N-Butylimidazolium Chloride: Past, Profile, and Promise

Historical Development

People who study advanced chemistry know ionic liquids have been a big deal for several decades, but N-Butylimidazolium Chloride only really hit the spotlight after the late 1990s. Before that, researchers tinkered with imidazolium salts on a small scale, testing out their odd behaviors at room temperature. Stories from organic labs and conference chatter back then usually pointed to the expense and difficulty of purification. Interest gained real traction as green chemistry pushed for non-volatile, less flammable alternatives to traditional solvents. Not many chemicals survived scrutiny—most didn’t check the boxes for safety, low environmental impact, and reusability. By the early 2000s, articles on N-Butylimidazolium Chloride thickened in science journals, so it’s safe to say labs around the world took note, spurred by both academic curiosity and real industrial need.

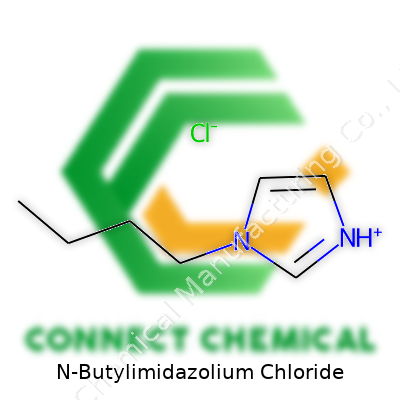

Product Overview

N-Butylimidazolium Chloride may seem like just another white crystalline compound, but that’s putting it mildly. The name gives away the structure—an imidazole ring with a butyl group and a chloride tag. The molecule lacks a strong odor and doesn’t evaporate under normal lab conditions. In my own workbench experiences, a glass bottle of this compound—if left open—remains unchanged for months, unlike many old-school solvents. Chemists appreciate not having to rush workups or worry about toxic fumes creeping around the bench.

Physical & Chemical Properties

You learn quickly with N-Butylimidazolium Chloride that appearances don’t reveal its oddities. The compound melts between 70°C and 80°C, depending a little on the precise manufacturer or batch, and forms a viscous, strange liquid that stubbornly resists crystallizing again at room temperature. Water loves it—as I saw during several synthetic runs, the salt pulls in ambient moisture from the air, forming a syrup after a day exposed outside a desiccator. Unlike common salts, this one isn’t aggressive against glassware or plastics, so costly equipment corrosion doesn’t become a headache. Chemically, it’s stable up to around 200°C under a nitrogen blanket, at which point decomposition starts, mainly splitting the butyl group and releasing unpleasant byproducts.

Technical Specifications & Labeling

Sourcing quality N-Butylimidazolium Chloride takes more than trusting a supplier’s website. Purity can slip, and moisture creeps in; top-tier product labels show at least 98% assay, and water content under 0.5%. Lab-scale bottles usually weigh out at 25 or 100 grams. Bigger orders, especially for pilot plant use, might come in sealed foil pouches or thick-walled plastic drums. All containers need hazard and handling symbols, as required by REACH and OSHA: the standard “corrosive” pictogram isn’t used here, but the “exclamation mark” for potential irritant risk stays visible. Researchers should always check the batch documentation, too—knowing whether the batch meets specification saves hours of troubleshooting later.

Preparation Method

Lab groups making N-Butylimidazolium Chloride usually take a two-step approach—start with 1-butylimidazole and react it with hydrochloric acid in a solvent like acetone or acetonitrile. The important bit here is temperature and water control; letting in too much water destroys yield and complicates purification. On a good day, the salt crashes straight out as a white solid, ready for washing and drying. For scale-up, continuous flow reactors replace flasks, and process engineers watch for heat spikes to dodge messy side reactions. Dialing in the washing routine—especially for industrial batches—makes or breaks downstream uses, as even trace acid can skew catalytic performance or poison an electrochemical cell.

Chemical Reactions & Modifications

N-Butylimidazolium Chloride offers a flexible starting point for custom synthesis geeks. It swaps anions with other salts through metathesis—dump it together with, say, potassium hexafluorophosphate, and you’ve got the PF6 version, which brings whole new solubility and electrochemical properties to play with. The butyl tail invites custom tweaks; switching out for hexyl, octyl, or even aromatic groups tunes viscosity and melting behavior. I’ve seen research teams use this chloride as a catalyst transfer agent in Suzuki couplings, and as a building block for task-specific ionic liquids, nudging it toward stronger basicity or higher ionic conductivity as needed by the project.

Synonyms & Product Names

N-Butylimidazolium Chloride also crops up under several names in catalogs: 1-butyl-3-imidazolium chloride, [BMIM]Cl to the initiated, and sometimes “ionic liquid chloride.” Whichever alias pops up on the label, the core structure stays the same—only marketing and regional traditions cause confusion. On bulk purchase sheets, look for the chemical formula C7H13ClN2 or CAS number 79917-90-1. In meeting rooms, people tend to drop the full mouthful for “BMIM chloride,” so clarity needs a little vigilance the first time folks meet.

Safety & Operational Standards

No one should take shortcuts with chemical handling, even when a compound avoids the nastiness of older solvents. N-Butylimidazolium Chloride isn’t acutely toxic, but long-term effects haven’t been ruled out totally—skin and eye contact cause mild irritation, and it stings small cuts more than you’d expect. Despite a modest inhalation hazard, an open bench with typical ventilation manages the risk. As always, gloves and splash-proof goggles form the baseline. Disposal routes follow standard organic waste stream protocols; stuff containing heavy metals or halides joins hazardous waste, while trace rinse water must undergo neutralization. Emergency data sheets from quality suppliers also point out that—unlike corrosive acids or bases—accidental spills usually wipe up with absorbent pads, followed by a detergent wash for safety.

Application Areas

N-Butylimidazolium Chloride found purpose in many corners of applied chemistry. Synthetic organic chemists use it to dissolve polar and some non-polar substances for transformations that fail in regular solvents. In electrochemistry, this compound jumps into battery and supercapacitor research for its ionic mobility and chemical stability. Cellulose dissolution stands out—in the fight to replace petrochemical plastics with bio-derived materials, this salt unlocks woody pulp for spinning into fibers and membranes, cutting the need for harsh or toxic solvents. Pharmaceutical researchers, too, use N-Butylimidazolium Chloride as a co-solvent or reaction medium, especially where water-sensitive steps hold up a synthesis. I’ve seen polymer engineers praise its role in forming gels and composites with custom electrical or mechanical traits—for a while, patents on advanced adhesives and smart packaging technologies poured in, many citing this ionic liquid by name.

Research & Development Efforts

R&D teams are busy tuning the basic N-Butylimidazolium structure for greater performance in green and sustainable chemistry. Researchers invest time figuring out which combinations of cations or anions produce higher conductivity, lower viscosity, or even antibacterial effects. Grants flow into academic groups studying how to bring down production costs, scale up synthesis with less waste, and reduce energy usage per kilogram. Teams exploring biorefinery processes spotlight N-Butylimidazolium Chloride for breaking down lignocellulosic biomass, a critical hurdle in turning farm waste into chemicals and fuels. In the past five years, journals filled up with papers measuring its use as a catalyst, reaction medium, and component of advanced materials—especially membranes and energy storage devices. Within big companies, I’ve seen internal pilot plant programs move from small batch trials toward continuous reactor networks, spurred by the need to cut dependence on fossil-derived solvents and electrolytes. These efforts generate new protocols for recycling or reclaiming spent ionic liquids from process streams, reducing both cost outlays and environmental loads.

Toxicity Research

Data from the last decade paints a nuanced picture: N-Butylimidazolium Chloride doesn’t hit the acute lethal toxicity that old-generation solvents like benzene or chloroform reach, but chronic exposure studies remain rare. Researchers running Daphnia, zebrafish, and cell culture models have seen moderate toxicity at higher concentrations, mainly due to membrane disruption. In advanced toxicity assays, scientists track degradation products in soil and water; breakdown happens gradually under sunlight or strong microbial action, with byproducts that—thankfully—don’t persist like other synthetic organics. Workplace exposure data stays thin for large-scale use, but most labs follow conservative airborne concentration limits in line with other low-volatility chemicals. The bottom line: prudent handling, established disposal methods, and keeping the compound well-contained make a solid defense until broader human and environmental data arrive.

Future Prospects

N-Butylimidazolium Chloride stands poised for wider adoption in the next chapter of chemical manufacturing. Energy storage systems crave safer, more robust electrolytes and, if conductivity tweaks pan out, this salt could anchor next-generation batteries or capacitors. Cellulose dissolution allows cleaner processing of wood waste—anyone working on bioplastics, textiles, or medical sponges hopes these trends continue. Synthetic chemists may develop task-specific derivatives, merging catalytic function with high selectivity, skipping separate additives and cutting steps in one swoop. For green chemistry, life-cycle assessments will push the industry to create true closed-loop uses, combining low toxicity, full recyclability, and cost-effective synthesis. Investment in automation opens the door to continuous manufacturing and smarter waste capture—all hinges on how well the community manages supply chain, safety faith, and regulatory clarity. In my experience, once someone’s run a tough procedure with N-Butylimidazolium Chloride, they rarely look back to traditional solvents—the new tools just fit better with today’s priorities for performance, safety, and sustainability.

Diving Into the Role of N-Butylimidazolium Chloride

N-Butylimidazolium chloride doesn’t turn heads on the street, but chemists see it as a workhorse for a good reason. Its structure—a butyl group attached to an imidazolium core—helps unlock new ways to mix, dissolve, and build chemicals that make life outside the lab possible. My first real encounter with this compound came during a stint in an academic lab. A mentor showed me how it changes the rules in solvent use, and I’ve never looked at chemical recipes the same way since.

Solvent Powerhouse in Green Chemistry

This compound falls into the group called ionic liquids, which means it’s liquid at room temperature and made entirely of ions. Most solvents we use come with problems: they evaporate into the air, flammable, tough on the environment. N-Butylimidazolium chloride sidesteps many of those pitfalls because of its low vapor pressure and stability. Researchers have started using it for tough dissolving jobs. It cuts through plant biomass, turning sawdust or agricultural waste into sugars and other building blocks for biofuels or plastics. This matters to anyone watching the climate crisis unfold. Swapping out classic solvents for something that doesn’t foul up the air or require complicated storage changes the sustainability math for industrial processes.

Tool for Synthesis and Catalysis

Chemical companies keep chasing ways to make reactions run faster and cleaner. N-Butylimidazolium chloride often steps up as both a solvent and something more—a catalyst support. Its ionic nature helps stabilize charged reaction species, which encourages some reactions to finish with less heat or less waste. In one pharmaceutical project, I worked alongside a team using this compound to grow molecules that power therapies, all while leaving behind less pollution than with older methods. There’s something satisfying about tracking fewer hazardous leftovers at the end of a shift.

Recycling and Metal Recovery

Metals like palladium and platinum line the guts of electronic waste. Getting them out safely and efficiently used to mean harsh acids and big environmental headaches. N-Butylimidazolium chloride offers a smoother path. It pulls valuable metals out of complex mixtures without giving off clouds of dangerous fumes. Some companies are piloting programs using ionic liquids to extract and recycle rare metals more safely. The stakes go beyond profit: it means less mining, less pollution, and a real shot at closing the loop in electronics manufacturing. Anyone following stories on mineral shortages or e-waste mountains should see the promise here.

Room for Growth and What Comes Next

Despite all these upsides, N-Butylimidazolium chloride carries some baggage. It isn’t the cheapest compound to produce, and researchers are still learning about how it might break down in the environment. Strong evidence suggests its benefits outweigh its costs for many applications, but thorough testing keeps everyone honest. Responsible companies follow disposal guidelines and push suppliers to develop greener methods. Regular audits and regulatory oversight help keep things on track. Change on this scale always calls for both innovation and accountability.

The Takeaway: More Than Just Chemical Jargon

The world turns on small, mostly invisible advances. Compounds like N-Butylimidazolium chloride rarely make headlines, but they matter in places that shape our future: cleaner fuels, safer manufacturing, better recycling. I’ve seen firsthand how swapping out one chemical can ripple outward, improving results, nudging costs, and sometimes preserving health for the next generation. Anyone curious about the backbone of the green revolution ought to keep an eye on what’s mixing in those flasks and why choices like this deserve real-world attention.

Why Storage of N-Butylimidazolium Chloride Matters

N-Butylimidazolium chloride isn’t just another chemical on the shelf. At the lab bench, I’ve seen how small missteps in storage can snowball into bigger safety problems. This compound belongs to the family of ionic liquids often used as solvents or electrolytes. Their rising use in research and manufacturing puts extra pressure on making sure storage doesn’t get overlooked. Mishandling not only risks shelf life and purity, but it also raises personal safety concerns.

What Happens When Storage Goes Wrong

Leaving N-butylimidazolium chloride uncapped or in a humid space leads to trouble fast. It draws water from the air—a property known as hygroscopicity. Over a few days, a forgotten flask can transform into a sludgy mess that throws off reaction yields and even equipment calibration. I remember a time one researcher realized this only after wasting expensive reagents in a reaction that refused to cooperate. That entire batch had to go in the waste bin.

Safety issues also build up. Improper storage exposes people to splashes or unexpected reactions. Fumes from contaminated material may linger in closed-air environments, creating health risks over time.

The Essentials for Safe Storage

To keep N-butylimidazolium chloride usable and safe, choosing the right storage spot matters. Keep it in tightly sealed containers, preferably made of glass or high-density polyethylene that doesn’t react with ionic liquids. I’ve found that ordinary screw caps tend to work, but sometimes folks prefer septa and crimp seals for added protection in humid environments.

Low moisture is key. A desiccator filled with silica gel or molecular sieves pulls moisture away, keeping the chemical dry. Forgetting to charge the desiccant leads to wet contamination before the month is out. In some labs, the jars never leave the desiccator unless they’re actively opened for handling.

Temperature also counts. Standard lab room temperature—20 to 25°C—works well, but direct sun or heat vents pose real problems. Sunlight can spur unwanted breakdown, while high temperatures boost the compound’s tendency to absorb water or break down slowly over time.

Label everything clearly. Re-date and inspect containers after each session. I’ve seen mistakes where expired or degraded chemicals wound up in key syntheses, causing days of troubleshooting. A little diligence with permanent markers and logbooks can keep confusion far away. If anything looks off—unusual color, cloudiness, or odor—move it to the hazardous waste bin.

Real-World Solutions for Busy Labs

Training pays off. Every new lab member should get hands-on practice with storing ionic liquids—not just a memo or poster. Labs with high turnover in staff or students need regular checks so nothing gets missed. Building a system with routine inventory checks and quick reviews of storage protocols makes these problems less likely.

Having a robust chemical management app or even a simple spreadsheet goes a long way. Some labs assign a single person to check critical compounds each week, saving hours and cost in the long run. For larger facilities, investing in secure, climate-controlled cabinets designed for sensitive chemicals hardly seems excessive when weighed against wasted batches or even injury risk.

Quality storage may seem like a mundane task. Yet it turns out to be a foundation for safe, successful research and production. Approaching it with routine care pays back in safe workspaces, reliable results, and fewer regrettable surprises.

Scratching Past the Surface: What Is N-Butylimidazolium Chloride?

N-Butylimidazolium chloride lands on lab benches as a so-called "ionic liquid." It's beloved in some industries for dissolving cellulose, separating chemicals, or even as a solvent in energy applications. More manufacturers now experiment with this class of chemicals because traditional solvents raise health and pollution alarms. Some tout ionic liquids as “green” or environmentally friendlier. The real question is whether that label sticks under scrutiny.

Is It Safe Around People? Looking Beyond the Hype

Step into a lab and crack open the safety sheets—N-Butylimidazolium chloride triggers warnings. Skin and eye irritation remain common risks if it splashes. Inhalation rarely matters because this stuff doesn't evaporate easily, but spills or dust can become a problem in a busy workspace. If someone's careless, even a so-called "benign" chemical leads to allergy-like reactions or sneaky long-term problems.

Academic labs in Europe and Asia have run a handful of studies on imidazolium-based salts in general. They saw moderate toxicity to cultured human cells. Tiny fish and water bugs also don't fare well at high doses, which paints the opposite of a green picture. There's no evidence for cancer or major endocrine issues in people, but nobody has run years-long studies outside of test tubes or aquariums. Taking lessons from other chemicals, absence of evidence rarely equals evidence of no harm.

Environmental Concerns: Here’s Where the Drain Leads

Early headlines claimed ionic liquids don’t evaporate so much, so they can't pollute the air like regular solvents. Fact is, every solvent ends up somewhere. Researchers at Germany's University of Stuttgart tested how N-butylimidazolium chloride breaks down. In wastewater treatment, it didn’t degrade much and tended to pass through, landing downstream. Because ionic liquids stick around, local aquatic life ends up the test subject—sometimes with worrisome results for the health of streams and rivers.

One 2020 paper in Ecotoxicology and Environmental Safety found that this class of chemicals made water fleas sluggish and disrupted their development at low concentrations. Other studies showed chronic exposure may stunt algae and plant growth, even in water diluted thousands of times. Food chains don’t recover fast, so even low-level leaks could stack up in the real world.

Responsibility in the Lab and Industry

No chemical takes full blame or earns absolute praise. From experience in shared research spaces, the best safety practices take all chemicals seriously—the label “ionic liquid” doesn’t give N-butylimidazolium chloride a pass. Good air exchange, face shields, and gloves make accidents rare. Waste streams shouldn't slide into public drains. Environmental regulators can require manufacturers to test for these chemicals in runoff, similar to how firefighting foams and pesticides get tracked today.

Companies sometimes look for other solvents less toxic to both humans and wildlife. Greener design means screening new chemicals for breakdown in water and soil before scaling up. Industry groups and university partnerships can publish real-world spill data and toxicity test results instead of keeping risks buried in technical files. Transparency nudges everyone, including regulators, toward smarter decisions.

The push for greener chemistry brings new materials and new risks. Safety expertise, direct testing, and honesty about unknowns keep progress from turning into regret. People—and the environment—benefit when companies and labs take neither panic nor blind trust as their guide.

Breaking Down the Chemistry

N-Butylimidazolium chloride sits among the family of ionic liquids—salts that hold their liquid form at lower temperatures. The chemical structure brings together two key parts: the organic cation and the inorganic anion. Here, the cation is N-butylimidazolium, formed from an imidazole ring that picks up a butyl group (a four-carbon chain) linked to the nitrogen atom. The anion is the simple chloride ion, nothing exotic, just Cl−. The chemical formula looks like this: C7H13N2Cl.

I came across N-butylimidazolium chloride while researching ionic liquids as alternative solvents. Most conventional solvents bring baggage—flammability, volatility, hazardous residues. Ionic liquids like this one dodge many of those headaches. Stable at room temperature, they don’t give off harmful vapors, making them easier to handle in the lab or during manufacturing.

Seeing the Pieces

The backbone of the cation is imidazole—an aromatic heterocycle with two nitrogen atoms at positions 1 and 3. Swap in a butyl group at one of the nitrogens and you get N-butylimidazolium. Pairing this cation with a chloride anion turns it into a salt. Instead of a white powder like table salt, you find a viscous, often colorless liquid. The imidazolium ring with its butyl tail shapes much of the chemical’s traits: it’s non-volatile, mixes with water, and interacts strongly with both polar and non-polar molecules.

Why the Structure Matters

This combination changes the playing field in a few ways. N-butylimidazolium chloride shines as a solvent for synthetic chemistry. The butyl side chain dials up the liquid’s ability to dissolve both organic and inorganic substances. In some extraction work, researchers lean on this salt to pull metal ions out of solution with fewer environmental risks compared to the harsh, volatile chemicals of older processes. Imidazolium-based ionic liquids keep grabbing attention as possible “green solvents” for their performance and safer handling.

Looking deeper, the chloride ion’s presence matters for reactivity and stability. Some ionic liquids swap in larger, more complex anions, but chloride can bump up melting points and shift solubility patterns. The balance lets chemists fine-tune the liquid for a specific reaction or separation. It comes down to matching the solvent’s prowess with the task—chromatography, catalysis, electrochemistry, or extraction.

Current Challenges and Future Uses

Every chemical has trade-offs. N-butylimidazolium chloride’s low volatility lowers toxic emissions, but its environmental story isn’t perfect. It can resist degradation if spilled, and some ionic liquids aren’t as benign as early headlines promised. Research testing for aquatic toxicity and persistence needs more data. Production costs remain a hurdle—the price point holds back large-scale adoption.

Researchers keep searching for cleaner, cheaper ways to make compounds like this in bulk. Routes that use renewable feedstocks or greener synthesis can bring down costs and build trust in industrial use. Also, recycling and recovering these liquids cuts down on waste and overall hazards. Investment in building clear regulatory and safety profiles would let companies move from lab to market with more confidence.

Summing Up the Importance

In my time in the lab, working with ionic liquids gave me safer, more flexible reactions without the headaches of classic solvents. This one, N-butylimidazolium chloride, shows that with the right combination of atoms, the chemistry toolbox keeps growing. It’s not perfect, but it’s pushing science in a direction less tied to the toxic choices of the past. If we keep pushing for safer, cheaper, and more sustainable chemistry, salts like these might shape the future of manufacturing, research, and green tech.

Understanding the Supply Chain

Research labs and manufacturers look to specialty chemical suppliers for N-Butylimidazolium Chloride. This isn’t a substance that pops up in everyday stores, so the journey starts with companies rooted in custom synthesis and fine chemicals. Years of ordering chemicals for a busy lab taught me to never take the sourcing of ionic liquids lightly. Reliable partners matter. Trucking in a low-quality batch costs labs not just cash, but also time spent troubleshooting experiments that should have worked.

Bulk orders often come sealed in sturdy, chemically compatible bottles or drums, depending on the volume requested. Typical sizes hit the small-scale sweet spot – 25 grams to a kilogram – but for industrial experiments, drums weighing up to 25 kilograms show up at your loading dock. Chemical compatibility stands out for a reason: this ionic liquid reacts with water and some plastics, so reputable suppliers use high-quality polyethylene or glass containers. No one wants to open a bottle and find a ruined mess because of a careless packaging choice.

Shipping N-Butylimidazolium Chloride means respecting climate and regulations. Couriers need paperwork showing compliance with safety and transport laws. Nobody wants a regulatory headache or to harm the environment through sloppy transport.

Purity Concerns and Real-World Impacts

On paper, most suppliers list the purity as 98% or 99%. But scratch beneath the surface, and you’ll find chemists keeping a close eye out for contaminants like water, halides, and organic residues. A bottle labeled “99%” still leaves behind the nagging worry of what that last 1% might be doing. In practice, even a fraction of a percent in impurities – especially water for hydrophilic liquids – can wreck sensitive catalytic cycles or organic synthesis yields.

Having managed plenty of reactions gone wrong, I learned to check the certificate of analysis (COA) and demand recent, reliable analytical data. No lab wants to burn a week's work only to discover their starting material let them down. Some labs even run their own NMR or Karl Fischer titration to catch issues missed by vendors. Not every synthetic route can tolerate impurities, especially in pharmaceutical and fine chemical research.

The Role of Regulation and Transparency

Transparency runs side by side with trust in chemical supply. In regulated industries – pharmaceuticals, electronics, green chemistry – trace impurities can quickly escalate into headlights-blazing recalls. Smart suppliers break down their purity profile, offering data on metals, halide levels, and water. Labs with ISO or GMP requirements need to file away documentation for later inspections.

Direct, honest communication from sellers makes a difference. If you see “purity: >99%” but can’t get a breakdown on what else skews that last percent, then it’s time to look elsewhere. In some regions, new environmental guidelines now require companies to track provenance and safe disposal pathways. This pressure forces suppliers to up their game, and that benefits research long-term.

Improving the System

Better supply chains start by listening to feedback from users, not just company procurement officers. Chemical producers who take time to develop robust documentation win repeat business from top labs. As a practical step, companies should invite third-party auditors to check purity and handling practices. End-users—especially those running reactions where a single contaminant creates disaster—could push for more batch-specific data.

For researchers and industrial buyers, it pays to request samples and run a quick round of quality control checks. Time spent qualifying a supplier avoids the kind of scenario where a whole campaign of syntheses fails. The field is moving toward tighter standards as new applications in battery research and pharmaceuticals expand. The more supplier and user talk frankly about needs and experiences, the stronger the chain gets for everyone.