N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate: Moving Science Forward with Ionic Liquids

Historical Development

People who’ve followed the growth of green chemistry have seen N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate—often known as BMPyrr PF6—move from a laboratory curiosity to a valuable workhorse. BMPyrr PF6 comes from a long line of ionic liquids developed to meet new demands in electrochemistry and materials research. Scientists first explored pyrrolidinium salts as a way to break free from the constraints of volatile, flammable solvents. The demand for safer, higher performance materials in batteries and separations drove heavy research investment in the early 2000s. By 2005, BMPyrr PF6 regularly appeared in research papers focused on lithium-ion batteries and advanced supercapacitors, with researchers looking for replacements for the flammable mixtures used since the dawn of portable electronics.

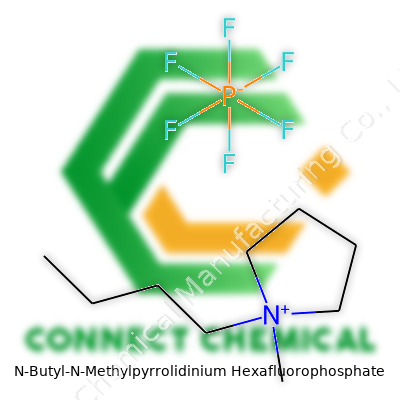

Product Overview

BMPyrr PF6 stands out in the ionic liquid crowd thanks to its stability, low vapor pressure, and electrochemical resilience. The compound’s structure combines a pyrrolidinium ring, an N-butyl group, and an N-methyl group, paired with a hexafluorophosphate anion. This design gives the liquid both hydrophobic and hydrophilic interactions, which matter for solubility and phase separation. Market forms range from pure liquid for laboratory exploration to custom-blended solutions for electrochemical devices.

Physical & Chemical Properties

Room temperature, you’ll usually find BMPyrr PF6 as a clear, colorless liquid. High thermal stability makes it tough enough for demanding equipment, withstanding up to 300°C before decomposing. Its melting point sits below typical room temp, so it handles like a thick oil. Water won’t dissolve it easily, thanks to the bulky nonpolar groups and the hexafluorophosphate anion. You get decent dielectric properties, mild conductivity, and virtually zero vapor pressure. Its viscosity makes some processing steps slower, but that’s a tradeoff for safety and longevity. Where volatile organic solvents fail, BMPyrr PF6 holds steady, not producing fumes or catching fire.

Technical Specifications & Labeling

Reputable manufacturers lay out purity above 99 percent for research and battery applications. Labels cover water content, mostly kept below 200 ppm to ensure predictable performance in electrochemical setups. Residue and trace metals come in under tight limits, since impurities create problems in batteries and lab research. Packaging uses glass or compatible plastics that resist chemical attack. Labels often include the CAS number, chemical formula (C9H20F6NP), and batch data for traceability—a safeguard anyone in a regulated lab should appreciate.

Preparation Method

Synthesis usually starts with N-methylpyrrolidine, which reacts with butyl bromide in a classic alkylation. Isolation yields N-butyl-N-methylpyrrolidinium bromide, which then undergoes anion exchange with potassium hexafluorophosphate. Pure BMPyrr PF6 comes after careful washing and vacuum drying to drive off unwanted ions or water. The prep stays straightforward, though cleanup and purification require plenty of patience and reliable analytical tools—residual byproducts spell trouble in sensitive applications.

Chemical Reactions & Modifications

BMPyrr PF6 doesn’t just sit there—it changes the game for chemists who need a stable, non-flammable solvent. It resists most nucleophilic and electrophilic attacks, making it suitable for demanding environments. Mixing it with other ionic liquids broadens the temperature window and tweaks conductivity. Researchers occasionally swap out the hexafluorophosphate for alternative anions to tune physical or chemical performance. The pyrrolidinium ring’s side groups can also be switched for longer or branched alkyl chains to reduce viscosity or boost solubility for particular solutes. These modifications expand its use in catalysis, extraction, and surface science.

Synonyms & Product Names

Anyone scouring catalogs or research papers finds BMPyrr PF6 under names such as N-Butyl-N-methylpyrrolidinium hexafluorophosphate, 1-butyl-1-methylpyrrolidinium hexafluorophosphate, and its acronym, [BMPy][PF6]. Some manufacturers throw in custom trade names, making it even more important to check chemical structure or registry numbers. Synonyms reflect only the chemical identity, since small structural tweaks in the pyrrolidinium ring can lead to very different liquids.

Safety & Operational Standards

BMPyrr PF6 carries a much safer profile than legacy solvents, avoiding flammability and destructive volatility. Those working with it still watch for toxicity from the hexafluorophosphate component when exposed to water or acids, as it can slowly break down and release hydrogen fluoride. This risk grows at high temperatures or under electric fields. Labs keep well-ventilated hoods, use gloves, and opt for chemical-resistant goggles. Facilities follow strict handling and disposal rules, treating BMPyrr PF6 as chemical waste. Aging research finds minimal skin uptake, but ingestion dangers remain. Routine industrial hygiene practices keep most facilities incident-free, but comprehensive safety data sheets get updated as new findings emerge.

Application Area

Battery scientists praise BMPyrr PF6 for reliable performance in next-generation lithium-ion systems, where thermal runaway risks drive demand for non-flammable electrolytes. Supercapacitor designs benefit from the broad electrochemical window. In separation science, it enables greener extraction processes; hydrophobicity and thermal stability favor applications in rare earth or pharmaceutical separations. Lubricants mixed with BMPyrr PF6 resist breakdown at high speeds and temperatures. Analytical chemists employ it for solvent extraction and sample prep, enabling protocols where traditional solvents lag. Research in solar cells and fuel cells taps its resilience to electrochemical stresses. Where safety, longevity, and new performance push innovation, BMPyrr PF6 finds a role.

Research & Development

Every year brings a longer list of journal articles and patents describing new tweaks to the BMPyrr PF6 formula. Research teams target lower viscosity, better lithium-ion transport, and improved recyclability. Computational chemists dig into simulations, predicting how backbone or anion switches could yield better device performance. Collaborative partnerships between chemical manufacturers and academic labs funnel research dollars into both large-scale production and bench-top optimization. Ongoing studies into biodegradability and lifecycle impact respond to growing regulatory scrutiny worldwide. BMPyrr PF6 serves as both a benchmark and a springboard for adjoining fields such as flow batteries and electrolytic water splitting.

Toxicity Research

Compared to hydrocarbon solvents, BMPyrr PF6 looks much safer for people and the environment, but the full picture evolves. Toxicity testing in zebrafish and rodents shows low acute exposure risks, with little bioaccumulation at low concentrations. Questions remain about long-term persistence, as fluorinated anions can resist biodegradation, especially in waterways. Researchers actively measure breakdown rates under sunlight, in soil, and after incineration. Workplace exposure studies, though rare, point to mainly skin or eye irritation when handled in bulk. Monitoring programs in academic labs and industry sites check for chronic effects or unpredicted metabolic products. Loose disposal or spills could create future liabilities, so well-documented waste controls and updated risk assessments rank as best practice for all users.

Future Prospects

BMPyrr PF6 represents what many in chemistry hope to see—materials that combine safety and advanced performance without heavy tradeoffs. Battery electrification for global transport grows every year, so demand for stable electrolytes only gets stronger. As recycling standards tighten and the world faces legacy pollution, greener, less persistent ionic liquids will draw research investment. BMPyrr PF6 won’t serve as a panacea, but it fast-tracks a move away from more toxic, flammable options. Development now focuses on tweaking this core structure to cut both cost and environmental impacts. Effective partnerships between chemistry companies, battery builders, and environmental scientists are likely to produce even better candidates over the next decade. Watching funding trends and regulatory policies will show just how quickly BMPyrr PF6, or its next-gen siblings, move from niche to mainstream.

Beyond the Chemistry Lab

Most people haven’t come across N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate in daily life, but its impact runs deep on technologies we count on each day. This compound belongs to a family known as ionic liquids—salts in liquid form at room temperature. I spent half a decade working in battery research, and I’ve watched how interest in these liquids keeps growing in labs and industry. Their power comes from unique features—low volatility, high thermal stability, and, most important for engineers, the ability to conduct ions without turning into a fire hazard. While testing battery prototypes, safer choices made all the difference.

Supporting Safer, Next-Gen Batteries

Lithium-ion battery fires have made international headlines. In my time at an energy lab, every researcher felt this risk breathing down their neck. N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate goes into the heart of safer battery electrolytes, helping reduce flammability compared to traditional organic solvents. The compound forms a stable ionic atmosphere around electrodes, which supports extended battery cycles. Reports from the Journal of Power Sources show batteries using ionic liquid electrolytes can survive high heat and charge-discharge stress better than classic systems. Seeing real test data from field trials, it’s clear how these materials cut down on catastrophic battery failures.

Green Chemistry in Practice

Working at a startup, I saw how the environmental footprint of chemicals raised concern at every decision point. Traditional solvents leak fumes and create disposal headaches. N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate offers low vapor pressure, slashing airborne pollution and lowering workplace hazards. The European Chemicals Agency and multiple academic studies point to the role of ionic liquids in pushing sustainable chemical processes forward. Cutting out volatile, flammable compounds lowers insurance costs for manufacturers, too, which ripples out to consumers.

The Surprising World of Supercapacitors and Solar Cells

I sat in on conferences where scientists talked more about storage technologies than headlines let on. Supercapacitors store and release energy faster than any battery, but older electrolyte formulas held them back. By using N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate, labs ramped up both charge density and operational safety. The same goes for next-generation solar cells—ionic liquids help assemble more stable, efficient cells in real-world sunlight without the risk of solvent breakdown. As highlighted in Advanced Materials, research continues, but the practical returns already change how renewable energy systems look at materials.

Getting the Best Out of Ionic Liquids

Scaling up these breakthroughs hasn’t come without hurdles. Ionic liquids remain costlier than legacy materials. Early batches sometimes brought impurities, and not every supplier met the reliability needed for commercial production. Still, demand for safer, greener, and longer-lasting materials keeps pressure on chemical firms. As more companies invest in cleaner processes and as recycling of these specialized liquids improves—both steps I’ve heard executives discuss firsthand—prices start to level out.

Final Thoughts from the Field

My time in battery development proved one thing: safety and reliability sell more than hype. Chemicals like N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate don’t show up on store shelves, but behind the scenes, they support a shift toward greener energy and safer rechargeable technology. People want gadgets that won’t overheat or pollute the environment. Science is meeting those expectations with better building blocks. That’s a shift worth keeping an eye on.

What Makes This Chemical Worth Talking About?

People handling chemicals at work or in school labs know the feeling: reading a label and spotting words that sound like a mouthful — like N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate (often called BMPyPF6). It shows up in battery research, ionic liquids, and some specialty solvents. The full name alone signals a need to step carefully, and not just because it’s hard to say three times fast.

Why Safety Becomes a Real Priority

Having seen what can happen when strong salts get spilled or used wrong, I learned to respect more than just acids or bases. BMPyPF6 brings real risks to the table. Spills and skin contact can lead to irritation and possible chemical burns. Much like other salts based on hexafluorophosphate, it poses a risk if heated — breaking down and releasing nasty gases like hydrogen fluoride. Everybody working around these compounds owes it to their lungs and their long-term health to treat them like the hazards they are.

Solid Habits Mean Fewer Accidents

The routine always starts with personal protective equipment. Nitrile gloves offer a reliable barrier. Regular lab coats or, even better, chemical-resistant aprons, help keep splashes from reaching your clothes or skin. Most sites I’ve worked at expect workers to put on safety goggles or shields to keep eyes safe from stray droplets.

Ventilation matters. A well-maintained fume hood can prevent inhalation of dangerous vapors and dust. During my time as a research assistant, hoods were always humming whenever anything containing hexafluorophosphate came out — nobody wants to breathe in the byproducts of accidental heating or spills.

Good Sense in Handling

People sometimes get careless with small scoops, but weighing and transferring BMPyPF6 should never go bare-handed. I saw one new intern ignore this rule, thinking the powder looked harmless. They came off with a mild rash, and a tough conversation with the safety manager. Water won’t always neutralize this salt, so if it touches your skin, rinsing with plenty of running water really helps, but a visit to occupational health is also a smart call.

Always use clean, labeled containers. The chemical doesn’t mix well with moisture, so I learned to store it in a dry, airtight vessel, often inside a desiccator. Store it out of direct sunlight and far from acids — hexafluorophosphate breaks down much faster in acidic conditions, bringing extra danger.

Dealing with Disposal and Spills

You can’t just toss unused or spilled BMPyPF6 in the trash or down the drain. Hazardous waste bins with tight lids and the right labeling become mandatory here. I have watched coworkers mop up small spills with absorbent pads, then slide everything, gloves included, into hazardous waste containers. Always, spills get logged — a habit that helps track patterns before mistakes become habits.

Training and Culture Make the Difference

In every workplace I’ve visited, the safest teams did not treat safety as something extra. Everyone got training — from senior scientists to undergrads. Updates about recent incidents or changes in handling protocols made a difference. Emergency showers, eyewash stations, and up-to-date spill kits stayed prepped nearby, and people checked labels twice before reaching for any chemical.

A Safer Path Forward

BMPyPF6 brings a lot to battery labs and advanced chemistry, but it also demands respect. Building safer habits takes practice, but it starts with honest conversations, protective gear, and attention to the details that keep labs from turning dangerous. The best teams lead by example and remind each other, every shift, what’s really at risk — their own safety and the safety of those around them.

Getting Into the Details

N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate is a mouthful, no question. In the lab, we just call it BMPyrr PF6. Look at the formula: C9H20N2PF6. The cation itself is N-Butyl-N-Methylpyrrolidinium, which shows up as C9H20N+, and the anion is hexafluorophosphate, PF6-.

Structure: Picture a five-membered pyrrolidine ring. One nitrogen in that ring links to a methyl group and a butyl chain—these substitutions bulk up what would otherwise be a basic salt. On the flip side, PF6- is a phosphorus atom surrounded by six fluorine atoms, balanced out by the positive charge from the cation.

Why It Shows Up in Real-World Science

I ran across BMPyrr PF6 the first time in a graduate energy storage research project. It’s not just lab curiosity. Ionic liquids like this one cut a wide path: safer electrolytes for lithium batteries, solvents for chemical separations, and even as anti-static agents. In batteries, classic solvents catch fire easily, especially under strain or short circuits. BMPyrr PF6 brings a lower volatility, making accidental fires less likely. It resists breaking down across a broad range of voltages, which makes a difference in high-powered devices.

A colleague working in environmental chemistry shared that these ionic liquids dissolve metals and organic contaminants with a fraction of the waste traditional solvents leave behind. You might not see them on a product label, but as pushback grows against toxic fluorinated chemicals and environmental exposure, the industry keeps BMPyrr PF6 and its kin on the short list for green chemistry alternatives.

What’s the Catch?

The fluorinated anion opens the door to both opportunity and risk. PF6- creates excellent ion conductivity, but fluorinated chemicals tend to break down into tough-to-remove pollutants. As BMPyrr PF6 ramps up in production, questions about biodegradability and toxicity turn up in journal articles and patent filings. Researchers with the European Chemicals Agency have flagged PF6--containing ionic liquids as “persistent,” so keeping tabs on waste streams turns into a priority.

The other hard reality is cost. Ionic liquids do the job well and open paths for advanced technology, but they don’t come cheap. For commercial battery manufacturers, every added dollar can mean trouble for already-tight profit margins.

Potential Solutions Stepping Forward

Tweaking the structure opens new directions. Chemists experiment with swapping the hexafluorophosphate for less persistent anions or using alternative cations to keep the performance but drop the price or environmental impact. More green chemistry research could lead to bio-based ionic liquids without fluorine content.

On the regulatory and manufacturing front, improving recycling processes for solvents and electrolytes will stretch resources and keep potentially harmful chemicals from slipping into waterways or soil. In my own lab work, we always tracked where every drop of ionic liquid ended up, even if it meant triple-washing glassware and logging chemical disposal for inspection.

At the end of the day, understanding the chemistry of molecules like N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate isn’t just academic. It shapes cleaner tech, better batteries, and safer industrial practices. Those chemical formulas and structures don’t stay in the textbook—they ripple out into real-world change.

The Essentials of Safe Storage

N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate doesn’t show up in household pantries or common workshops; it belongs to a special class of chemicals used mainly in labs, battery research, and specialty manufacturing. Even so, the way we store it affects safety, product integrity, and long-term costs. Mishandling can trigger dangerous leaks, environmental contamination, or expensive waste. It’s not just about following a checklist; it comes down to respect for chemistry, infrastructure, and the people who work with these substances every day.

Keeping It Cool and Dry

Direct sunlight turns many fine chemicals unstable. I remember a dusty storeroom at a university where an overlooked shelf near a window spoiled thousands of dollars’ worth of solvents—temperature and light matter. N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate fares best in a cool, dry spot, ideally around 15–25°C. Damp or fluctuating storage means moisture sneaks in, kicking off reactions that ruin purity and turn small mishaps into emergencies.

Standard chemical storage cabinets, well-sealed and shaded from direct heat, do a solid job. Reliable humidity control—dehumidifiers, silica gel pouches, or built-in cabinet drying systems—keep moisture at bay. All staff should learn to spot signs of condensation and review logs for sudden temperature swings, because even a small oversight costs money and lab time.

Airtight, Compatible Containers

This material needs strong barriers. Choose containers from materials like glass or high-grade plastics proven not to react with ionic liquids or their salts. Avoid cheap plastics, because they crack, bleed chemicals, or leach contaminants into your most expensive research. Factory-sealed packaging often includes double sealing—an inner screw-cap and an outer layer. After opening, quickly reseal and keep the lid tight.

Label everything with the date received, date opened, and clear chemical identity. Hazmat teams, students, and newcomers often find poorly labeled bottles, sometimes filled with unknown, aging substances. Accurate labelling prevents accidental misuse and supports regular inventory checks.

Safe Distance from Incompatibles and Ignition Sources

Not everything belongs together in a chemical storeroom. Separate N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate from acids, alkalis, and oxidizers. Mixing can set off runaway chemical reactions, corrosion, or fire. Dedicated shelves—or, even better, segregated cabinets—could save lives.

Keep every chemical far from sparks, open flames, or anything that could overheat a bottle. These rules seem simple, yet industrial accident reports show how routine shortcuts bring disaster. Everyone in the building, not just lab techs, needs to understand who can access the chemical storage area and under what conditions.

Training, Documentation, and Emergency Readiness

In my own early years working in a chemistry department, we made real progress when training sessions ran regularly, not just for new hires. Hands-on walkthroughs—how to store, seal, and move chemicals—built habits and caught bad practices before they became routine. Safety data sheets belong on hand both in physical binders and digital files, so no one is guessing if something spills.

Every facility storing this chemical would do well to run periodic drills: simulate a spill, test the eyewash stations, and walk through evacuation plans. These steps won’t halt every risk, but they turn possible emergencies into manageable events.

The Bottom Line

Storing N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate means more than locking a door and hoping for the best. Proper shelving, ventilation, airtight containers, clear labels, and a well-trained crew form the backbone of safe industrial and research work. It’s a collective responsibility that protects us all: from the seasoned chemist, to the new intern, to the community outside the lab walls.

Getting to Know the Chemical Up Close

Anyone who spends time with ionic liquids knows there’s a lot more to them than fancy names. N-Butyl-N-Methylpyrrolidinium Hexafluorophosphate (let’s call it BMPyrr PF6 for short) is one such specialty chemical. It trades in the open market of high-end laboratories and, more recently, industries hunting for safer alternatives to old-school solvents or electrolytes. Some see weird glass bottles of it and keep walking. Others see possibility.

Appearance: A Clear Signal

Here’s the first thing that catches your eye: BMPyrr PF6 doesn’t look like a menacing substance used in those stylized “dangerous scientist” labs. In its pure form, it pours as a colorless to faintly yellow liquid. The consistency feels oddly familiar for anyone who’s handled viscous oils—slippery, but not sticky like a syrup. No strong fumes leap out of the bottle. If you spilled a little, you’d probably mistake it for some benign oil at first glance.

In reality, the visual calm hides some real chemical action. Any work with an ionic liquid this clean makes you notice impurities almost right away. A hint of brown is an instant red flag; genuine BMPyrr PF6 doesn’t ask for a filter or decanter, unless it’s been mistreated or left open to ambient moisture.

Melting Point: Tackling Temperatures

Its melting point sits at a practical level—roughly -3 °C. My own first experience with this compound came on a cold January day. Even as the lab refrigerator got crowded, the vial of BMPyrr PF6 didn’t crystallize into a useless block. That means fewer headaches over solidifying in pipelines or clogging up valves. As long as you avoid storing it anywhere that freezes over, it stays ready for work.

This low melting point gives researchers a clear advantage in battery development and precision applications where temperature swings play havoc with more fragile salts. You never need to drag out a heat gun or worry about fragile glass cracking from expansion. Labs that handle experiments through different seasons don’t need to double up on cold-weather protocols just to keep things moving.

Solubility: Standing Apart in Water and Solvents

BMPyrr PF6 breaks some of the traditional ionic mold regarding solubility. It won’t dissolve in water, thanks in part to the spell Hexafluorophosphate casts. Dumping it in an aqueous solution leaves you with a separate layer, much like oil and vinegar. This matters, especially in purification work. Let’s say you’re trying to wash out a reaction mixture; water alone can’t drag BMPyrr PF6 away, so it stays pure and doesn’t vanish down the drain.

On the other hand, this ionic liquid loves a chance to mingle with organic solvents. Put it in acetone, acetonitrile, or other polar aprotic solvents, and you’ll find it dissolves smoothly. I’ve seen it slip unnoticed into solvent mixtures, doing its job with barely a ripple. This brings down barriers in the lab—chemists can tweak reaction media and extract with precision instead of wrestling with sludge or cloudy residues.

Accessibility and Future Potentials

Ionic liquids like BMPyrr PF6 still get side-eyed by folks used to ‘safer’ chemistry. Yet, anyone working to design safer batteries, new supercapacitors, or less volatile solvents looks for chemicals that can stand heat, avoid waterlogging, and tolerate tough treatment. The traits of BMPyrr PF6 fit those needs so well. We need to keep asking tough questions about disposal and long-term safety, but its physical properties keep it at the front of innovation in material science, electrochemistry, and beyond.