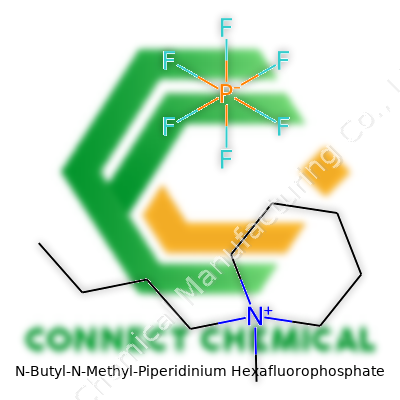

N-Butyl-N-Methyl-Piperidinium Hexafluorophosphate: A Commentary

Historical Development: Shaping Modern Electrolyte Science

The journey of N-Butyl-N-Methyl-Piperidinium Hexafluorophosphate has roots stretching back to explorations into ionic liquids during the late 20th century. Early researchers chased alternatives to volatile organic electrolytes that plagued conventional batteries and electrochemical setups. One milestone arrived as chemists started tweaking the piperidinium cation, which led to a family of salts with remarkable electrochemical windows and reduced flammability. By deliberately incorporating butyl and methyl groups, scientists balanced fluidity and thermal stability, while pairing the cation with hexafluorophosphate produced a salt that stood out for both robustness and low viscosity. Research labs worldwide, especially those focused on green chemistry and next-generation energy storage, drew insights from each refinement. In my time synthesizing ionic liquids, we often referenced early N-butyl-piperidinium platforms for building safer, more versatile electrolytes, and these molecules kept showing up in studies aiming for better lithium-ion battery safety profiles.

Product Overview: Defining Features and Market Presence

N-Butyl-N-Methyl-Piperidinium Hexafluorophosphate serves as a high-purity ionic liquid used in advanced electrochemistry, extraction, catalysis, and as a solvent in organic synthesis. Labs depend on its stability and non-flammability, while battery designers look for its broad electrochemical window. The salt usually appears as a clear, viscous liquid at ambient temperatures. Manufacturers highlight its consistent purity, and shelf-life exceeds that of many traditional organic solvents. In practice, bottles of this salt become staples for specialists tuning supercapacitors and experimental lithium-metal batteries.

Physical & Chemical Properties: Practical Laboratory Realities

Colorless and with a modest, sweet odor, this salt’s viscosity stays manageable near room temperature, avoiding the sluggishness that hampers many ionic liquids. Its melting point falls well below zero Celsius, sidestepping the crystal formation that complicates storage. The hexafluorophosphate anion secures thermal stability, and the cation’s alkyl chains help prevent excessive crystallization. Boiling at high temperatures—often above 300°C—prevents evaporation-related hazards, a feature especially noticeable during solvent removal from glovebox operations. Solubility shines in polar organic solvents while resisting mixing with water, a trait lab workers exploit when seeking non-aqueous reaction environments. Electrochemical studies often report windows up to 5 volts, making battery engineers hopeful for applications demanding high-voltage stability.

Technical Specifications & Labeling

Suppliers provide N-Butyl-N-Methyl-Piperidinium Hexafluorophosphate in tightly sealed amber glass to block UV degradation. Labels state purity—often 99% or higher—and indicate moisture content, since trace water affects both conductivity and stability. Density, melting/b> point, and viscosity measurements appear on the technical sheet, alongside CAS numbers and molecular structure diagrams. Compliance with GHS and REACH regulations shows up on value-added product literature, with detailed handling and transport guidelines for laboratory and industrial users. These details matter when comparing lots for consistency across electrochemical measurements.

Preparation Method: Everyday Lab Synthesis

Typical preparation starts with N-Butylpiperidine and methylating agents in a controlled atmosphere. The resulting N-Butyl-N-Methylpiperidinium salt undergoes anion exchange with a sodium or potassium hexafluorophosphate solution. Purification cycles rely on extraction with non-polar solvents, filtration, and repeated recrystallization. In smaller labs, I often handled glassware covered in condensation, tracking each wash to secure product free from inorganic byproducts. Monitoring by NMR and FTIR verified structure and absence of residual halides—a key step for battery uses. Large industrial syntheses depend on closed systems to trap HF byproduct and minimize operator risk.

Chemical Reactions & Modifications: Adaptability in the Lab

N-Butyl-N-Methyl-Piperidinium Hexafluorophosphate resists degradation under most ambient lab conditions, holding up to cyclic voltammetry and moderate redox stress. Chemical alterations usually take place at the piperidinium ring or side chains, enabling custom-tailoring of properties such as viscosity or melting point. Sometimes, the hexafluorophosphate gets traded for other anions like bis(trifluoromethylsulfonyl)imide for better ionic conductivity. My own efforts in modifying side chains sometimes led to marked shifts in solubility and interaction with lithium metal, something battery chemists actively pursue for suppressing dendrite formation.

Synonyms & Product Names: Recognizing the Lingo

In the catalogues and technical bulletins, names like BMPyPF6, BMPP, and N-Butyl-N-Methylpiperidinium hexafluorophosphate compete for attention. Trade names sometimes appear for specific grades, especially those certified for battery electrolytes or high-throughput catalytic screening. The abundance of synonyms occasionally creates confusion in ordering, so cross-referencing the CAS number ensures the right substance arrives at the bench. For those deep in the literature, tracking even small spelling changes makes the difference in comparing properties.

Safety & Operational Standards: Daily Practice in Handling

Despite lower volatility, this compound still demands respect. Hexafluorophosphate anions can emit HF if hydrolyzed, pushing facilities to establish robust ventilation, sealed containers, and rigorously dry workstations. Spillage protocols revolve around rapid cleanup with absorbent material followed by solvent rinses, all while wearing nitrile gloves and eye protection. Technicians train to recognize faint odors and any signs of decomposition. Regular moisture testing and meticulous labeling prevent accidents in multi-user labs. I can recall days where overlooking a cracked stopper led to slow water ingress, with the sharp odor of HF reminding us to check seals every shift.

Application Area: Powering Modern Technologies

The surge of interest in advanced batteries places this salt in the spotlight. Its stability and conductivity appear in devices from electric vehicles to grid storage. Supercapacitor electrodes lean on its ionic profile for rapid charge-discharge cycles. In synthetic chemistry, chemists use the salt for catalysis or extractions that require non-aqueous and high-stability conditions. Research teams experiment with blends of this and related salts to tune output for fuel cells and sensors. Demand grows every year as new patents propose fresh uses, and companies race to lock in supply chains for large-scale deployment.

Research & Development: Fueling Innovation

Teams at research institutions focus on extending the electrochemical window and improving compatibility with lithium metal anodes. Experiments with mixed cation-anion systems seek routes to safer, more durable batteries, especially important as electric mobility scales up. Others pursue computational simulations to predict modifications that enhance transport properties or minimize side reactions during cycling. I’ve watched graduate students deploy high-throughput robotic platforms to screen hundreds of minor variations, shaving months off optimization cycles. The cross-pollination of computational modeling and hands-on synthesis rapidly moves new variations out of journals and into pilot projects.

Toxicity Research: Public Health Considerations

Toxicologists dig deep into the fate of piperidinium-derived salts in both lab and environmental contexts. Acute toxicity remains lower than for most organic solvents, though chronic exposure still raises concerns. Ingestion and skin exposure studies prompt strict personal protective protocols in labs. Decomposition produces trace fluoride ions, mandating clear disposal procedures and avoidance of acidic waste streams. Eco-toxicological reviews show some persistence, so companies look into recycling streams and recovery techniques to decrease environmental legacy. Close attention to the literature and regulatory updates keeps both university labs and manufacturers in compliance.

Future Prospects: Beyond Today’s Boundaries

Engineers and chemists see N-Butyl-N-Methyl-Piperidinium Hexafluorophosphate as a stepping stone toward more stable, safer, and environmentally responsible ionic liquids. Expansion into semi-solid-state batteries, next-gen supercapacitors, and hybrid energy devices stands within reach. Anticipating global growth in energy storage, chemical producers invest in scaling processes and recovering spent product. Researchers target fine-tuning alkyl side chains and seeking out less persistent byproducts—moves likely to improve both performance and environmental footprint. Lessons from decades of small-scale experimentation feed into today’s industry roadmaps, ensuring the compound will shape technology for years to come.

Stepping Into Electrochemical Applications

In my experience working with specialty chemicals, I’ve seen N-Butyl-N-Methyl-Piperidinium Hexafluorophosphate carve out a real place in the energy sector, especially inside batteries and supercapacitors. Laboratories and industry players pay attention to ionic liquids like this because these compounds keep their chemical structure together even when electronics demand high heat or rigorous cycling. In lithium-ion batteries, for example, this salt helps form electrolytes that won’t catch fire as easily and can operate across a wide temperature range.

Electrolytes give batteries a path for ions to travel from one electrode to another. From a user’s perspective, that translates to longer battery life, better power output, and less risk if devices overheat. The popularity of electric cars and wearable tech has only raised the bar here. Automakers and electronics giants don’t want to rely on flammable and less stable materials. Research from institutions like the Fraunhofer Institute and reports in Science have pointed out that ionic liquids cut down on vapor pressure and unwanted chemical reactions. In practice, this means better safety knobs for engineers to fine-tune as they design next-gen batteries.

Shifting the Scene in Supercapacitors and Electrochemical Windows

Supercapacitors call for materials that can handle wide voltage swings without breaking down. Interestingly, the same chemical features that give promise in batteries also make a difference here. Wide electrochemical windows let storage devices run at higher voltage. More voltage equals more stored energy, and that gives engineers the leeway to design smaller, lighter packs. In industrial settings, I’ve watched researchers focus on N-Butyl-N-Methyl-Piperidinium Hexafluorophosphate blends, looking for tweaks that keep charging speeds high while cutting down on degradation.

Supporting Green Chemistry and Molecular Separations

Outside of energy, you also find this salt in the world of solvent systems. Certain chemical processes still rely on volatile, toxic solvents. Ionic liquids bring down the danger level, making it easier for labs to recycle solvents and reduce emissions. I’ve talked with environmental scientists who point to these salts during the design of extraction methods, especially for removing metals or rare elements from complex matrices. The ability to adjust the liquid’s polarity and solubility through specific ion combinations helps chemists get the selectivity they need, with less environmental harm than traditional organic solvents.

Companies searching for greener processing options keep pushing for regulations that reward lower emissions and safer production floors. If industry shifts toward ionic liquid-based solvents for tasks like catalyst recycling or rare earth separation, both worker safety and global sustainability stand to gain. It’s pie-in-the-sky to say these liquids solve every problem, but they open routes that didn’t exist before.

Challenges and Paths Forward

No story runs free from difficulty. Cost holds back widespread adoption—manufacturing ionic liquids at an industrial scale stacks up expenses quickly. Some also question their long-term toxicity and recyclability, so more research needs to dig into the full life cycle. As a worker in this area, I’ve followed lab-scale successes that never made it past pilot stages because of price tags and tight supply chains.

Progress here looks like collaborative research between industry, academia, and government labs. Incentives for recycling ionic liquids, as well as transparent reporting of environmental impacts, can help avoid the mistakes of the past. If science closes the loop on waste and drives down production costs, broader adoption seems not just possible, but necessary for safer, cleaner chemistry in the future.

Everyday Trust in Product Purity

Many folks pick up a bottle of medicine or a cleaning solution and trust the label without thinking much about the science behind it. Purity—something talked about in labs, on supply lists, and in marketing—makes all the difference between something useful and something dangerous. In my own years working around chemical products and pharmaceuticals, I learned pretty quickly that what’s inside isn’t just a technical number for the experts. For me, one impure batch of a lab reagent meant an entire project wasted, and the lesson stuck: purity isn’t just a formality.

Why Purity Guarantees Value

I once bought baking soda from a supermarket and then another batch labeled “for laboratory use.” The difference seems small, but lab-grade baking soda often sits well above 99% purity, while grocery store options allow more impurities. In industries relying on chemical reactions—medicines, electronics, even food—these details matter. Pharmaceutical producers, for example, follow Good Manufacturing Practices that demand rigorous identification and quantification of impurities, measured in tiny decimals. A small contaminant can throw off entire batches: drugs work less, batteries perform poorly, and sometimes a contaminant even causes harm. The FDA, for instance, closely watches for nitrosamine impurities in blood pressure medications, recalling products whenever levels get too high. Knowing the purity cuts down risk and builds consumer trust.

Physical State Isn’t Only Cosmetic

Physical state—solid, liquid, or gas—sounds like basic school science. In reality, it shapes how we store and handle a product. Pure substances can change form if impurities exist, leading to clumping, sediment formation, or changes in solubility. I’ve opened containers of sugar that turned into bricks after moisture got in, while higher-purity laboratory sugars stayed powdery for months. Even tiny changes in texture make a difference for machines that need to dose or blend ingredients. Hospitals, factories, and bakeries all look for specific consistency, otherwise machines choke and production stalls.

Accountability and Testing

Consumers often trust seals, labels, or a glossy technical sheet. In reality, purity comes down to the work inside a manufacturer’s laboratory. Good labs use validated tests: chromatography, spectrometry, melting point analysis. I remember failing a school chemistry experiment because my “pure” salt had too much moisture. In the real world, companies can’t afford that. Many industries now require certificates showing exact purity and batch data, not just broad claims. Third-party audits and spot checks back up data, holding suppliers to account if their product doesn’t match promises. The system isn’t perfect. Costs rise with each extra test and regulation, but the flipside—untested, low-purity products—brings recalls, lawsuits, and sometimes real injury.

Finding Solutions in Real-World Habits

Reading a label or trusting a supplier used to be enough. Tougher rules now protect us, but users need to keep up their end too. I always store chemical products as recommended, keep them dry, and use up older stocks first, since even the purest item can get contaminated once the seal breaks. For larger projects, asking for a recent test report makes sense—especially in industries where the tiniest impurity changes the result. Training staff to spot changes in smell, color, or flow goes further than any regulation. The more users understand and respect these details, the less risk of accidents, unexpected results, and costly recalls.

Bottom Line

Purity and physical state aren’t just technical side notes. They’re safety, quality, and value, every time a shopper opens a box or a technician loads a machine. Relying on best practices—with a good dose of personal vigilance—keeps products, and the people who use them, out of trouble.

Treating Sensitive Chemicals with Respect

Working with specialty chemicals demands more than just reading labels or skimming bulletin boards. I’ve moved dozens of odd salts and ionic liquids over the years, N-Butyl-N-Methyl-Piperidinium Hexafluorophosphate among them, and can’t count the number of times a simple storage error turned a pricey compound into a clean-up headache or worse.

Every chemist picks up the same hard lesson fast: moisture, light, and heat all act as slow poison to chemicals like this. This salt’s hexafluorophosphate anion makes it fussy — it reacts with water. Keeping air and humidity away isn’t just about tidy habits. Even a hint of damp can start a slow breakdown, releasing HF, which wrecks both containers and lungs. Nothing sharpens respect for proper storage like cleaning up after a leaky bottle that’s turned gritty, crusted, and smells off.

Real Lab Experience Shows What Works

In my own lab, stubbornness ruled until the first mishap. A colleague left a jar out after weighing. Over the weekend, some moisture crept in, and by Monday, the chemical looked like snow slush. Since then, we never let hexafluorophosphate salts see daylight or damp. The only way to keep their integrity: use airtight bottles, store under an inert gas like argon or nitrogen, double-check the seals, and keep everything as dry as possible. A glovebox offers the safest bet for both storage and weighing if the compound stays in demand. Not every lab uses one daily, but even just popping a silica gel pack in a tightly sealed bottle inside a desiccator drops the risk to almost zero.

Direct sunlight cooks plenty of reagents, so this salt deserves a dark place. We choose amber glass containers that filter out UV rays, which can set off slow but steady decomposition. Any time a compound smells fishy, develops crystals on the lid, or changes color, get rid of it—never cut corners. The shelf stays neat, confidence in your results stays high, and nobody’s risking their health on a shortcut.

Health and Environmental Stakes

Labs that treat these requirements as overkill gamble with safety and bank accounts. Mishandled hexafluorophosphates generate toxic HF—the kind that eats skin and glass, and never belongs in a standard waste stream. I’ve seen accidents from lazy storage send both vials and researchers to chemical safety officers. Tracing fumes or residue back to poor sealing or forgotten bottles means paperwork, lost research, and sometimes hefty fines. Government regulators treat HF-generating compounds with particular suspicion for good reason.

Building Safer Habits, Supporting Good Research

It surprises me how much safer handling routines have become just by changing habits: don’t skimp on thick gloves and lab coats, and keep a calcium gluconate gel kit nearby in case someone gets splashed. Training new staff takes patience, but presentation counts—showing, not just telling, makes storage protocols stick. Logging each transfer in a notebook, labeling every container, makes sure nothing slips through the cracks. Inspections become a simple matter of process, not panic.

If you want results you can trust, you look after your starting materials. N-Butyl-N-Methyl-Piperidinium Hexafluorophosphate brings value to battery research, solvent work, and green chemistry. Mishandling cuts that value to zero, and invites risk. A sensible approach costs nothing compared to the price of lost chemicals, wasted experiments, or hurt people.

Best Practices from Real-World Labs

Use sealed, labeled, impact-resistant amber glass. Store in a desiccator, keep it cool, out of sunlight, and always use dry, clean tools. Invest in small-scale orders and only open what you use up in two or three months. Pay attention—prevention is cheaper than cleanup, and respect for details matters more than fancy equipment or big budgets. After all, safe, effective storage means more reliable research — and healthier chemists down the line.

Everyday Workers, Everyday Risks

I’ve spent a chunk of my career standing between workers and hazardous chemicals. The funny thing is, a substance’s name or how it looks rarely tells the full story. Even something that smells harmless or shows up in household products could give you skin rashes, wreck your lungs, or stick around in places you don't want it. The chemical’s label and its datasheet—those often odd-looking packets taped to a wall or buried in a binder—hold most of the truth. Sometimes a chemical calls for gloves, goggles, or even a full suit. Others release fumes that sneak up and trigger health trouble long after a regular workday ends.

Learning from the Hard Lessons

News stories keep showing what can go wrong. Think of the disaster in West, Texas with ammonium nitrate, or smaller incidents where someone grabbed the wrong bottle in a school lab. These aren’t just cautionary tales for factories. Every neighborhood hardware store stocks things that can blind, burn, or poison. An error in a garden shed, shop classroom, or medical clinic can upturn lives. It’s not about paranoia. It’s about recognizing that most dangerous events come from routine actions—mixing, transferring, or storing without reading the instructions or understanding the symbols.

How to Identify Danger

The law doesn’t expect you to be a chemist. Labels and safety data sheets (SDS) point out real concerns—words like “corrosive,” “toxic,” “flammable.” The orange or red diamond symbols on the side of a drum count for a lot. Bleach, for instance, stands out as both common and hazardous, causing trouble for eyes and lungs, especially if mixed with the wrong cleaner. Even if the risk doesn’t leap out at you—say, talcum powder or a solvent that evaporates in seconds—the SDS gives bottom-line advice: stay ventilated, wear the right gloves, store below a certain heat. Over the years, I’ve seen simple steps miss the mark because folks wanted to save time, or thought “I’ve done this for years, nothing’s happened yet.” That’s a trap.

The Facts That Matter Most

According to the U.S. Bureau of Labor Statistics, chemical exposure leads to thousands of lost workdays each year. OSHA rules exist for good reason, and not just for show. They build on stories where lives were cut short or people carried lung damage, skin burns, or worse into retirement years. If your skin tingles, if a room smells off, if you find yourself coughing or dizzy, that’s your body’s warning light. Don’t wait to check the SDS or speak up.

Real Solutions Go Further than Checklists

More than once, I’ve walked into shops where people skipped goggles or re-used torn gloves. That never ends well. It helps to run short training sessions where folks actually handle their protective gear, practice cleaning spills, and quiz each other on chemical labels. Smart companies keep a binder of SDS sheets out in the open and update it when a new shipment arrives. Digital tracking tools can help, but only if folks trust them and take the advice seriously. It also makes sense to encourage a culture where someone can speak up or slow down a job if something feels wrong, without fear of blame or lost pay. Safety minds build around shared experience, not just policy or paperwork.

Why Packaging Choices Have a Big Impact

Packaging size goes beyond just a label on a product. Speaking from experience, there’s nothing quite like dealing with a supply room packed full of material in the wrong-sized containers, eating up space and racking up storage fees. Finding a match—between how much product you receive and how much you actually use—saves real money and helps cut down on waste. If you run a small business, juggling oversized drums becomes trouble fast; for a larger operation, tiny bags slow things down. It’s a puzzle that gets solved with better packaging options.

The Common Packaging Sizes You Actually See in the Field

People never see one-size-fits-all in packaging. I’ve worked with outfits where products landed in little 500-gram pouches, and I’ve seen the same goods shipped out in 25-kilogram sacks. In the chemicals or ingredients space, you can usually get packs ranging from single kilograms for trial runs up to full pallet quantities, filling drums and bulk totes.

Food-grade items, specialty chemicals, and even basic raw materials seem to follow a similar pattern: pouches and bags for small runs, boxes for mid-tier needs, and bulk containers—like super sacks—for major throughput. You can’t ignore safety standards either. For hazardous or fragile materials, packaging shapes up differently to follow rules and protect workers, so manufacturers often give choices that fit both the product and the person using it.

Delivery Lead Times: Planning vs. Reality

Now, let’s talk about how long it actually takes to get that packaging through your door. Everyone promises fast shipping, but the real answer comes from experience. On paper, a supplier might quote three to five days for delivery, but a surge in demand or a hiccup in customs can stretch that to a few weeks. A smart buyer builds in wiggle room. For high-volume, ready-stock items, two to seven days feels realistic. If the product needs a custom package or comes from overseas, expect a few weeks—sometimes more if the market is hot.

Holidays, weather, and global shipping drama can add days where you don’t want them. Living through the supply shortages of recent years taught many business owners the value of reliable partners and open communication. Watching tracking dashboards becomes a ritual, not an afterthought.

Why Transparency Pays Off

No one wants to sit on hold or dig through an endless email chain to find out when an order will show up. Companies that lay everything out—what sizes they have, what’s in stock, and accurate shipping estimates—keep customers loyal. In my own work, I lean heavily toward the suppliers who answer straight and tell me up front if materials need extra lead time. Surprises belong in birthday parties, not in supply chains.

Practical Solutions for Smoother Orders

Getting the right packaging at the right time doesn’t need advanced tech. Ask direct questions before placing an order: Can you actually ship quantities I want in the packaging I need? What’s the honest lead time—assuming there aren’t any shipping slowdowns? Build a basic plan for emergencies by keeping a buffer stock, even if it feels old-fashioned. If you’re working on longer-term projects, batch planning and scheduled orders go a long way.

Strong supplier relationships and open lines of communication make the real difference. You’ll spot trouble sooner, and you get better service. In the end, packaging size and delivery time can make or break a production schedule—they deserve way more attention than most people give them.