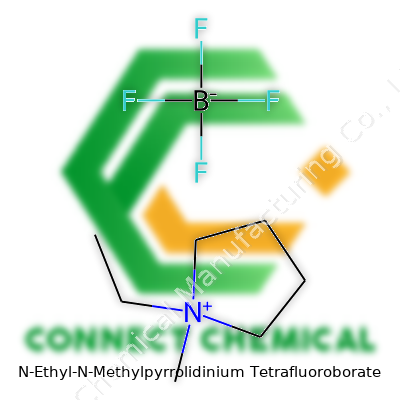

N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate: An In-Depth Commentary

Historical Development

People first saw N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate pop up in the literature as part of the rise in interest around ionic liquids during the late 1990s and early 2000s. As chemists looked for better salts that avoided the downsides of older ionic liquids, this compound emerged as a strong candidate. Its popularity grew because it offered improved thermal stability, a manageable viscosity, and less volatility than many of the competitors on the bench. Researchers across Europe and Asia published papers mapping its synthesis and performance, sometimes chasing battery breakthroughs or more robust organic reaction conditions. Over the years, its role in electrolyte research cemented its place in journals and patent filings, with industrial labs catching on only after academics published favorable results on its electrochemical window and environmental safety profile compared to older quaternary ammonium salts.

Product Overview

N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate lands on the shelf as a consistently pure crystalline solid or liquid, depending on storage temperature and local humidity. Companies label it as both a specialty chemical and a research-grade ionic liquid. What stands out is its use in electrochemistry; it steers clear of water and many organic solvents, providing a steady medium for charge transfer. Practically, anyone searching for materials that resist hydrolysis and support modern battery development starts eyeing it after the stalwarts like imidazolium salts. With growing attention on clean technology, producers have started offering this salt in scalable, contamination-controlled packaging, aware that both lab-scale users and pilot plant operators want reliable, repeatable performance.

Physical & Chemical Properties

This compound gives a clear, colorless liquid at room temperature with a density close to 1.09 g/cm³, often ever-so-slightly viscous depending on additives and moisture. It boasts a melting point hovering around 10–16°C, kicking into a fully liquid state above standard refrigeration conditions. Its tetrafluoroborate part keeps the salt stable under strong alkaline and acidic conditions, resisting breakdown in environments that would chew through acetates or chlorides. Electricians and engineers appreciate the broad electrochemical window; the cation does not break down until reaching high potentials, making sustained electrochemical performance much more reliable than with older solvents. Its low volatility means that it stays put, whether powering a small battery or supporting a chemical reactor's operation.

Technical Specifications & Labeling

Most product labels show purity levels ranging between 98% and 99.5%, with water content listed under 0.2% by Karl Fischer titration. CAS number 155371-19-0 and EC number 695-474-9 help differentiate it for regulatory filing or customs checks. Companies flag storage conditions as tightly controlled, cool, and dry, alerting users that exposure to air or sunlight can degrade the salt over time. Other technical sheets warn about handling with gloves, as both the undiluted ionic liquid and the tetrafluoroborate counterion require care. Packaging sizes stretch from small research vials to bulk kilogram drums, always sealed in high-barrier materials to keep contaminants and stray humidity out.

Preparation Method

Synthesis follows a rational route compared to earlier ionic liquids. Typically, producers start with N-methylpyrrolidine, reacting it with ethyl bromide under gentle reflux. After quaternization, the resulting N-ethyl-N-methylpyrrolidinium bromide undergoes metathesis with sodium tetrafluoroborate in water. Post-reaction, the mixture separates into phases, and careful washing removes residual bromide or sodium. Drying under reduced pressure and sieving through molecular sieves ensures the final product avoids unwanted moisture or inorganic impurities. Not just chemists but chemical engineers watch for salt formation and thorough purification, since even trace bromide or water destroys the delicate performance in batteries or capacitors.

Chemical Reactions & Modifications

The pyrrolidinium backbone opens up a window to N-substitution chemistry. Although many prefer the ethyl and methyl configuration, researchers explore longer alkyl chains, introducing branching or fluorinated groups to dial in viscosity or improve resistance to electrochemical breakdown. Chemical modifications often swap out the tetrafluoroborate anion for alternatives like bis(trifluoromethanesulfonyl)imide, pushing performance in supercapacitors or experimental fuel cells. The parent compound itself resists oxidation and shows only minimal reactivity at moderate temperatures, giving it an edge in applications that see wide thermal swings. Academic groups regularly revisit the cation as a building block, looking for improved low-temperature fluidity or expanded voltage stability in more unforgiving applications.

Synonyms & Product Names

You will see N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate listed under several names, including [EMPyr][BF₄], 1-Ethyl-1-methylpyrrolidinium Tetrafluoroborate, and the standard abbreviations like EMPy-BF4. Chemical suppliers sometimes market it under internal catalog names, but industry events and published patent documents stick with the IUPAC or empirical shorthand. Searching for any of these in research databases or product catalogs usually leads to the same molecule and a suite of related ionic liquids that share its core structure, often described as “pyrrolidinium-based ionic liquids.”

Safety & Operational Standards

People working with this compound know to treat it with respect. Tetrafluoroborate salts can break down under strong heating or in the presence of acids, giving off potentially toxic fluorides and boron compounds. Best practices call for using it in a fume hood, wearing nitrile gloves and eye protection. As with most ionic liquids, spills tend to be sticky and hard to mop up—so labs keep plenty of absorbent on hand. Regulatory agencies assess it under REACH and TSCA as a low-to-moderate-hazard material, but require proper documentation and waste disposal. European safety datasheets assign the “harmful if ingested” and “can cause skin irritation” categories, with real risks coming mostly from chronic exposure or from mismanaging cleanup. Industrial users rely on closed transfer systems and robust ventilation any time they scale up, not just for legal compliance but for peace of mind when handling liters instead of milligrams.

Application Area

Engineers and chemists see real value in this salt’s performance for electrochemical energy storage, especially in next-generation lithium-ion and sodium-ion batteries. Its stability lets designers push battery potential higher, stretching performance without triggering breakdown. The salt also fits well in supercapacitor electrolytes, where its wide voltage tolerance bumps up energy delivery. Researchers dip into its solvent properties, applying it to organic synthesis as a medium that shields sensitive intermediates from hydrolysis or decomposition. Some teams use it for electrodeposition of metals in microelectronics, as the ionic liquid environment often offers smoother laying down of metal films. Future uses look promising in areas like carbon dioxide capture, thanks to the ionic liquid’s chemical robustness and low vapor pressure, which ease recycling and process integration.

Research & Development

Universities and industry labs pour resources into understanding this salt’s limits. Electrochemists measure its conductivity across wide temperature spreads, seeking the best performance for automotive or grid-scale batteries. Material scientists probe interactions between the salt and novel electrode materials, chasing higher cycle life and charge capacity. Synthetic chemists rework the cation, adjusting the ethyl, methyl, or pyrrolidinium ring to boost ionic mobility or tune viscosity. Startups experiment with cheaper preparation routes and improved purification, all while keeping an eye on regulatory requirements that change as data accumulates. In scientific journals, you can track dozens of papers a year examining everything from basic ionic conductivity to advanced applications like supported ionic liquid membranes for selective gas separation, especially in fuel cell research and emissions control.

Toxicity Research

Toxicologists keep a close watch on pyrrolidinium salts. Early studies suggest low acute toxicity in rodents, though long-term exposure causes reproductive effects in animal models for related cations. Researchers test environmental persistence, finding slow breakdown under sunlight but rare bioaccumulation, mostly because the salt interacts poorly with living cell membranes. Regulatory pressure increases as production ramps up, with countries like Germany and Japan calling for chronic toxicity and ecological impact studies before approving large-scale industrial use. Waste treatment experts recommend incineration at high temperatures to break down the anion completely, with filtration systems set up to scrub out fluoride emissions. The scientific community keeps pressing for more transparent data from both makers and users to close gaps in understanding about degradation products and risks.

Future Prospects

Graduating from a niche chemical curiosity to a staple in clean tech, N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate sits in an exciting spot. As battery technology keeps vaulting forward, its robust profile lets designers try daring new electrode materials and advanced architectures—without sacrificing safety or longevity. With climate policies steering industry toward greener, longer-lived storage technology and solvent-free reactions, the salt finds a growing audience. Ongoing toxicity and environmental impact research will shape its role, both in regulatory clearance and public perception. Looking at how new generations of ionic liquids rise and fall, real success depends on making both synthesis and disposal as clean and cost-effective as performance itself. People who stay flexible and keep one eye on both lab-scale breakthroughs and full-scale deployment will steer this compound into wider applications, matched to the big push for sustainable energy infrastructure and greener industrial chemistry.

Unpacking Its Real-World Purpose

At first glance, the name N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate confuses most people. It's a mouthful, one of many names that crop up when searching for safer, better-performing batteries. This chemical isn’t just a curiosity in a lab; it’s playing a crucial role in how our rechargeable devices work—and how they might change in the next decade. Years of working around tech startups showed me how chemists hunt for new ways to squeeze more energy into smaller packages without blowing things up or breaking the bank. This is where compounds like N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate step in.

Why Electrolytes Matter

Every lithium battery, whether in your phone or an electric car, depends on a material called an electrolyte. The electrolyte lets charges move from one side of the battery to the other. Most companies stick with liquids that work, but sometimes they run into problems: flammability, leaks, fast wear-out, and limits on how cold or hot the device can get. Instead of pouring more risky liquid into each battery, researchers turn to “ionic liquids.” N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate belongs to this family. Because it doesn’t catch fire easily and handles higher temperatures, it allows batteries to charge faster and last longer. I’ve seen battery engineers breathe a little easier in labs because of this stability; their test cells hold up better and make fewer headlines for bursting into flames.

Fueling The Push for Greener Tech

Scientists started to lean on this compound because it sidesteps some nasty pitfalls. Many standard electrolytes can release harmful gases. N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate stays put, even under stress. By resisting breakdown, it supports development of safer electric vehicles. Europe and East Asia use it in advanced research on solid-state batteries. If you want more vehicles to go electric, safety needs attention, not just marketing. Markets need alternatives; people make choices based on fears and facts. This compound can take some of those fears off the table.

Beyond Batteries—Bigger Responsibility

Not every use links back to your phone or car. I’ve talked with scientists who use this compound as a “green” solvent for chemistry that clamps down on pollution. Pharmaceutical firms use it in synthesis, chasing better yields and less waste. Its non-volatile nature helps in rooms packed with sensitive instruments. Labs care about this because replacing toxic materials isn’t just about ticking boxes for regulators; it shapes public trust in science. Even in the world of capacitors and fuel cells, N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate improves cycle life, which saves material and energy over time.

What Could Slow Progress?

Still, there’s no magic bullet in chemistry. Some manufacturers face tough sourcing and cost issues; advanced ionic liquids don’t flow as cheaply as old-school solvents. Not every battery plant can retrofit their lines overnight. My experience with green supply chains tells me that scaling up production, cutting costs, and ensuring honesty in labeling will take a real-world, step-by-step plan. Regulatory frameworks need to catch up, too, so the global market rewards innovation in safety. Watchdog groups and independent testers push for results, not just claims. That is the only path to move compounds like N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate from labs into mainstream manufacturing, reshaping energy storage for millions.

Why Attention to Handling Matters

Stumbling on N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate in the lab for the first time, I remember how easy it was to overlook some of the smaller details on the safety data sheet. That’s no casual mistake, since this salt isn’t your ordinary table seasoning. It pops up as a neat solvent in electrochemistry and sometimes in battery research. Ignoring safety with it invites issues both for people and equipment.

Understanding the Hazards

This compound’s structure hands it some unique traits. Unlike the more notorious chloro-solvents, it doesn’t reek up the room, but it still sneaks into your skin and eyes if you skip gloves or splash around. Respiratory irritation can follow from careless opening of the bottle. The salt also hates water — not because of any fancy reaction, but plain old hydrolysis messes up its purpose and can damage experiments. I’ve seen researchers lose days of work to a forgotten cap or tattered glove.

Practical Storage Advice

Packing away this ionic liquid smartly starts with a good seal. A glass bottle with a decent stopper will keep the compound dry. Tossing a silica gel packet inside the storage cabinet never hurts — it’s a cheap line of insurance against humidity. No point letting months of research slip away just because of a rainy afternoon and an open lid.

Sticking bottles in a cool spot beats leaving them near radiators or computers. Elevated temperature nudges many chemicals toward slow change — not always explosive, but enough to degrade their quality. I made a habit of labeling my bottles with date-opened tags. This way, I never had to play guessing games about the age or exposure time of what I had. The best labs I’ve worked in make clear distinctions: “This shelf is for hygroscopic solvents, that one holds acids.” Mistakes plummet when each material fits its type of risk and use.

Sensible Handling Practices

Personal protective equipment gets a lot of attention in training, and for good reason. Nitrile gloves, goggles, and lab coats block that chance for mild burns or irritation. There’s a temptation to go fast and skip them — a bad habit that only survives until the first emergency. Regular disposable gloves work, but I’ve noticed specialty gloves last longer if you know you’ll be handling the salt repeatedly.

Ventilation sneaks past some safety checklists, but I’ve seen best results with well-ventilated fume hoods. Cracking a window only shifts risk farther away in a shared lab; a hood pulls risk away from everyone’s lungs.

Disposal Is Part of the Cycle

Dumping unused N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate down a sink earns you hefty trouble from the waste desk. Collected solvent waste needs to hit designated hazardous waste bins rather than the drain. Waste contractors will ask for detailed labels. Missing information just means your department gets a long phone call and a possible fine. I learned to keep small logbooks right in the storage area: every bottle out, every droplet discarded, gets tracked. This simple trick pairs well with digital systems for larger labs.

Simple Steps Build Trust and Results

Most errors with this compound begin as honest mistakes — missing a warning label, skimping on the lid, skipping a glove just once. Nothing replaces the value of forming habits over shortcuts. Honest conversations with colleagues about reminders and checklists help more than a wall of unread safety posters. Following storage and handling rules guards both the people mixing the solutions and the science they’re after. I’ve watched safer, tidier labs turn out better results, healthier workers, and way fewer avoidable spills or exposures.

The Chemical Under the Microscope

N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate doesn’t pop up in daily conversation, but it shows up in advanced battery research, ionic liquids, and some specialized chemical processes. People who know their way around a lab recognize it as a go-to ionic liquid. As science rushes forward with new tech and materials, figuring out what’s risky, what’s safe, and where the gray areas hide—matters more than ever.

Digging Into the Risks

Every new material ends up under scrutiny. With N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate, concerns mostly revolve around toxicity and its impact on humans and the planet. Hazards don’t just come from fumes or skin contact; disposal and breakdown products can build up in the ecosystem or living tissue. Labs and manufacturers rely on published Material Safety Data Sheets (MSDS), and these report it may cause skin, eye, or respiratory irritation. Swallowing or inhaling even small amounts raises red flags, especially for those handling the chemical daily. It isn’t just about short-term rashes or coughs, either. Long-term exposure can build up and trigger deeper health issues, in part because we simply don’t have decades of data for these newer compounds.

Why the Details Matter

Some substances fly under the radar for years until researchers catch up. Ionic liquids like this one initially earned a green reputation—low volatility, so they don’t evaporate like traditional solvents. That image had tech companies and scientists pushing for them as cleaner alternatives. But studies in the last decade question how “green” ionic liquids really are. Biomagnification and accumulation have shown up in lab studies with fish and soil organisms. One study, published in Environmental Science & Technology, traced persistent toxicity in earthworms after exposure to similar compounds. This isn’t just about fish in a tank—aquatic runoff from factories can escalate the problem across a food chain.

The Knowledge Gap

Solid facts about N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate’s long-term toxicity remain thin. This bothers me because I’ve worked in chemical research: sometimes we only discover serious hazards years later after a pattern of accidents or illness emerges. Most info comes from closely related chemicals. The uncertainty isn’t an excuse for carelessness; it’s a call for cautious handling. No matter how friendly an ionic liquid seems, basic lab safety—gloves, eye protection, fume hoods—still shields workers from unknown risks.

Steps Toward Safer Practice

Every workplace using this chemical should commit to training, good ventilation, and regular health monitoring for staff. Safe storage and detailed spill protocols protect people and prevent contamination. Disposal rules can’t just follow local regulations—chemicals like this could slip through the cracks if treated like typical waste. Research money can nudge companies and universities to test the substance more rigorously, especially for long-term effects and breakdown products.

People outside the chemistry world don’t always get a full picture of these risks. Open reporting and better communication—using plain language—pushes everyone to treat emerging materials with both excitement and caution. New tech should improve life, not trade health for progress.

Why Purity Holds Real-World Weight

Chemists hardly overlook purity, especially with ionic liquids like N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate. A pure compound means experiments and processes run smoother. Results stay predictable. Dial in on this salt, and reputable suppliers often quote a purity of 99% or higher. That number matters, not just for the peace of mind—it really impacts reactions like electrochemical applications, battery research, and catalysis. You risk less noise in your data, fewer strange artifacts, and less time troubleshooting impurity-driven problems.

I spent time in a lab that developed energy storage devices using ionic liquids. A single percent drop in reagent purity sometimes meant hours sorting out odd results that couldn't be chalked up to mistakes in measurement. That pain point stuck with me. It’s why folks involved in research and scale-up both dig deep into the details behind those purity certificates. A good supplier provides not just the number, but analysis data—often high-performance liquid chromatography (HPLC) or nuclear magnetic resonance (NMR) spectra. No reputable lab rolls the dice with unverified chemical sources.

Packaging for Real-World Handling

Handling air-sensitive salts like this one often involves some headache. The tetrafluoroborate anion can react with moisture, releasing hydrofluoric acid in a worst-case scenario. That’s not just bad for your experiment—it's hazardous health-wise. Reliable vendors ship N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate in tightly sealed bottles. Glass is common, especially for smaller quantities (10g, 25g, 100g). For larger requests, high-density polyethylene containers line up as favorites. An inert atmosphere—argon or nitrogen-filled bags—adds security for sensitive batches.

Shipping practices matter just as much as lab technique here. I’ve unboxed products that arrived sweating with condensation inside, and it only took one mistake there to realize the value of protective packaging. Desiccant packs and double-bagging keep moisture from sneaking in, keeping the salt ready for action without needing labor-intensive drying steps before use.

Importance of Batch Size Options

Research and industry rarely ask for the same quantities. Someone running exploratory tests probably doesn’t need a kilo. Custom packaging helps. Vendors routinely offer sizes from as small as a gram to multi-kilo drums. That range serves everyone: students, postdocs, up to manufacturers piloting larger battery batches. Smaller packages cut down on waste and lower costs, making it easier for researchers to try out new materials without burning through tight budgets.

Lab-scale orders don’t just prevent waste—they help cut down on contamination risk, too. Each time you open a bottle, oxygen and water vapor sneak in (no matter how fast you move). Smaller, single-use vials solve this. For regular users with bigger operations, manufacturers often offer industrial drums lined with protective materials or even pump-out systems, making access easier while reducing exposure.

What Practical Steps Can Make a Difference?

Better supply chain transparency ranks high on my list. Knowing exactly where a chemical comes from, how it’s stored, and what documentation ships with it weeds out problems before they land in your workroom. For a compound as valuable as this ionic liquid, that’s more than a box-ticking exercise; it’s a must. Open, detailed batch records, third-party spot testing, and clear safety data sheets build trust between supplier and researcher.

Developing robust protocols for checking and storing incoming chemicals pays off. In my lab years, we slashed issues after adopting moisture sensors and regular batch-to-batch purity testing. It costs a bit more up front, but the reduction in flawed data and safety incidents made it a smart investment.

Looking Ahead

As applications for advanced ionic liquids keep growing, so does the need for trusted, high-purity supply lines and thoughtfully engineered packaging. The little details—how dry, how clean, and how well-sealed—make the difference between frustration and success in the lab or the factory. If you’ve put in the work, you want your chemicals to do their job, no distractions.

Understanding the Risk

N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate might sound like a tongue-twister, but for those who work in chemical labs, battery research, or electrochemistry projects, it’s a familiar sight. It acts as an ionic liquid, often prized for its stability and low volatility compared to solvents based on volatile organic compounds. These properties make it useful but they do not mean a free pass when it’s time to get rid of leftover material.

Every day, research labs and some factories generate small amounts of surplus or waste like this. Turning a blind eye to safe disposal risks more than just a nasty mess. Mishandling can lead to soil contamination, impact aquatic life, and damage infrastructure over time because of fluorinated byproducts.

Personal Experiences from the Bench

Years ago, I remember being tempted to toss the leftover electrolyte into the general organic waste because it looked rather innocent. The colorless liquid didn’t carry the aggressive warnings posted on bottles of toluene or nitric acid. Only through hands-on safety training did I learn about the persistent impact of the tetrafluoroborate anion. The fluoride content can react with moisture, forming HF, a toxic and corrosive gas. I’ve seen glassware etch and warning signs pop up on safety audits when just a small spill went unreported.

Regulation and Why Careful Disposal Counts

Countries like the US and members of the EU have rules that treat ionic liquids with care, especially those containing fluorinated groups. These substances fall under hazardous waste regulations. Anything with the potential to release toxic fluorine compounds or damage water systems deserves special handling. Failure to respect this goes beyond fines — nearby communities pay the price if hazardous runoff makes its way into groundwater, an issue documented by the EPA and reflected in global case studies.

Keeping track of chemicals in your workspace, labeling secondary containers, and keeping materials out of sinks form the backbone of chemical hygiene. I learned early—sometimes from seeing colleagues’ mistakes—how quickly a shortcut becomes a reportable accident.

Steps Toward Proper Disposal

Getting rid of ionic liquids like this one means working with licensed hazardous waste contractors. The right move: pour all unused or spent liquid into a clearly marked, sealable waste container. These containers must resist corrosion because residual acids or traces of decomposed tetrafluoroborate can eat through plastics over time. Agencies recommend segregating this waste from flammable solvents. Not every disposal firm accepts mixed waste, and improper mixing ups the risk of fire or toxic offgassing.

Each user has a responsibility to keep their safety data sheets close. These contain disposal directions based on chemical behavior, not just copy-pasted legalese. Some companies offer take-back programs or partner with certified disposal agencies—my old lab worked with one that picked up hazardous bottles monthly, tracked manifests, and provided disposal certificates for audit trails.

Dilution in a drain or tossing bottles in the trash only spreads the problem. Most materials recovery facilities lack the tools for advanced neutralization or controlled incineration needed to handle fluorinated waste safely. Proper disposal breaks the cycle of environmental persistence. Cleanups that fail to remove fluoride residues cost cities dearly and push regulators to tighten enforcement.

Looking Forward

Disposing of N-Ethyl-N-Methylpyrrolidinium Tetrafluoroborate safely sounds complicated but it comes down to a few non-negotiables: respect the hazards, separate waste streams, and rely on professional handlers. Manufacturers and labs reduce their risks by investing in education and sticking with certified partners. This approach not only checks compliance boxes, it protects the air, water, and colleagues down the hall.