N-Ethylimidazolium Chloride: A Practical Look at Its Background, Properties, and Future

Historical Development

Chemists stumbled onto the potential of imidazolium salts long before N-ethylimidazolium chloride entered specialty labs and industrial catalogs. Early imidazole research in the late 19th century focused on natural alkaloids and the foundations of heterocyclic chemistry. The journey from those bench experiments to today's ionic liquids and catalysts involved steady progress, starting with structural studies and extending into synthetic tweaks. N-ethylimidazolium chloride became a popular target as interest in room-temperature ionic liquids grew through the 1990s, fueled by demand for greener solvents and unusual electrolytes. The context for this compound changed once researchers recognized the value in tuning ionic species for each distinct task, whether for stabilizing fleeting intermediates or dissolving stubborn biological or polymeric substrates.

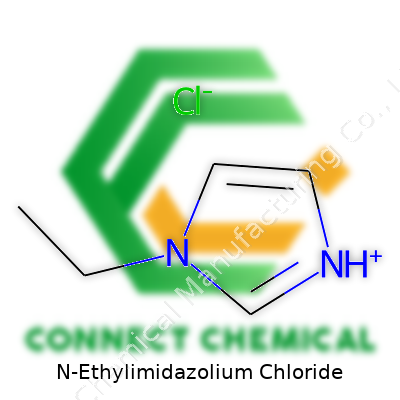

Product Overview, Synonyms, and Product Names

In most catalogs, N-ethylimidazolium chloride pops up labeled as 1-ethyl-3-imidazolium chloride or simply EMI-Cl. Some brands write it as ethylimidazolium chloride. The chemical formula—C5H9ClN2—reflects a basic imidazole ring with an ethyl group on the nitrogen and a chloride anion. Firms sell it as a powder or crystalline solid, sometimes ground extra fine for use in sensitive synthesis or electrochemical setups. With the popularity of ionic liquids, suppliers often group EMI-Cl with other imidazolium-based salts, highlighting its blendable nature for custom solvent or catalysis needs. Its CAS number, 65039-08-9, helps researchers source it with solid confidence in its identity and purity.

Physical and Chemical Properties

N-ethylimidazolium chloride shows up as a pale white or off-white solid, sometimes with a faint odor. Its melting point sits between 70 and 80°C under standard pressure, but its true secret lies in its ability to lower the melting point of mixtures through ionic interactions—think of how it helps create so-called “deep eutectic solvents” that liquefy far below an ordinary salt’s melting point. The structure gives it respectably high thermal stability, usually resisting breakdown even at 150°C. EMI-Cl dissolves readily in water, alcohols, and polar aprotic solvents like DMSO. It stays non-volatile, avoiding headaches around vapor exposure, but its ionic character means strong attraction toward charged or polar compounds and coordination complexes. On the reactivity front, it rarely acts on its own, but serves as a supporting salt, medium, or phase-transfer partner.

Technical Specifications & Labeling

Suppliers package N-ethylimidazolium chloride in airtight bottles—often glass or thick plastic—to block moisture and carbon dioxide. Quality labeling details batch number, purity (often above 98% for laboratory use), year of manufacture, and any stabilizers or anti-caking agents. Most labs request particle size data for process optimization, as tiny grains dissolve fastest, but larger chunks keep longer on the shelf. Storage advice sticks to cool, dry, dark places. For technical buyers, certificates of analysis show not just elemental composition but spectral confirmation, usually with NMR and mass spectrometry tabs checked off. This tracking matters for academics hunting reproducibility and for industries where trace impurities in a salt can wreck high-value syntheses.

Preparation Method

Lab-scale preparation starts with N-ethylimidazole, available as a liquid base, and treats it with hydrochloric acid or another chloride donor. The protocol relies on controlled mixing under cooling, often with slow acid addition to stop runaway exotherms. As the salt forms, white crystals precipitate. The solid gets filtered, washed with cold ether or acetone to strip away unreacted organics, and dried under vacuum. Technicians then grind and sieve the solid to reach the desired particle size. Scale-up for bulk manufacturing repeats the recipe, swapping benchtop glassware for jacketed stainless reactors and automated controls to monitor pH, temperature, and yield. Factories design processes to recover solvents and acid more efficiently as costs rise and waste rules tighten.

Chemical Reactions and Modifications

N-ethylimidazolium chloride stands out for how it interacts with other ions and molecules. Chemists often swap chloride for other anions—like tetrafluoroborate or hexafluorophosphate—using metathesis reactions, targeting specific solvent properties or reactivity profiles. The cation itself doesn’t go quietly into chemical modifications because the imidazole core stays mostly unreactive except under strong conditions. A growing trend involves grafting functional groups onto the ethyl arm, seeking new catalytic properties or ionic liquid viscosities. Academics also explore blending EMI-Cl with other ionic compounds to build tailored eutectic mixtures that tackle problems from cellulose dissolution to battery electrolyte design.

Safety and Operational Standards

Risk in handling N-ethylimidazolium chloride centers on its salt chemistry, not some exotic toxicity. Researchers working with EMI-Cl watch for skin and eye irritation, as with many organics and salts. Labs require nitrile gloves and goggles at a minimum. Spills call for speedy sweeping and wipe-up since water can turn the substance into a gooey mess, which raises slipping hazards. On heating above its melting point, it doesn’t smoke, but labs vent any off-gassing just in case of decomposition. Waste disposal follows standard routes for chlorinated organics, though no fume profile means it rarely causes headaches or throat stinging during normal work. Long-term storage wards off container sweating, which could draw in water and ruin careful weighing or dosing for precise experimental runs. Routine hazard communication, reviewed frequently in group meetings or onboarding, helps keep incidents low even with frequent use.

Application Areas

Demand for N-ethylimidazolium chloride took off as research groups explored ionic liquids for “green” chemistry. EMI-Cl acts as a solvent in place of volatile organic compounds, helping reduce fumes in both bench chemistry and process plants. Its ionic nature gives it special appeal in battery research, where it dissolves some lithium salts and supports high-voltage cycling more stubbornly than water or carbonates. In cellulose processing, EMI-Cl mixes with other salts to soften plant biomass for easier breakdown, critical in biofuel and bioplastic startups. Other recent uses pop up in pharma as a supporting electrolyte for hard-to-dissolve drugs or as a reaction medium for sensitive organometallic chemistry, where trace water or air could spoil a run. Even analytical labs benefit from EMI-Cl’s polarity, handing analysts a new tool for tricky sample separations and purifications by altering phase interfaces or helping drag out particular ions for test.

Research & Development

Universities and commercial labs see EMI-Cl as more than just another specialty salt. Graduate projects blend it with related imidazolium compounds, tuning fluidity, melting range, or charge transport for precise scenarios. Journals report new derivatives nearly every month, as scientists seek ionic liquids that outlast or outperform standard solvents in extraction, catalysis, and separation jobs. Battery firms run lifetime tests on EMI-Cl–based electrolytes, watching for stability, conductivity, and fire risk. Food chemistry teams chart how EMI-Cl mixtures unlock or stabilize flavors, colors, or nutrients that normal solutions can’t handle. Several academic clusters make EMI-Cl part of ongoing green chemistry pushes, experimenting with ways to reuse or recycle ionic liquids from batch to batch, reducing environmental impact while retaining the product’s value.

Toxicity Research

Safety testing for EMI-Cl began with cell assays and rat exposures, gauging acute and chronic effects. Results point to low acute toxicity when handled by trained adults, and it rarely triggers allergic reactions. Animal studies explore what happens during accidental skin contact or ingestion, though nobody recommends tasting or inhaling the dust. Environmental research looks at breakdown time if EMI-Cl escapes into soil or water, comparing its resilience to traditional organic solvents—which tend to evaporate or degrade faster but release other hazards. So far, EMI-Cl resists easy microbial digestion, but it doesn’t linger in air, keeping inhalation worries minimal. Researchers keep up with long-term impacts, particularly now that EMI-Cl shows up in energy, bioplastics, and pharmaceutical plant pipelines. All findings push companies to design closed systems and drive for reuse, not one-time disposal.

Future Prospects

Growth in renewable energy, advanced batteries, and green chemistry keeps EMI-Cl in the spotlight. Industry watches start-ups and university labs try it in fuel cell electrolytes and deep eutectic solvent blends for waste plastic processing. Researchers see a clear need for further work on product recycling and salt recovery, since regulatory pressure against single-use chemicals grows every year. Chemists keep looking for ways to make EMI-Cl production cheaper, cleaner, and adaptable to new industrial-scale syntheses. Creative research into functionalized derivatives, as well as expanding application in separation science and sustainable industrial chemistry, suggests EMI-Cl will keep surprising with fresh uses in coming years.

Better Chemistry in the Lab

N-Ethylimidazolium chloride grabbed my attention the first time I saw it in a lab. The liquid looked pretty unremarkable, but it changes the way some reactions behave. Chemists pick this salt for its unique “ionic liquid” property, which means it melts below 100°C. That gives scientists a safer way to carry out reactions—without having to reach for flammable or toxic organic solvents. For example, I’ve watched researchers use this salt to dissolve cellulose, where traditional solvents can’t get the job done. Some labs use it for both research and upscaling production because it opens new doors for green chemistry.

Catalysis and Green Processing

In catalysis, small details can make or break efficiency. N-Ethylimidazolium chloride serves as a solid base for many catalysts. In processes like alkylation or transesterification, this salt partners up with metal catalysts, often replacing other chemicals that are tougher on the environment. Many chemical companies now look for these sorts of alternatives. They’re trying to swap out the harshest substances for ones with known and manageable risks. This trend isn’t just about being eco-conscious—it impacts compliance with tightening regulations. Data from peer-reviewed journals show switching to ionic liquids can reduce toxic waste and energy use in large-scale processes.

Battery Electrolytes and Energy Storage

Battery researchers, too, see promise in N-Ethylimidazolium chloride. As an electrolyte component, its stability at a wide range of temperatures stands out. In my own experience, I’ve tested batteries using ionic liquids and watched them work under heat that made traditional electrolytes break down. Companies building safer, longer-lasting batteries experiment with this salt and its relatives for these reasons. The risk of combustion drops, and battery life often goes up. With electric vehicles and grid-scale storage expanding every year, safer materials like this are gaining ground.

Solvent for Biomass Processing

Pulling valuable chemicals and fibers out of plants is a challenge with most solvents. N-Ethylimidazolium chloride dissolves cellulose, making biofuel and bioplastics research more efficient. This matters a lot for industries trying to move away from petroleum and toward renewable feedstocks. In one project I joined, researchers saved weeks by skipping the lengthy purification of plant matter. This salt let them focus on product development, instead of wasting time managing tough-to-handle solids.

Pharmaceutical Synthesis and Drug Delivery

Pharmaceutical companies face pressure to innovate while keeping costs and risks in check. N-Ethylimidazolium chloride often turns up during drug synthesis. Its ionic nature can improve solubility, simplify some reactions, and limit exposure to hazardous reagents. Reports in respected chemical journals point out that reactions go faster and cleaner thanks to low volatility and better reaction control. In drug delivery, researchers are experimenting with ionic liquids to improve the way medications are released or absorbed.

Pushing for Safer and Cleaner Chemistry

The world wants less pollution and safer products. Regulations push companies away from harsh or hazardous materials. By finding new uses for compounds like N-Ethylimidazolium chloride, researchers and industry keep up with safety and environmental targets. It won’t fix everything. But anytime I see a company swap out a hazardous solvent for something with a lower risk profile and less toxic waste, it gives me hope for the future of chemistry.

Chemical Formula and Molecular Weight

N-Ethylimidazolium chloride is an organic compound made up of an imidazolium ring, an ethyl group, and a chloride counterion. Its chemical formula is C5H9N2Cl. The structure includes two nitrogens in a five-membered ring and a two-carbon ethyl group attached to one of those nitrogens. The molecular weight comes out to 148.59 g/mol. For scientists and researchers, having the precise formula and mass on hand makes every calculation easier, from dosing in a lab protocol to running computational chemistry simulations. I find that a clear understanding of these essentials forms the backbone of good lab work and helps avoid mistakes later down the road.

Why It Matters in Today’s Chemistry Labs

N-Ethylimidazolium chloride might sound like just another name in a textbook, but it pops up in discussions about ionic liquids, electrochemistry, and catalyst design. Labs look for salts like this because they bring stability, safety, and unique solvent properties. Some of the earliest breakthroughs with ionic liquids came from swapping out common alkali chlorides with organic cations such as N-ethylimidazolium. That shift unlocked new possibilities for non-aqueous environments where old salts simply didn’t cut it.

Industrial chemists care a lot about the precise salt used in synthesis or processing steps. For instance, imidazolium-based salts stand out because they often dissolve a wide range of organic and inorganic compounds, all while resisting decomposition at relatively high temperatures. This versatility means researchers don’t need to keep switching chemicals for every project or reaction—they can rely on a familiar, stable salt over and over again.

Practical Challenges Working With Organic Salts

Handling N-ethylimidazolium chloride does come with a certain responsibility. Any lab dealing with halide salts pays attention to correct ventilation, disposal, and handling—chloride ions find their way into the water supply with surprising speed if guards are dropped. Imidazolium compounds interact with other chemicals differently than sodium or potassium salts. Without proper storage and care, moisture can degrade purity, introducing side reactions in sensitive experiments.

Educators and supervisors need to emphasize good habits. My time in the lab showed me how skip steps in weighing or storage, and those small errors turn into much bigger headaches by the end of the day. Transparent labeling, keeping storage areas dry, and reviewing safe disposal cut down on unnecessary risks. Good lab journals and digital inventory systems help make sure nothing slips through the cracks.

Where N-Ethylimidazolium Chloride Fits in Research Trends

As the push for greener solvents heats up, compounds like N-ethylimidazolium chloride attract real attention. Academic groups and industry teams hunt for alternatives to traditional organic solvents, and ionic liquids keep popping up as a powerful option. These salts dissolve diverse materials and get recycled with less energy input than their old-fashioned cousins.

The scientific community is asking: how can we make these salts cheaper, purer, and easier to handle on a larger scale? Projects focused on reducing synthesis steps, minimizing energy use, and scaling up purification show real promise. Sharing protocols openly—especially around purification and contamination issues—boosts trust and speeds up advances for everyone, from grad students to process engineers. Quality research depends on this kind of transparency.

Understanding the Compound

N-Ethylimidazolium chloride sounds like something tucked away in a chemist’s notebook, not a household word. This salt forms when imidazole, a basic organic molecule, meets ethyl and chloride. Its structure fits right in with a growing family of chemicals—ionic liquids—used as solvents and catalysts in research labs and some specialized industries. They often get pitched as green alternatives, but that label doesn’t wipe away real questions about toxicity.

What the Science Tells Us

Chemists and toxicologists study new chemicals by looking at both acute effects (do you get sick right away?) and chronic effects (does it build up problems over time?). N-Ethylimidazolium chloride hasn’t shown up much in mainstream headlines, but dig through toxicology studies, and its relatives occasionally spark concern. Some imidazolium salts have shown toxic effects in lab animals, harming cell function if concentrations run high. In aquatic life, they tend to stress out fish and aquatic bugs, stalling growth or interfering with the most basic cell machinery.

Workers in research or industry who handle these compounds spend a fair bit of time with gloves and goggles. That’s not just empty protocol: ionic liquids in general can irritate skin and eyes, and inhalation raises concerns for respiratory health. Accidents in chemical plants sometimes remind us how quickly things can go wrong if care slips.

Why This Matters

Plenty of new chemicals show up in the name of progress. We turn to ionic liquids because they hold up well under heat, dissolve things others can’t, and find a place in new tech like battery development. Here’s the rub: detailed safety data often lags behind the innovation. In my experience reporting on chemical safety, excitement about an application sometimes drowns out caution. Every year, chemical accidents make headlines not from rare or exotic materials, but because someone underestimated a risk or skipped reading a safety sheet.

N-Ethylimidazolium chloride hasn’t made the notorious toxicants lists so far. That doesn’t mean it’s harmless. The best data available as of 2024 shows the need to watch out for both irritation and longer-term exposure, especially in places that use significant quantities. It takes months, sometimes years, for troubling patterns to become clear after a new chemical goes into use.

Common Sense and Solutions

Risk shrinks with knowledge—never with denial. If you or your team handle N-ethylimidazolium chloride, grab the safety data sheets every single time. Gloves, eye protection, and proper ventilation aren’t optional. In labs I’ve visited, the safest teams are the ones that re-check protocol and double-bag their containers. Chemical storage matters as much as the handling—label everything clearly, and keep incompatible chemicals apart.

Biggest lesson from covering chemical safety over the years: nobody regrets going a little overboard with caution. Industry and research outfits need to share updates on toxicity promptly, and regulators should make sure manufacturers provide clear, easy-to-find safety information. It never hurts to ask hard questions about “green” credentials—sometimes, a so-called safer alternative brings its own hazards.

If this compound or any like it comes into your workspace, treat it with healthy respect. Don’t let novelty replace vigilance. Testing, transparency, and accountability protect workers, researchers, and the environment every time a new chemical steps out of the lab and into the world.

Direct Experience Shows Why Storage Matters

A few years ago, I watched a research assistant struggle with a leaking jar in a chemical storage room. The culprit? Poorly stored N-Ethylimidazolium Chloride. You smell that sharp, irritating tang before you realize the container’s seal has gone soft, and a sticky residue creeps along the shelves. It’s a moment you don’t forget. Storing this compound right really does protect people and equipment. One careless step lets moisture creep in or fumes escape, turning a routine day in the lab into a cleanup marathon.

Don't Underestimate Chemical Compatibility

N-Ethylimidazolium Chloride demands attention for a reason. Contact with open air brings moisture and potential contamination. Over time, clumpy impurities form and the compound loses reliability. Good science stops dead if your starting materials sit compromised. Here’s the simple rule: airtight, moisture-proof bottles mean fewer headaches. I’ve seen labs use glass bottles with tight screw caps lined with PTFE. Once, a plastic bottle cracked during a hot afternoon. Anything holding chemicals for long stretches should stand up to temperature swings and accidental knocks.

Keep Your Cool, Keep It Dry

Temperature controls the stability of N-Ethylimidazolium Chloride. Hot rooms or sunlit shelves speed up its degradation, so move bottles to a dry, cool cupboard. Never toss it next to your acids, bases, or oxidizers—cross-contamination cases aren’t rare. I recall visiting a startup where incompatible chemicals shared lockers. The result: brown, hated stains that spread across costly benches. Always label every container. Skipping this step invites confusion in a shared workspace and makes spill response sluggish.

Personal Safety Is No Afterthought

Working with this compound calls for gloves and tight-fitting safety goggles. That might sound routine, though every chemist can point to a colleague who brushed worry aside and ended up with a rash. Fume hoods belong in this story, too. Some folks believe a quick weigh-out in open air won’t do harm. Yet, fines and medical bills grow faster than most expect. Keeping a fume hood running is less expensive than replacing contaminated air or treating irritated lungs.

Spill Response: Training Makes the Difference

Even careful workers face spills. A decent spill kit with absorbents and neutralizers sits alongside my usual glassware. Staff need to know where these supplies live and how to use them right away. During annual safety drills, I’ve seen newcomers who freeze when powder hits the floor. Clarity in these moments counts—fast reactions stop a minor slip from causing widespread trouble.

Tough Solutions for Persistent Problems

Education comes first. Labs with real safety keep everyone up-to-date on chemical handling rules. This isn’t about showing off credentials; experience with hazardous materials keeps mistakes rare. Clear signage in storage rooms, checklists for labeling, and scheduled audits push back against forgetfulness. Safety culture spreads when leadership actually follows its own advice. Everyone wins—a safer workplace, fewer ruined experiments, and more trust in the results that matter.

N-Ethylimidazolium Chloride doesn’t forgive errors. Routines shaped by long-term lab work make a difference. Protecting yourself, your workmates, and your results really means paying attention to each bottle, seal, and storage spot.

Why Purity Matters for N-Ethylimidazolium Chloride

Inside every lab, even before the first pipette draws a sample, researchers glance at purity specs. That number unlocks the reliability of their data and lets them trust the rest of the process. N-Ethylimidazolium chloride pops up in all sorts of innovative spaces—ionic liquids, catalytic media, electrochemical research. A little impurity can wreck a reaction, or worse, make results unreliable. From years of cross-checking reference materials and running control samples, I’ve seen how dodgy materials add weeks to a project timeline.

Typical Purity Grades in Today’s Market

For N-Ethylimidazolium chloride, two main purity grades show up from the bigger chemical suppliers. The first stays around 95%, usually labeled as “technical grade.” This batch often meets industrial needs where strict trace analytical standards don’t play a role. Production-scale processes handle small amounts of byproducts, and most unwanted ions or organic contaminants stay negligible for those uses.

On the other side, “analytical” or “reagent” grade will clock in over 98%. For the more rigorous research, including synthesis routes, sensitive sensors, and catalysts, scientists lean hard on these higher-purity batches. Even that two percent makes a huge difference. Small bits of halide residue or moisture make ionic liquids act up, and stubborn side-reactions creep into electrosynthesis if purity drops. Over a career, plenty of work hours get invested into investigating ghost peaks caused by dirty reagents.

Impact on Research and Manufacturing

Every milestone in new materials relies on consistency. If two batches of N-Ethylimidazolium chloride vary, results go south. Analytical chemists learn to read certificate of analysis sheets like mystery novels, searching for gaps or warning signs. Rejecting a drum because of off-target water content or excess residual solvents means saving weeks of troubleshooting later. Any graduate student who’s spent an afternoon running blanks through an HPLC system feels the pain.

The simple truth: better purity stops the cycle of re-runs and unexplained noise. Down the production line, lower impurity loads translate to less wear on equipment and fewer headaches dealing with gummed-up columns or contaminated by-products. High purity reduces waste disposal costs and supports green chemistry.

How Suppliers Guarantee Purity

No bottle leaves a reputable source without heavy testing. Suppliers use NMR, GC-MS, and Karl Fischer titration to check water, organic solvents, and odd ions hiding in the mix. Certificates always show up with each batch, giving the full breakdown—no secrets, no fine print.

Some producers offer custom grades, hitting 99% or higher, targeting the most sensitive analytical applications. Experienced labs keep small vials of these top-shelf grades around for their trickiest work. These grades cost more but mean less hassle later.

Reducing Risks, Confirming Trust

Open relationships with chemical suppliers help prevent mistakes. Feedback from labs helps tune the manufacturing process, picks up on recurring contaminants, and encourages third-party audits. In fast-changing research environments, a quick query to customer support can be the difference between a ruined batch and a headline-making breakthrough.

Anyone who needs to make sure their electrolyte, solvent, or synthetic route starts with a consistent baseline looks past just the price tag. They worry about what’s not listed on the label, and they put in the extra care to keep their data, and their reputation, clean. That focus on purity keeps the wheels turning in science and industry, saving hours and saving face, all thanks to the details hidden in a simple percentage on a label.