price tag, but it’s not just about the cost—it’s about trust and reliability.

For example, chemical producers offer purities like 98%, 99%, or even 99.9%, each serving different buyers with different risk tolerances. Industries like pharmaceuticals or electronics often demand the highest grades. The smallest trace contaminant triggers big headaches in downstream applications. In other sectors, chemical engineers can tolerate minor impurities if the cost savings help margins.

Packaging Sizes and Real-Life Logistics

Packaging size matters a lot, more than people admit. In my time managing an R&D facility, we always looked for suppliers with flexible packaging. Small teams testing new processes asked for 500-gram samples—nobody wants a shelf full of unopened drums. At full scale, you expect drums, totes, or even tanker trucks rising up at the loading dock. Getting stuck with one size never helps anyone.

Chemical suppliers learned fast: offer 1 kg, 5 kg, and 25 kg packs, but also the large 200 kg drums for factories that run 24/7. Some vendors get creative—custom packs by the pallet, lined bags, or tamper-evident containers for sensitive materials. These aren’t marketing gimmicks—they’re risk reduction tools. I once saw contaminated packaging spoil a whole order. Reliable packaging isn’t just about protecting what’s inside—it keeps people safe, keeps auditors happy, and cuts waste.

Smaller batches can help research and medical labs keep budgets in check, while big players want consistent supply in bulk. I’ve seen startups stuck with outdated raw material because the only packaging available was much too large for their needs. Flexible options help companies scale—nobody wants to overpay for storage or throw out unused product months later.

Quality, Availability, and Trust: More Than Just a Purchase Decision

Anybody buying raw materials deals with more than just quantities and stats on a spec sheet. There’s a direct link between purity and the stability of finished goods, whether that’s a tablet, an adhesive, or a specialty gas. A supplier’s willingness to provide detailed purity data (spectral analysis, batch certificates) shows real transparency.

On the packaging side, too many choices to list won’t fix supply chain headaches. What really changes the game is strong communication with the supplier. Clear, honest availability updates, and helpful documentation, make all the difference. If a company offers rush service or specialty packaging for temperature-sensitive goods, that speaks to real understanding of end-user needs—not just selling a product, but supporting operations.

Smart Buying: Asking the Right Questions

Buyers have leverage, especially when they start asking questions beyond the numbers. What contaminants are present, how often is that checked, who certifies the claims? What’s the packaging material, how is it stored, what if my needs change next quarter? These questions don’t just protect the investment—they keep people and processes safe.

Looking past the headline purity and basic sizes, a company’s real value comes through in the fine details. Someone who’s managed purchasing lives through the headaches of overlooked specs and inconvenient deliveries. There’s real peace of mind in a supply partnership that puts both purity and flexibility first.