N-Butyl-N-Methylpyrrolidinium Chloride: A Deep Dive Into Chemistry and Application

Historical Development

N-Butyl-N-Methylpyrrolidinium Chloride doesn’t get the spotlight of more famous industrial chemicals, yet researchers have explored its properties since the surge of interest in ionic liquids during the 1990s. As scientists searched for alternatives to volatile organic solvents, quaternary ammonium and pyrrolidinium-based salts picked up attention for their low vapor pressure and high thermal stability. This chemical grew from laboratory curiosities into serious candidates for green chemistry. The groundwork on these salts built a bridge between classic pyrrolidinium salts and newer, task-specific ionic liquids. Over time, advances in synthetic organic chemistry enabled efficient routes for making these salts, and labs worldwide started tapping into their potential. I remember reading reports on ionic liquid cells just a decade ago where this salt cropped up repeatedly, showing that it didn’t just get filed away as another chemical oddity.

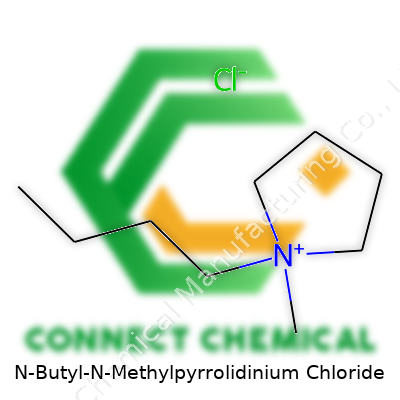

Product Overview

N-Butyl-N-Methylpyrrolidinium Chloride belongs to a family of quaternary ammonium salts where the pyrrolidine ring gets adorned with butyl and methyl side chains. Its ionic nature comes from the positively charged nitrogen and the chloride anion. White to off-white in its pure form and solid at standard conditions, it usually appears as a crystalline powder that can sweep up moisture easily if left open. From lab-scale synthesis to industrial pinches, it gets packed in tight containers, as moisture and light can degrade its quality over time. Chemists use it both as a reagent and as a building block for further chemical manipulation, especially in developing room-temperature ionic liquids.

Physical & Chemical Properties

At room temperature, N-Butyl-N-Methylpyrrolidinium Chloride keeps stable, resisting both heat and light better than older alkyl ammonium salts. A melting point that nudges around 50-70°C means it can be weighed and dispensed with less hassle in standard lab conditions. Good solubility in water and alcohol makes it a flexible player for chemistry work, but it won’t dissolve well in nonpolar solvents like hexane or toluene. It stands tough against hydrolysis across a wide pH range due to the stable pyrrolidinium core. In terms of chemical behaviors, it doesn’t flinch under normal storage or mixing yet reacts predictably in syntheses calling for quaternary ammonium reactivity. Its hygroscopic character keeps chemists on their toes, as a little slip in sealing can mean caked bottles and degraded material.

Technical Specifications & Labeling

Industrial product data sheets rank N-Butyl-N-Methylpyrrolidinium Chloride into different grades, mostly depending on assays and trace impurity levels. Common specs show purity above 98%, sodium and potassium contents below 0.05%, and water content held under 0.5%. Packaging info usually spells out dangers of moisture and calls for airtight drums, with each label carrying the required dangerous goods classification. Labels cite the UN number and hazard pictograms, as tight regulation manages the safe movement and handling of most ionic salts. I’ve handled bottles with warnings about dust inhalation and chemical burns — mild compared to some organics, but still worth respect. Product sheets place batch number, production date, and shelf life clearly so users know what they’re getting.

Preparation Method

Manufacturers synthesize N-Butyl-N-Methylpyrrolidinium Chloride through direct alkylation. The process generally begins with pyrrolidine, which reacts with methyl chloride gas to land N-Methylpyrrolidine, then gets treated with 1-chlorobutane to cap off the butyl group at the nitrogen. The core of this synthesis focuses on full conversion, as leftover amines not only skew yields but also produce wastes that are harder to clean up downstream. Vigorous stirring, good temperature control, and high-purity reagents keep impurities low. Afterward, the final salt crystallizes as a fine powder, washed with non-polar solvents to slough off greasy organic byproducts. This overall route gives high yield and fits both small, academic-scale production and the gated complexity of commercial chemical manufacturing.

Chemical Reactions & Modifications

This salt steps forward as a solid candidate for anion exchange reactions. By swapping the chloride with PF6, BF4, NTf2, or other large anions, chemists make new ionic liquids tuned for specific properties like hydrophobicity or ionic conductivity. N-Butyl-N-Methylpyrrolidinium Chloride also links with organometallics in homogeneous catalysis, where its ionic character boosts solubility for stubborn metal complexes. It performs in phase transfer catalysis, helping shuttle reactants across water-organic boundaries. In the hands of polymer chemists, it serves as a template or initiator, leveraging the reactivity at the nitrogen. Every year, new papers highlight syntheses where swapping its alkyl groups leads to subtle property shifts — proof that modifications aren’t just academic, but drive results in real-world applications from batteries to sensors.

Synonyms & Product Names

This salt appears on product sheets under different names, which can confuse in fast-paced lab settings. Researchers recognize it as 1-Butyl-1-Methylpyrrolidinium Chloride, BMPC, or BMPyrrCl. Some catalogues use a systematic IUPAC name: N-butyl-N-methylpyrrolidin-1-ium chloride. Trade names change by supplier. Chemists running literature searches keep all names handy, as missing just one abbreviation can lose access to key references. No matter the label, the core structure remains unchanged — what matters is recognizing the various faces it shows in catalogs and journals alike.

Safety & Operational Standards

N-Butyl-N-Methylpyrrolidinium Chloride doesn’t carry the volatility risk of traditional organics, but not handling it properly brings its own troubles. Fine powders raise dust that can irritate airways, and direct skin contact draws out rashes if left unchecked. Gloves and goggles come standard, as do fume hoods and dust masks for bulk handling. Storage plans keep it dry, away from acids and bases that can spur unwanted decomposition. Cleanup from spills revolves around damp cloths instead of sweeping, to clamp down on airborne exposure. Disposal requires segregated chemical waste handling, as regulations pin ionic liquids and related salts under stricter hazard listings. The safety data sheets loudly stress that just because it’s stable and non-flammable, it’s not a candidate for casual handling.

Application Area

Most of the buzz around N-Butyl-N-Methylpyrrolidinium Chloride lands in electrochemistry and solvent technology. Energy researchers build ionic liquid batteries with this cation to boost conductivity and suppress side reactions in high-voltage cells. Its use in supercapacitors cuts resistance and often extends cycle life — exactly where battery developers focus their time. In catalysis, it improves selectivity and conversion, giving reaction designers more leeway. Other labs pour it into separations as an extractant phase, teasing out metals or organic compounds with high efficiency. Outside chemistry, it finds small niche uses in spectroscopy and thermal analysis, where its clear, stable nature simplifies measurements. I reached for this salt during graduate research to tweak solvent properties without sparking unwanted reactions, an experience echoed by thousands of technical practitioners in green labs across the world.

Research & Development

Research on N-Butyl-N-Methylpyrrolidinium Chloride surges as more fields demand safer, high-performance solvents. Materials scientists aim to unlock better performance in solid-state batteries, using ionic liquids as both electrolyte and structural binder. Newer work investigates hybrid organic-inorganic materials hosted in these ionic matrices, finding tweaks in morphology and stability. Some teams probe its role in transition metal catalysis, reporting improved yields in pharmaceutical cleanrooms and petrochemical pilot plants. Others dig into its toxicity and waste products, with environmental chemists aiming to define limits and mitigate ecological impact. As universities and industry pull the salt in competing directions, open-access journals keep piling up data on its adaptability and real-world tradeoffs.

Toxicity Research

Toxicologists give N-Butyl-N-Methylpyrrolidinium Chloride a moderate risk label mostly due to its ionic structure — more persistent than simple alcohols or glycol ethers. Studies in aquatic organisms point to limited bioaccumulation but warn of chronic exposure risks in sensitive species. Skin contact rarely leads to dangerous effects but can spark irritation with repeated exposure. Inhalation hazards focus on airborne dust; with proper PPE, risks to lab workers stay manageable. Its low volatility keeps workplace air concentrations far below common limits, a blessing compared to aromatic solvents. Ongoing research aims to clear up gaps in understanding its fate in wastewater, as many ionic liquids resist breakdown in standard treatment facilities. Environmental policies already call for tighter controls, so disposal and spill prevention top safety officers’ lists wherever ionic salts get used in bulk.

Future Prospects

The next decade looks packed with promise for N-Butyl-N-Methylpyrrolidinium Chloride, especially with the electric vehicle boom pushing battery chemistry forward. Engineers keep demanding safer, more robust electrolytes, and this salt fits the bill. As energy storage shifts toward denser chemistries and faster charge rates, the ionic liquid sector could see demand double. Green chemistry circles likely keep chasing even lower toxicity variants — or improved recycling methods for waste streams — to keep in step with environmental regulations. Demand from advanced separations and analytical fields grows too, as labs hunt for alternatives to halogenated solvents. With research branching into new anion combinations and hybrid materials, the flexibility of the pyrrolidinium core points to long-term staying power. If there’s a lesson to draw here, it’s that the chemistry community keeps finding ways to stretch one molecule’s impact, far beyond its original laboratory birth.

Beyond the Lab: What N-Butyl-N-Methylpyrrolidinium Chloride Does

Ask anyone who’s worked around advanced materials or tried to keep up with the surprising tricks of modern chemistry, and they’ll point out how little household names reveal about what shapes our devices and fuels our industries. N-Butyl-N-Methylpyrrolidinium Chloride isn’t a name you’ll see on a supermarket shelf, but it quietly keeps things moving behind the scenes. This substance, which folks in labs simply call BMPyrrCl, belongs to the ionic liquid family. Instead of behaving like table salt or sugar, ionic liquids flow like syrup even at room temperature. BMPyrrCl often steps in as a solvent, standing up to the kind of heat and chemical stress that would wreck ordinary liquids.

I caught wind of BMPyrrCl after visiting a friend who worked at a research facility. He explained how researchers lean on it for its chemical stability. Organic chemists turn to solvents like this when working with delicate reactions—especially those where the wrong kind of moisture or a hint of the wrong acid would ruin the result. Ionic liquids help protect sensitive molecules during these fragile processes. BMPyrrCl offers a level of control that water and alcohol don’t match, allowing researchers to steer chemical reactions that drive modern innovations, from materials for batteries to new medicines.

Greener Choices and Real Environmental Benefits

Every so often, someone asks about the “green credentials” of compounds like this. Unlike old-school solvents, BMPyrrCl generally gives off fewer fumes. That means labs and factories run cleaner, and workers breathe in less hazardous stuff—a step toward safer workspaces and less pollution. Modern manufacturing keeps searching for less toxic, more recyclable alternatives. BMPyrrCl promises to deliver, especially since you can recover and re-use it in some industrial setups. The EPA and chemical safety boards track the environmental impact of industrial solvents, and alternatives like BMPyrrCl get plenty of attention for this reason.

I’ve listened in on researchers sharing stories at conferences about trying to cut down on waste. They highlight how cycling ionic liquids through several reactions saves companies money while trimming their environmental footprint. Saving costs isn’t just about pinching pennies. It also gives the next generation of solvents a fair shot at replacing more harmful chemicals.

Performance in Energy Storage and Electrochemistry

People love talking about electric cars and grid storage, but few consider the chemistry powering those batteries. BMPyrrCl helps designers boost battery performance since it can survive at higher voltages than most common liquid electrolytes. It’s less flammable, adding a layer of safety to products like lithium-ion batteries. Research teams worldwide study ionic liquids in the hope that tomorrow’s batteries will charge faster, last longer, and stay safer—BMPyrrCl stands among the contenders.

Outside of batteries, you’ll find BMPyrrCl in supercapacitors and electroplating. Both fields value electrolytes that can survive repeated cycles without breaking down or forming unwanted byproducts. A friend in the coatings industry once mentioned how much time they save by using ionic liquids: fewer shutdowns, less maintenance, and more consistent results. Stability pays off, both in cash and peace of mind.

Barriers and Solutions in Industrial Uptake

No chemical magic bullet comes without strings attached. The high cost of production and limited data on long-term exposure still slow adoption in some sectors. Universities and specialty manufacturers are working to iron out supply chain kinks by scaling up production methods and studying the safety profile in more detail. Open collaboration between academia and industry could shrink costs further and bring better alternatives to workplaces across the globe.

BMPyrrCl won’t turn heads in the way a new smartphone does, but it plays a quiet, vital role. Companies willing to invest in safer, more advanced manufacturing keep pushing for solutions, and the chemistry world answers one molecule at a time.

Dissecting the Formula

Most people see a long chemical name and feel like chemistry belongs in a far-away lab. N-Butyl-N-Methylpyrrolidinium Chloride packs a lot into its name, but when you break it down, it carries a formula of C9H20ClN. For those who want to understand the reason behind this formula, it helps to look at each part. The pyrrolidinium ring forms the core, with a nitrogen atom holding both a butyl and a methyl group. Adding a chloride ion balances the charge and completes the whole structure.

Why Structure Shapes Usefulness

From my time in a specialty chemical warehouse, I learned that knowing a compound’s formula is not just for taking chemistry tests. The arrangement of atoms gives this salt its unique personality. Pyrrolidinium-based salts, especially those with butyl and methyl groups, have been popping up in research on ionic liquids. These compounds show promise as alternatives to traditional solvents, cutting down on volatility and, at times, toxicity concerns.

Take battery electrolytes or green chemistry applications. The right structure can give N-Butyl-N-Methylpyrrolidinium Chloride strong electrochemical stability. These features open the door for breakthroughs in safer, more efficient technologies. Research from the Journal of Physical Chemistry reports that ionic liquids with structures like this one can stabilize sensitive reactions, boost ion transport, and reduce the risk of fire compared to classic organic solvents.

Safety and Responsibility

Spending years handling chemicals reminds a person that small formula changes can create big safety gaps. Chloride salts can interact with water, metals, or even other organics in unpredictable ways. Knowing the exact formula guides storage decisions, helps choose the right containers, and keeps people safe in the lab, shipping dock, or classroom. Mistaking a single atom in a formula might seem minor but in real-life chemistry, it can mean a spill, a clogged pipe, or an unexpected reaction.

Producers and suppliers should always verify products with proper testing. Infrared spectroscopy, NMR, or elemental analysis brings accuracy. Without this step, downstream users risk accidents or get sub-par results. I remember a time a mislabeled container sent an entire process back to square one until we tracked down the source—a formula mix-up at the supplier.

Looking Beyond the Formula

In the world of research and industry, new regulations and tougher environmental standards are leading companies to try safer compounds. N-Butyl-N-Methylpyrrolidinium Chloride offers options for greener chemistry, but every step needs accurate, reliable product information. As new uses come forward, companies, researchers, and regulators will benefit from data sharing, transparent labeling, and ongoing testing.

If labs invest in clear chemical tracking and focus on education around chemical formulas, safety becomes automatic instead of an afterthought. Detailed product sheets, technical support access, and verified sourcing all stack up to build trust and prevent the kind of surprises that cost time and money.

The Value of Getting It Right

Every bottle of N-Butyl-N-Methylpyrrolidinium Chloride starts as a chemical formula on a page, but its impact stretches from advanced energy storage research to safer chemical handling policies. Pinning down the formula isn’t just an academic exercise for a textbook. It brings real-world consequences in the lab, on the production line, and in the finished product’s final use.

Everyday Encounters with Chemical Compounds

Step into any lab, glance at an industrial shelf, and you’ll meet names like N-Butyl-N-Methylpyrrolidinium Chloride. On paper, it’s just another ionic liquid, often grabbed for its stability and versatility. Dig a little deeper, and the question arises—what does this substance do to people and the places we live?

How Safe Are These Compounds?

Ionic liquids have picked up a bit of a reputation for being green, but not every story has a happy ending. N-Butyl-N-Methylpyrrolidinium Chloride doesn’t have a thick stack of public toxicity data. That matters, especially as companies experiment with these materials in batteries, catalysis, and extraction. The few studies out there point out that it can irritate skin and eyes. If swallowed or inhaled, the risks climb, especially with repeated exposure. Lab techs who handle large amounts tend to wear gloves and goggles for a reason.

Some related compounds have shown toxicity to aquatic life. Fish and small water insects don’t always feel the brunt of it until concentrations build up. This kind of subtle, slow-moving threat gets missed in a busy workspace. I remember cleaning out a lab sink, not thinking about what sits in the drain trap, until a local university study flagged ionic liquids sticking around in water systems far longer than expected. A rinse with water does less than most think. So even if a chemical seems to break down easily, traces add up—and not all municipal treatment plants are ready for these new guests.

Digging Into the Environmental Side

Go back a few decades and the world saw ionic liquids as the cleaner cousins to volatile organics. The lack of vapor isn’t a free pass. Persistence in the environment poses trouble of its own. Long-lived compounds often turn up in odd places. The balance between safe use and reckless dumping gets tipped fast, especially when the supply chain grows.

I saw one battery prototyping project using this chemical get stalled over concerns about worker exposure and local waste laws. We underestimated disposal costs, not realizing that ionic liquids sometimes qualify as hazardous waste. Tough to burn off, easy to mishandle.

Protecting People and Planet

Straightforward rules go a long way. Gloves, eye protection, and careful tracking of spent material help lower risk for lab workers. Workers benefit when companies support open discussion and quick reporting for spills or splashes. For the environment, treating these compounds as potentially hazardous in all stages—handling, storage, and disposal—kills short cuts.

Policies lag behind chemical innovation. Researchers can push for quicker hazard profiling; more open-access data would change the game. Municipal planners and plant operators need updated training too. Simple mistakes, like a drain-pour in the wrong sink, can ripple across neighborhoods.

Better Choices for the Next Batch

Clear science and unambiguous rules keep everyone safer. Substituting less persistent or more biodegradable options eases the load downstream. Education helps as much as regulation. Before buying another drum of N-Butyl-N-Methylpyrrolidinium Chloride, labs and factories should check the newest safety findings and talk to disposal services. Combining sharp awareness and smart policy creates a real shot at progress.

The Real-World Importance of Respecting Chemical Safety

I’ve spent more hours than I’d like to admit in labs. Chemicals like N-Butyl-N-Methylpyrrolidinium Chloride aren’t household names, but anyone who spends time around specialty solvents and ionic liquids knows their risks. A lapse in attention or cutting corners when storing or handling this material doesn’t just ruin experiments; it can threaten health, ruin equipment, and even trigger regulatory headaches.

Understanding Storage Needs

This compound often comes in tightly sealed bottles, usually glass or chemical-resistant plastic, sometimes wrapped again with an extra barrier. These precautions make sense. I’ve opened containers left in humid, sunny corners and seen caked or discolored products. Sunlight or humidity can break down sensitive chemicals. N-Butyl-N-Methylpyrrolidinium Chloride prefers cool, dry, dark places. On a shelf shared with acids, bases, and oxidizers, cross-contamination risks skyrocket. A spill or a leaky cap invites unexpected reactions. Keep it away from moisture and incompatible chemicals. Stick to original containers whenever possible. Proper sealing keeps purity high and moisture out. If pouring material into a smaller container for bench work, label it clearly — confusion invites mistakes, and mistakes cause incidents.

Personal Protection Doesn’t Take a Day Off

Gloves and goggles aren’t optional just because the material rarely escapes as vapor. I’ve seen colleagues brush powder off hands “just for a second” and pay for it with skin irritation or worse. N-Butyl-N-Methylpyrrolidinium Chloride may sound mild, but direct skin or eye contact tells a different story. Choose nitrile or neoprene gloves – latex breaks down with some solvents. I always keep goggles on the hook by the main bench. It saves time and vision. Double-layer lab coats protect arms and stops splash downs from reaching regular clothes. And don’t forget simple habits: wash up well and keep hands away from your face even if “it’s only a trace.” Most accidents come from routine tasks, not the complicated experimental set-ups.

Ventilation and Clean-Up

I have worked in labs with and without proper fume hoods. The difference shows up over years. Even compounds with low volatility can create dangerous dust during transfers. A good exhaust system means headaches and chronic exposure don’t creep up on you. If you spill, act right away. Scoop up solids with dedicated tools—not bare hands or shared equipment. Wipe down with inert absorbents, then scrub with soap and water. Bag the waste for hazardous pickup—never down the sink. Too many places have faced big fines for “small” waste problems.

Ongoing Training Isn’t Just Bureaucracy

The best labs I’ve worked in keep staff up to date on chemical safety—even for the old hands. Refresher sessions matter. Recent recalls and incidents across the chemical industry show how fast new risks emerge. Training shouldn’t stop at a handbook or a yearly safety video. Regular demonstrations help drive the point home. Keep emergency numbers and spill kits within arm’s reach. Facility walkthroughs open everyone’s eyes to problems before they grow. If everyone treats these routines with respect, you rarely end up in trouble.

Better Practices Lead to Safer Labs

Keeping N-Butyl-N-Methylpyrrolidinium Chloride secure, dry, and isolated reduces regret later on. Using the right gloves and eye protection makes small accidents less likely. Quick action and a strict clean-up routine turn big problems into little ones. None of this takes much extra time, but it saves years in health, credibility, and cost. It’s more than just ticking off a box—it’s giving yourself and your coworkers peace of mind.

Why Purity Matters More Than Numbers

Many folks believe chemical purity is just a selling point. Having spent years working in analytical labs, I've seen that high-stakes research and scalable industrial processes live or die on the details in the specs. A reagent like N-Butyl-N-Methylpyrrolidinium Chloride might come stamped with a 98% or 99% purity grade, but the story runs deeper than that number.

The True Face of "Purity" in the Lab

Purity standards for this compound often reach upwards of 98%, sometimes as high as 99%. This figure gets verified by high-performance methods like NMR, HPLC, and mass spectrometry. What does that guarantee? The bottle contains nearly all active compound, but the last one or two percent covers water, residual solvents, and sometimes, leftover starting materials. During one project in grad school, I traced a contamination problem to a reagent’s “harmless” one percent impurity. Down the line, it changed results and ruined reproducibility. It’s easy to overlook those small amounts, but in sensitive work—catalysis, ionic liquids engineering, or battery research—they act as the silent saboteurs.

Beyond the Certificate of Analysis

Suppliers usually provide a certificate detailing physical properties: appearance, melting point, and chemical composition. I've learned not to rely solely on these sheets. In some cases, chloride content can swing due to small and invisible mistakes in synthesis or storage. For folks in synthetic chemistry, a difference of 0.2% can mean more cleanup steps later or interactions with other reagents you didn't plan for.

Handling Moisture and Storage Tricks

This compound tends to absorb water from the air. Purity drops fast if left open on a bench for even a few hours. I’ve watched crystalline product turn sticky-pronged overnight. Labs that manage to protect their materials with dry boxes and smart storage strategies see much better yields across the board. Every shipment I order gets double-sealed and goes straight into a desiccator. The cost in effort beats the pain of unpredictability.

Keeping Suppliers Honest

Track record matters as much as listed purity. Some suppliers back up their paperwork with independent third-party analysis, offering transparency. Others change grades depending on customer demand. The best way to keep your workflow tight comes from ordering small test samples and running your own purity checks before scaling up. Cutting costs up front with lower grades can hurt longer-term output—something I’ve seen many startups regret when troubleshooting root causes.

Building Trust With Clear Information

Trust builds on details, not marketing slogans. N-Butyl-N-Methylpyrrolidinium Chloride’s impact depends on how seriously purity gets treated from manufacturing to storage—all steps matter. Whether running an academic project or refining an industrial process, asking clear questions and demanding hard data from suppliers shapes every successful outcome.

How Users Can Push for Better Purity Guarantees

Talk openly with vendors about your application. Explain why low water or specific metal-ion limits matter. Reliable suppliers answer with batch-specific test data, including moisture content, halide analysis, and absence of heavy metals. Labs that build honest relationships with partners get stronger results and fewer surprises on big deadlines.