N-Butylpyridinium Hydrogen Sulfate: A Real-World Look at Its Impact and Future

Historical Development

Chemical innovation marches fast, but sometimes a compound rewrites expectations. This happened with N-Butylpyridinium Hydrogen Sulfate, a room-temperature ionic liquid that caught serious attention in the late 1990s. People working in green chemistry and sustainable processes grew frustrated by persistent issues—volatile organic solvents, hazardous byproducts, rare recyclability. N-Butylpyridinium Hydrogen Sulfate arrived at a time when laboratories sought alternatives that worked as well as old solvents but with fewer environmental headaches. Researchers turned up the heat on synthesis trials, and soon, industries outside the lab took notice. Progress moved fast partly because this salt doesn't evaporate like typical solvents, slashing concerns around inhalation risks and flammable environments.

Product Overview

This ionic liquid stands out for its liquid state at room temperature. N-Butylpyridinium Hydrogen Sulfate combines a butyl-substituted pyridine cation with a hydrogen sulfate anion, making it different from its relatives that stick to more traditional alkyl groups or pair with halide anions. You can spot it marketed under names like [C4Py][HSO4] or as 1-butylpyridinium hydrogen sulfate. Out in the wild, it's used not just in specialized organic syntheses, but also in tasks like cellulose processing, catalytic cycles, and electrochemical work.

Physical & Chemical Properties

This compound pours out as a colorless to pale yellow liquid. Unlike many classical salts, it's neither crystalline nor brittle, avoiding the dust and static concerns that dry chemicals bring to the bench. Laboratory hands soon find that it doesn’t give off much odor. Its melting point stays well below 50°C, so it doesn’t need special heating to handle. Viscosity runs higher than water, which actually helps control reactions, especially when mixing with volatile reagents. It resists oxidizing agents and common acids but disassembles under strong bases or at high temperatures. In the field, immiscibility with non-polar solvents confers separations advantages, letting recyclers recover it more easily after a reaction run.

Technical Specifications & Labeling

Producers aim for N-Butylpyridinium Hydrogen Sulfate of high purity, often above 98%, with water content kept low—sometimes below 1%—to avoid interfering with sensitive reactions. Labels on delivery bottles typically show its CAS number (such as 262297-13-2), molecular weight of roughly 243 grams per mole, and key hazard information. A clear hazard sign on the label signals risk for eye and skin irritation, and import/export paperwork always describes its ionic character to help handlers know what they're dealing with when shipping across borders or through customs labs.

Preparation Method

Manufacturers often turn to a straightforward synthesis route. Pyridine reacts with butyl bromide via nucleophilic substitution, yielding N-butylpyridinium bromide as a precursor. This intermediate salt undergoes metathesis with sodium hydrogen sulfate in water. Filtration and extraction steps deliver the final ionic liquid, which workers dry with vacuum to bring water content down. This approach avoids toxic reagents lurking in older methods and generates only benign side products like sodium bromide, swept away in aqueous washes.

Chemical Reactions & Modifications

The beauty of N-Butylpyridinium Hydrogen Sulfate lies in its resilience during harsh reaction conditions. Chemists routinely mix it into acid-catalyzed processes—dehydrations, esterifications, and alkylations—which would rip simpler salts apart. It can serve as both solvent and catalyst, resulting in higher yields and cleaner products. Its molecular structure gives space for additional modifications, so custom-tailored ionic liquids can come about with little extra work. Teams alter the pyridine ring or swap out the alkyl chain to adjust the liquid’s viscosity, polarity, or acidity, addressing new chemical challenges.

Synonyms & Product Names

Listing synonyms helps researchers find trustworthy suppliers and avoid misidentification. N-Butylpyridinium Hydrogen Sulfate goes by 1-butylpyridinium hydrosulfate, 1-butylpyridinium hydrogen sulfate, or [C4Py][HSO4]. Labs and stores in different regions stick to one name or another based on their regulations or supplier networks. Commercial batches sometimes hide among abbreviations or catalogue numbers, which slows down procurement or hazard review if a buyer isn’t careful.

Safety & Operational Standards

No compound gets into industrial and research labs without scrutiny. For this ionic liquid, safety reviews warn about skin and eye contact—nothing rare for a sulfate-based reagent. Material safety data sheets recommend gloves, eye protection, and well-ventilated workspaces. Any technician or scientist using N-Butylpyridinium Hydrogen Sulfate follows well-established spill management. If the liquid escapes containment, clean-up teams use absorbent pads and water plus soap, careful not to flush it into sewage systems or groundwater. Storage stays in tightly sealed containers in cool, dry locations, reducing water uptake that could interfere with chemical work.

Application Area

What really matters is practical use. In cellulose processing, N-Butylpyridinium Hydrogen Sulfate dissolves plant fibers more effectively than traditional solvents, which opens doors for easier biofuel and biodegradable plastic production. In organic synthesis, chemists rely on it to promote efficient esterification or to act as both solvent and acid catalyst in single-pot reactions. Battery developers explore it for electrochemical work, betting on improved stability in fuel cells and supercapacitors. In pharmaceutical labs, teams run screening reactions under its influence, chasing complex molecules without risking mixed waste streams or persistent vapor emissions.

Research & Development

The R&D engine keeps humming. Over the last decade, I’ve seen collaboration bloom between academic chemists, industry labs, and sustainability advocates. Together, they push N-Butylpyridinium Hydrogen Sulfate into new frontiers—green chemistry, nanomaterials, energy storage, even pollution control. Projects focus on lowering synthesis costs, dialing up recyclability, or boosting the ionic liquid’s specificity for chosen chemical transformations. There’s plenty left to discover as more teams share data, and many hope these efforts will drive down the price so small-scale or developing world producers can test novel applications.

Toxicity Research

Real progress depends on clear-eyed evaluation. Early toxicity data from animal trials and aquatic assays show N-Butylpyridinium Hydrogen Sulfate isn’t as benign as table sugar but causes less environmental harm than some halide-based ionic liquids. It shows moderate acute toxicity if swallowed, and disposal regulations restrict large-scale release to waste streams. Aquatic studies warn about possible buildup in fish and water plants, so stewardship guidelines push users to capture and recycle it as often as possible. This discipline in containment, rather than relaxed policies, slows entry into markets like agriculture or consumer products, but chemists and safety experts keep working to clarify risks as testing expands.

Future Prospects

Out on the horizon, experts forecast strong growth for N-Butylpyridinium Hydrogen Sulfate, especially as industries push for solvents that don’t evaporate to the atmosphere or clog up filtration systems as persistent organics. It’s got promise in electrochemical energy storage, controlled-release pharmaceuticals, and even in extraction of rare earth metals for electronics. With each new field, demand grows for robust supply chains, regionally relevant regulations, and accessible toxicity data. Future researchers may focus efforts on closing economic and environmental loops, finding new catalysts or hybrid processes that take full advantage of this sturdy and flexible compound.

What Makes This Chemical Stand Out

N-Butylpyridinium hydrogen sulfate isn’t something you’re likely to see on a supermarket shelf, but people in research labs and a few specialized industries know its value. This compound falls under the class of ionic liquids, which basically means it usually stays in liquid form at room temperature. Unlike most salty substances, ionic liquids like this one can be handled without any fancy setups or extreme temperatures, which makes them pretty unique in the world of chemistry.

Chemistry's Quiet Workhorse

I’ve spent time in university labs watching students try to separate out difficult-to-crystallize products. Regular solvents have their ups and downs—they evaporate, they’re flammable, and some harm the environment. N-Butylpyridinium hydrogen sulfate provides an alternative. It doesn’t catch fire easily, doesn’t evaporate under normal conditions, and researchers have noted its lower toxicity compared to several classic solvents. Most chemists seem interested in the way this chemical acts as both a solvent and a catalyst. For folks working with organic synthesis—making medicines, new materials, or even some modern batteries—this means cleaner reactions and, sometimes, fewer side products. Research shows that using ionic liquids can boost yields for some reactions and make separation of products a lot less messy. That's a real advantage in the lab, especially when you're running the same process over and over.

Environmental Benefits and Concerns

People care about green chemistry more than ever. The industry is looking for chemicals that don’t poison waterways and can be reused. N-Butylpyridinium hydrogen sulfate, with its low vapor pressure, typically doesn’t escape into the air like solvents such as acetone or ether. This means less pollution and less stink in the workspace. Some studies from the last decade rank this ionic liquid as less hazardous by comparison. Researchers also recycle it: after a reaction, they recover it, clean it up, and use it again. That saves money and helps reduce waste.

Still, it matters to point out that just because a compound is labeled “green” or “less toxic,” doesn’t mean we can ignore safe handling. Waste management needs improvement. As more labs and small factories pick up on ionic liquids, keeping track of disposal and long-term impact on soil and water becomes even more important. Regulators and safety pros have a job to keep everyone honest and responsible.

More Than Just a Lab Tool

Beyond organic chemistry, N-butylpyridinium hydrogen sulfate pops up in other spots. Some teams use it in electrochemistry for batteries, supercapacitors, and even fuel cells. Its consistent conductivity and stability attract engineers designing systems that need to run clean and steady for years. I’ve seen companies dip their toes into using ionic liquids for extracting rare earth metals from electronic waste. Recovering useful metals in a cleaner way gives a second life to old phones and laptops and cuts down on mining’s environmental issues.

What Happens Next?

N-Butylpyridinium hydrogen sulfate shows that everyday chemistry keeps evolving. Safer, more versatile chemicals give scientists options for greener, smarter work. To move forward, industry and academia need to keep sharing data, tightening safety protocols, and checking up on long-term effects. Working with this compound demands care and curiosity. If the field keeps paying attention, it could help power new ideas in materials science, recycling, clean energy, and medicine for years ahead.

Understanding What You’re Handling

N-Butylpyridinium hydrogen sulfate belongs to a class of chemicals called ionic liquids. These compounds get plenty of attention in labs, sometimes in industry, thanks to their ability to dissolve or stabilize a variety of substances. But not everything that shows promise comes trouble-free. N-Butylpyridinium hydrogen sulfate can irritate the skin and eyes, can mess with breathing if inhaled, and needs careful handling to avoid dangerous reactions, especially if it slips into the wrong waste stream.

Personal Protective Equipment Isn’t Optional

Anyone who’s ever knocked over a beaker or gotten a splash of something odd on their hands knows that gloves and goggles aren’t just for show. With this compound, Nitrile gloves create a good barrier because they stand up to chemical splashes. Simple latex breaks down a bit too easily, so it falls short here. I always go for chemical splash goggles. Working in a lab, even one with good ventilation, never tempted me to skip on these basics. Some days, I’d see folks roll up their sleeves and take a chance—right up to the point when they reach for the eyewash. Not worth it.

Good Ventilation Matters

Pouring, pipetting, or weighing this chemical, the smell starts creeping in, and irritation hits the back of your throat fast. I open the fume hood, double-check the airflow, and make sure it’s working as intended. A stuffy office or closed room only increases the risk of exposure. It only takes a few minutes of breathing in vapors to regret not opening up that window or turning on the exhaust. The right level of ventilation beats coughing fits every time.

Spill Response: Quick, Calm, and Complete

All spills need attention, especially when dealing with ionic liquids like N-Butylpyridinium hydrogen sulfate. The spill kit stays close by. Getting granular absorbents and neutralizing agents on the scene right away stops a little mess from turning into a bigger one. I teach anyone who’ll listen to block off the area, sweep up gently, stash the waste in the right bin, and keep hands away from their face until after a thorough wash. Time and again I’ve seen people skipping these steps, only to learn too late that chemical burns on the skin don’t fade overnight.

Proper Storage: Simple Steps, Big Payoff

I never crowd this chemical in with others that react with acids or organics. A cool, dry cabinet, away from sunlight, keeps surprises to a minimum. Labels face out for easy identification, lids seal tight, and the logbook gets updated right away. Missing a small leak can mean melted gloves or a ruined shelf over time. That’s a lesson that stuck after replacing entire storage racks in a shared lab.

Waste Disposal: Don’t Cut Corners

Where disposal is concerned, regular garbage won’t cut it. N-Butylpyridinium hydrogen sulfate lands in the hazardous waste bin. I flag containers for the waste team, fill out the manifest, and make sure no water or other chemicals mix in when cleaning glassware after use. If a facility lacks a chemical disposal system, it becomes critical to partner with certified disposal companies. Stories of folks washing stuff down the drain only pop up in textbooks these days, for good reason.

Looking Ahead

No chemical rewards shortcuts. Safety routines stay simple, but every step earns its place. Solid training, reliable gear, and a few good habits turn a risky process into a manageable one. Past mistakes—in my own work or from others—have shown me that protecting skin, lungs, and eyes is a measure of skill, not hesitation. With all the excitement around new materials, it pays to remember: the cleaner your practices, the safer your science.

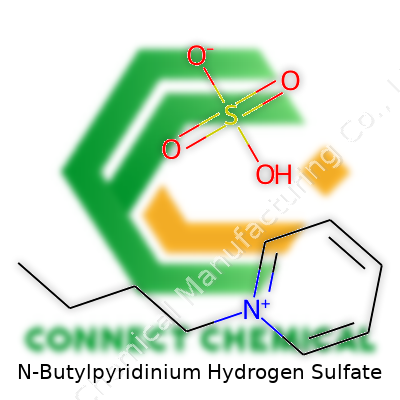

Breaking Down the Formula

N-Butylpyridinium hydrogen sulfate packs a bit of a mouthful in its name, but this ionic liquid keeps things relatively straightforward once you look at its components. The chemical formula is C9H15N.C4H8SO4. If you prefer the more condensed ionic representation, it becomes [C4Py][HSO4]. The cation is N-butylpyridinium—a pyridine ring bonded to a butyl group on the nitrogen. The anion is hydrogen sulfate, a close cousin to the usual sulfate anion but packing a hydrogen atom for added acidity.

Put simply, the molecule fuses organic and inorganic chemistry. That fusion grabs my attention because it leads to some remarkable physical and chemical properties. Ionic liquids like this one stay liquid at much lower temperatures than you might expect. That means chemists or engineers looking to avoid volatile organic solvents lean into options like N-butylpyridinium hydrogen sulfate for safer and more sustainable processes.

Structure Tells the Story

Let’s sketch out the structure. The N-butylpyridinium cation features a six-membered pyridine ring (that’s five carbons, one nitrogen) with the nitrogen atom carrying a butyl group. The positive charge settles on the nitrogen. Then, the hydrogen sulfate anion, HSO4−, couples up with this cation via ionic interactions. You don’t find direct bonds connecting these two ions, but rather electrostatic forces holding the salt together.

This pairing matters. Hydrogen bonds often form between the hydrogen sulfate’s acidic proton and the nitrogen on the cation. Such interactions affect everything from viscosity to solubility in water or organic solvents. In my experience, researchers care deeply about these features, especially when planning a new synthetic route or designing a safer lab protocol. These ionic liquids rarely evaporate, thanks to the strong ion pairing, so inhalation risks and flammability go way down compared to familiar but risky solvents like acetone or ether.

Real-World Importance and Use Cases

Ionic liquids like N-butylpyridinium hydrogen sulfate pop up in a range of fields. In electrochemistry, for instance, they function as electrolytes for batteries or capacitors. The low volatility and high conductivity make them suitable for devices that need stability across a range of temperatures. In green chemistry, these liquids replace more hazardous organic solvents in catalytic reactions or separations. Their tunable properties—not just boiling point but also the ability to dissolve unusual combinations of solutes—set them apart. From what I’ve seen, academic and industrial labs look toward these liquids as building blocks for a less toxic, more efficient future in chemical manufacturing.

The environmental side matters, too. The low vapor pressure means emissions to air remain minimal, though the structure also demands a look at biodegradability and long-term toxicity, especially as production scales up. Responsible handling and disposal need attention, and further research into alternatives or derivatives with even better environmental profiles makes sense.

What Comes Next?

To tap into the promise of compounds like N-butylpyridinium hydrogen sulfate, more researchers and companies should keep pushing into greener chemical approaches. Better studies of toxicity, recyclability, and compatibility with large-scale processes open doors to broader use. Engineering new ionic liquids, tweaking the cation or anion for specialty applications, and integrating these materials into renewable cycles will shape the next decade of sustainable chemistry. As long as the science keeps moving, so does the potential for safer and smarter materials.

Understanding the Risks and Hazards

N-Butylpyridinium hydrogen sulfate shows up in several labs as a room-temperature ionic liquid. It’s a specialty chemical, often used as a solvent, catalyst, or in electrochemical applications. Like many ionic liquids, this one sounds exotic, but it brings very real risks—most notably, it pulls in moisture from the air and reacts with strong oxidizers. Leaving it on a dusty shelf without care creates problems not just for results, but for anyone around it.

Why Secure Storage Supports Safety

From experience, I know that a misplaced bottle of anything corrosive—or a desk coated with a few accidental drips—makes cleanup slow and nerve-wracking. N-Butylpyridinium hydrogen sulfate has a tendency to draw out water. It can start breaking down over time, turning into something far more unpredictable. If you catch the faint rotten egg smell, that’s hydrogen sulfide gas, which means some of that liquid broke down and released a toxic product.

Accidents involving strong acids or chemically active compounds stick in memory. I remember a summer job where improper storage left bottles sweating on open benches. Even with the right warning labels, someone always treated them like regular glassware. On one occasion, spilled ionic liquid corroded a metal scale, rusting everything and setting off the gas sensors. So often, a simple storage solution would have kept everyone safer.

Setting Up Safe Storage and Handling

Keep this compound in airtight, corrosion-resistant containers—pick glass or certain plastics like PTFE, which don’t react over time. Make sure containers use tightly sealing lids, since letting moisture inside means degradation starts fast. That “hydrogen sulfate” half of the compound reacts with water or humidity, often with heat or fumes. Extra care avoids surprise chemical changes that can ruin experiments or, worse, cause a hazard.

Always label containers clearly. A good label should list full chemical names and hazard symbols. In my lab experience, missing or faded labels invited confusion when someone needed the right supplies in a hurry. If you see condensation or an unusual color, that’s a warning the chemical might have changed. Never store it near bases or oxidizers, since those can trigger dangerous reactions.

Environment and Disposal Concerns

Never throw away leftover N-butylpyridinium hydrogen sulfate down the drain. It’s not just about what’s in the bottle, but where it ends up. Many ionic liquids look harmless, but some pose threats to water systems and aquatic life. Ask your facility’s environmental health and safety team about appropriate waste disposal options. If in doubt, collect waste in a separate, closed, and labeled container with a spill tray underneath.

Practical Steps That Work

Place bottles in a cool, well-ventilated area away from direct sunlight or sources of heat. Sunlight and warmth can speed up unwanted reactions or vapor release, especially if the bottle isn’t airtight. Shelves should be sturdy, with secondary containment like trays to catch drips. If a location stores many hazardous chemicals, keep a detailed log and check it regularly. Rotating stock makes sure nothing sits forgotten and unstable over time.

PPE isn’t optional. Use chemical-resistant gloves and splash goggles every time you open or transfer the liquid. Even careful workers make splashes or get interrupted. I’ve caught hurried colleagues wiping chemical residue with bare hands out of habit—easy to prevent with proper reminders and gear laid out at each station.

Building Reliable Habits

Good habits around chemical storage save a lot more than damaged gear or wasted material. They protect everyone who passes through the space and keeps the lab running smoothly. Store N-butylpyridinium hydrogen sulfate with care, and the risks stay manageable—let those habits slip, and trouble doesn’t take long to find.

Understanding the Real-World Grades

N-Butylpyridinium hydrogen sulfate pops up often in the world of ionic liquids and specialty chemicals. Labs and manufacturers need to know the purity levels since applications range from catalysis to advanced material synthesis. Over the years, sourcing chemicals for research or pilot-scale work has taught me a few things. Purity isn’t just a number; it’s about consistency and trust in supply. Most suppliers set their high-purity products at a minimum of 98%. Top-tier sources offer it at this level, backed by certificates of analysis. This isn’t just for show—lesser purity can introduce impurities that throw off reactions, especially in sensitive organic syntheses where side products mean wasted time and money.

The Logic Behind Package Sizes

Ordering chemicals always brings up questions about sizing. Too little and you pause the workflow; too much and you’re left sitting on expensive inventory. N-Butylpyridinium hydrogen sulfate, offered by most reputable chemical companies, usually comes in small bottles—100g or 250g—for bench research. Sometimes you’ll find 500g packs or 1kg containers if the demand shifts towards scale-up stages. In true bulk applications, suppliers work with buyers to fill custom drum or carboy orders, often ranging from 5kg up to 25kg. This kind of flexibility caters to both academic labs and industrial settings. Over the years, I’ve seen both ends: a grad student eking out milligrams, and a plant engineer requiring kilos for a feasibility trial.

Why Purity and Quantity Matter in Real Projects

Each percentage point in purity can translate to hours saved or lost in downstream purification. One overlooked batch with trace contaminants can stall an entire project. Take a real example from a green chemistry trial: a synth led by a postdoc failed because an 80g batch had unexpected halides. The supplier only provided “lab grade” with no guaranteed purity. After switching to a company providing 98% guaranteed grade, reactions stabilized and productivity rebounded. This isn’t just about numbers; it’s about the reality of keeping science on track.

Diving Into Practical Solutions

The market keeps shifting. Users looking for reliable batches should always seek out products with transparent certificates of analysis. Since suppliers come and go, it helps to work directly with sales reps who understand technical demands, not just logistics. For those needing bulk, long-term contracts with quality stipulations protect you from sudden purity drops. Research teams pulling from a single bottle for months should check manufacturers’ packaging—I’ve seen glass-stoppered bottles cut down on moisture contamination, an issue with this hygroscopic salt.

Staying Safe and Up to Date

Storing N-butylpyridinium hydrogen sulfate eats up shelf life if not handled right. Dry, cool storage with sealed lids keeps the material stable, and clear labeling prevents mix-ups. Reading through the Safety Data Sheets from trustworthy suppliers protects users in the lab, which really matters when protocols change hands. Hazards with ionic liquids can be subtle; every user should brush up before handling new packaging sizes, especially since larger drums can lead to accidental spills if not properly managed.

Choosing the Right Supplier and Format

Researchers and industry users keep a keen eye on source transparency, documentation, and delivery options. Those facts shape who becomes a go-to supplier. Packaging sizes line up with real-life workflows, from 100g for a semester-long project to kilograms for production runs. The best path always starts with conversations—ask about batch testing, shelf lives, and guarantees on purity. The future of experimentation depends on those details lining up.