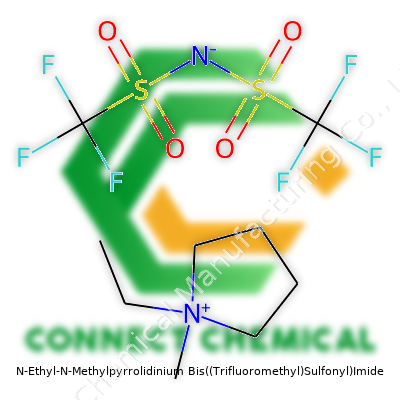

N-Ethyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide: More Than a Name in Chemistry

Historical Development

Chemists worldwide spent years searching for advanced electrolytes to power shifting technology needs. N-Ethyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide, a mouthful by name, grew out of this search for stable ionic liquids. This compound’s roots reach back to the late 20th century, springing from intensive work to improve conductivity and stability for batteries and electrochemistry. I remember thumbing through journals where research teams in Japan and Europe buzzed about ionic liquids as greener, safer alternatives to volatile organic solvents. The demand for safer, more efficient power sources pulled compounds like this into focus, shifting the chemical marketplace in real time. Seeing major battery players adopt it instead of earlier, less stable salts showed industry eyes turn toward improved safety and functionality.

Product Overview

Chemists produce N-Ethyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide as a clear-to-yellowish liquid. Unlike typical solvents, it does not evaporate or catch fire easily under room conditions. On my own bench, I’ve found this ionic liquid resists water and oxygen, making it a handy medium for moisture-sensitive reactions or electrolytic cells. Developers value its lasting power, stubbornly stable performance under harsh conditions, and low vapor pressure. Some manufacturers market it under synonyms such as NEMP-TFSI, EMPI TFSI, or just “pyrrolidinium TFSI,” reflecting its key chemical chunks. Whatever the brand, its essential trait is outlasting traditional salts under stress.

Physical & Chemical Properties

With a molecular weight above 400 g/mol, this compound impresses with its toughness against decomposition. I learned quickly that its melting point sits well below freezing, dribbling as a liquid even at subzero temperatures. In the glovebox, its negligible vapor pressure stands out. It behaves nearly odorless, a real improvement compared to pungent, older electrolytes. Its ionic conductivity rivals, and sometimes beats, the usual suspects in electrolytes for lithium ion and supercapacitors. The compound’s hydrophobic nature ensures water has little impact on its electrical properties, sidestepping complications seen with more hydrophilic salts. Compatibility with a broad range of cations and anions shapes its chemical versatility. Scientists also appreciate the thermal window, which gives process engineers breathing room for pilot-scale mixing and blending.

Technical Specifications & Labeling

Producers route this compound through strict quality control, guaranteeing purity levels greater than 99%. In the plant, chemists scrutinize residual water content, halide contaminants, and color. For industrial shipments, labeling standards spell out storage temperatures—usually between 2 and 8°C to control decomposition, and to keep the product away from acids, strong oxidizers, or open flames. Drum and bottle packing needs tamper-resistant seals, secondary containment, and available Safety Data Sheets (SDS) for all crew handling it. Barcode tracking and batch number records help large buyers trace back stock in case of performance hiccups or recalls.

Preparation Method

Making this compound at scale depends on careful design. The process begins with the synthesis of N-ethyl-N-methylpyrrolidinium, usually by quaternization of N-methylpyrrolidine with ethyl halides. The intermediate then undergoes anion metathesis, swapping halides for bis((trifluoromethyl)sulfonyl)imide using salts like lithium TFSI. Engineers control moisture and temperature rigorously to prevent side reactions. In my time shadowing production at a specialty chemical plant, I saw each batch aligned with high-vacuum, argon-purged reactors. Washing, filtration, and solvent extraction clean up residues, giving a product ready for commercial packing.

Chemical Reactions & Modifications

Reaction chemists often probe this ionic liquid for further functionalization. Its quaternary ammonium structure withstands most bases and acids; the TFSI anion grants surprising resistance to redox reactions under standard lab conditions. On occasion, operators introduce various pyrrolidinium substituents, exploring how side groups tune physicochemical traits like viscosity or electrochemical window. I’ve read case studies describing use in catalysis, where partners dissolve tailored catalytic metals into the liquid, exploiting its solvation power for novel transformations. Once reactivity is dialed in, tweaking the compound for custom applications becomes more straightforward.

Synonyms & Product Names

Though a tongue-twister on paper, this chemical travels under many aliases in the marketplace. N-Ethyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide invites quick nicknames: EMPTFSI, NEMP-TFSI, or simply EMPI TFSI. Catalog listings by major chemical firms reference CAS Number 933769-19-0. Specialty suppliers sometimes call it “ionic liquid TFSI, pyrrolidinium-based.” Shoppers intent on technical accuracy pay attention to suffixes and salt forms, avoiding confusion with related imides or shorter-chain pyrrolidinium varieties.

Safety & Operational Standards

Operator safety relies on mature protocols, given the compound’s potential hazards. Standard practice means using gloves, safety goggles, and chemical-resistant coats. Workers need good ventilation or fume hoods, since even low-volatility liquids can present exposure risks over time. The compound usually avoids explosive or acute toxicity ratings, but chronic inhalation or skin absorption concerns remain under study. Storage must stay segregated from acids and reducers, and all tools in direct contact cleaned thoroughly. I once witnessed a near miss when a small spill sat unnoticed—quick response protocols and absorbent pads kept the situation from ballooning. Regular training and up-to-date SDS sheets equip teams to handle every aspect from opening bottles to long-term archival.

Application Area

N-Ethyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide features most often in next-generation energy storage. My own work, and the broader research literature, record its star turn in supercapacitor electrolytes. Automotive and grid-level lithium-ion batteries rely on its electrochemical performance for both energy density and cycle life. Applied in redox flow batteries, this liquid supports unique stability in acidic or basic environments where other salts can break down. Researchers explore its role in electroplating, niche organic syntheses, solar cells, and even pharmaceutical crystallizations. Each sector values something different—either the wide voltage window, ability to stabilize reactive intermediates, or its nearly non-flammable signature. Materials science teams provide evidence for its use in fabricating conductive polymers or as a dispersant for nanoparticles, expanding its reach every year.

Research & Development

The scientific community never stops hunting for improvement. R&D teams now focus on reducing the cost of synthesis, scaling up greener production routes, and diversifying functional groups to tweak physical properties. I’ve witnessed universities and industrial partners collaborating on pilot lines where ionic liquids like EMPI TFSI anchor novel membrane developments, hoping to realize safer, longer-lasting batteries. Published studies scrutinize interactions between this compound and active materials, trying to decode the fine print of interface chemistry and degradation. Startups seek regulatory clarity and performance data good enough for consumer electronics, automotive, and aerospace buyers, many of which bet on breakthroughs for competitive edge.

Toxicity Research

Toxicologists started by worrying about skin or eye irritation. Most lab tests point toward moderate risk if handled neatly, but the story complicates as people push for broader usage. Chronic exposure studies raise concerns about bioaccumulation and environmental persistence. The TFSI anion resists breakdown, making wastewater disposal a sticking point. Data so far put most ionic liquids in a low-to-moderate toxicity bracket, but regulators demand deeper, long-term studies on aquatic and soil organisms before widespread adoption. From my own environmental health work, it's clear that transparency and ongoing surveillance from both producers and regulators will tip the scales toward safe, ethical deployment.

Future Prospects

Two decades ago, few imagined such niche molecules would matter beyond the lab. Now, energy security, climate targets, and the electrification of everything drive chemists and engineers to look past traditional solvents and salts. N-Ethyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide illustrates this shift. Its broad adoption depends on tighter toxicology data, better recycling technology, and falling production costs. Real innovation may come from hybrid materials where these ionic liquids form part of solid-state electrolytes or multifunctional composites. Keeping an eye on large-scale demonstration projects, and how governments incentivize green chemistry, will reveal the next big leaps. If chemists and funders keep betting on sustainability and robust performance, this compound could help shape a low-carbon, high-efficiency future for everyone from battery makers to grid operators to carmakers.

The Workhorse of Modern Electrochemistry

Most people probably won't ever hear the full name N-Ethyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide, let alone say it out loud. In labs and industry settings, it's usually shortened to PYR12TFSI. Despite its mouthful of a name, this compound keeps showing up in technologies that shape the future. I’ve watched its journey across research papers and trade events—this ionic liquid earns its keep.

Inside High-Performance Batteries

Researchers and battery engineers put PYR12TFSI to work because of its standout chemical stability and low volatility. These qualities make it a favorite for next-generation lithium-ion and sodium-ion batteries. Regular solvents boil off or react if pushed too hard. This ionic liquid shrugs off high heat, giving batteries longer life and a safer operating window. That matters when cars, bikes, or even grid storage systems demand power in all conditions. Major studies from universities in Asia and Europe show that batteries using PYR12TFSI can keep the lights on longer between charges, and don’t catch fire as easily.

Supporting Supercapacitors and Energy Storage

Supercapacitors need electrolytes that transfer charge fast without breaking down or catching fire. PYR12TFSI stands tall here, too. I’ve seen startups trying to balance performance with safety in fast-charging devices—this compound often shows up in their prototypes. Its large electrochemical window lets devices crank up the voltage without triggering unwanted reactions. Charge and discharge cycles run smoother, electronics last longer, and engineers don't lose sleep worrying about leaks or corrosion.

Getting Precise With Electroplating

Electroplating relies on a stable, tunable solvent to carry metal ions. Old-school approaches risk toxic fumes or unpredictable results. Labs switched to ionic liquids like PYR12TFSI for better uniformity and lower environmental impact. Jewelry makers, microchip producers, and aerospace builders benefit from precise metal coatings that protect against wear and tear. Several industry white papers describe a drop in waste and a boost in finish quality after swapping out legacy solvents for this ionic liquid.

Helping Out in Advanced Sensors and Fuel Cells

Chemical sensors and fuel cells keep growing in importance as more smart devices edge into our daily lives. PYR12TFSI delivers a stable platform for both. Sensitive chemical detectors get fewer false signals and longer shelf lives. Proton exchange membrane fuel cells running with this electrolyte put up stronger, reliable numbers, especially in setups that need to last months or years without maintenance.

Tackling the Downsides

It’s not all smooth sailing. PYR12TFSI can cost quite a bit. Sourcing enough for mass production still has roadblocks. Research groups work to cut the price by tweaking manufacturing methods. Some hunt for greener syntheses, since fluorine-based chemicals bring persistence issues in nature. Recycling and recovery technologies keep gaining attention, aiming to keep this valuable chemical moving in circles instead of into waste streams.

Pushing Forward with Real-World Impact

Innovation depends on workhorses like PYR12TFSI. Every time I see a demonstration where a phone charges in minutes or a drone keeps flying in the cold, odds are good that this compound had a role somewhere in the build. Industry and academia keep pushing the limits, searching for better performance and safer, more sustainable ways to use the tools we've got. With a bit more progress in cost and recycling, its reach could expand even further, and that means smarter, longer-lasting devices everywhere.

Everyday Impact of Physical Properties

People run into physical properties every day—even if most don’t stop to think about it. Consider a product’s form: powder, liquid, solid. For parents measuring out medicine, it’s easier to pour a clear syrup than weigh a chalky tablet. Density and bulk might sound like science class jargon, but those puzzle pieces tell you how a product will store, how easily it pours, and if it’s likely to clump up in a damp bathroom. Granules that cake together can frustrate workers and health professionals alike. Moisture content doesn’t just affect shelf life; it leads to molds, loss of effectiveness, or plain old mess.

Particle size can affect how fast something dissolves. A fine grain sugar turns into syrup faster, a coarse salt stays crunchy. That’s not just about taste—it changes how a product behaves in manufacturing, and it shapes safety. No one wants dust flying about causing coughing fits or fire hazards. Color and odor might seem simple, but a chemical’s odd smell often tips people off to spoilage or contamination before the label says anything’s wrong.

Chemical Properties and Safety

Anyone who’s mixed bleach and ammonia too close together learns the hard way that chemical properties mean more than names on bottles. Reactivity jumps out as crucial. A product might sit quietly in its packaging, but combine two household cleaners or store something near a heat source, and you end up with fumes, gas, or even fire. That’s not a far-off industrial concern—these accidents send families to emergency rooms every year.

Knowing pH, you gauge if something’s going to burn skin or taste sour. Battery acid and lemon juice live at opposite ends of this scale, and plenty of products fall somewhere between. Flammability matters in garages, kitchens, and classrooms. Paint thinner, nail polish remover, hairspray—crack a window, keep them away from sparks. No one expects a fire from a simple spill, until it happens.

Stability matters more than most folks realize. Some products break down with sunlight, heat, or just time. Food turns, medicines lose their punch, garden chemicals turn into something you can’t safely use. For folks with allergies or sensitivities, chemical composition answers questions about what they’re actually coming into contact with, not just what the marketing claims.

Importance of Transparency

People deserve to know what’s inside the products they bring into their lives. Labels should go beyond slogans and cover the facts: is a product safe around kids, do you need gloves, does it leave a residue? Regulators and watchdogs shape rules for these disclosures, but pushback from consumers and honest reporting from companies hold everyone accountable.

Testing and third-party certifications reduce the guessing game. That means less risk, better performance, and fewer unpleasant surprises. This transparency boosts trust, and helps smaller producers compete with bigger names—something I’ve seen in growing demand for local health and cleaning products.

Paths Forward

Education makes the biggest impact. Most people don’t want a chemistry degree just to buy laundry soap, but simple infographics or QR codes help. Schools can offer basics about chemical safety alongside practical life skills. Community groups can invite experts for workshops, letting people ask questions about what they use at home. For manufacturers, clear ingredient lists and real-life performance tests, instead of confusing guarantees, show respect for customers. In the end, understanding these properties keeps families safer and less at the mercy of fine print.

Understanding the Compound’s Nature

N-Ethyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide, known to some as an ionic liquid with a tongue-twister of a name, shows up often in labs experimenting with energy storage, electrochemistry, and advanced manufacturing. Its chemical character means it keeps stable over a broad range of temperatures and doesn’t catch fire easily, unlike so many flammable solvents. That’s not a free pass to treat it carelessly. Just because something refuses to burst into flames doesn’t mean it poses no risk to health or environment.

Respecting Personal Safety

While working with this substance in the university lab, I never skipped gloves or goggles. It doesn’t ruin skin on contact like some acids but chronic exposure hasn’t been studied in depth. Over time, these complex organic salts can dry out skin, irritate eyes, and, if inhaled as fine mist or dust, could trouble the lungs. Chemical hygiene isn’t just a lab policy—nobody wants respiratory problems or a rash that lingers for weeks. I also kept the lab coat handy and washed hands right after moving on from a synthesis or clean-up task. Simple steps, but they save a lot of regret.

Best Practices for Storage

From years spent poking around storerooms, I learned not to store chemicals like this in sunlit spaces or in rooms where temperatures swing wildly. This ionic liquid benefits from a cool, dry cabinet. Pinky promise, the top shelf next to the radiator turns out to be the wrong place—heat might not set off a blaze, but it could still degrade the stuff over months. Any chance moisture sneaks in can mess up high-purity batches. A tightly sealed, chemical-resistant bottle keeps both air and humidity out. I grew to appreciate clear labeling and logbooks to track what went in, and what came out. It only takes one mix-up to ruin a whole experiment, and then your Tuesday is shot.

Spill Containment and Environmental Concerns

I’ve seen junior researchers panic at the sight of a spilled beaker. Keeping spill kits nearby, complete with absorbent pads and suitable neutralizers, helps everyone stay calm. Sweep up any solid and wipe liquids with absorbent material rated for fluorinated compounds. Never wash it down the drain. These fluorinated molecules hang around in nature far longer than they should, and local water boards don’t fancy them showing up downstream. Waste disposal should follow hazardous chemical rules: bottle it, tag it, let trained folks haul it away.

Ventilation and Air Quality

Pouring or transferring this liquid under a fume hood keeps vapor exposure low, and it matters in busy settings—especially since nobody wants an untested chemical loading up the air everyone breathes. Upgrading to fume hoods with real airflow indicators made a big difference in our lab. It became easy to spot a blocked vent and fix it before anyone complained of headaches. Even home hobbyists can do better than a cracked window—low-cost vent fans and HEPA filters spare a lot of later grief if experimentation ever leaves the classroom or factory.

Learning from Practice

I found that training beats written protocol every time. Walking through sample handling with newcomers built muscle memory and confidence. Quick access to material safety data sheets (MSDS) kept everyone sharp about what kind of first aid or fire extinguisher to reach for. Laboratories and companies who treat these as living documents see fewer accidents and less confusion during emergencies. Good habits stick; one careful colleague often turns into a cautious team.

Moving Forward

With the growing popularity of advanced ionic liquids, awareness matters as much as proper handling. Thorough training, accessible safety resources, and smart workspace layout turn these chemicals from potential hazards into powerful research tools. As more industries put these molecules to work, staying conscious of both health and environmental risks gives everyone an extra layer of protection, long after the bottle returns to the shelf.

Chemical Curiosity Meets Safety Questions

N-Ethyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide, or simply someone’s new favorite tongue-twister in the chemistry lab, keeps coming up in discussions about ionic liquids. Engineers and scientists use this substance for a reason: it helps with battery research and supercapacitors, plus it mixes well in labs working with advanced electronics. These applications sound cutting-edge, but sit down with a safety officer, and the questions get pretty real. Is this substance hazardous? What should regular folks or lab workers worry about?

Chemical Properties Don’t Always Stay on Paper

This ionic liquid touts a history of low volatility, which means you won’t see much of it jumping into the air like alcohol or gasoline. Some researchers breathe easy, thinking lower vapor equals lower risk. That works right up until someone spills a bottle, touches a bit, or fails to wear gloves. The trifluoromethanesulfonyl groups in its structure suggest persistence and the potential for tricky biodegradation. Chemicals that hang around in the environment often leave long-term headaches.

Acute toxicity data looks thin. That’s not a comfort—just a lack of evidence. Some older studies show skin and eye contact can cause irritation. Accidental ingestion or inhaling dust during transfer brings its own set of risks, mostly because breakdown products could hurt. Even though this compound might not smell strong or fume like ammonia, hands-off is still smart policy without equipment.

Looking at the Facts: What Do Safety Sheets Say?

I pulled up several safety data sheets from major suppliers. They all stick to the basics: avoid direct contact, don’t inhale dust or mist, and use eye protection. This echoes what experienced chemists say—treat all novel or complex chemicals as potentially hazardous, especially those with fluorinated parts. Fluorinated sulfonyls often signal resistance to breakdown, but also bring health worries if a person does breathe, eat, or touch enough of the material.

Long-term safety studies haven’t reached the level that you’ll see for table salt or even household cleaning products. That tells a story in itself—industrial use doesn’t always mean chemical safety for everyone, especially end-users or workers who see the barrels up close. The best labs keep written logs of any spill or accident, and update their SOPs as more hazard data rolls in.

Minimizing Hazards: Real-World Solutions

From my time in industrial chemistry, I never saw a true replacement for standard gloves and goggles. Folks working with N-Ethyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide should keep labs well-ventilated, stow bottles in sealed containers, and consult safety sheets every time. Even for small trials, a safety review can flag unexpected reactions, or environmental release.

Labs and companies shouldn’t just stop at personal protection. Push for more research into its full life cycle—environmental chemists ought to track what happens if it washes down drains or sits in landfill. Don’t shut out better alternatives just to stick to tradition. Some EU recommendations call for controlling discharge of per- and polyfluoroalkyl substances, since similar fluorinated compounds often linger in water and soil, with unknown health effects. Policies moving forward could require pushback against chemical persistence, not just short-term toxicity.

Trust Earns Itself with Open Information

N-Ethyl-N-Methylpyrrolidinium Bis((Trifluoromethyl)Sulfonyl)Imide fascinates both engineers and environmentalists. Ignoring possible hazards or brushing off incomplete toxicity data doesn’t match the care science deserves. Anyone using or disposing of this compound benefits from honesty, new research, and willingness to press for safer alternatives. Only that approach protects workers, the environment, and—by extension—the rest of us who rely on products these chemicals help create.

Why Purity Matters on the Shop Floor

Looking at any chemical or pharmaceutical ingredient, purity doesn't just sit on a spec sheet as a percentage. It makes the difference between consistent batches and ruined ones. Anyone working hands-on with raw materials knows contamination causes more than just trouble—it hits the bottom line. A simple impurity can turn a safe drug into a recalled one, or a strong building material into something structurally unreliable. Purity standards protect both producers and end users, giving everyone along the supply chain some peace of mind.

Defining Grade: One Size Fits Nobody

Grade tells you who the product is for and how strict the requirements get. Lab professionals, food processors, and manufacturers all look for different grades: technical, reagent, food, or pharmaceutical. Imagine baking bread at home using industrial flour—it won’t just taste “off”; contamination or inconsistent grind size can threaten safety. That’s how professionals think about product grade. An active ingredient for a headache pill needs checks far beyond what’s expected for an ingredient in a cleaning fluid. Industry groups like the USP or ISO define what those standards should be, and regulators demand documentation for every batch.

What Real Purity Levels Look Like

Purity means more than avoiding dirt in a product. Look at sodium chloride (common salt): table salt sits around 97-99%, but medical-grade saline requires 99.5% purity or better. Those numbers aren’t arbitrary—small amounts of certain metals or byproducts can harm patients. In electronics, contaminants that look harmless by weight can cause circuits to corrode faster or fail testing. When I worked alongside process engineers at a plant, we spent hours reviewing reports, chasing down trace impurities, and documenting sources—not just trusting an outside lab's word.

How Grades Get Verified

Real trust in a material’s grade comes from regular, transparent testing. Lab workers collect samples, run them against methods like gas chromatography or atomic absorption. They check for heavy metals, solvents, and other problem chemicals, then compare those to published standards. Any anomaly sparks an investigation. Trusted suppliers send certificates of analysis with every shipment. Customers demand random audits. These habits don’t slow things down—they prevent major problems through early catches.

Mixing Purity, Cost, and Safety

Anyone sourcing ingredients faces a balance. Higher purity means stricter controls and tighter profit margins, particularly for food and drug makers. Cheaper products sometimes cut corners that aren't obvious until something fails. I’ve seen buyers try to cut costs, only to end up discarding entire lots when they couldn't verify the grade. That’s why sticking to verified suppliers with clear purity and grade information pays off in the long run.

Staying Informed and Responsible

Getting the right grade isn’t about bureaucracy or red tape—it's about knowing exactly what goes into your recipe, product, or process. Companies that check specs and verify sources stand out in customer trust and reliability. In my experience, quality assurance keeps everyone out of emergencies later. Investing in training, regular audits, and honest recordkeeping creates stronger teams and safer products. Everyone from the shop floor to company leadership gets pulled along when quality comes first. And that’s how business builds a reputation that lasts.