N-Ethylpyridinium Dicyanamide: Insightful Review and Practical Perspectives

Historical Development

Back in the late twentieth century, chemists explored ionic liquids in the search for safer and more adaptable solvents. Among this cluster, N-Ethylpyridinium Dicyanamide caught attention for a balance between ionic structure and relative thermal stability. While many ionic liquids before suffered from hydrolysis or narrow liquid ranges, this compound arrived as a contender to address those gaps. Over the years, both academic and commercial labs have scrutinized its synthesis, with incremental modifications always circling around purity, environmental footprints, and scalability. Patents reflect a steady pour of innovations, especially from the early 2000s, as researchers challenged themselves to control not only side reactions but also batch-to-batch uniformity with the growing need for reproducible results.

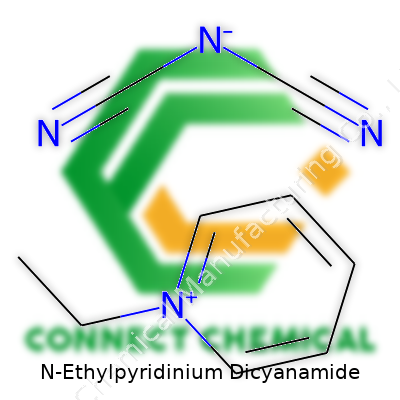

Product Overview

N-Ethylpyridinium Dicyanamide, known by other names like 1-Ethylpyridinium Dicyanamide or abbreviated as [EtPy][DCA], belongs to ionic liquids boasting low volatility and distinct solvating abilities. Producers supply it both in lab-grade for synthesis and higher-purity batches for sensitive industrial steps. In day-to-day lab use, you’ll find it as a colorless to pale yellow liquid. Its ionic nature lends both a unique range of compatibility with organic and inorganic substances and a footprint that differs from the high vapor pressure solvents so common in the past.

Physical and Chemical Properties

Holding a molecular formula of C8H10N4, the compound weighs in around 162.19 g/mol. At room temperature, it remains liquid, melting at roughly -10 to -5°C, and boiling well past 200°C without significant decomposition. The hazard of inhalation or rapid combustion remains low compared to volatile organics, thanks to negligible vapor pressure. Solubility stretches towards water, alcohols, and some non-polar organics, letting it navigate both polar and apolar environments. Its dicyanamide anion resists hydrolysis even in humid conditions, defying the sensitivity that often plagues less robust ionic compounds. While thermally stable, strong acids or oxidizers churn out rapid reactions, calling for careful separation protocols.

Technical Specifications & Labeling

Suppliers direct attention to purity, specifying minor contaminants at no more than 0.1%. Labels feature hazard symbols flagging eye and skin irritancy, and manufacturers often issue technical sheets emphasizing storage under inert or dry gas to lengthen shelf life. Product documentation covers melting and boiling data, density values (typically hovering about 1.1 g/mL at 20°C), plus both CAS number and batch analysis for every shipment. For larger scale operators, suppliers will draft extra paperwork regarding shipment under the UN 2811 regulations, if applicable, due to the dicyanamide moiety.

Preparation Method

In labs, preparation flows from quaternization of pyridine with ethyl bromide, giving N-ethylpyridinium bromide. After dissolving in water, this intermediate receives an aqueous stream of sodium dicyanamide. Metathesis kicks in, yielding the target product and precipitating out sodium bromide, which can be removed via filtration. Purification involves extraction and drying over anhydrous salts, repeated until both water and inorganic halides no longer pose a risk. Full-scale manufacturers automate much of this, employing inline conductivity checks and solvent recycling setups to shrink environmental burdens while bolstering reproducibility when meeting market demand.

Chemical Reactions and Modifications

The dicyanamide anion, rich in nitrile groups, opens avenues for multi-electron exchange, sometimes pairing with transition metals in catalysis. Substitution on the pyridine ring itself allows developers to fine-tune solubility or reactivity. While mostly stable below 250°C, vigorous heating or strong electrophiles prompt degradation to cyanide traces—a red flag for waste management. Research outfits sometimes graft the ethylpyridinium cation to different functional groups, testing performance as co-catalysts in organic syntheses or searching for less toxic analogs for specialized roles in materials science.

Synonyms and Product Names

Beyond N-Ethylpyridinium Dicyanamide, chemists toss around titles like Ethylpyridinium Dicyanamide, 1-Ethylpyridinium Dicyanamide, and [EtPy][DCA], cropping up in catalogues from Sigma-Aldrich to TCI. Synonym confusion sometimes muddies literature searches, especially as alternative spellings or abbreviations emerge in patents. A consistent labeling framework helps cut through, especially vital as industrial uptake expands and traceability demands sharpen.

Safety and Operational Standards

While N-Ethylpyridinium Dicyanamide dodges the volatility headaches of typical organic solvents, it doesn’t dodge health scrutiny. Direct skin or eye contact leaves irritation, and spill management means gloves, goggles, and lab coats as basic kit. Laboratories enforce indoor air handling, and Material Safety Data Sheets point out not just acute hazard factors but special instructions for accidental release, waste collection, and spill neutralization with basic sorbent media. Waste policy beyond the benchtop means incineration with flue gas treatment, since breakdown can generate nitrogen oxides or traces of cyanides which raise environmental red flags.

Application Area

Research circles see N-Ethylpyridinium Dicyanamide in electrodeposition processes, especially for metals that struggled with legacy solvents due to environmental or conductivity constraints. Paint laboratories often turn to it for templating, finding it imparts structural advantages to polymer films. In catalysis, the dicyanamide piece helps bind and stabilize transition metals, lending itself to both homogeneous and heterogeneous phase reactions. More recently, battery research leverages its ionic conductivity and thermal resilience, particularly as a potential non-flammable electrolyte for next-generation systems. Academic groups keep revisiting it, spurred by the lure of safer, more robust materials in manufacturing or resource extraction where old solvents draw regulatory concern.

Research and Development

In my own experience hunting for solvents that won’t blow up at modest heating, ionic liquids like N-Ethylpyridinium Dicyanamide show a lot to recommend them. Whether screening compounds as replacement process fluids for pharmaceutical separations or tweaking conditions in catalysis, researchers hunger for wider liquid ranges, suppressed vapor emissions, and resilience to water or mild acids. Recent R&D pushes hit both ends — low-scale laboratory trials refining purification, and big-firm industrial pilots testing process integration. Partnerships emerge between companies and universities tracking downstream implications such as recyclability, degradation pathways, and worker exposure. Grants and patent filings show a focus on pushing the banality out of “green chemistry” arguments by giving clear, scalable routes to safer production.

Toxicity Research

Early animal data clocks acute oral LD50 values at the millimolar range, pointing towards modest acute toxicity. Chronic studies linger in the shadows but suggest metabolic instability may yield nitriles or ammonia after prolonged exposure. Eye and dermal irritation, as flagged on product sheets, grew out of both anecdotal lab incidents and controlled tests, so any new application calls for tailored risk assessment. Waste workers and environmental bodies keep a close eye on spill scenarios, since containment or improper incineration yields nitrogenous gases, including some not easily scrubbed with standard fume hoods. In regulatory spaces, risk communication steers attention toward engineering controls as the front line of defense — building safe habits and reinforcing why “inert and harmless” isn’t a useful stance simply because vapor pressure stays low.

Future Prospects

Looking forward, N-Ethylpyridinium Dicyanamide’s versatility signals more than a passing trend. Sustainability laws challenge the chokehold of halogenated organics and greasy aromatics in industrial spaces, and ionic liquids bring both practical and regulatory breathing room. Battery and fuel cell researchers chase the next leap in safe, stable electrolytes, and this compound remains on shortlists for field trials. The open challenge still hangs over cost: raw materials, purification steps, and end-of-life management, each of them needing tweaks for a more solid business case. In education, more labs introduce these compounds early to build hands-on safety skills and inform future R&D. As new generations face tougher restrictions on both workplace exposure and planetary impact, chemicals like N-Ethylpyridinium Dicyanamide shift from the fringe to mainstream, serving as both practical workhorses and springboards for smarter design in the chemistry of tomorrow.

A Close Look at Its Real-World Applications

N-Ethylpyridinium dicyanamide may not grab the headlines like new battery breakthroughs or the latest tech device, but its impact quietly influences industries pushing for safer, greener processes. My career spent exploring specialty chemicals makes it clear: the choices behind the scenes shape what is possible in both research labs and manufacturing plants.

Green Solvents in Modern Chemistry

This compound gained real attention as a component in ionic liquids. Traditional solvents raise several safety alarms—flammability, toxicity, and significant environmental fallout. Chemists look for replacements that work harder without adding risks. N-Ethylpyridinium dicyanamide forms stable ionic liquids, offering reduced volatility and a lower threat of fire. These properties sit high on the checklist of labs trying to keep pace with stricter workplace safety rules.

In my own experience, labs have swapped hazardous organic solvents for ionic liquids, using compounds like this one to extract metals, break down cellulose, and run sensitive reactions for pharmaceutical synthesis. Compared to familiar solvents, these mixtures allow for easier recycling and reuse. Fewer liquid drums piling up in storage and less worry about accidental exposure changes lab culture. Scientists want results, but they want to make it home safe as well.

Batteries and Energy Storage

Engineers and chemists love to point to battery efficiency as the key to a sustainable future. N-Ethylpyridinium dicyanamide helps create electrolytes with expanded voltage ranges and improved thermal stability. Some types of lithium-ion and next-generation batteries use ionic liquids based on this compound. Safer electrolytes reduce the chances of fires in electric vehicles and electronic devices, a concern I hear about often from folks working on new transportation tech. Now, it’s common to see startups experimenting with modified dicyanamide salts trying to squeeze out another few hours of battery life or improve the charging speed.

Environmental and Catalytic Processes

Research into wastewater treatment and pollutant removal leans on the selectivity offered by ionic liquids. Chemists who specialize in rare earth and valuable metal recovery use this compound’s unique blend of physical and chemical stability. For instance, copper and gold extractions work better with these solvents, slashing the number of hazardous byproducts. I remember fieldwork at a mine that showed how effective these approaches have become. Cleaner separation left less mess behind, satisfying regulators and environmental groups alike.

Catalysis sits at the heart of many large-scale chemical plants. N-Ethylpyridinium dicyanamide’s ionic nature improves yields for reactions that once depended on strong acids or bases. Reducing harsh reagents means fewer corrosive spill cleanups and less wear on expensive equipment. Operators spend less, and downtime shrinks.

What’s Down the Road?

More teams are tweaking dicyanamide-based ionic liquids, targeting biofuel production and carbon capture efforts. Field results from pilot projects suggest improvements in both cost and environmental footprint. Investment follows practicality—companies will keep pushing for chemicals that deliver performance and make compliance easier.

Access to safer and more efficient chemicals like N-Ethylpyridinium dicyanamide shapes what’s possible in research and product development. Getting to know its uses helps everyone—researchers, workers, and end-users—see the value in quiet chemical innovation that often goes unseen but rarely goes unfelt.

The Building Blocks

N-Ethylpyridinium dicyanamide pulls together a familiar molecule, pyridine, and blends it with something a little less common: the dicyanamide ion. Anyone who has worked with pyridine knows its sharp smell and unique role in organic chemistry. Here, the nitrogen of the ring grabs onto an ethyl group, becoming N-ethylpyridinium. This cation looks like a benzene ring with a nitrogen atom — swap one hydrogen out and attach an ethyl group to that nitrogen. The formula for N-ethylpyridinium becomes C7H10N+.

On the other side, dicyanamide brings a different kind of chemistry. It gives up hydrogen, picking up a negative charge in the process. Picture two cyano groups attached to a single nitrogen: N(CN)2- or C2N3-. It’s a long, skinny ion with a twist of triple bonds, making the negative charge easy to share.

Piecing Together the Salt

In the lab, folks combine these two to get a salt — N-ethylpyridinium dicyanamide. The formula for the full salt is C7H10N+•C2N3-, or written fully, C9H10N4. Draw the structure out and you’ll get a pyridine ring bearing an ethyl group on the nitrogen, balanced by the dagger-shaped dicyanamide. This salt belongs to a class now recognized for their strange behaviors — room temperature ionic liquids that almost feel oily and resist crystallizing like table salt.

Why the Details Matter

Structure matters most once people start thinking about purpose or application. For chemists eyeing green chemistry approaches, ionic liquids sound attractive. N-ethylpyridinium dicyanamide, with its slippery consistency and low volatility, finds a place as a solvent, an electrolyte, or even a catalyst booster for some reactions. Many common organic solvents end up lost to the atmosphere or stick with toxic residues. The salt’s structure keeps it liquid at room temperature, so it doesn’t evaporate or pollute like solvents of the last few decades.

Over the last ten years, research looked closely at dicyanamide’s effect on the environment. The anion, flexible and unusual in charge distribution, can sometimes resist breakdown. Studies out of Germany and Japan find that, compared to halide-based ionic liquids, those with dicyanamide show less tendency to bioaccumulate. That means the risk of building up in soils, plants, and organisms remains smaller, though not completely absent.

Troubles and Approaches

Safety data calls for gloves and eye protection — the salt can irritate, and the dicyanamide group needs careful handling. In university labs, staff keep spills off shared benches and flush waste to specialized disposal rather than a regular drain. Synthetic chemists sometimes tweak the pyridinium ring or swap dicyanamide for greener alternatives. Swapping different alkyl groups onto the pyridine gives them ways to control melting point, viscosity, or even ionic conductivity.

Out in industry, compliance teams push for salts that won’t leak into waterways or break down into anything hazardous. Researchers develop enzyme and bacterial treatments to break up dicyanamide, and early signs show some promise — but the pace lags behind adoption. Working with these chemicals calls for more than trust in formulas; folks need thorough study, hands-on testing, and open sharing of results.

Outlook

N-Ethylpyridinium dicyanamide brings a lot to the table for scientists seeking alternatives to classic solvents. Careful scrutiny of structure shows why it acts the way it does, where it excels, and where its limits show up. It pays to keep the eyes on both the reaction flask and the local water supply before these new salts move from lab to market in a big way.

Understanding Real Risks

N-Ethylpyridinium dicyanamide shows up more in discussions around research labs and chemical synthesis than on any household supply list. Still, the dangers don’t care about familiarity; this compound brings real risks. The dicyanamide part can release hydrogen cyanide, especially if it ends up in contact with strong acids or if it burns. Unlike working with table salt or vinegar, a slip-up with this stuff brings immediate consequences. Take it from anyone who’s ever dodged a chemical splash or caught a whiff of something they shouldn’t have—they remember it all their lives.

Gloves, Goggles, and Beyond

Personal protective equipment makes a difference. Not all gloves do the job. Standard latex can melt with solvents and leak harmful stuff. Get your hands into nitrile or butyl rubber gloves instead, and double up if a splash seems likely. Forgetting goggles once turned a friend’s chemistry session into an ER visit. Keep those goggles on. The eyes heal slowly, if at all, after chemical burns.

A disposable lab coat and a face shield go even further. Clothes with an open weave or bare skin under rolled sleeves never belong near active handling. Shoes with solid tops, not sandals, close the gap. Safety rules like this aren’t just for chemical hygiene officers—they’re for anyone who values their eyesight and hands.

Ventilation Isn’t Optional

An open window doesn’t move air the way a real fume hood does. Fume hoods pull vapors away from your breathing zone, piped straight out where they belong. The old trick of “working quickly” or “only a small amount” doesn’t cut it here. If an accident brings a spill or if the dicyanamide decomposes, the air inside a closed room fills up fast. Symptoms from inhaling cyano compounds don’t give much warning before the headache, confusion, or worse set in.

Handling and Storage

N-Ethylpyridinium dicyanamide deserves real respect in storage and handling. Keep it dry, away from heat, sparks, and especially away from acids or strong oxidizers. Leaky containers have caused more than a few panicked evacuations in shared lab spaces. Store it in a labeled, tightly closed chemical-resistant bottle. The label deserves bold print and hazard warnings—not just “Compound #17.” Even a sleepy lab partner knows what’s at risk then.

Tidy Work, Fast Cleanup

Careless habits add up. Wipe down surfaces right after finishing, and don’t leave tools unwashed on counters. Collect any spills right away using material designed for cyanide chemicals, not just paper towels. Used gloves, wipes, and broken glass all go into a chemical waste bag, not in ordinary trash. Regular training helps refresh safe techniques; everyone in a shared space should feel empowered to call out shortcuts and ask for backup.

If Trouble Strikes

Emergency stations matter—the eyewash, safety shower, and emergency phone should be easy to reach, not blocked by boxes or carts. Anyone on-site for hazardous work should know how to sound an alarm and get help if a spill or exposure happens. Creating that strong safety culture isn’t a checklist, it’s a shared promise between colleagues.

Moving Forward

Smart labs apply the lessons from close calls and near-misses. Clear protocols, continuous training, and real investment in safety gear shape the path toward handling even tough hazards with confidence. No experiment or shortcut is worth the cost of a health scare. Taking care today means getting to do the science again tomorrow.

Handling Chemicals Isn’t Just a Lab Task

Chemical safety covers more than goggles and gloves. It’s about respect for the stuff on the shelf. Someone in the lab once tried to squeeze another bottle onto an already over-crowded shelf, and it led to a dropped beaker and a pretty expensive afternoon. Storage isn’t a checklist item—it sets the tone for everything that comes after. N-Ethylpyridinium Dicyanamide, with a name only a chemist loves, deserves a share of that focus.

What Makes This Compound Special Enough to Talk About?

This chemical features a dicyanamide anion—a configuration known for reactivity. Anyone who’s handled substances like it knows that reactivity isn’t just for the textbook; a little humidity or light can change its behavior. Dry, dark places work wonders for stability. I’ve seen bottles left on sunny windowsills in shared labs, only for the contents to clump or degrade. Top shelves near heat vents do no one any favors either.

Simple Rules That Go Far

A cool, stable environment helps prevent unwanted reactions. Too much heat gives molecules extra kick to break apart—no good for long-term storage. I always look for spots away from direct sunlight and those sneaky sources of warmth hiding behind shelves or near equipment.

Humidity tells its own story. Even small leaks in a cap allow moisture to sneak in. Desiccators work, silica gel packs provide an easy backup, and tight-sealing bottles lower the risk of water drifting inside.

Materials Matter

Glass offers a clear edge. I’ve used plastics before, but not all plastics stand up to more reactive chemicals. Some turn color, some turn brittle. With sensitive compounds, staying away from plastic lessens the risk of leaching or breakdown. Label that jar clearly; faded ink is a guaranteed headache if a spill ever happens or the shelf gets rearranged. Everybody in the lab should know what’s inside before picking it up.

Contamination Isn't Just About Dust

Cross-contamination often happens when folks move between projects too quickly. Dedicated spatulas, pipettes, and gloves help avoid mixing strong compounds. In a busy lab, I’ve seen mistakes turn minor labs into cleaning marathons. Having a storage plan, and sticking to it, cuts those risks in half. Using secondary containment—like storing the main bottle inside a larger container—adds an extra layer of protection in case something leaks or tips.

Regulations and Training

Legal rules for storage are strict for a reason. Safety Data Sheets aren’t decoration—they lay out temperature limits and things to never store alongside each other. It takes five minutes to double-check the documentation, and that’s a practice worth keeping. My best learning moments in the lab came not from a professor’s lecture, but from seeing a label out of place and digging into what belonged where.

Small Steps Prevent Big Problems

Proper storage feels routine until it isn’t. Over the years, the most careful spaces share a common habit: a culture of putting materials away right every time. Buddy checks, standard logs, and a dry, labeled glass bottle take care of most issues before they start. Labs run smoother, budgets stretch further, and people stay out of harm’s way. Storage, at its best, shows care for the whole process, not just the chemical.

Understanding Purity: Why It Matters

Working in research and development, I’ve learned that the success of a project often hangs on the purity of chemicals used. N-Ethylpyridinium dicyanamide, an ionic liquid found in multiple fields—from electrochemistry to organic synthesis—shows this principle in action. Checking the certificate of analysis serves as the first step for anyone ordering this compound. Labs and industry players usually find grades offering at least 98% purity, with trace metals and water at low ppm levels. Too many impurities may cause side reactions or noise in analytical instruments, so buyers lean toward higher purity even if that sometimes brings a slightly higher price tag.

Available Grades: What Labs and Industry Use

Suppliers, from Sigma-Aldrich to TCI and niche producers in Europe and China, keep a close grip on quality. Most offer a standard 98% purity, which already covers the vast majority of applications. For customers running sensitive chromatography or battery research, some companies add extra purification steps—these lots reach 99% or more. The main challenge here: higher purity brings a higher cost, and handling these grades often requires clean-room conditions because this compound loves to absorb moisture from the air.

Curiosity from my own lab work taught me to call vendors for full breakdowns: chloride, sodium, other alkali metals, water, and organic impurities pop up in the most recent quality sheets. Sometimes specific end-uses, such as quantum computing materials or electrolytes for supercapacitors, push teams to order custom batches filtered through additional processing. Yet, for most chemical synthesis or proof-of-concept research, the 98% grade works just fine—a good balance of cost, safety, and function.

Packaging Sizes: Adapting to Different Needs

Packaging size isn’t just a line in a catalog; it shapes how material blends into a workflow. For research and proof-of-concept studies, small bottles—10 grams, 25 grams, up to 100 grams—are the usual pick. These bottles often come with moisture-resistant seals and sometimes double bags, since this salt absorbs water fast enough to ruin weeks of planning.

Scale-ups or industrial users grab larger containers: 500 grams, 1 kilogram, or even 5 kilograms. In my time ordering bulk amounts for pilot projects, weighty, airtight HDPE bottles or aluminum-lined drums arrived packed with enough silica gel to keep the Sahara dry. This focus on tight sealing isn't just about keeping up appearances—moisture can break down both the container and the compound, making smaller and more secure sizes a better fit for many users.

Addressing Issues: Supply Chains and Handling

Quality doesn’t stop at high-purity synthesis. The wider supply chain also raises hurdles: raw material inconsistency or weak packaging might trip up research or push costs. I’ve seen colleagues turn to new vendors after a single batch brought disappointing results. Honest conversations with suppliers about quality assurance, transit stability, and shelf-life help avoid headaches in the long run.

One potential fix: more transparent documentation and standardized reporting on both purity and packaging conditions. If suppliers list every trace impurity and freshness factor, buyers can compare apples to apples and dodge surprises. Pushing for better transparency aligns with Responsible Care values and supports safer, smarter science across industries.

Supporting Knowledge and Safety

Access to clear safety sheets and real-world advice aids newcomers navigating N-Ethylpyridinium dicyanamide, especially before scaling up. Strict labeling, solid documentation, and training around handling large packs keep accidents rare. As more applications for this salt take shape, everyone from procurement managers to lab assistants wins when suppliers lead with trust, clarity, and open conversation.

Resources:- Sigma-Aldrich Product Data Sheet

- TCI Chemical Certificates of Analysis

- OECD Guidance on Chemical Safety and Documentation