N-Butylpyridinium Dicyanamide: Unpacking History, Practice, and Possibility

Historical Development

Chemists have always sought ways to develop safer, more versatile solvents. N-Butylpyridinium dicyanamide reflects decades of work in ionic liquid research. Its story goes back to the late twentieth century and the worldwide push for greener chemistry. Environmental regulations spurred the industry to invest in alternatives to volatile organic compounds, notorious for hazardous emissions. Research labs, often on modest budgets, chased a material with low vapor pressure and higher thermal stability. Researchers gravitated toward ionic liquids like N-Butylpyridinium dicyanamide because they ticked so many of those boxes. It didn’t take long for the compound to find its way into specialized chemical catalogs, referenced in academic grants, and netted into patent filings that hint at ongoing industrial adoption.

Product Overview

This compound is an ionic liquid built from pairing N-Butylpyridinium as a cation with dicyanamide as an anion. Its significance comes from this unique combination. Compared to common organic solvents, it barely evaporates and has no smell. N-Butylpyridinium dicyanamide has carved out a niche in research circles, powering studies from extraction methods to catalysis. Labs list several synonyms and chemical short-hands in the catalogs—sometimes just “[BPy][DCA]”—but the stretch of its story goes beyond lab benches. I’ve seen small start-ups try it for niche separations, while more established companies weigh its pros and cons for large-scale extractions.

Physical & Chemical Properties

N-Butylpyridinium dicyanamide appears as a colorless to pale yellow liquid at room temperature. Its melting point usually falls below standard room temperature, around -6°C. Its viscosity usually feels close to syrup, yet it pours far more smoothly than honey. Thermal decomposition doesn’t start before 260°C in a typical setup. It's nearly insoluble in traditional nonpolar solvents, but it fully mixes with water and common polar organic liquids. Electrochemical stability is a selling point; it easily supports currents in batteries and electrochemical devices, and doesn’t break down under moderate electrical loads. These specifics take on special meaning to me whenever I see tech teams scrutinizing ingredient lists in advanced batteries or functional coatings.

Technical Specifications & Labeling

Bottles arrive with detailed labeling. Tech sheets enumerate parameters: purity (generally above 98%), water content, melting behavior, and storage advice. Labels describe not just the structural formula and molecular weight, but also make clear any impurities that could disrupt sensitive applications. Data sheets stress that the compound must stay tightly capped, stashed away from direct sunlight, or any source of strong acids or oxidizers. Chemical companies tailor the product forms—samples in glass, bulk in commercial drums—to match the nature of their purchase orders. For professionals, there’s always an eye on paperwork that aligns exactly with international shipping standards and hazard communication.

Preparation Method

Most syntheses start with 1-butylpyridinium halide, which reacts with sodium dicyanamide in water or another compatible solvent. In a standard setup, the two reactants mix and are stirred, coaxing the ionic exchange. Byproducts like sodium chloride drop out or are washed away with extraction solvents such as dichloromethane. The organic layer gets separated, then dried, and lab techs finally remove any remnant solvent by rotary evaporator. That final product—the ionic liquid—undergoes vacuum drying to squeeze out any errant water molecules. For scaling beyond a beaker, facilities adopt continuous flow reactors that cut batch time and improve safety. In my own experience, ensuring complete salt removal and dryness always separates the successful prep from the middling one.

Chemical Reactions & Modifications

N-Butylpyridinium dicyanamide stays stable under ordinary lab conditions, but chemists keep a cautious hand around strong acids and bases. The dicyanamide anion does open doors to more chemistry: certain conditions prompt cyclization or nucleophilic reactions. Synthetic chemists run modifications on the pyridinium ring itself, swapping alkyl chains or ring substitutions to modulate solubility or reactivity. These modifications shape new ionic liquids shot for specialty catalysts or extractants. Across countless publications, the compound finds itself as a reactant and as a medium. My own trial runs in catalysis with this liquid highlight its agnosticism to many common reagents—this stability adds real value, especially when planning multi-step reactions without constant solvent swaps.

Synonyms & Product Names

Catalogs read off several aliases: 1-Butylpyridinium dicyanamide, [BPy][DCA], and at times just Butylpyridinium-dicyanamide. Product lines reflect variations in purity, packaging, and certification. Chemical distributors who specialize in high-purity ionic liquids keep it among their standard listings, often alongside formal registry numbers and international safety identifiers. This alphabet soup sometimes causes confusion for newcomers, although well-stocked data sheets make cross-referencing manageable.

Safety & Operational Standards

Safety profiles stress careful handling. Direct skin or eye exposure runs a risk of irritation; gloves, goggles, and good ventilation rule the day in even small-scale use. Local and national regulations classify this substance on the basis of dicyanamide’s toxicity. Storage conditions—from temperature to container type—tie directly into outcome; leaks or exposure to incompatible chemicals trigger breakdowns or toxic off-gassing. Operational protocols include spill kits, chemical-proof aprons, and updated SDS forms. Site training usually walks staff through symptom recognition, first response, and proper disposal. I recall one small workshop where demand for safe handling practices led to a full-day certification; best practices prove their worth once a mishap arises.

Application Area

Fields embracing this compound stretch across battery electrolytes, extraction science, catalysis, and analytical chemistry. Electrolyte research stands out—lab groups aim to push lithium-ion batteries past their shelf-life limits, and this ionic liquid adds both safety and increased energy density. Separation science takes advantage of its solvating power for rare earth recovery, pharmaceutical intermediates, or even environmental clean-up. The high thermal and chemical stability supports applications where conventional solvents disqualify themselves. I’ve watched teams adapt the material in pilot-scale nanotechnology coatings, always searching for an edge in anti-corrosive or selective barrier properties. Academic grants often pair its use with up-and-coming green chemistry initiatives, and industrial insiders keep a close eye on patent filings related to new uses.

Research & Development

R&D keeps this material at the cutting edge. Research programs aim for deeper understanding of molecular interactions, environmental fate, and safer synthesis routes. Teams lean on powerful analytical tools—NMR, IR, mass spectrometry, and thermal gravimetric analysis—to map stability tags and minor impurities. Efforts ramp up regularly to green the production steps, cut waste, and increase yield. Some labs test new derivatives, modifying the pyridinium or dicyanamide building blocks to tune properties for demanding applications. Many institutions share data openly, accelerating the understanding of long-term environmental safety and lifecycle for ionic liquids in manufacturing. My own experience watching talented researchers spend months perfecting purification highlights the technical complexity and rigor pouring into each technical advance.

Toxicity Research

Toxicological studies delve into both acute and chronic effects. Much of the early concern centered on potential cyanide release or bioaccumulation in aquatic organisms. Standard test batteries look at mammalian cell lines and rodents, checking for organ damage, reproductive effects, and neurotoxicity. Comparative data with other common ionic liquids show N-Butylpyridinium dicyanamide tends toward moderate toxicity; it’s neither the safest nor most hazardous in its class. Ongoing studies track environmental breakdown products, investigating biodegradation, soil interactions, and risks to ecosystems. Regulatory filings demand full disclosure, updated as new evidence surfaces. Researchers who use it for method development often share personal insights about exposure controls, emphasizing the need for continued vigilance as usage scales up.

Future Prospects

Demand for safer, more robust performance chemicals keeps N-Butylpyridinium dicyanamide on the innovation front. Next-gen batteries could benefit from ionic liquids with tunable conductivity and minimal flammability risk. Environmental engineering targets better separation agents for rare or problematic pollutants, with this compound high on candidate lists. Large-scale industrial adoption faces cost and regulatory barriers, but the search for alternatives to conventional toxics will only intensify. Forward-looking research explores biodegradable or less toxic analogs, taking lessons learned from the current crop of ionic liquids. Many expect progress in both synthesis efficiency and lifecycle analyses, ultimately broadening the range of applications. I see a future where niche specialty chemicals like N-Butylpyridinium dicyanamide fold into bigger sustainability conversations, driven by both regulatory shifts and inventive chemists with an eye for real-world impact.

Making Energy Storage Work Better

Scientists and engineers keep searching for safer and more reliable ways to store energy. N-Butylpyridinium dicyanamide steps into that scene as a helpful ionic liquid for advanced batteries and supercapacitors. Most lithium-ion batteries face troubles, like overheating or fires. By using this compound, battery designers found a path toward lower risks, solid stability, and longer working lives. Its stable chemical structure makes it much less likely to catch fire. The substance's resistance to high temperatures brings crucial safety to electric vehicles and consumer gadgets alike. Cars, phones, and home energy systems benefit when safer electrolytes make everyday use less stressful.

Green Chemistry Pushes Forward

Industrial labs and research centers focus on chemistry that causes less damage to the environment. Many toxic solvents cling to old habits, but N-Butylpyridinium dicyanamide avoids that trap. It's a room-temperature liquid with very low volatility. This quality means it doesn't fill the air with harmful fumes during research or manufacturing. The chemical has shown promise in replacing traditional, petroleum-based solvents for extractions and syntheses. People working with precious metals now use this compound in extraction and purification, looking for more selective and environmentally sound ways to separate valuable elements from waste. By putting less strain on air and water quality, this solvent gives green chemistry leaders a real example to follow.

Stepping Up Organic Synthesis

Synthetic chemists always try to produce complex molecules with fewer steps and less pollution. N-Butylpyridinium dicyanamide stands out as both a solvent and a catalyst in several organic reactions. Doctors and researchers working with medicines often need cleaner, more reproducible processes, and this compound answers that call. For example, pharmaceutical labs have used ionic liquids to tighten up yields and improve the quality of their products. They handle temperature swings without breaking down, support reactions that struggle in water or hydrocarbons, and often speed them up. All those qualities cut down on waste and up the safety for workers.

Uncovering New Paths in Material Science

Material scientists have come to rely on ionic liquids to craft new polymers, coatings, and electrochemical sensors. N-Butylpyridinium dicyanamide brings flexibility to polymerization, giving chemists a more controlled environment and helping prevent unwanted byproducts. Researchers working with nanomaterials have used this liquid to fine-tune the size and shape of nanoparticles. Its unique nature also assists in producing thin films for electronics, which could shape the future of flexible displays, solar panels, and microchips. These improvements help manufacturers get predictable results in technologies that count on small tolerances.

Looking at the Challenges and Solutions

Of course, every new chemical puts up hurdles. Cost is one. Processes using N-Butylpyridinium dicyanamide often demand higher purity, and that adds expense. There's also the question of scaling up from lab to factory floor. Environmental and safety impacts, while much better than older solvents, still call for research. That means continuous testing for toxicity, better waste handling, and recycling of ionic liquids where possible.

With more collaboration between industrial chemists and regulatory agencies, the field can set clear rules and best practices. Professional societies and journals need to keep publishing real-world safety data, not just promising laboratory results. By keeping the conversation open, the chemical sector can help guide new compounds like N-Butylpyridinium dicyanamide from the bench to the market with a strong commitment to safety, performance, and responsibility.

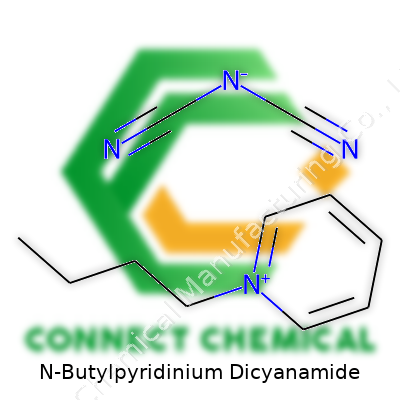

Chemical Makeup and Structure

N-Butylpyridinium dicyanamide stands out in the world of room-temperature ionic liquids, thanks to its combination of unique ions. Its chemical formula is C9H15N5, which comes together from two parts: the N-butylpyridinium cation (C9H14N+) and the dicyanamide anion (N(CN)2−). The cation houses a pyridine ring attached to a four-carbon butyl chain, giving it an organic backbone. The anion, dicyanamide, shows up as N(CN)2−, containing two cyano (–C≡N) groups bound to a central nitrogen atom. Together, these ions build a liquid with serious staying power and resistance to decomposition.

Why Structure Matters

Structure drives how this ionic liquid behaves. The big organic cation doesn’t pack tightly, resulting in a low melting point, so it usually ends up as a liquid under room conditions. Experience in research labs keeps showing that these liquids dissolve a lot of chemical species that water or regular solvents can’t touch. The flexible butyl chain increases the liquid’s ability to dissolve both organic and inorganic compounds. On the anion side, dicyanamide’s linear shape helps reduce viscosity compared to other ionic liquids built on bulkier anions. Less viscosity means easier mixing and more efficient reactions, which explains why chemists keep turning to N-butylpyridinium dicyanamide for tasks like metal extraction, battery electrolytes, and catalysis.

Role in Research and Industry

This compound doesn’t just end up collecting dust on a chemical shelf. Synthetic chemists have leaned on it when separating rare earth elements, as it features both stability and a knack for solvating charged and neutral species. The liquid’s tunable characteristics let researchers tweak reaction environments and adjust selectivity for difficult separations. Battery engineers also dive into studies with dicyanamide-based ionic liquids, attracted by the non-flammable character and wide electrochemical window. No evaporating or catching fire; compared to traditional organic solvents, it stands up to increased voltages and rough handling.

On a bench level, this chemical won’t release volatile organic compounds. This comes as a relief in tight spaces or poorly ventilated labs. Green chemistry calls often highlight such properties, pushing for safer alternatives to the flammable, odorous liquids that fill many factory floors. In my own experience chasing alternative solvents, the lack of sharp odors and reduced hazard warnings leads to fewer headaches—both figuratively and literally—during long syntheses.

Tackling Safety and Environmental Challenges

No chemical carries a completely free pass. While N-butylpyridinium dicyanamide scores well on handling and safety during everyday use, researchers still track its environmental journey. Some studies suggest that dicyanamide anions don’t break down especially fast in wastewater. Regulators and inventors watch this space closely, working to create better degradation methods and more eco-friendly versions. Smart engineering of both cation and anion could yield ionic liquids that don’t hang around in ecosystems while keeping all the advantages chemists count on.

Solutions rest on balance: tightening up disposal strategies and recycling spent ionic liquids cuts down on environmental impact. Companies start shifting toward closed-loop processes, capturing everything that leaves a reactor or bench. Organizations with a proven record in chemical stewardship push the standards higher, showing that it’s possible to keep innovative solvents like N-butylpyridinium dicyanamide in the toolbox while protecting public health.

Final Thoughts

N-Butylpyridinium dicyanamide, with its compact chemical structure and useful liquid properties, repeats a lesson common in science: ingredient selection shapes results. It supports experimentation across sustainable chemistry and cutting-edge devices, provided everyone keeps one eye on safety and stewardship as well as performance. Work on refining, recycling, and improving environmental fate will decide how far and wide these advanced materials travel.

A Closer Look at Safety Concerns

Stepping into any chemistry lab, a person can sense that every bottle comes with its own set of risks and lessons. N-Butylpyridinium dicyanamide finds its place among ionic liquids, a class of chemicals that grabbed attention in research for their “greener” profile compared to typical solvents. Despite these greener claims, diving into its safety data paints a picture worth careful inspection.

What The Science Says About The Risks

Reading the Material Safety Data Sheet (MSDS) for N-Butylpyridinium dicyanamide reveals some concerning details. This compound isn’t just a theoretical hazard. Acute toxicity data shows moderate dangers if swallowed, inhaled, or if it touches the skin. The “dicyanamide” portion hints at possible release of toxic gases; hydrolysis or mishandling can produce hydrogen cyanide—a potent, rapidly acting poison. With years spent teaching lab safety at the university, I never understate the seriousness of cyanide compounds. Even “mild” exposure leads to headaches, nausea, dizziness, and in high concentrations, much worse outcomes.

Researchers in 2016 published data on cellular toxicity, showing moderate cytotoxic effects for this ionic liquid versus others. They raised concerns about environmental persistence and bioaccumulation, particularly in aquatic settings. Now, while lab work often skips over these environmental consequences, anyone familiar with hazardous waste clean-up understands the legacy chemicals leave behind.

Practical Hazards In Everyday Handling

It’s easy to gloss over warnings in pursuit of pure science. Yet improper storage—say, exposure to moisture or acids—raises the risk of dangerous gases. Personal experience with a minor leak during a humid July in a shared lab lingers in my mind: headaches, need for immediate ventilation, the distinct “almond” cyanide scent that everyone learns to recognize—and fear. The reminder? Even with gloves and fume hoods, small mistakes can have big effects.

These compounds do not behave as passively as some catalog listings suggest. Small spills need professional cleaning. Regular butyl gloves, untested for resistance, tear when least expected. I’ve seen early-career chemists discover this the hard way.

Real-World Approaches To Safer Use

Complaints aren’t enough. Solutions start with PPE—face shields, nitrile gloves, and airtight goggles. Local ventilation matters more than cost-cutting. Labs stick to closed handling systems for ionic liquids, especially those with cyanide ions. Training young scientists to respect warnings saves more than just paperwork headaches; it saves lives.

Waste disposal makes a difference. Compliance with hazardous waste policies ensures compounds like N-Butylpyridinium dicyanamide find their way to proper disposal, not down drains or regular trash bins. Specialists can chemically neutralize and contain toxic residues, reducing risk to people downstream.

The push for “green” chemistry often misses hidden threats. Careful balance of lab promises with practical awareness keeps these compounds both fascinating and respected. Any claim of safety must meet the standard of day-to-day use—honest about the risks, clear about the tools and protocols that make science possible without compromise.

Why Proper Storage Matters

I’ve worked with chemicals for years, and nothing replaces the peace of mind that comes from knowing bottles are where they belong, undisturbed, and labeled. N-Butylpyridinium dicyanamide isn’t the sort of compound to ignore. Organics like this can react in unexpected ways. Humid air, sunlight, or the wrong shelving can kick off changes that nobody wants in their lab or storeroom.

Strong safety starts by locking these chemicals away from sunlight and heat. Direct rays cause temperature swings and even minor breakdown in sensitive compounds. Cool rooms help reduce that risk. For N-Butylpyridinium dicyanamide, I always keep it in a designated chemical storage cabinet, clearly marked. Flammable storage lockers, if unknowns about reactivity exist, give added security and help meet local fire code regulations.

You don’t want confusion about what’s in that bottle. Labels list the name, hazard category, and even the date received. Old or poorly labeled stock causes accidental misuse, mixing, or exposure. With chemicals like this, the little habits—double-checking dates, clearing out expired batches—make the big difference.

Health and Environmental Concerns

This dicyanamide salt doesn’t fit into the “household use” category. Inhaling, ingesting, or spilling can have real consequences. Workers need chemical gloves and safety goggles. Even after handling containers, I wash hands before eating, drinking, or touching my face. These steps protect not just the user but families at home too, avoiding cross-contamination.

Lab ventilation isn’t negotiable. I turn on the hood fan and avoid storing any organics near acids, bases, or oxidizers. Mixing chemicals because of lazy storage routines can trigger dangerous reactions—and the news reports for those sorts of accidents make anyone in the industry wince.

Thoughtful Disposal Steps

No one wants dicyanamide compounds in drinking water or landfill run-off. I keep waste in sealed, labeled containers—never dumped down the drain. Trained hazardous waste teams know how to neutralize or incinerate these salts without putting themselves, their neighbors, or wildlife at risk. Records track every batch, so nobody loses track or tries to cut corners.

Many universities offer specialist chemical take-back schemes. I make a habit of calling the environmental health and safety office before assuming disposal methods. State laws can penalize improper disposal, but even more powerful motivation is stewardship—leaving the benches, cabinets, and planet healthier for those who come after.

Finding Safer Paths Forward

Safer handling practices start with strong awareness. Read the material safety data sheets fully, and talk to colleagues if something’s unclear. Regular staff training, clear labeling, sturdy gloves, and a clean, locked storage area shape a culture where accidents rarely take root. In my experience, openness to question processes and adapt them keeps people healthy.

Safe chemical use doesn’t just protect the present—it’s about respect for those who will work in our spaces tomorrow. Every step from storage through to responsible disposal spells out whether we care enough to get it right.

An Everyday Look at a Modern Ionic Liquid

N-Butylpyridinium dicyanamide doesn’t roll off the tongue, but folks in the chemical world know it by its comfort in labs and a surprising toughness in harsh settings. You pour out this liquid and find it clear, sometimes lightly yellow, and it refuses to turn solid until the thermometer dips below -40°C. It flows like oil and won’t evaporate much, which beats a whole lot of traditional solvents that vanish under warm light or open benchwork.

Structure and Stability in the Lab

This compound features a big organic cation from pyridine attached to a butyl chain—giving it some weight and making it more stable on a shelf. Dicyanamide, with two cyano groups hooked to a nitrogen, brings a twist of reactivity and makes the liquid just right for special tasks. In my own experience prepping catalysts, this stability saved time: there's less fuss about container loss or chemical changes on storage, and its shelf life exceeds plenty of other ionic liquids.

Lab workers see N-butylpyridinium dicyanamide as not just another clear liquid—they know it stays inert to air and moisture, which means you can handle your experiments without worrying about water sneaking into the reaction. No one likes failed runs from rogue humidity, and this is one solvent that doesn’t throw those headaches into the mix.

Chemical Behavior and Why It Stands Out

Most ionic liquids compete on chemical play. This salt has almost no flammability. Its vapor pressure sticks close to zero at room temperature, allowing safer handling and storage. In fact, that’s one key reason industrial labs swap out more toxic organics for this choice, especially for energy storage or green chemistry benches. The dicyanamide anion gives it ability to dissolve unusual materials. Metal ions dissolve smoothly, as I’ve seen firsthand while testing electrodeposition baths—metals like nickel or copper spread through the liquid, producing better coatings without extra additives.

The compound acts as a strong polar solvent. That means chemists use it to break down or blend substances that water and other organics can’t touch. This property lets companies step away from more volatile, dangerous solvents. For example, when recycling rare metals, this ionic liquid allows pulling valuable ions out of electronic wastes without resorting to sulfuric acid baths. That’s a win for lab safety and for the folks working near those fumes.

Facing Down the Tough Issues

No substance comes without questions. The toxicity of dicyanamide salts has raised eyebrows in environmental circles. Accidental spills could trouble aquatic systems if regulations aren't followed. Responsible labs use containment and avoid dumping any waste down standard drains. Better training and closed-loop systems help—methods I’ve seen adopted at universities and in some forward-thinking industrial sites. Ongoing research aims to tweak the dicyanamide group or find similar ionic liquids that deliver the same perks while keeping risks lower.

Where Innovation Calls For More

For energy storage, researchers look at N-butylpyridinium dicyanamide as an electrolyte. Its conductivity supports next-generation batteries, such as lithium-ion variants, that need safer, low-volatility liquids. Companies exploring flexible electronics and smart windows tap this compound for thin coatings. These sectors focus on finding green, sustainable materials, so it helps that this liquid can often be recycled and reused with proper setup.

Working with this chemical boils down to balance: safe work practices, strong containment, and real attention to disposal routes. With focus on smarter design and rigorous purity checks, this ionic liquid stands ready for new science, as long as people stay informed and careful about its journey from lab to industry.