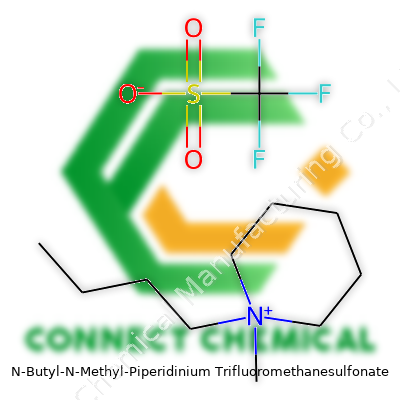

N-Butyl-N-Methyl-Piperidinium Trifluoromethanesulfonate: A Comprehensive Commentary

Historical Development and Scientific Progress

Back in the early 2000s, research into ionic liquids started to gain momentum. Labs grew increasingly interested in these compounds as scientists looked for safer, greener alternatives to the volatile organic solvents that had long dominated the chemical industry. N-Butyl-N-Methyl-Piperidinium Trifluoromethanesulfonate didn’t pop up overnight—it took years of trial and error for chemists to reliably synthesize salts like this with consistent yields and purity. A shift towards sustainability pushed academics and industry to dig deeper into structures combining piperidinium cations with strong sulfonate-based anions. My own lab work with ionic liquids left a lasting impression: glassware stained from mistakes, endless tweaking of reaction conditions, and tangible excitement each time a new sample came off the rotavap. The move from theory to scalable synthesis reflected a broader change in how the field looked at solvent technology.

Product Overview and Real-World Profiles

N-Butyl-N-Methyl-Piperidinium Trifluoromethanesulfonate stands out in the ionic liquid family thanks to its remarkable stability and low volatility. People working in battery research or advanced catalysis often know it simply by one of its trade names, but at the bench, it’s the smell, feel, and stubborn residue that sticks in memory. The chemical pops up as a colorless to pale yellow liquid—odors can be faintly detectable, especially as the temperature rises. Its most common form ships in small amber bottles from suppliers, stored carefully to avoid moisture, since hydration can change its properties on the fly. Synthetic chemists value its consistent physical qualities, and labs across Europe and Asia report similar user experiences.

Physical & Chemical Properties in Practice

Boiling down to the details, this compound delivers a melting point well below room temperature thanks to its ionic structure, which also explains its negligible vapor pressure. That matters because many applications demand solvents that won’t evaporate away or contribute to air pollution. Density trends around 1.2 g/cm³ give it a reassuring heft on the balance, but it’s the electrochemical window that usually gets battery researchers excited. Its high ionic conductivity, low flammability, and resistance to oxidative breakdown push it ahead of older organic salts. In tests for battery electrolytes, its stability against lithium metal and common cathode materials proved reliable, which isn’t always true with similar piperidinium systems.

Technical Specifications & Labeling: What Matters in the Lab

Every bottle comes with paperwork. Spec sheets usually promise purity above 98%, with residual water content and halide levels closely monitored because these side impurities can wreck sensitive experiments. Commercial sources use clear, direct product codes and outline storage conditions—cool, dry, with limited light exposure. Labels warn about potential inhalation risks and suggest using the liquid in a well-ventilated fume hood. As someone who’s spent plenty of time reconciling vendor catalogues with actual results, clear documentation saves a lot of confusion, especially for research teams managing large chemical inventories.

Methods of Preparation: Doing the Work

Building N-Butyl-N-Methyl-Piperidinium Trifluoromethanesulfonate starts with some familiar organic reactions. Most syntheses use an alkylation route: piperidine reacts with butyl halide and methyl halide in a two-step process. This reaction needs constant stirring, controlled addition, and careful monitoring—I recall running TLC plates at odd hours just to make sure the reaction had reached completion without byproducts sneaking in. After forming the quaternary ammonium salt, exchanging the counterion with trifluoromethanesulfonic acid generates the final liquid. Repeated water washes strip away excess acid, and vacuum drying removes solvent traces. It’s meticulous work, but the payoff comes with a clear, stable liquid.

Chemical Reactions & Modifications: Possibilities in the Flask

Beyond acting as a solvent, this molecule’s cation and anion open the door to more than just “green” chemistry. It can support phase transfer catalysis or serve as an electrolyte in electrochemical cells. In my own hands, ionic liquids like this allowed more control over rate and selectivity in alkylation reactions compared to old-school organic solvents. Substitute the butyl group, play with cation ring size, or swap in different sulfonate anions, and new variants quickly pop up. Each tweak changes viscosity, solubility, or toxicity, which means new uses keep appearing, especially in fields hunting for specialized nonaqueous solvents.

Synonyms & Product Names: Clearing Up the Confusion

Anyone scanning chemical catalogues can find this compound under several names, and it’s a headache for buying teams and bench scientists. Some suppliers use the formal “N-Butyl-N-Methylpiperidinium Trifluoromethanesulfonate.” Others shorten it to BMPipOTf. The triflate name sometimes gets tossed in, blurring lines between similar but distinct salts. For anyone ordering or stocking chemicals, keeping an eye on both synonyms and CAS numbers is essential to avoid mix-ups, especially as some trade names only appear in certain regions.

Safety & Operational Standards: Learning the Hard Way

Early on, handling this liquid without gloves or eye protection triggered mild skin and respiratory irritation—something safety data sheets only hint at. Labs now set strict handling protocols: fume hood use, nitrile gloves, and splash protection count as must-haves for routine work. EHS policies across organizations push for spill kits and clear disposal instructions, since the triflate anion raises questions about potential environmental impact. Monitoring air quality and mandating closed transfer systems reduce exposure, a move seen in both academic and industrial settings. Lessons learned from minor mishaps drive much of today’s operational rigor.

Application Area: Where the Rubber Meets the Road

People seek out N-Butyl-N-Methyl-Piperidinium Trifluoromethanesulfonate for uses that take advantage of its unique liquid state and extreme chemical stability. Battery makers rely on it for high-voltage lithium or sodium cells, where traditional solvents just can’t keep up with cycle life or safety benchmarks. It’s shown promise in supercapacitors and, on the catalysis side, it opens up new pathways for C–H activations, oxidation reactions, and even enzymatic processes that standard solvents disrupt. Some R&D programs push the boundaries further: using the ionic liquid in separation science, protein folding studies, or even new carbon capture setups. These applications hint at its broad potential, especially as performance data starts backing up early optimism.

Research & Development: Chasing Better Outcomes

Academic labs and major chemical companies continue to pour effort into understanding how small changes in the molecule’s architecture impact bulk properties. Research articles keep surfacing with new insights: swapping out side chains, pairing the cation with rarer anions, or recycling used liquids from reaction waste. At conferences, presenters share comparative conductivity graphs, cycle life measurements, and synthetic tweaks. A lot of R&D flows into reducing cost and improving purification, making the compound accessible to smaller labs and start-ups. Looking back at my own collaborations, having direct access to advanced ionic liquids brought more creative questions about what kinds of compounds could be stabilized or activated by changing up the electrolyte environment.

Toxicity Research: Sorting Out Fact from Fiction

Long-term toxicity screening is still catching up. Data from cell assays and aquatic models show mild to moderate toxicity, but far less than classic organic solvents like acetonitrile or DMSO. Regulators keep a watchful eye on environmental fate, since ionic liquids resist breakdown and could accumulate if not managed correctly. Inhalation and skin contact tests underscore the need for good lab practice. A few recent reports show promise for degradation under advanced oxidation, opening the door for safer disposal. Anyone using this compound in larger quantities must track safety bulletins for updates, since new findings could change how facilities handle waste and protect workers.

Future Prospects: Where This Story Goes Next

The road ahead for N-Butyl-N-Methyl-Piperidinium Trifluoromethanesulfonate looks promising, especially if research keeps driving down production costs and improving bio-degradability. Demand grows as battery technology shifts from traditional lithium-ion to alternatives with safer, longer-lasting electrolytes. Green chemistry circles recognize its role in switching away from petroleum-derived solvents. Regulatory agencies may tighten rules as more toxicity data rolls in; companies gearing up for scale-up know that regulatory trouble could slow adoption. Open questions remain about large-scale recovery and recycling, but the growing interest in circular chemistry and sustainable manufacturing suggests that solutions will emerge with collaboration between basic researchers, commercial teams, and policy leaders. Veteran chemists see these ionic liquids as both a challenge and an opportunity, underscoring how much impact the right molecular design can have outside the lab walls.

What Sets This Ionic Liquid Apart

Chemists aren’t strangers to long names, but N-Butyl-N-Methyl-Piperidinium Trifluoromethanesulfonate, often called BMPy OTf, is more than just a mouthful. It’s a room temperature ionic liquid, which sets it apart from traditional solvents. This means it stays in liquid form even without heat, and it doesn’t evaporate or catch fire easily. That helps a lot in labs where keeping things safe and stable can be tough.

Playing a Key Role in Batteries

Battery research has seen a spike in demand for safer and more reliable electrolytes, especially for lithium and sodium batteries. BMPy OTf shows real promise here. Typical liquid electrolytes in lithium-ion batteries can lead to fires if punctured or overcharged. BMPy OTf brings a level of stability missing from standard organic solvents. It doesn’t catch fire and resists degradation, which reduces the risk of battery failure. Researchers in 2023 published work in Electrochimica Acta showing this ionic liquid allowed lithium batteries to run at higher voltages and temperatures without losing performance.

Trusted in Green Chemistry and Synthesis

Making chemicals often generates a lot of unwanted waste. BMPy OTf stands out because it is recyclable and helps reduce the mess. Traditional organic solvents end up on the hazardous waste list, but ionic liquids like this one can be used over and over. For chemists running reactions that involve demanding temperature swings or aggressive reagents, the toughness and reuse factor of BMPy OTf improve both cost and environmental impact.

Breaking Ground in Electroplating

Coating metals with thin layers of gold or nickel isn’t a new idea, but the baths used for this process are usually full of toxic chemicals. BMPy OTf steps in as a safer solvent. It dissolves metal salts and supports the electroplating current without the risks and fumes of traditional choices. The electronics sector, which constantly pushes for smaller and cleaner metal coatings, makes good use of this property. Studies out of Japan show smoother layers and fewer defects when using this ionic liquid compared to old-school solvents.

Supporting High-Performance Capacitors

Supercapacitors need electrolytes that can handle strong voltages and fast charge-discharge cycles. BMPy OTf’s electrochemical window—how much voltage it can safely support—outperforms many choices on the market. Researchers from Germany measured reliable cycling and low loss of energy even after thousands of uses. This appeals to industries looking for stable power storage in everything from grid backups to mobile electronics.

Challenges and Next Steps

Even with all these strengths, BMPy OTf isn’t perfect. Its price stays high, limiting use in bulk applications. While it doesn’t evaporate much, the triflate part can build up if not handled properly, raising disposal concerns. Manufacturing at scale puts pressure on sourcing fluorinated chemicals, a pain point as regulations get stricter.

Moving forward calls for new routes to make ionic liquids more affordable, with less reliance on rare starting materials. Developing ways to reclaim and recycle BMPy OTf after use could ease both costs and environmental worries. Chemists keep tweaking the recipe, chasing even safer, cheaper, and greener ionic liquids that could one day show up in every lab and battery pack.

Understanding What Impacts Stability

Stability depends on a product’s chemical makeup and its environment. Temperature, humidity, and light all play a big part. Some chemicals handle room conditions and dry air just fine. Others go off if the temperature jumps or moisture sneaks in. Every time a storage site breaks from recommendations, you invite trouble—think hazardous reactions, product breakdown, or a mess with wasted supplies.

Based on my lab experience, even a basic mistake—like storing a sensitive compound next to a window—can cause surprises. Once, a box of samples ended up exposed to sunlight, and within days, they looked and smelled different. That batch hit the waste bin. Small slips cost money and can even put people at risk. So, people in charge of chemical storage need to respect the science, read the data sheets, and ask questions if needed.

Temperature: The Quiet Saboteur

Many folks think room temperature always works, but reality gets messier. Pharmaceuticals, food additives, and solvents can show real changes just from warm storage or a cold snap. One supplier’s cream stacked in a warehouse on a hot day turned yellow and lost strength long before its shelf life ended. Cold rooms and climate controls sound simple, but maintaining steady conditions is tough. Regular checks on thermometers and the backup systems—those keep your inventory safe and costs down.

Humidity and Why Dry Storage Matters

Too much moisture ruins powders, crystals, and many organics. Opening a jar in a humid storeroom lets water vapor settle in, sometimes launching unwanted chemical reactions. I remember opening what looked like dry sodium carbonate, only to find a soggy clump stuck to the sides of the jar. With the US Pharmacopeia stressing low humidity for many chemicals, keeping containers closed, using desiccants, and controlling the room’s air provide a basic but solid defense.

Light and Its Surprising Reactions

Light-sensitive products need a close eye. Chemicals like hydrogen peroxide and many vitamins degrade quickly under fluorescent bulbs or sunlight. The best practice is clear: use amber bottles, keep storage cabinets closed, and move containers only when needed. Energy from light often triggers chemical breakdown, a path to less potency and quality. This comes straight from a case in grad school, where photosensitive reagents in clear bottles gave erratic results, all due to a careless storage shelf near a window.

Labels, Audits, and Smart Inventory

Every bottle, drum, or jar shows its own clues: expiration date, recommended conditions, even emergency first aid steps. Clear and honest labels help every worker make the right call—no guessing. Scheduled audits spot problems, like forgotten chemicals long past their best by date or a sticky cap hinting at leaks. Modern inventory software flags upcoming expiries and tracks usage patterns, helping avoid both waste and surprise shortages.

Good Storage: Simple, Practical Steps

Follow the manufacturer’s advice and review each chemical’s safety sheet before stacking anything on the shelf. Separate incompatibles—acids go nowhere near bases. Shelve heavy drums low, and flammables use approved cabinets, away from ignition sources. Keep emergency gear accessible, from spill kits to eye wash stations. Smart, basic habits protect everyone and cut costs over time.

Most product losses, injuries, or compliance fines can be traced back to poor storage or ignoring chemical changes. For anyone working around chemicals, steady attention to detail keeps work safe and predictable, from the stockroom to the production line.

Getting to Know the Chemistry

Mixing a new compound into a soup of solvents and electrolytes is a bit like adding a secret ingredient to a family recipe—sometimes everything comes together beautifully, and other times, you’re left scraping a disaster off the pot. The heart of compatibility boils down to how these molecules behave in different environments: some dissolve quickly, some clump into tiny islands, and a few start unwanted reactions that can make everything fall apart. I’ve seen more than one promising project fizzle out just because the chemistry went sour after the first round of mixing.

Why Chemists Care About Compatibility

People who work in labs spend long hours wrestling with solubility charts and chemical tables. It’s not because they like tedium but because a mismatch can waste not only money but months of work. An organic solvent could strip electrons from a compound, sending your reaction in the wrong direction, or an electrolyte can turn a liquid mixture into an unpredictable sludge. Even in fields like battery development, a careful match makes the difference between a cell that holds power and one that fails on the shelf.

Experience at the Bench

I’ve spent time trying to coax new compounds into dissolving in everything from water to DMSO to ethylene carbonate. Sometimes, even a little humidity can wreck efforts to blend components or store materials long-term. Some compounds take to protic solvents like ducks to water, while others start falling apart, forming byproducts, or dropping out of solution as soon as you turn your back. Add lithium salts or other electrolytes into the mix and the challenge levels up—salts can change the pH or ionic strength and turn a stable mixture into a ticking time bomb.

Real-World Stakes

This isn’t just a headache for researchers. In the manufacturing world, mixing unstable combinations means ruined product, lost time, and angry customers. Safety is also no joke—certain compounds react violently with popular solvents, generating heat, gas, or worse. These aren’t abstract risks; they can send people to the hospital. So, understanding the quirks of a compound in different liquids isn’t some optional step, it’s safety, money, and trust on the line.

Some Facts That Matter

Looking at recent work on electrolyte development for lithium-ion batteries, I noticed a single contaminant can shorten battery life by half. Organic solvents like acetonitrile might sound versatile, but they can attack seals and plastic, making leak-proof packaging a guessing game. In pharmaceuticals, picking the wrong solvent means a delayed batch and regulatory headaches, since chemical residues and byproducts must be cleared for safety.

Possible Ways Forward

There’s no magic bullet. A good start comes from tables and published compatibility charts, but these rarely tell the full story. Small-batch testing gives a truer read—you can see how the compound mixes, settles, or heats up with a particular combination. Modern tools let us see molecular-level tweaks: spectroscopy lets you catch tiny changes in a compound’s behavior, while chromatography can spot degradation products that suggest trouble is brewing.

I always recommend talking with people who have run similar mixes before, whether in research or industry. They can save huge amounts of effort, since small technical details get lost in published papers. Keeping clear records and asking hard questions during procurement aren’t about following red tape—they’re a way to stay on track when everything from safety to shelf-life hangs in the balance.

Purity: Why It Matters More Than Numbers

Any time someone deals with chemicals, purity isn’t just a technical metric. In the lab, a slight impurity can throw off a whole batch of results. On a bigger scale, manufacturers risk product failure, safety issues, and regulatory headaches. A friend shared a story where a reagent listed at 99%, but it came with enough water trace to ruin an entire synth run. That blip cost her team days. It’s no stretch to say purity levels can separate consistent outcomes from costly failure.

I find it helpful to pay attention beyond the advertised purity—say, 98% or 99.9% isn’t always the true picture. The leftover bit, often called “impurities,” can include moisture, other chemicals, metals, or even trace solvents from a factory cleaning process. Some technical grades fit industrial use just fine, but research labs usually search for analytical, reagent, or high purity options. Pharmaceuticals don’t settle for less than what passes USP or BP standards. Food and beverage sectors check for food grade. These distinctions can prevent a shipping headache or an epic product recall.

Packaging: More Than Just a Container

Anyone who’s received a battered drum or a leaking bottle knows how important packaging gets. Strong, leak-proof bottles help avoid contamination and waste. Lab chemicals come in smaller amber glass bottles or high-density polyethylene plastic, usually in 100g, 500g, or 1kg sizes. In industry, 25kg bags or steel drums show up just as commonly. Shipping restrictions, chemical compatibility, and safety play big roles in the packaging decision.

While working in a biochem lab, I learned the hard way that packaging affects stability as much as shelf life. A sample in a basic plastic tub might degrade quicker than the same chemical stored in a light-proof, airtight vessel. Any moisture-sensitive material goes into vacuum-sealed or nitrogen-purged pouches. Strong acids often require sturdy jerricans with pressure relief caps. The right choice means less spoilage, safer transportation, and less mess on my lab bench.

Safety, Regulation, and Documentation

Every chemical, whether bulk or specialty, comes with its own regulations. The conversation quickly moves beyond cost and availability. For hazardous stuff, UN packaging standards apply. Any technician or purchasing officer worth their salt looks for a clear COA (certificate of analysis). This document spells out purity in detail—sodium, metals, even obscure byproducts. Safety data sheets fill in the rest, including shipping restrictions and emergency procedures.

Some chemicals can’t ship by air in specific packaging. Others need temperature-controlled containers. Importers follow local rules—China, the EU, the US each pick their own registration and labeling standards. What seems like a simple order can spiral if paperwork doesn’t match up.

Improving the Scene

Everyone wins from clearer purity data and well-designed packaging. Producers who publish impurity profiles score trust points. Better packaging cuts waste and accidents. Some startups focus on eco-friendly, tamper-evident containers or smart labels that monitor temp or humidity. Supply chains work faster when all the right paperwork lines up. In my experience, a clear phone call with a supplier beats five back-and-forth emails about purity specs. Collaboration and transparency make life easier for factories, labs, and anyone in between.

Understanding the Substance

N-Butyl-N-Methyl-Piperidinium Trifluoromethanesulfonate is quite a mouthful, and it signals something more than a routine chemical. Chemists often turn to these ionic liquids because they're stable, non-volatile, and useful in areas like batteries or catalysis. Just because something doesn't burn your nose off like ammonia doesn’t make it risk-free. I’ve been in enough labs to see people forget that quiet liquids still pack a punch.

Why Safety Precautions Count

Chemicals like this one rarely scream danger at first sight. It doesn’t mean gloves-off. A few years back, I got careless with an unfamiliar solvent, thinking “it’s not that reactive.” Ended up with a rash on my wrists and a ruined watch from splatter. N-Butyl-N-Methyl-Piperidinium Trifluoromethanesulfonate isn’t particularly nasty compared to old-school acids, but it follows the rule: minimize skin and eye contact, avoid inhaling vapors, and don’t taste test.

What the Science Says

The trifluoromethanesulfonate part suggests a strong ion presence and high solubility in organic solvents. Ionic liquids like this don't evaporate much, but spills linger, and nobody wants super-slick floors in their workspace. Studies have shown some ionic liquids can irritate the skin and eyes, and long-term exposure risks are not fully mapped out. I'd rather not be the one to discover what chronic exposure does.

Practical Precautions

Start by keeping it off your skin. Use gloves—nitrile or compatible chemical-resistant materials. Eye protection isn’t optional. All it takes is one splash for a trip to the eyewash station. Lab coats help shield your body and street clothes.

Don’t pour down the sink after use. Ionic liquids often require special disposal because water treatment plants can’t handle their byproducts. I remember my first environmental safety briefing—what goes down the drain usually circles back, maybe not tomorrow but someday, somewhere.

Work in a ventilated space. Even if you can’t smell fumes, it doesn’t mean your lungs escape. Fume hoods trap and vent out volatile escapees. People sometimes get lazy with this, especially with liquids that don’t have a strong odor. That’s a mistake that sneaks up over time.

Emergency Know-How

Spills call for immediate cleanup with absorbent pads and the right waste containers. Skin exposure? Rinse fast, strip contaminated clothes, and flag it with your supervisor or safety officer. Any chemical that soaks through gloves or splashes into the eyes demands more than a quick rinse—you need a proper safety shower and eyewash.

Building a Safer Lab Culture

In my experience, the safest labs operate on the principle that every chemical can bite back. Sharing near-misses and enforcing careful protocols works a lot better than locking things up and counting on warning labels. If a new person walks in, someone walks them through storage, handling, and cleanup for every unfamiliar compound.

A lot of big accidents come from mixing ignorance with routine. Keeping up-to-date with safety data sheets, refreshing spill drills every few months, and never treating a new bottle like the old standbys makes a difference. The real safety upgrade comes not from fancier gloves, but from steady habits and forcing ourselves to stay alert—even on Friday afternoons.