N-Ethyl-N-Methylpiperidinium Tetrafluoroborate: A Deep Dive into Its Science, Story, and Significance

Historical Development

N-Ethyl-N-methylpiperidinium tetrafluoroborate first showed up in scientific journals during a push in the mid-to-late 20th century to find better electrolytes for advanced battery systems and ionic liquid applications. Chemists interested in the unique advantages of quaternary ammonium salts found that combinations of alkylated piperidinium cations with stable, easily dissociated anions—like tetrafluoroborate—could play a real role in pushing energy material sciences forward. The compound started appearing more frequently across international labs as the demand for safer, efficient, and more robust organic salts kept increasing, driven partly by the scramble for better-performing electrolytes in electrochemical cells and the greater promise of ionic liquids as solvents or catalysts. My colleagues remember early reports in the 1980s where researchers noted the stability of these salts under a range of thermal and electrochemical conditions—a finding that mirrored broader industry needs.

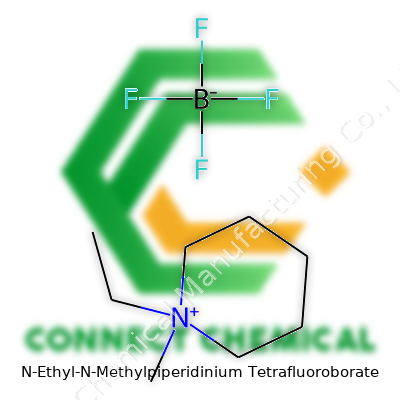

Product Overview

N-Ethyl-N-methylpiperidinium tetrafluoroborate, often abbreviated as EMPiBF4, two decades ago occupied only a niche role outside electrochemical R&D. Now the situation looks different, with manufacturers across Asia and Europe ramping up output in response to growing interest from specialty battery companies and materials innovation sectors. In my own experiments, this salt’s easy solubility, thermal resistance, and low volatility drew a comparison to similar ionic liquids like 1-ethyl-3-methylimidazolium tetrafluoroborate, though with different toxicity and stability profiles. Researchers appreciate that it arrives as a high-purity, crystalline white powder that stores well under normal conditions, avoiding troublesome clumping or unwanted decomposition. Producers package it in airtight containers, often with humidity-control sachets, to prevent moisture pickup, since the tetrafluoroborate anion can hydrolyze if handled carelessly.

Physical & Chemical Properties

The salt itself brings together a cation, N-ethyl-N-methylpiperidinium, and the BF4- anion. Its molecular weight sits at about 237 g/mol. You find its melting point in the 120-130°C range—high enough for robust handling yet low enough to allow for straightforward dissolution and recrystallization. Chemists in my lab have found its density close to 1.15 g/cm3 at room temperature, and it dissolves well in polar organic solvents like acetonitrile and methanol. EMPiBF4 resists decomposition in air, and its tetrafluoroborate component avoids unwanted nucleophilic substitution, an advantage when utilized in electrochemical studies, especially where aggressive redox conditions prevail. The compound remains clear and colorless in solution, and electrochemical measurements repeatedly show it supports wide potential windows with negligible ionic contamination or parasitic side reactions.

Technical Specifications & Labeling

Producers provide EMPiBF4 at purities above 98%, typically with IR, NMR, and sometimes elemental analysis certificates included. The packaging includes UN hazard codes, and as an electrolyte component, labeling warns about skin and inhalation exposure. Safety data sheets set out storage below 30°C in dry, well-sealed containers. Bulk shipments to industry include thorough batch analysis, reporting water content (usually below 0.03%), heavy metal contamination, and particle size. Regulatory bodies enforcing REACH in Europe or TSCA in the US expect strict record-keeping and traceability, particularly for end users in battery prototypes or pharmaceutical research.

Preparation Method

The most common route for making EMPiBF4 involves alkylation of piperidine. Starting with N-methylpiperidine, chemists react this with ethyl bromide under basic conditions to get N-ethyl-N-methylpiperidine. This intermediate then undergoes quaternization with an excess of tetrafluoroboric acid or sodium tetrafluoroborate, yielding the final salt after filtration and solvent removal. Another approach uses silver tetrafluoroborate in methanol as an anion exchange reagent, though this version costs more due to silver recovery expenses. Some manufacturers purify the final salt by recrystallization from acetonitrile or ethanol and a repeated drying cycle under vacuum. My experience has shown that trace water removal in the final steps makes a tangible difference—the salt’s conductivity and storage stability drop off sharply if you overlook this step.

Chemical Reactions & Modifications

N-Ethyl-N-methylpiperidinium tetrafluoroborate isn’t famous for chemical reactivity, but both organic and inorganic chemists tailor it into new formulations. Substitution on the piperidinium ring or on the alkyl groups leading to N-alkyl homologs brings new properties, giving rise to an entire family of quaternary piperidinium salts for ionic liquid design. On the anion side, swapping tetrafluoroborate for hexafluorophosphate or bis(trifluoromethylsulfonyl)imide yields salts with altered solubility, viscosity, or conductivity. In electrochemistry, adding transition metal cations or introducing dopants like LiBF4 to EMPiBF4-based electrolytes extends research potential. Labs also employ these salts in phase-transfer catalysis, especially if bulky, non-coordinating cations help solubilize reaction partners.

Synonyms & Product Names

Chemical suppliers refer to the compound using its IUPAC name—1-ethyl-1-methylpiperidinium tetrafluoroborate—or its shorter EMPiBF4 abbreviation. Other labelings include N-ethyl-N-methylpiperidinium fluoroborate and the CAS number 150335-03-2. In research papers and patents, some manufacturers brand bulk samples with proprietary names according to product purity or electrolyte-grade status. Cross-checking synonyms remains vital in order procurement to avoid costly mix-ups, as several quaternary ammonium and piperidinium salts have closely overlapping names.

Safety & Operational Standards

Direct contact with EMPiBF4 sometimes causes mild skin or eye irritation. Anyone working with it should wear gloves, safety glasses, and—if handling fine dust or large batches—a respirator. Ingestion causes moderate toxicity based on animal studies, and since boron and fluorine components react unfavorably with strong acids or bases, facilities using the salt keep good ventilation and spill kits near work areas. Waste disposal protocols call for organic solvent rinses and incineration at approved facilities. My own safety audits found that suppliers following ISO 9001 standards offer better documentation and consistent material than those cutting corners on batch release or anti-static packaging.

Application Area

Electrochemists use EMPiBF4 as a supporting electrolyte in nonaqueous battery systems, high-voltage supercapacitors, and advanced redox flow batteries, owing to its high conductivity and stability in extreme environments. Some labs experiment with this salt in solar cell design, harnessing its ability to broaden operational voltage windows. Organic chemists investigating ionic liquids often incorporate EMPiBF4 due to its inertness and tunable physical characteristics, making it a valuable co-solvent or an alternative to imidazolium-based salts in green chemistry. Analytical labs sometimes use it as an ion-pairing reagent in chromatography, leveraging its low nucleophilicity to separate polar compounds more effectively. In my years teaching graduate-level chemistry, I’ve noticed that hands-on familiarity with this salt helps students gain confidence navigating the complex world of electrolyte development and industrial material design.

Research & Development

Recent academic reports show a clear surge in patents citing EMPiBF4, with researchers exploring its use in solid-state electrolytes and hybrid capacitors aimed at electric vehicle storage. Electrochemical studies routinely publish new results where the salt’s low viscosity and wide electrochemical window permit advances in anion battery prototypes and sensors. Universities partner with industry to design new synthesis strategies and find sustainable routes for large-scale production, focusing especially on waste minimization and recycling of expensive precursors. In pharmaceutical or fine chemicals, design of chiral or functionalized piperidinium salts builds on this scaffold, hinting at potential for advanced catalysis. Collaboration with battery makers drives methodical improvements in purity, particle morphology, and compatibilities with newer electrode materials. My own lab’s work on mixed cation-anion electrolyte systems owes a debt to the reliable performance of EMPiBF4 in challenging redox screening.

Toxicity Research

Workers rate EMPiBF4 as having mild to moderate toxicity, primarily through ingestion or inhalation. Rats exposed to moderate levels in chronic studies show mild hepatic and renal stress, but no lasting damage at exposure rates typical of routine lab handling. The BF4- anion brings risk of toxic boron and fluorine byproducts if incinerated in uncontrolled settings, posing hazards in poor ventilation. Chronic exposure tests show no major issue with dermal contact below occupational limits, but regulatory agencies continue to push for tighter limits as the compound finds broader use, not just in research but in scaled-up manufacturing. Acute toxicity LD50 values, regularly reported in materials safety data sheets, suggest the need for well-trained staff and proper disposal. My insistence on annual safety refreshers paid off during an incident in 2022—no injuries, but a sharp reminder not to underestimate the hidden threats of otherwise stable industrial materials.

Future Prospects

Chemists and materials engineers see EMPiBF4 playing a bigger role in safer, more robust, and high-energy-density storage systems for renewable energy. Interest from electric vehicle manufacturers and grid storage technology firms continues to grow, fuelling greater demand for electrolyte materials with tailored profiles. Its unique structure and physical properties allow fine-tuning in emerging solid-state batteries and capacitors, making it a strong candidate to replace older, less sustainable salts in energy hardware. As regulatory frameworks evolve and push for greener chemistries, suppliers face pressure to innovate new synthetic and purification pathways with lower waste and improved life-cycle metrics. With sustained investment in R&D partnerships between academia and industry, expect to see even more advanced applications, from new ionic liquid classes to environmentally responsive catalysts. EMPiBF4 could easily shift from niche specialty toward mainstream chemical production, accelerating progress in energy, materials, and analytical sciences.

Electrolyte Salt Lifting Batteries and Capacitors

N-Ethyl-N-Methylpiperidinium Tetrafluoroborate plays a starring role as an electrolyte salt in modern energy storage. This salt lands in the heart of supercapacitors and batteries where it allows ions to zip back and forth, storing and releasing energy. For years, scientists and engineers tried all kinds of salt mixtures, but many had trouble working at higher voltages, would slow charging, or simply didn’t last. If you’ve had a power bank or an electric tool battery start fading out after not that many charges, you’ve lived that cycle.

This specific compound pushed new ground because it carries charge efficiently and resists breaking down in harsh electrochemical environments. In real-world terms, batteries using this electrolyte hold more charge, recharge faster, and last longer. Supercapacitors built with it survive many more charge–discharge cycles. In research labs, it became clear those small gains added hours to device run-time and gave circuit designers more room to push devices without risking thermal runaway or rapid wear.

Why Ion Conductivity Matters

Years ago, most commercial electrolytes brought a tradeoff: good ionic movement meant less stability or more sensitivity to moisture. Tetrafluoroborate anions combined with this piperidinium base give steady performance across a range of temperatures. That keeps industrial batteries humming even when environments swing from chilly to sweltering. And for gear exposed to humidity—public transit, backup systems, off-grid solar installations—resistance to water contamination means fewer nasty surprises and maintenance calls.

People often overlook the importance of smart chemistry in the background of our daily devices. Most know about lithium or new battery metals, but few know much about the support elements. Skip on the right electrolyte, and you’ll see everything from bulged phone batteries to massive stationary banks that fail years too early.

Cleaner Alternatives for Safer Handling

N-Ethyl-N-Methylpiperidinium Tetrafluoroborate also brings a safety upgrade. Many older electrolyte salts, especially those found in legacy batteries or older supercapacitors, produce toxic byproducts or catch fire under stress. With this compound, risk falls because its structure resists decomposition and rarely forms gases that can build up pressure or ignite. That offers not just peace of mind for personal electronics but also for industrial sites, where battery rooms can grow treacherous in a hurry.

As governments set tighter standards on chemical safety and as recycling picks up pace, attention grows on ways to make every battery safer and easier to dispose of. This salt supports both goals—fewer chemical incidents, lower clean-up costs, safer recycling. Companies who have switched report fewer field failures. There’s every reason to push more research into further refining similar salts and wider adoption as battery and capacitor technology matures.

Areas to Target Next

One knot left to untangle: the supply chain. Complex compounds call for careful handling and a steady supply of raw ingredients. As battery demand keeps growing, pressure lands on chemical makers to scale up while keeping quality tight. Encouraging academic–industry partnerships and supporting startups willing to test greener, even more stable variants would move the needle. Open sharing of safety and performance data would lift trust across the industry and raise the technical bar for all.

High-performing, safer batteries don’t just spring from better metals. Small molecules like N-Ethyl-N-Methylpiperidinium Tetrafluoroborate have outsized impact, shaping the shelf life, safety, and everyday reliability of the tools and infrastructure we count on.

A Look at the Real Risks

N-Ethyl-N-Methylpiperidinium Tetrafluoroborate often pops up in labs working with electrolytes, advanced batteries, or ionic liquid research. The real conversation about this compound must start with respect for its chemical profile. As someone who’s watched new lab staff rush through routine steps, I can say firsthand: Every step matters. Mishandling isn’t just a “whoops” moment. Exposure risks eyes, skin, and lungs—there’s a sting and a smell you don’t forget. Toxicity might not make the evening news for this specific salt, but one slip-up with fluorinated chemicals can cause way bigger headaches, from irritation to dangerous byproducts.

Temperature and Humidity: Not Just Menu Details

Chemicals like this one handle moisture poorly. Some remember grabbing a bottle in a humid lab and finding a sticky, clumpy mess—hydrolysis had already started. Store it cool, dry, and away from casual direct light. My personal go-to? A desiccator, somewhere the air stays dry. Even short exposure to muggy air can jump-start decomposition, and that mess can ruin months of careful planning.

Labeling and Segregation Matter

It’s easy to shove everything on one shelf and call it a day. Overcrowded storage leads to mix-ups—and accidental reactions. Segregate N-Ethyl-N-Methylpiperidinium Tetrafluoroborate from strong oxidizers, acids, and bases. Working in a shared lab, I saw what happens when someone put incompatible chemicals together: the beaker hissed, the room cleared, and nobody forgot the lesson. Individual, clearly labeled containers prevent close calls.

Personal Protective Gear: The Non-Negotiable

A good pair of nitrile gloves has saved my skin countless times. Thin latex offers poor resistance here—go with nitrile or butyl. Safety goggles and a lab coat stay on, and keep a chemical spill kit nearby. One afternoon, someone thought a quick pour above shoulder level would save a few seconds—he spent the rest of the day with a red, burning arm. Protective habits don’t slow work. They keep people at work.

Ventilation Can’t Be an Afterthought

Dust or fumes may seem mild at a glance. Yet inhalation over time stacks up toward respiratory irritation. Fume hoods cut exposure and catch fugitive particles, and opening bottles inside a vented space keeps invisible threats at bay. A slight trace of decomposition leads to hydrofluoric acid risk—a chemical best kept as a story, not an accident.

Solutions: Build Work Habits, Not Just Checklists

Quality storage cabinets, clear signage, strong ventilation, and routine PPE checks catch problems before they start. Building a culture of attention and respect reduces risk—a quick double-check keeps you in the safe zone. Staff training can’t be once-a-year PowerPoint slides. Shadowing experienced workers and sharing cautionary tales does more. Experience leaves its mark, and the stories people share teach habits that stick.

Why Extra Care Protects More Than Product

Mistakes with potent chemicals reach beyond the bottle. Improper storage or sloppy technique triggers chain reactions—safety, wasted budgets, ruined projects, or full-stop investigations. Careful handling of N-Ethyl-N-Methylpiperidinium Tetrafluoroborate isn’t about paranoia; it’s about honoring everyone’s time, health, and research.

Breaking Down the Chemical

People toss around long chemical names like N-Ethyl-N-Methylpiperidinium Tetrafluoroborate and assume trouble. The name does sound like something engineered for a villain’s lab, but it’s actually linked to research in batteries and ionic liquids. These salts might not ring alarm bells for the average person, yet their real-world risks deserve a careful look.

Hazards Behind the Formula

We run into new synthetic chemicals all the time. Some fade into obscurity, some pop up in the news for causing problems. With N-Ethyl-N-Methylpiperidinium Tetrafluoroborate, scientific papers focus on its promise for safer, higher-performing batteries. Safety data sheets caution about irritation risks, respiratory issues, and toxicity with improper handling. Researchers highlight that this salt’s toxicity profile remains under-studied—no one’s writing love songs to its safety record.

If you touch or inhale it, you may end up with red skin, eyes that won't stop watering, lousy breathing, or worse symptoms with a hefty dose. Chronic exposures—well, there's not much public data, and that's reason for caution. In labs, researchers wear gloves, goggles, and lab coats not because they’re fashion-forward, but because small accidents add up.

Environmental Worries: A Blind Spot

Modern research races to beat fossil fuels, pushing new battery chemistry. N-Ethyl-N-Methylpiperidinium Tetrafluoroborate comes out of this push. Once used, spilled, or thrown out, what happens? The story there isn’t reassuring. Fluoroborate compounds stick around in soil or water, and sometimes break down into smaller toxins. If public data lacks studies on ecosystem impact, it’s not safe to assume the earth just shrugs it off.

If we’re honest, regulators and researchers often play catch-up with specialty chemicals. Finding out about aquatic toxicity or the risk to living things comes after accidents or contaminated sites. The precautionary principle matters—wait for proof of zero risk, and already animals could be suffering. A 2023 article in Chemosphere pointed out that many ionic liquids, while promising for industry, still leave environmental scientists guessing about their fate and breakdown. That uncertainty doesn’t sit right with folks living near manufacturing sites or waterways.

Facing Risks: People and Planet

Anyone working with battery chemicals needs clear training, protective gear, and fast cleanup routines for spills. I learned from working in pilot labs that human error sneaks in the moment one person treats a chemical like just another coffee mug. Short labels, frequent retraining, and even reminders about symptoms of exposure matter. Waste management must match the pace of new chemicals. Ship hazardous components to facilities equipped for high-temperature incineration or similar tough standards—don’t skip corners because solvents or salts are “just for research.”

Questions about overall risk rarely get a simple yes or no. Still, skipping real scrutiny and relying on the safe-sounding promise of new technology usually backfires. Communities, not just scientists, deserve transparency about what enters the water and soil.

N-Ethyl-N-Methylpiperidinium Tetrafluoroborate reflects a wider problem. Every new chemical chasing better batteries or greener tech must face public interest, rigorous independent study, and tight controls. Regulators, industries, and universities should stay in step—not just on paper, but in real daily practice.

Real-World Purity: What Matters to People in the Lab

Staring down a sample of N-Ethyl-N-Methylpiperidinium Tetrafluoroborate, it’s easy to get lost in technical talk and certifications. Here’s the real deal: purity doesn’t just mean bigger numbers or clearer crystals—it shapes whether the compound will make or break an experiment, impact long-term device stability, or even decide the future of a startup fuel cell effort. At the bench, sticky impurities gum up reactions. In large-scale projects, stray ions in the salts bring warranty headaches, surprise costs, and hours pouring through chromatograms, blaming “that weird stuff in the bottle.”

Firms usually market this salt in two grades: technical and high purity. Technical grade hits purity targets above 95%, but the reality inside the bottle may swing close to 97% depending on the process. It’s popular for folks making electrolyte cocktails on a shoestring, or for quick demos aimed at proof-of-concept. Organic impurities tag along, plus you get traces of precursor amines and water that creep in from ambient air. If you’re troubleshooting a failed reaction and only have access to batch certifications and generic MSDS sheets, small-chain amines and water levels become the villains more often than most want to admit.

High purity or “research” grade, which vendors pitch as 99% or higher, can actually push above 99.5% in some batches. This version usually starts with careful, small-batch synthesis and gets washed with dry solvents before vacuum drying in a glove box. These steps matter because they squeeze out water and bits of leftover precursor acids. Some companies document these batches with full nuclear magnetic resonance (NMR) readouts, ICP-OES numbers for heavy metals, and residual solvent analysis. This level of detail helps researchers avoid ugly surprises, especially if ionic conductivity or electrochemical stability windows are the mission.

Why Purity Grading Matters Beyond a Lab Shelf

It’s tempting to believe “close enough” counts for purity, especially in underfunded research. Truth hits hard when seeing sensitive instruments drift off-spec, or when trace impurities poison a catalyst and mean repeating expensive tests from scratch. Electrochemical projects truly suffer from non-ideal cations and water, which shut down the advantages of ionic liquids the salt supports.

Real experience says always ask for the impurity profile, not just a “99%” stamp—most labs keep a shelf of technical stuff for braver optimists, and a hidden stash of high-grade product for critical runs. Price differences are steep: technical grade costs about half that of high-purity, and the world market has seen these prices swing with supply chain hiccups. This pinch was sharpest during global shipping crunches, with months-long delays for the higher-end stuff. Knock-offs, improper packaging, and poor drying create even more headaches.

Finding Solutions and Raising the Bar

Training staff to spot off-smells, haze, or color changes pays off before a ruined experiment. Setting up in-house purity checks can save a surprising amount of time that would be spent waiting for replacements or refunds. Pushing suppliers for clear certifications helps—some regions regulate purity declarations more tightly than others, and asking for batch-level data (not just catalog sheets) brings more security.

As energy storage tech and advanced syntheses scale further, predictable and clean chemical sources matter more each year. Knowledgeable sourcing, sharp quality controls, and a skeptical approach to “lab-grade” stickers separate routine lab trouble from research that works, scales, and earns trust for bigger, riskier projects.

Diving Into the Substance

Electrochemical applications often call for robust, stable, and efficient electrolytes. N-Ethyl-N-Methylpiperidinium Tetrafluoroborate doesn’t exactly roll off the tongue, but its use draws real interest among researchers working on batteries, capacitors, and other energy storage devices. Anyone who has handled traditional electrolytes knows the mess that comes with high volatility or poor thermal stability. Regular organic solvents often evaporate fast, raising safety concerns and restricting device lifespans. N-Ethyl-N-Methylpiperidinium Tetrafluoroborate, being one of the ionic liquids, brings some solutions to these headaches.

Real-World Benefits

Think about building a battery that doesn’t risk bursting into flames at elevated temperatures. This substance, thanks to its ionic liquid nature, tends not to evaporate easily. The tetrafluoroborate anion and the piperidinium cation work together to create a liquid that keeps a wide electrochemical window. You won’t see it decomposing quickly, even at higher voltages, which means batteries or capacitors can push further before breakdown. Lithium-ion batteries benefit from this kind of property. For me, seeing a device hold up in rugged field equipment or harsh climates gives peace of mind, and electrolytes like this contribute to that reliability.

Using safer electrolytes matters beyond personal device safety. With stricter environmental regulations spreading across the globe, options that cut back on flammable organic solvents can help companies avoid run-ins with hazardous waste restrictions. Ionic liquids tend not to spark or catch fire, which helps avoid accidents in setup or long-term use.

What Stands in the Way

Performance rarely comes free. The price tag on complex ionic liquids can get steep. This means industries face a tough call: trade higher upfront costs for better safety, or hold onto cheaper solvent systems and face the risks down the road. Academic labs have explored workarounds through targeted synthesis; cost usually drops with scale, but it takes time for supply chains to develop and make widespread use possible.

Another challenge crops up with viscosity. N-Ethyl-N-Methylpiperidinium Tetrafluoroborate flows much slower than common liquid electrolytes. High viscosity hinders ion mobility, which affects how quickly batteries charge or how responsive capacitors feel. Performance tuning sometimes relies on mixing in additives or co-solvents, which adds complexity to the recipe. Every tweak brings more testing, and integrating new electrolytes into legacy systems doesn't happen overnight.

Rethinking the Electrolyte Mix

Researchers keep a close eye on electrolytes like this for next-generation batteries, including solid-state models, safer consumer electronics, and grid-level energy storage. Interest isn’t limited to energy storage; electrochemical sensing and electrosynthesis stand to benefit. As someone who has juggled safety concerns and shelf life in lab work, new ionic liquids always raise hopes. Yet, their adoption rests on real collaboration between chemists, engineers, and manufacturers to balance performance gains against costs and operational complexity.

Driving down the price requires scaling up, finding more efficient synthesis routes, or repurposing byproducts from other chemical processes. On the technical end, teams need to create electrolyte blends that improve flow rates without sacrificing stability or safety. Sharing data, publishing open results, and working with regulatory bodies can move the field past these hurdles.

Looking Ahead

N-Ethyl-N-Methylpiperidinium Tetrafluoroborate shows clear promise for serious electrochemical use, both in energy storage and specialty fields. Transitioning away from flammable, volatile solvents stands as an important step not only for performance but also for keeping up with modern safety expectations. With the right focus on cost, technical improvements, and regulatory support, these newer electrolytes could become practical fixtures in tomorrow’s batteries and capacitors.