N-Ethyl-N-Methylpyrrolidinium Chloride: An In-Depth Commentary

Historical Development

Chemists looking for stable quaternary ammonium salts have turned to pyrrolidinium derivatives for decades. Some early research around the mid-20th century dug into heterocyclic amines to find more stable ionic compounds that would face less hydrolysis or breakdown in harsh environments. N-Ethyl-N-Methylpyrrolidinium Chloride stems from this work. As ionic liquids took center stage in the 1990s and 2000s, thanks to their low volatility and unique solvation properties, this specific salt attracted attention from both academics and industries searching for more sustainable solvents and electrolytes. Patents emerged and demand for ionic liquids in batteries, catalysis, and separation increased, pushing N-Ethyl-N-Methylpyrrolidinium Chloride further into chemical catalogs and pilot-scale production facilities.

Product Overview

N-Ethyl-N-Methylpyrrolidinium Chloride exists as a white or off-white crystalline powder with a faint amine odor. Found in tightly sealed containers, the salt avoids exposure to moisture, which can degrade its performance and shelf life. Most people at the bench recognize it by code names from chemical suppliers, but underneath each label, the basic structure points to a charged, nitrogen-based ring that readily dissolves in water and polar organic solvents. The product caters mainly to customers in research, electronics, and advanced manufacturing.

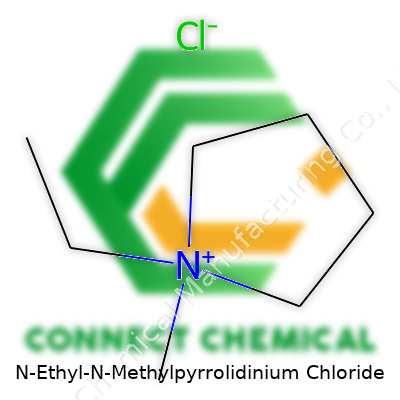

Physical & Chemical Properties

This compound stands out with its melting point ranging between 140–160°C. The molecular formula, C7H16ClN, draws chemists into the napthalene-like smell typical of amines. The salt structure features a five-membered pyrrolidine ring, which keeps the molecule rigid and prevents easy breakdown. Its solubility outpaces many rival quaternary ammonium salts—handling teams don’t need special tricks to dissolve it in a beaker of deionized water or acetonitrile. Chemically, a lot hinges on the robust chloride counterion paired with the pyrrolidinium ring, which makes the salt less likely to participate in unwanted side reactions. The ionic character propels conductivity in solution, making it attractive for those in electrochemical research.

Technical Specifications & Labeling

Chemical suppliers list batch-specific data—such as melting range, purity (typically above 98%), and residual water content—on product labels. Each container shows a UN number, hazard codes, and storage class, suited for quick risk assessment by lab managers. SDS sheets lay out hazard statements, such as warning about skin or eye irritation, and include chemical structure diagrams. The lot number, net weight, and synthesis date let buyers track the origin. Added details, like shelf life and lot-specific elemental analysis, provide buyers confidence that what arrives matches quality promises.

Preparation Method

On the bench, chemists usually make N-Ethyl-N-Methylpyrrolidinium Chloride using a straightforward alkylation. They start with pyrrolidine, mix it with ethyl chloride for the first alkylation, and follow with methyl chloride to finish the job. This sequence happens in a pressure vessel or sealed tube, heading off any gas escape. Sometimes, a phase transfer catalyst shortens reaction time. After the reaction, the crude salt gets washed and recrystallized, sometimes in ethanol, until purity hits target specs. Yields depend on controlling moisture—water in the air or solvents can drag down efficiency and purity. Final drying under vacuum guarantees minimal contamination.

Chemical Reactions & Modifications

N-Ethyl-N-Methylpyrrolidinium Chloride doesn’t just sit quietly in a bottle. It serves as a stepping stone for more complex pyrrolidinium salts by swapping out the chloride ion for larger, bulkier anions—triflate, bis(trifluoromethane)sulfonimide, or hexafluorophosphate. These swaps often happen using metathesis, where the chloride salt faces off against another salt in solution and an ionic exchange happens. Aside from that, chemists sometimes tweak or tag the pyrrolidinium ring with different alkyl groups, pushing the ionic liquid’s melting or solubility range to match new applications. This flexibility keeps the core structure useful in emerging technologies like supercapacitors and advanced solvent systems.

Synonyms & Product Names

Forget about searching only one chemical name; this product appears as N-Ethyl-N-Methyl-2-pyrrolidinium Chloride, 1-Ethyl-1-Methylpyrrolidinium Chloride, or simply EMPyrrCl in distributor lists. Some manufacturers give it catalog numbers—Aldrich’s, Tokyo Chemical Industry’s, or Acros Organics’ each apply their own alphanumeric shorthand. This variation in naming means buyers need to check structure and CAS number (usually 153832-46-3) to avoid costly ordering mistakes. Lab teams sometimes call it by acronyms or on-the-spot shorthand once it becomes a staple for a synthesis route or characterization project.

Safety & Operational Standards

This salt demands attention for safe handling. Although its toxicity stays relatively low compared to more reactive alkylating agents, N-Ethyl-N-Methylpyrrolidinium Chloride still causes moderate eye and skin irritation. Splashing or aerosolization can lead to burning sensations or redness, so gloves, goggles, and proper ventilation belong in every procedure. The material, while not notably flammable or explosive, releases irritating fumes when heated to decomposition or mixed with strong oxidizers. Storage should avoid direct sunlight and damp air—these conditions cut shelf life and ramp up hydrolysis. Most labs train staff to store in original packaging, under desiccation, in dedicated cabinets. Chemical disposal follows standard quaternary ammonium salt guidelines, steering clear of sinks or public drains.

Application Area

People use N-Ethyl-N-Methylpyrrolidinium Chloride well beyond the lab notebook. In the energy sector, its ionic character lets it work inside advanced batteries and supercapacitors as an electrolyte. Electrochemists see it as a medium for electrodeposition and as a carrier for metal salts thanks to its high conductivity. In separation science, chemists value this salt’s ability to dissolve pollutants or serve as an extraction phase for metals and organics that fail to partition well into water or other solvents. Polymer scientists mix in this salt to tweak the physical properties of membranes and coatings, looking for new combinations of strength and flexibility. Even pharmaceutical development has eyes on pyrrolidinium ionic liquids for improving drug formulation and solubility profiles.

Research & Development

Labs worldwide keep probing the limits of N-Ethyl-N-Methylpyrrolidinium Chloride. Green chemistry research leans into its low volatility to limit workplace exposure and environmental release—a big selling point for academic grants pushing safer solvent alternatives. Teams running batteries tweak this salt with new anions or blend it with other ionic liquids to improve conductivity and electrolyte window, aiming for longer cycle life and thermal stability. In analytical chemistry, development keeps shifting toward finding ionic liquid mixtures that enhance resolution and speed up separation in chromatography. The search for better processability, lower cost, and easier recycling remains active, as pilot plants stress the need for scalable, greener synthesis routes. Collaboration between industry and academia keeps ideas flowing and challenges old assumptions about where and how this salt gets used.

Toxicity Research

Animal testing and cell culture studies help pin down the safety window. Compared to more toxic quaternary ammonium compounds—some widely used as disinfectants—N-Ethyl-N-Methylpyrrolidinium Chloride shows moderate cytotoxicity. At high doses or chronic exposures, researchers notice effects on liver function and nervous system activity. Aquatic toxicity also captures attention, as ionic liquids can leach into water and disrupt fish or microbe populations. Regulatory bodies in the EU and North America keep delivering new data requirements and labeling for all ionic liquids, not just this one. Researchers continue to push for improved biodegradability, urging manufacturers to modify the alkyl chains or tweak the ring structure to cut back persistence once the chemical enters the environment. Medical and environmental toxicologists keep updating protocols and recommending patch testing and careful personal protection.

Future Prospects

The story of N-Ethyl-N-Methylpyrrolidinium Chloride seems far from over. Global interest in cleaner, safer chemical manufacturing drives more companies to consider ionic liquids as drop-in replacements for volatile or hazardous solvents. Battery companies keep searching for the perfect blend of stability, conductivity, and affordability, and compounds like this show promise as the world ramps up the shift to renewable energy. Green chemistry pushes for more tailored, biodegradable versions, paving pathways to reduce the potential for bioaccumulation or environmental impact. Research dollars flow into scale-up efforts and predictive modeling, looking to trim production costs and widen access to these next-generation materials. Training and outreach help build a broader understanding, supporting safer workplaces and industry-wide innovation.

Understanding Its Function

N-Ethyl-N-Methylpyrrolidinium Chloride shows up in labs and factories more often these days. The chemical world uses this compound as a part of ionic liquids, which are salts in liquid form at room temperature. Unlike many traditional solvents, these liquids stay stable, don’t evaporate quickly, and can handle a wide temperature range. Scientists like working with them because they create cleaner processes.

Back in college, I remember professors stressing how traditional solvents cause headaches: volatile organic compounds, tricky disposal, and fire hazards. Using ionic liquids like those made from N-Ethyl-N-Methylpyrrolidinium Chloride takes away a chunk of those problems. Less mess, less risk, and smaller environmental footprint — that’s already a win.

Electrochemistry Steps Forward

Electrochemical devices have changed with these new liquids. Laboratories often need electrolytes that stay safe when exposed to air or heat. Here, N-Ethyl-N-Methylpyrrolidinium Chloride plays a key role; batteries and capacitors use salts to move ions back and forth, and this compound keeps things running without breaking down.

I once watched a research group demonstrating a basic battery with traditional salt water. The results looked lackluster, and evaporation always messed things up. Replace that with ionic liquids made from this chloride, and you see better stability and efficiency. Keeping devices running for a longer time helps with green energy projects too.

Green Chemistry and Environmental Value

Most everyday solvents come with strong odors and complicated disposal protocols. Factories often vent harmful fumes or wrestle with hazardous waste. N-Ethyl-N-Methylpyrrolidinium Chloride, being part of the ionic liquid family, keeps emissions lower and cuts down on toxic byproducts. This means staff work with fewer risks and companies avoid extra regulations.

Green chemistry isn’t just a buzzword. The growing trend focuses on designing chemicals that do more, waste less, and keep toxins out of watersheds. As regulations tighten around the globe, chemicals like this one could replace old standbys in anything from manufacturing to research. The key lies in combining science with responsibility.

Challenges and Solutions

Handling new chemicals brings questions about production costs and long-term safety. N-Ethyl-N-Methylpyrrolidinium Chloride looks great on paper, but new technologies often need time to mature before mass adoption. Factories switching to ionic liquids will need equipment tweaks, and not every application fits the mold. That said, strong partnerships between chemists and engineers usually iron out those wrinkles.

One smart approach comes from combining organic chemistry insights with practical input from plant operators. Early collaboration finds issues no lab test will reveal, like material compatibility or strange reactions under stress. Reporting results openly, not glossing over mistakes, helps improve the recipe for the next batch.

Looking Ahead

N-Ethyl-N-Methylpyrrolidinium Chloride stands as more than just a specialty ingredient. Its use in ionic liquids points toward a safer and less polluting chemical industry. Real progress doesn’t sit on the shelf; it moves forward with careful use, honest reporting, and teamwork. Turning bright ideas into working solutions is how labs, factories, and ecosystems benefit together.

Digging Into the Chemical Formula

N-Ethyl-N-Methylpyrrolidinium Chloride walks into the room with its chemical formula C7H16ClN. In clearer terms, this compound combines a pyrrolidinium ring—the five-membered chunk with one nitrogen—attached to ethyl and methyl groups, linked with chloride as the counterion. Chemistry speaks a universal language: count the atoms and you see seven carbons, sixteen hydrogens, one chlorine, and one nitrogen making up the backbone.

Molecular Weight Keeps It Honest

Step on the scale, and N-Ethyl-N-Methylpyrrolidinium Chloride shows a molecular weight of roughly 165.66 g/mol. This number doesn’t just float around for show. It’s important for handling the substance in the lab. The molecular weight tells us how much of this chemical sits in a gram, making it straight-forward to prepare solutions and stock up for experiments. Measuring out compounds based on precise weights keeps chemical reactions reproducible. As someone who’s spent late nights watching glowing flasks settle, I know quick math sometimes saves the day.

Not Just a Name—What It’s Used For

People unfamiliar with ionic liquids may not have crossed paths with N-Ethyl-N-Methylpyrrolidinium Chloride, but in recent years the chatter about cleaner solvents has grown louder. This compound finds a home in research focused on green chemistry. Its structure gives it unique properties like low volatility and thermal stability. These features mean less evaporation into the air, making for a cleaner process—no need for a mask, even in a small lab. Materials like this see action in battery research, catalysis, and extractions. Better eco-profiles encourage industry to shift toward less toxic alternatives, especially with regulatory pressure ramping up in chemicals management.

Safety and Risks—What Everyone Should Know

Lab safety books don’t gather dust for good reason. N-Ethyl-N-Methylpyrrolidinium Chloride isn’t labeled a major hazard, but the presence of the chloride ion and the compound’s cationic nature mean it deserves respect. Gloves and goggles make sense because any salt in the eye turns a workday sour. Like other ionic salts, it can cause mild irritation if handled without protection. Safety Data Sheets point out to keep it dry and avoid heating above its standard tolerance to stay on the safe side.

Facts Back Up Demand

The market for compounds with these characteristics—ionic liquids that help replace hazardous solvents—is expanding. Data from the American Chemical Society and recent industry reports show a year-over-year increase in the adoption of alternative solvents. Academic labs and chemical plants alike hunt for molecules like N-Ethyl-N-Methylpyrrolidinium Chloride because they balance function and greener profiles. As researchers turn the page on outdated, polluting substances, the facts reinforce that safer options shape not only experiments but workplace health and the environment.

Where Challenges Meet Solutions

Supply consistency stands out as a common complaint. Labs can’t chase purity with every batch, which wastes time better spent analyzing results. Chemical suppliers must strengthen their quality controls to meet the rising need from both academic and commercial customers. Transparency in sourcing, tighter batch testing, and easy-to-follow documentation move the field forward. As demand rises, education about safe handling and storage becomes even more essential. Chemistry has always leaned on clear facts, careful weighing, and people willing to keep asking tough questions—qualities that build trust and keep breakthroughs coming.

Understanding the Chemical

N-Ethyl-N-Methylpyrrolidinium chloride belongs to the family of ionic liquids, which are known for their unique properties. Labs and industries experiment with ionic liquids for their stability and solvency, but these same qualities can raise questions once handling moves out of theory and into practice. Just because a substance is useful in controlled reactions does not mean it’s safe for daily exposure, and N-Ethyl-N-Methylpyrrolidinium chloride is a good example here.

Real-World Hazards

Workers face crucial questions: Will skin contact cause burns or rashes? Could breathing dust from a powder or vapor in the air cause harm? According to published literature, N-Ethyl-N-Methylpyrrolidinium chloride is irritating to eyes, skin, and the respiratory tract. Some studies have flagged possible cytotoxicity—meaning it can damage cells in a lab dish. The chemical isn’t as notorious as formaldehyde or benzene, but the fact remains: it’s not risk-free.

Toxicologists have not studied this compound to the depth seen with common industrial solvents. What does exist suggests moderate acute toxicity if swallowed or inhaled, based on animal models and reports from workers exposed in research or pilot plants. Chronic effects or links to cancer haven’t cropped up in public health reports, but absence of evidence doesn’t always guarantee safety. I’ve seen researchers use thick gloves, eye protection, and even full face shields with chemicals far less suspicious—caution just makes sense.

Environmental Impact and Disposal

Ionic liquids continue to generate buzz as “green solvents” because they often don’t evaporate quickly or carry volatile organic compound (VOC) risks. Some folks use this to argue that spills pose limited threat. But most aquatic testing with these compounds is still unfolding. N-Ethyl-N-Methylpyrrolidinium chloride doesn’t break down easily in water or soil, and early evidence suggests it can harm aquatic life if dumped in sufficient quantity. The worst-case scenario involves persistent bioaccumulation: chemicals that build up in living systems and cause trouble for years.

Lab managers I’ve worked with store spent material in marked, sealed drums for special disposal—no pouring down the drain. Responsible waste handling may seem expensive, but the price of ignoring it shows up quickly in environmental fines and lost reputation.

Safe Handling and Solutions

Prevention always beats clean-up. Managing risk from N-Ethyl-N-Methylpyrrolidinium chloride starts with the basics: gloves that resist chemical penetration, goggles that seal against splashes, and workspace ventilation. I’ve seen researchers read Safety Data Sheets (SDS) before every project, not out of formality, but because one missed section can lead to a hospital visit.

Training and vigilance matter more than any single piece of gear. I remember the relief in a lab group when a proper hazard review led to a switch in chemicals, trading something more dangerous for a safer alternative. Chemical substitution remains the smartest solution: find out if a less hazardous compound can do the job and swap it in when possible. For processes that demand this chloride, thoughtful engineering controls and storage protocols go a long way.

The Big Picture

N-Ethyl-N-Methylpyrrolidinium chloride has a place in modern chemistry and industry, but risk can’t be shrugged off. Whether you run a commercial facility or a research bench, taking time to evaluate hazards and invest in training does more than prevent personal harm—it stabilizes the workplace, protects the environment, and keeps innovation on the right track.

Why Safe Handling Matters

You’ll rarely find a chemical story that doesn’t start with safety, because every chemist who’s spent time in a lab knows that the smallest misstep leads to a world of trouble. N-Ethyl-N-Methylpyrrolidinium Chloride (EMPyrrCl) is no different. This ionic liquid pops up in specialty applications, especially in batteries and solvents, so it tends not to be something you’ll find in a random workplace. Still, its hazards deserve straight talk.

EMPyrrCl doesn’t shout danger as loudly as some other chemicals, but that makes it easy to treat it too casually. I’ve seen colleagues brush off personal protection when pouring from a container, only to have unexpected splashes cause skin irritation or worse. Its quaternary ammonium structure can pose risks. I always make sure the lab techs wear protective gloves and goggles — you never want a chemical of unknown long-term effects making direct contact.

Storage Needs Backed by Experience

Small differences in how chemicals are kept don’t seem important—until you realize what’s evaporated, or worse, degraded. EMPyrrCl prefers to stay cool and dry. I learned early on that humidity messes with more than just powders; even liquids like EMPyrrCl start to break down if the storage room gets muggy. That’s avoidable with a tightly sealed container and a desiccator, or at least an air-conditioned chemical cabinet.

Direct sunlight pushes this compound to break down over time. Bulky amber bottles shield against light, and refrigeration further slows degradation—though you never want it to freeze. Not every workplace has purpose-built chemical fridges, but even a basic dorm-sized fridge set above freezing works in a pinch. I’ve relied on ordinary fridges in community college labs, and as long as those bottles are clearly labeled and separated from food, you dodge a big problem.

Keeping incompatible chemicals away from EMPyrrCl matters. Acids, bases, and oxidizers should stay in separate bins or shelves. I’ve heard of fires triggered by careless storage, all because someone tossed a chloride salt near a strong acid bottle. The extra three steps to read a label beat grabbing the wrong jar in a hurry.

Spill Response and Best Practices

One thing about this chemical: it flows easily. A knocked-over bottle makes a mess. I always keep paper towels, spill kits, and gloves handy. Sorbent pads work best, especially since they prevent spreading. Never sweep it under the rug — literally or figuratively. Even after wiping up, you want to wash the area with water and mild soap.

Don’t skip the Material Safety Data Sheet (MSDS) for EMPyrrCl. This is not paperwork for the sake of paperwork; MSDS lists exposure symptoms, fire risks, and cleanup steps. I keep those sheets at eye level in the storage area, not buried in a binder. The best lesson I’ve learned over the years is to make safety routines obvious and unavoidable.

Improving Practices

Periodic training makes a difference. Even if you handle chemicals daily, refreshers matter. I’ve seen workers miss label changes or skip gloves because habits crept in. Short, twice-yearly sessions help stop that drift.

A sensible labeling system goes a long way, too. Big-print hazard symbols and clear English warnings on every container make mistakes less likely, especially for new hires. It’s become clear in my experience: accidents drop when everyone on the team feels confident identifying hazards on sight.

Closing Thoughts

Chemicals like N-Ethyl-N-Methylpyrrolidinium Chloride become just another supplier invoice unless something goes wrong. Treating it with respect, setting up proper storage, and insisting on full training — those are lessons paid for by stories you never want to live through yourself.

Understanding Purity in the Lab and Beyond

N-Ethyl-N-Methylpyrrolidinium Chloride often shows up wherever ionic liquids or advanced solvents play a role, from electrochemical research to pharmaceutical development. Real-world results depend on how pure the raw materials are. Most credible suppliers offer a purity of 98% or higher for this salt. This isn't just about the number itself—it's what happens if contaminants sneak in. Any impurity, even fractions of a percent, can influence experimental outcomes, especially in sensitive fields like energy storage or drug chemistry. On the bench, I’ve noticed that skipping the math on purity can mean confusion between a genuine breakthrough and a false lead.

Labs trust high-purity versions for small-scale reactions and pilot studies. When I worked in a university lab, we sometimes gambled with lower-grade chemicals to keep costs down for rough drafts, but publication-grade work always needed high-purity batches. Anything short of at least 98% starts to limit repeatability and calls results into question during peer review.

Package Sizes Align with Real-World Needs

The size of the package shapes convenience and safety. For specialty salts like N-Ethyl-N-Methylpyrrolidinium Chloride, 1-gram and 5-gram vials cover most early R&D needs, reducing waste and cost for those just trying a few reactions. Larger 25-gram, 100-gram, and sometimes up to 500-gram bottles appear in catalogs for groups scaling up to pilot runs or prepping batches for prototypes. While working in small batches, I've seen the risks of buying too much—chemical exposure grows, storage becomes tricky, and costs add up fast if the material isn't used quickly.

Manufacturers often vacuum-seal the salt in glass or high-density polyethylene bottles to dodge moisture and air, since it can be hygroscopic. Secure caps and careful labeling matter just as much as the actual quantity. Good suppliers ship with detailed certificates, listing not only purity, but moisture content, storage guidance, and lot tracking.

Safety and Compliance Factors

No matter the purity or package size, chemical handling and regulation shadow every purchase. Inexperienced teams sometimes forget that even common salts deserve respect. Spills from big containers multiply hazards, especially in busy labs. Packaging that matches project scale trims this risk. Strong labeling, clear hazard statements, and updated safety data sheets aren’t luxuries—they keep folks out of urgent care, and projects off the compliance blacklist.

The Value of Trusted Sourcing

Upfront savings can fade away if poor-quality N-Ethyl-N-Methylpyrrolidinium Chloride ruins a run, or compliance teams catch a snag during audits. My own work has run smoother after switching to suppliers who prove batch consistency and back it with live technical support. Browsing catalogs is less about price or one-off purity ticks, and more about how those companies keep samples traceable and safe.

Lab teams should ask for clear paperwork with every purchase. Accredited suppliers often join programs like ISO 9001, which means better traceability. Consistently high purity and sizes that fit both test tube and bench-scale workflows let chemists avoid waste and rework.