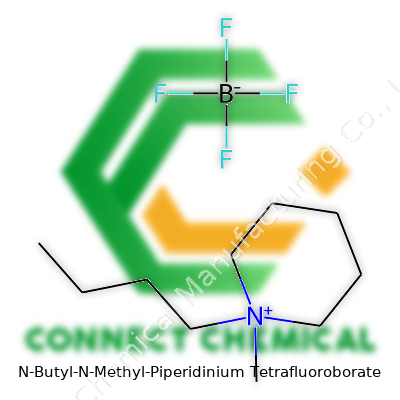

N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate: A Practical Look at a Modern Ionic Liquid

Historical Development

Back in the late twentieth century, researchers started hunting for alternatives to volatile organic solvents because of growing concerns about environmental pollution and workplace safety. Ionic liquids began getting attention for their low vapor pressure and high chemical stability, offering a fresh take on how chemists could design more eco-friendly chemical processes. As research in ionics took off, N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate found its way into labs looking for robust materials with low flammability. Early experiments showed it could be synthesized from simple amine precursors and the robust tetrafluoroborate anion, which laid the groundwork for scalable production and more diverse applications.

Product Overview

This ionic liquid brings something different to the lab bench. Its piperidinium backbone, with butyl and methyl groups, gives a balanced mix of alkyl flexibility and steric stability, which impacts how the liquid behaves across different temperatures and under pressure. Commercially, the product is available in high-purity grades suited for electrochemical studies, catalysis, advanced batteries, and even green synthesis platforms. Transparency on its chemical fingerprint allows researchers and professionals to select the right grade for everything from industrial optimization to sensitive research projects.

Physical & Chemical Properties

In the bottle, N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate looks clear, sometimes slightly yellow. It holds up across a range of temperatures without breaking down or giving off fumes, which changes habits in how solvents get handled in both research and production. With a melting point typically below room temperature, it remains liquid even in chilly environments, letting chemists bypass heating equipment that often means more energy use. Its density and viscosity take a bit of getting used to, higher than water or traditional solvents, making it easy to spot leaks during handling. Featuring strong ionic conductivity, the liquid fits right into high-tech applications like supercapacitors and advanced lithium batteries.

Technical Specifications & Labeling

High-purity N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate generally gets shipped in well-sealed glass bottles or high-grade polymer vessels with labels showing exact batch numbers, purity levels, and recommended storage conditions. Technical data sheets list molecular formula, CAS number, appearance, pH stability range, moisture content, and typical impurity profile. This detail not only supports traceability required by strict quality management systems, but also helps users compare batches and suppliers with evidence-based data. Customs authorities and hazardous goods regulators demand thorough classification under international transport codes, so up-to-date and accurate labeling saves buyers headaches down the supply chain.

Preparation Method

The synthetic route of this ionic liquid usually starts with piperidine as base. An alkylation using butyl bromide and methyl iodide generates the desired N-Butyl-N-Methyl-Piperidinium salt. Metathesis with sodium tetrafluoroborate in water or polar solvent finishes the synthesis. Purification takes patience, repeating washing and filtration to reduce halide and moisture content. Manufacturers invest in controlled drying under vacuum and handle the finished product using air-free techniques to protect quality. Large-scale producers tweak solvent systems, reaction times, and stoichiometry to support both economic and environmental goals, making this route accessible for both academic and commercial settings.

Chemical Reactions & Modifications

N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate withstands strong acids, most bases, and moderate oxidation. Chemists blend it with other ionic liquids or organic solvents to tune conductivity and solubility for specific projects. Modifications to the cation, such as changing the alkyl groups, open new possibilities for custom liquids with more targeted uses. The tetrafluoroborate anion stands up well to hydrolysis unless subjected to strong acids, which can eventually release boron trifluoride and hydrogen fluoride—both hazardous. This is a reminder to keep process streams tightly controlled, especially in closed energy systems or chemical syntheses where side reactions can have wider impacts.

Synonyms & Product Names

N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate goes by various chemical descriptors, including [BMPI][BF4], Butylmethylpiperidinium tetrafluoroborate, or even 1-butyl-1-methylpiperidinium tetrafluoroborate. Catalog listings often simplify to BMPI-BF4 or N-Bu-N-Me-Pip BF4. This can create confusion, especially when researchers cross-reference international literature or databases. Clear naming and documentation prevents accidental mix-ups and keeps project datasets reliable over time.

Safety & Operational Standards

Nobody likes a safety incident. This ionic liquid, while lower in volatility, still needs careful handling. Direct skin and eye contact should be avoided, as the tetrafluoroborate anion can break down and irritate tissues with prolonged exposure. Good lab practice means wearing gloves, goggles, lab coats, and working under local exhaust or fume hoods. For larger operations, companies should invest in spill kits designed specifically for ionic liquids, which behave differently than typical hydrocarbons. All personnel should know the storage needs—keep containers tightly shut, away from open sources of moisture, and out of direct light. Disposal calls for trusted hazardous waste protocols, since breakdown can release boron compounds and perfluorinated species into the environment if not properly treated.

Application Area

Real-world uses of this compound stretch across fields. In batteries and supercapacitors, the ionic liquid acts as a safe, high-performing electrolyte that doesn’t catch fire or evaporate during normal operation. In catalysis, it dissolves a range of starting materials and can even boost the reactivity of transition-metal complexes. Enhanced dissolution properties bring environmental advantages, especially when paired with solvent recycling in green chemistry. In pharmaceutical and fine chemical processes, it occasionally serves as a reaction medium for selectivity, offering a unique polarity profile compared to old-school solvents. The growth in electrochemical research drives more custom electrolyte designs with this ionic liquid as a building block.

Research & Development

Teams at universities and private labs keep pushing the boundaries here. Researchers focus on tuning the structure of the piperidinium ion and swapping out the anion to create task-specific ionic liquids with even better chemical and electrochemical performance. Labs around the world share findings about new solubility parameters, thermal windows, or electrochemical stability ranges. Working with old and new collaborators, development teams look for ways to lower costs, improve environmental impact, and boost reusability. Patents show interest in data-driven optimization, combining computational chemistry with hands-on experimentation to discover the next generation of functional materials.

Toxicity Research

Long-term health and environmental data matter. Early studies suggested low acute toxicity but didn’t rule out long-term risks, particularly after breakdown or environmental accumulation. Animal testing explores oral, dermal, and inhalation exposures to set occupational limits. Some breakdown products, like perfluorinated borates, demand tighter controls to block soil and groundwater pollution. Researchers focus on understanding bioaccumulation potential and tracking aquatic toxicity, filling in gaps so companies and regulators can write responsible policies. Sometimes regulations lag behind discovery, so the industry and academia work together to proactively share safety data and raise red flags for unexplored hazards.

Future Prospects

More industries see value in safe, high-stability liquids. Battery makers chase new and better electrolytes as electric vehicles take over city streets, while chemical producers sharpen their green manufacturing strategies. Advances in predictive toxicology, lifecycle analysis, and closed-loop chemical processing could anchor ionic liquids as future-proof tools for sustainable technologies. A focus on cost reduction—using cheaper precursors or energy-efficient processes—will likely make these materials more available to small startups as well as large multinationals. Those who invest in robust supply chains, quality assurance, and hands-on research will shape how this ionic liquid, and its extended family, fit into cleaner, smarter industrial landscapes.

Chemistry’s Swiss Army Knife: More Than a Name

Many people outside the lab hear “N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate” and immediately tune out. For scientists, this salt means opportunity. Its structure puts an organic cation together with a stable inorganic tetrafluoroborate anion. This balance turns it into a star player in research, especially among folks working with ionic liquids.

Key Ingredient in the Push for Greener Solvents

I’ve seen labs scramble to reduce their reliance on old, hazardous organic solvents. Ionic liquids bring a chance to break from that past. N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate stays liquid at room temperature, resists evaporation, and remains tough against flames. Its low volatility cuts down on toxic fumes. That shift matters in crowded, small chemistry labs, and it also helps the environment by limiting emissions.

Stepping Stones for Battery and Fuel Cell Breakthroughs

Researchers want batteries that last longer and charge faster without catching fire. Traditional solvents carry major flammability and degradation problems. This salt doesn’t catch fire easily, and its electrochemical window opens the door for shaping safer energy storage. I remember a student-run project at the university pairing it with lithium salt for a solid-state electrolyte. The prototype cell didn’t overheat, and we didn’t need ventilation masks.Fuel cell teams like its ionic conductivity and wide application window. N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate showed up in early experiments on hydrogen fuel cells, replacing acidic membranes and reducing waste.

Electrochemistry Experiments Get a Boost

Standard solvents break down under tough conditions or mess with sensitive measurements. Lab work on electrodeposition and sensors goes smoother with stable ionic liquids. I’ve worked on copper nanowire synthesis, and controlling growth gets a boost when switching to a salt-based medium — the ions create a predictable environment for metal deposition.

Industrial Teams Eye New Ways to Separate and Process

Large-scale processes have a long history of generating messy waste streams. I’ve heard colleagues at process engineering plants considering ionic liquids for selective extraction and catalysis. Salts like N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate dissolve a wide range of organic and inorganic compounds and can act as catalysts themselves. Recovery and recycling become more realistic, driving down the use of petroleum solvents.

The Safety Perspective: Handling and Future Questions

This salt doesn’t remove all hazards. Long-term impacts on health and ecosystems remain uncertain. It’s less risky than some chemicals it can replace, but regulations have not kept pace with rapid adoption. MSDS documents call for gloves, goggles, and fume hoods. Disposal should always land in a chemical waste channel, never the drain. Lab managers and workers need clear training before any scale-up. Manufacturers need to be transparent about possible impurities and stability under industrial conditions.Peer-reviewed studies from 2020 suggest low acute toxicity, but I always stress caution around new materials — routine screenings beat assumptions.

Room for Innovation

N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate gives scientists tools to push toward greener chemistry and smarter manufacturing. Energy storage, sensing, and clean-up could all change as research continues. Open sharing of safety and performance results stands as the best way to move forward, so other labs aren’t starting from scratch and losing time to accidents or old habits.

Why Care About Proper Storage?

Anyone who handles chemicals in a lab knows the difference between a safe bench and a hazardous mess. For a specialty compound like N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate (BMP-PBF4), the way it’s stored doesn’t just protect budgets, but it also shields people from health risks and saves time. I’ve seen labs lose entire batches to moisture, or worse, risk an unexpected reaction because someone left an ionic liquid out. The right habits can make all the difference.

The Main Enemies: Water, Air, and Sunlight

BMP-PBF4 works best in controlled environments. Water in the air can hydrolyze the salt, breaking its structure and leaving byproducts that change results. Storing the compound in a dry, tightly sealed container keeps out moisture and saves that expensive batch from going to waste. You can use a desiccator or sealed jar with good seals. I’ve always used silica gel packs for an extra layer of dryness — simple, cheap insurance.

Air can carry more than just water vapor. Oxygen sometimes causes slow degradation in sensitive salts. Working with an inert atmosphere, such as nitrogen or argon, is smart, especially if you have to handle open containers. Labs with gloveboxes or Schlenk lines get this right, but even in a standard lab, purging containers with dry nitrogen before sealing helps.

Sunlight speeds up unwanted reactions in many chemicals, and even though BMP-PBF4 isn’t highly photosensitive, everyday lab practice tells me to keep all ionic liquids in amber bottles or at least away from windows. This habit makes a difference for trace impurities and keeps the product stable longer.

Temperature: Not Too Hot, Not Too Cold

Temperature swings stress chemical containers. BMP-PBF4 should be kept at room temperature, ideally below 25°C. Some colleagues stick every specialty salt in the fridge, but that can draw in water when you open cold bottles in a warm room. Continuous cold storage isn’t necessary, but staying away from heated benches or windowsills avoids thermal decomposition. Stable shelves in a dedicated chemical storage cabinet do the trick.

Safe Practice, Good Labeling

Some accidents happen because someone couldn’t find the right label or didn’t know what they had. Label every container with the compound’s name, date received, and the person responsible. If something goes wrong, you want a quick answer, not a guessing game. In busy labs, I’ve watched containers get swapped or chemicals disposed of because no one knew what they were or how old. Simple, clear labeling fixes that.

Maintaining Quality Over Time

Quality drops if the storage space gets dirty or containers get reused without cleaning. Only handle BMP-PBF4 with dedicated, clean spatulas and bottles. Even minor contamination can ruin an entire batch, especially for sensitive synthesis or electrochemistry. Routine checks on the storage area, along with inventory audits, give early warnings before a problem gets out of hand.

Better Storage Means Fewer Headaches

BMP-PBF4 isn’t cheap or easy to make, so every unit wasted cuts into research budgets and slows down projects. Good storage habits combine smart location, effective sealing, regular labeling, and common-sense handling. If you see condensation, strange smells, or color changes, don’t ignore them. Take action, clean up what needs it, and always check the quality before using the compound in a new run.

Chemical storage may sound boring until a batch fails or someone gets exposed. Thoughtful routines protect people, data, and money. For BMP-PBF4, keep it dry, sealed, shaded, and stable — and you’ll rarely face trouble.

Getting a Grip on Chemical Risk

The chemical world throws up plenty of unfamiliar names. N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate doesn’t exactly roll off the tongue, but it does come up more often as battery and electrochemical researchers look for safer and better-performing materials. Still, swapping one chemical for another always means weighing different sets of risks—mostly for the people handling these materials, but also for the surrounding environment. Understanding chemical safety isn't just about satisfying regulations; people’s health and well-being depend on practical caution and good information.

What We Actually Know About Its Hazards

This compound belongs to a group known as ionic liquids—a space that gets praise for low volatility and reduced flammability compared to older solvents and salts. This kind of reputation gave ionic liquids an eco-friendly shine, but there’s no such thing as a chemical with zero risks. A quick glance at the toxicity data for N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate shows large gaps. Most safety sheets point to the basics: irritation to skin and eyes, and possible trouble if inhaled or ingested. Published studies remain thin on longer-term effects or on what happens in real-world industrial spills. I’ve worked with ionic liquids in research labs; even with gloves and goggles on, you wouldn’t catch me taking shortcuts just because a product label hints at low hazard.

Reports from chemical suppliers and databases like PubChem flag the need to avoid breathing in the dust or vapors, and to store this stuff in cool, dry places. Direct skin contact brings redness or irritation, and the tetrafluoroborate part always sets off warning bells, since boron and fluorine compounds sometimes break down in the wrong conditions. Some ionic liquids break into substances that do real harm to waterways or soil—yet official environmental testing on this specific compound seems pretty sparse.

Why Caution Still Matters in Labs and Industry

Cutting back on volatile organic solvents counts as progress, but we’ve seen enough cases where substituting one risky material with another runs into trouble later. People remember incidents where chemicals with mild-sounding safety information turned out to cause headaches years later. Take the history of solvents in painting, or the way new flame retardants once seemed perfect until researchers discovered persistence and toxicity in the environment.

My own experience—from graduate school research to more recent consulting—shows that hazards usually show up when people get impatient. One person forgets lab goggles, another decides to skip a fume hood “just this once.” Any risk flagged on a chemical label deserves respect, and those safety data sheets only go as far as the available research. If no one knows what happens after years of low-level exposure, that doesn’t mean it’s perfectly safe; it just means no one’s spent the time to check.

Handling the Unknowns

Personal protection—gloves, goggles, lab coats—should become automatic. Good ventilation keeps the air safe, whether that means fume hoods or well-designed industrial setups. Safe disposal becomes important, because even compounds that look harmless could turn toxic further down the line. Collecting and sharing health data helps everyone: workers, chemical producers, and researchers. More open testing and transparency on chemicals like N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate would help keep surprises to a minimum, protecting bodies and water supplies for the long haul.

No Shortcuts with Purity in Lab Work

Anyone who has worked in a chemistry lab knows the dance around purity specifications. The quality of a reagent shapes the outcome of the experiment. N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate often lands on order lists for ionic liquid research, battery development, or as an electrolyte. Getting hold of a sample above 99% purity feels like a small victory. Even the tiniest contaminant can tangle reactions, build up in sensitive electrodes, or shift instrumental readings.

Numbers Matter in Real Labs

HPLC and NMR data tell the story straight. A benchmark for chemical purity in high-end N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate sits at 99%, sometimes pushing 99.5% for research that counts every decimal. Purity less than this can sneak in uninvited side effects—ghost peaks on chromatograms, sticky residues after evaporation, or a sluggish voltage response in electrochemical tests.

Research teams trust certificates of analysis for a reason. Recrystallization, vacuum distillation, and chromatography each chip away at impurities, but these processes cost time and money. For exploratory work or quick test runs, lower-grade material (maybe 97-98%) offers a shortcut, but anyone scaling up needs the higher grade if they want consistent outcomes.

What’s Lurking in the Bottle?

Manufacturers chase down ionic and organic fouling: leftover solvent, trace metals, moisture, or decomposition products. Water content above 500 ppm throws a wrench in air- or moisture-sensitive studies. Metals above a few parts per million can skew conductivity readings or deposit out onto electrodes.

Glassware contamination sticks out, too. Old flasks with sodium or potassium can leach just enough to appear in the mass spec. Proper cleaning cuts risk, but even new bottles aren’t perfect unless certified for trace analysis.

Why Battery Research Cares So Much

Labs pushing electrochemical windows or targeting long-lifetime batteries are some of the pickiest customers. A batch of N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate at 98% might send a half-cell’s performance off the rails. Side reactions slowly chew away at the real capacity, or create gas where it shouldn’t exist. Clean reagents mean fewer mysteries when performance lags.

In graduate school, a friend’s project lagged for months from a contaminant that kept fouling their electrolyte. Only after spending for ultra-high purity—switching from 98% to 99.9%—did their results suddenly line up with expectations. That lesson never faded: buy the best you can afford, or plan to chase ghosts.

Making Things Better

Clean production starts with tight process controls at the manufacturer. Batch tracing, proper drying, and careful packing reduce the chance of surprises. Researchers can check for water content with Karl Fischer titration or spot metals by ICP-MS before relying on the material for critical work.

I’ve seen research slow to a crawl from inconsistent reagent batches. Supplier communication helps. Ask for production specs, request third-party analysis, and keep a small library of trusted chemicals. Paying for better material sometimes saves weeks of searching for the root cause of an odd result.

Final Thoughts

High purity in N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate rarely makes headlines, but it shapes every downstream step. Cutting quality might save money upfront, but frustration and wasted time often follow. Investing in top-grade chemicals frees a researcher to focus on breakthroughs, not backtracking over potential mistakes in the bottle.

Working with a Lab-Grade Chemical

I’ve spent a chunk of my career around specialty chemicals, and it’s never lost on me that N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate brings both promise and real responsibility. Working with ionic liquids like this one, people crave their conductivity and stability for everything from batteries to new energy devices. But good results come from good practice, and nobody wins by taking shortcuts with safety.

Why Respecting Risks Matters

A bottle labeled “N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate” signals more than an experimental ingredient—it tells you fumes, splashes, or spills aren’t simply annoyances. This compound isn’t on the household hazard scale, but its tetrafluoroborate anion can release toxic fumes if mishandled, especially during heating or burning. The way I see it, eye goggles and nitrile gloves beat an ER trip every time, and I never skip a full lab coat.

Some researchers roll their eyes at ventilation warnings, but inhaling low-level vapors is the fastest way to learn just how far a cough or headache can take your day off track. A chemical fume hood isn’t just convenient—it’s a shield.

Spill Control Should Feel Routine

I’ve knocked over my share of flasks. Minor spills rarely cause panic if you grab your spill kit, toss on extra gloves, and work with absorbent pads right away. Dropping inert absorbents—think those gray pads in every properly stocked lab—contains the mess. Scrape up solids, mop residual liquids, and leave nothing behind. Stringent folks sweep the area with a diluted alkaline solution, just in case acidic vapor built up. Guess what? It cuts down on surprises tomorrow.

Storage Choices Create Peace of Mind

I store reactive chemicals on low shelves, away from heat or sunlight. Even a stable ionic liquid likes dark glass and tight seals—humidity or accidental contamination sets off more problems than people realize. I learned from a near miss: someone mislabeled a bottle, mixed it with a strong oxidizer, and spent the next day cleaning corrosive paste off a bench. Every label and log entry matters. Regular inspections reveal tiny leaks, crusting, or color changes before they put people or experiments at risk.

Disposal Isn’t a Box to Check

Professional pride shows most during disposal. Dumping anything with tetrafluoroborate down a sink can poison water or pipes, risking costly repairs and angry wastewater crews. The right path runs straight to a hazardous waste stream. Specialists treat spent solutions through incineration equipped with scrubbing systems to harm neither air nor water. Some places call for stabilization and burial in lined landfills, which beats uncontrolled leaching into the environment.

Waste manifests, secondary containment, and keeping acids or oxidizers away from disposal drums might sound tedious at the end of a long day. They last longer than any shortcut, though. The cost of safe disposal rarely matches the regret of contamination fines—or the phone call about a coworker’s chemical burn.

Fact-Based Steps, Human Stakes

Proper handling and disposal of complex chemicals like N-Butyl-N-Methyl-Piperidinium Tetrafluoroborate ground themselves in both science and common sense. PPE, ventilation, labelled storage, and professional disposal shape a culture where oversight rarely happens—and everyone leaves the lab healthy.