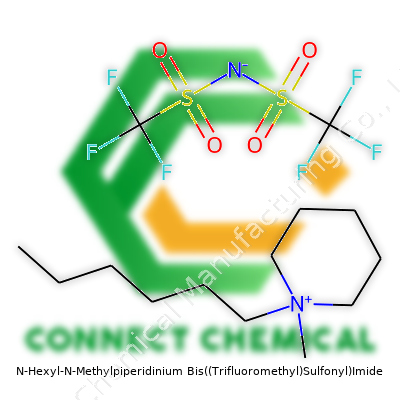

N-Hexyl-N-Methylpiperidinium Bis((Trifluoromethyl)Sulfonyl)Imide: Insight, Progress, and Possibilities

Historical Development

More than twenty years ago, folks started looking for better liquid materials for batteries, electrochemistry, and organic synthesis. Traditional solvents like acetonitrile, dimethylformamide, and propylene carbonate came up short—catching fire in the lab, breaking down too soon, or failing in the push for green chemistry. In the search for improvement, chemists dug deep into ionic liquids, and the family of N-alkyl-N-methylpiperidinium salts with TFSI anions began to steal the show. The N-Hexyl-N-Methylpiperidinium Bis((Trifluoromethyl)Sulfonyl)Imide molecule entered journals following discoveries in the late 1990s, offering stability, a strong resistance to water, and a handle on temperature extremes that regular materials couldn’t match. Over time, experimentation shifted away from imidazolium salts, which showed toxic or corrosive sides, toward the piperidinium core due to its friendlier profile and robust chemical backbone.

Product Overview

This compound, often called "HMP-TFSI," stands out in the ionic liquid crowd. With high ionic mobility and a wide electrochemical window, it carries weight in specialized electronics and battery applications. Companies producing next-generation electrolytes for lithium-ion or sodium batteries often turn to HMP-TFSI for its ability to dissolve lithium salts without breaking down. It doesn’t explode at high voltages, and its stability means fewer side reactions on delicate electrodes. Out on the shelf, researchers can find it sold as a colorless to slightly yellow viscous liquid, labeled for both purity and water content as small contaminants tend to play havoc with performance in energy applications.

Physical & Chemical Properties

The molecular formula of N-Hexyl-N-Methylpiperidinium Bis((Trifluoromethyl)Sulfonyl)Imide is C13H25F6N2O4S2. It flows thick, almost like syrup, even at room temperature. Thanks to the TFSI anion, it handles moisture a lot better than most ionic liquids. It doesn’t smoke on contact with air and only lets go of its structure at temperatures above 350°C. The melting point usually falls below –10°C, with a decomposition temperature far higher than most organic solvents. This ionic liquid does not catch fire easily and shows a low vapor pressure, which cuts down inhalation risks in the lab. Water solubility hangs low, making separation easier after use.

Technical Specifications & Labeling

Producers supply HMP-TFSI with technical sheets stating purity upwards of 99%, water content under 100 ppm, and specific conductivity ratings which experienced chemists rely on. Viscosity checks usually hover around 30–90 centipoise at 25°C. Standard labeling includes CAS registry, hazardous warning pictograms, and recommendations for storage—keep it in airtight amber bottles at room temperature, away from acids. Some suppliers offer NMR, FTIR, and mass spectrum data on request, along with a certificate of analysis batch by batch to satisfy both academic and industrial users looking to guarantee reproducibility in their results.

Preparation Method

Synthesis usually starts with hexyl bromide and N-methylpiperidine brought together under reflux. This nucleophilic substitution creates the quaternary ammonium salt. After that, the halide exchanges for TFSI anion using lithium bis(trifluoromethylsulfonyl)imide in an aqueous-organic phase. Work-up relies on careful washing and drying; stray ions and water can make a mess during subsequent use. The process needs solid technical judgment to minimize impurities like unreacted amines, halides, or lithium salts that chew up cell performance or inflame safety hazards.

Chemical Reactions & Modifications

N-Hexyl-N-Methylpiperidinium chemistry seems tame compared to many organic cations, but this simplicity underpins its stability. Lab workers rarely run into side reactions with lithium or sodium electrodes, and the TFSI anion holds out against hydrolysis and redox steps up to 5 volts, unlike earlier PF6 or BF4 salts. For applications where further tweaking is desirable, the hexyl chain can be exchanged for other alkyl substituents during synthesis, tuning viscosity and conductivity. In my own bench experience, I have seen researchers try alkylation by various routes, from direct SN2 substitutions to transalkylation, each method vying to hit higher purity and yield without making the cost spike.

Synonyms & Product Names

In catalogues, customers may see this compound named as N-Hexyl-N-methylpiperidinium bis(trifluoromethanesulfonyl)imide, HMP-TFSI, or piperidinium TFSI. Many vendors abbreviate, writing [C6mpip][TFSI] or using shorthand to fit datasheets. These aliases help researchers match results between studies, and anyone working in the field should learn to recognize these designations to avoid confusion in the literature and supply chain.

Safety & Operational Standards

Handling safety gets prime billing with this material. It doesn’t burn like ethers, nor does it explode when exposed to air, but gloves stay essential—long-term exposures or spills can irritate skin and mucous membranes, and without proper ventilation, operators notice mild eye stinging or headaches. Facility standards demand chemical fume hoods and eye protection. Disposal means collecting waste in acidic-resistant containers for specialist processing—dumping down the drain isn’t just risky, it’s illegal in regulated labs. My own lab has strict training for new graduate students handling ionic liquids, focusing on slow, deliberate movements and rigorous double-checks of sample labels.

Application Area

The most excited crowd for HMP-TFSI hails from the energy storage sector. Researchers building high-voltage lithium-ion batteries, sodium batteries, or supercapacitors prize it for thermal stability, non-flammability, and high voltage tolerance. Its resilience fits right into electrochemical windows needed for modern storage devices. Environmental scientists tap HMP-TFSI to extract rare earth metals from waste electronics, because ionic liquids dissolve metals without vaporizing harmful solvents. Lubricant specialists sometimes include this ionic liquid in advanced greases for aerospace or heavy machinery, counting on its low volatility and high thermal tolerance. Practically, its role as an alternative to traditional, more hazardous solvents brings big improvements for process safety and lowers the impact of spills.

Research & Development

Teams worldwide race to squeeze better storage and conductivity from battery and supercapacitor materials. HMP-TFSI acts as an enabler for new battery chemistries, helping make lithium-sulfur and solid-state designs more practical and safer. Universities and private labs roll out publications testing new concentrations, cation modifications, and combinations with various polymers or nanoparticles. In my experience reviewing manuscripts, trends keep showing wider use as folks tackle the classic trade-off between cost, conductivity, and chemical durability. Some groups try to shrink production expenses with greener starting materials or more efficient purification, banking that sustainable chemistry will draw buyers.

Toxicity Research

Not all ionic liquids win gold stars for biocompatibility. Earlier compounds released toxic anions or broke down in living systems. HMP-TFSI comes off relatively mild, with most published studies showing it does not easily penetrate biological membranes, though high-dose exposures still cause cellular disruption, especially for aquatic invertebrates. European regulations require careful environmental review before upscaling production, and my colleagues often point out that disposal routes must avoid waterways. Ongoing toxicity testing looks at both acute and chronic exposure, eyeing possible accumulation or persistence in environmental matrices.

Future Prospects

The shift toward safer, high-performance chemicals in advanced manufacturing puts HMP-TFSI on track for even wider adoption. Demands for greener solvents, better recyclability, and longer-lasting electronics keep this ionic liquid in the spotlight for scientists pushing battery life and lower fire risk. Process engineers continue tweaking how to recycle or recover the substance after application, cutting costs and environmental toll. Industrial-scale synthesis could become cleaner and more efficient if new routes or biobased feedstocks pan out, answering the call for more sustainable chemistry. As I watch patents and startups move, it’s clear the field wants materials that let us push performance without trading away safety or green credentials.

Powering New-Gen Batteries

From the workshops where engineers stress-test new devices to the labs developing electric cars, energy storage plays a big role in shaping what tomorrow looks like. I’ve seen researchers light up at the sight of ionic liquids—salts that stay liquid at room temperature—because they bring unique traits. N-Hexyl-N-Methylpiperidinium Bis((Trifluoromethyl)Sulfonyl)Imide falls squarely into this category. Its stability makes it a prime candidate for next-generation lithium-ion batteries and supercapacitors. Traditional electrolytes can catch fire or break down under heat. This ionic liquid pushes those risk factors down by staying stable under punishing conditions. That kind of reliability means batteries can push further into hotter climates or last longer without safety worries.

Electronics and Antistatic Solutions

Walk across a carpet, touch your computer, and you might learn a thing or two about static electricity the hard way. For the teams building microchips or delicate sensors, stray charges spell disaster. This is where ionic liquids make their mark. Because N-Hexyl-N-Methylpiperidinium Bis((Trifluoromethyl)Sulfonyl)Imide barely evaporates and resists breakdown under voltage, factories use it as an antistatic agent or in electrostatic layers. The reduction in accidental electric discharges means fewer ruined batches—and less waste. In consumer goods, that stability also helps with longer shelf life and better reliability out of the box.

Green Chemistry and Solvent Uses

I’ve watched chemists try to escape traditional solvents. Many give off fumes or struggle with recycling. That’s costly both for folks working in labs and the environment at large. This ionic liquid offers a welcome option. Its low vapor pressure means it stays where you put it, and its chemical backbone resists breakdown even in tough reaction conditions. Researchers use it to dissolve stubborn materials or serve as a reaction medium, cutting out the need for hazardous alternatives. That means less exposure risk for workers, and cleanup after the fact runs much simpler.

Electroplating and Surface Engineering

Metal finishing touches nearly every modern device, from smartphones to airplane parts. In workshops, plating with older chemicals kicks up worries about pollution or working conditions. Salts like N-Hexyl-N-Methylpiperidinium Bis((Trifluoromethyl)Sulfonyl)Imide provide a safer, more controlled environment for laying down metal coatings. Tunable properties mean technicians can dial in thickness, texture, or shine—all without the same harsh side effects traditional approaches bring. That makes it easier to meet tough industry standards while keeping production cycles smoother.

Supporting Safer Tech and Regulation

Growing up, I saw regulations push the paint and chemical industry to clean up, and for good reason. Compounds that combine low toxicity, thermal resilience, and minimal waste stand out to compliance officers and clean-tech companies. N-Hexyl-N-Methylpiperidinium Bis((Trifluoromethyl)Sulfonyl)Imide catches attention because it checks off those boxes. Its adoption goes hand-in-hand with a wider shift toward sustainable research, especially as labs and factories field more questions about life cycle impacts. New processes can lean on this ingredient to help meet both internal goals and government targets.

Direction for Improvement

Not every challenge melts away quickly. Sourcing raw materials, scaling up production, and keeping costs manageable put pressure not only on labs but on the chemical industry. Open conversations between suppliers, manufacturers, and regulators shape how quickly such compounds move from niche research to large-scale use. I look forward to seeing increased investment in recycling programs and greener synthesis routes, taking the economic sting out of shifting away from older, riskier chemicals.

Why Chemical Structure Matters

A chemical’s structure reveals its personality. Looking at the layout of atoms, you see clues about how a substance reacts, what it bonds with, and which uses make sense. Imagine standing in a kitchen. If someone asks you to cook but won’t tell you what ingredients you’re handling, there’s no way to predict the taste or if it’s even safe to eat. Knowledge of structure lets chemists avoid nasty surprises—or missed opportunities.

Simple shapes (like glucose’s classic ring) and more complex arrangements (like cholesterol’s twists and turns) tell the story of how molecules interact in our bodies and in the world. Ionic compounds deliver and receive charge. Branching chains change how a medicine absorbs in the gut. That blueprint matters in research, drug discovery, and manufacturing. Without it, you’re flying blind.

Molecular Weight Isn’t Just a Number

Whether you’re buying chemicals at a supply store or mixing something on the bench, the molecular weight holds practical value. That number lets you weigh out the right amount. Dosing a solution or filling a prescription relies on the math matching up with the substance at hand. Skipping this step can turn a treatment toxic or leave a product weak and ineffective.

Take penicillin as an example. Its structure includes sulfur and a β-lactam ring, setting it apart from similar drugs. The molecular weight clocks in at about 334 g/mol, and every pharmacist knows to measure precisely. If you swapped in something heavier or lighter without recalculating, the treatment could fail patients or cause harm. Mistakes breed distrust and possible tragedy.

Real-World Consequences and Public Safety

Accurate reporting on chemical structure and molecular weight saves lives and protects the environment. Headlines crop up about contaminated food, unsafe cosmetics, or industrial mishaps. At the root, tiny missteps in chemical identification sometimes snowball into large-scale recalls or public health emergencies. The old Bhopal disaster boiled down in part to gaps in handling and understanding of the chemicals involved. No detail is too small to neglect, not with stakes this high.

Many professionals rely on open-access databases like PubChem, Reaxys, or ChemSpider. These tools gather peer-reviewed data and allow anyone—from students to chemical engineers—to double-check work and avoid guesswork. When time is tight, and resources limited, data transparency lowers risk. Trust grows when everyone knows how to verify a structure or match a molecular weight to what’s actually being used.

Solutions: Education and Transparency

Better chemistry in real life comes from building knowledge early. Students need practice reading formulas, using molecular models, and understanding why structure changes everything. Companies should demand full certificates-of-analysis and lab reports, not just for complex drugs but for simple commodity chemicals too.

Government agencies, industry leaders, and editors have a role: publish clear, complete data and fix errors fast. Outdated information floats around, but peer-reviewed corrections, raw spectral data, and public chemical registries help keep everyone in sync. With the right approach, the kitchen stays safe—and what’s on the table doesn’t pose a hidden risk.

Understanding the Risks

N-Hexyl-N-Methylpiperidinium Bis((Trifluoromethyl)Sulfonyl)Imide sounds like a mouthful, but it’s getting more attention in labs and companies dealing with ionic liquids. My own time pulling overnight shifts in a university chemistry lab taught me how quickly even routine procedures can go sideways with specialty chemicals. This compound carries risks tied to chemical burns, inhalation hazards, and environmental persistence, so treating it like table salt is a mistake. Health and safety reminders can slip out of focus, especially once a task starts to feel familiar. One quick splash or a cracked bottle leaves a lasting impression.

Sensible Storage Methods

For storage, this chemical doesn’t play nice with humidity or heat. Moisture causes slow decomposition, releasing corrosive byproducts and lowering usable lifespan. A dry, cool place with stable temperatures proves essential. Airtight glass containers easily beat plastics here, since ionic liquids can weaken certain polymers most folks think of as sturdy. Standard practice in well-run labs relies on double-sealed containers, marked clearly with the full chemical name and hazard labels. Vague abbreviations just lead to confusion or accidents—especially after a few months pass and nobody remembers who wrote which label. Keeping incompatible chemicals separated avoids chain reactions from stray drips or mixed vapors. Flammable solvents, acids, or even a bit of water make poor neighbors for piperidinium salts.

Handling with Care

Pouring or transferring this liquid deserves real respect for personal protective equipment. I’ve seen more than one person rush through handling after lunch, wearing only thin disposable gloves or skipping safety glasses. Nitrile gloves, chemical splash goggles, and long sleeves serve as a basic starting point. Extending protection with a face shield or full lab coat gives an extra buffer against an unexpected spill. Decent ventilation matters too, especially since fumes build up even if somebody doesn’t notice any immediate smell. Chemical fume hoods beat open benches every time for this type of compound.

Environmental Considerations

Labs sometimes cut corners with drain disposal, figuring a few drops won’t matter. Trifluoromethyl groups and sulfonyl imide moieties stick around in the environment, so pouring leftovers down the drain spreads persistent contamination. Labeled collection vessels and a regular hazardous waste pickup routine keep things above board. Clean-ups after a spill call for absorbents rated for organic liquids, scooping up everything so the bench stays residue-free. I remember a grad student ignoring a small splash of an ionic liquid like this, and months later, the sticky patch corroded a metal tray and forced expensive equipment replacement.

Pushing for Better Safety Culture

Building good safety habits means more than reading MSDS documents and signing off on vague training forms. Sharing real stories of accidents, near misses, and long-term exposure outcomes gets people’s attention faster than charts or rulebooks. Supervisors and experienced team members can lead by example, making it clear that shortcuts won’t fly. Regular check-ins and visible investments in proper storage, protective equipment, and waste management send a strong message that health and safety matter more than squeezing a few minutes off the procedure. Reliable handling and storage come from daily choices, not just paperwork.

Looking Ahead

N-Hexyl-N-Methylpiperidinium Bis((Trifluoromethyl)Sulfonyl)Imide is useful, but safety doesn’t take care of itself. Treating these substances with care keeps people healthy, spaces clean, and projects running without ugly surprises or regulatory trouble. Every container closed tightly and every pair of safety goggles worn adds up to workplaces people trust—not stories of regret passed around in the break room.

Looking Beyond Labels

People want to know exactly what they are getting. Clean purity data and a transparent look at what lands in a bag or bottle give peace of mind. For most products, especially those used in labs or in manufacturing, purity stands as a dealbreaker. Something called “99% pure” might sound good enough, but that last one percent—filled with whatever else snuck in—can sabotage a project. Tiny impurities sometimes create major headaches. In my own years handling lab materials, a stray bit of the wrong stuff could mean wasted days and lost money.

The Numbers Game

Let’s focus on what purity really means. Certified lab-quality sodium chloride, for example, clocks in at more than 99.5% purity. The rest? Usually trace elements like magnesium or calcium. If you’re in food or pharmaceuticals, you need those numbers even higher; the United States Pharmacopeia sets acceptable impurity levels below 0.01%. Somewhere else, minor contamination means everything: In chip manufacturing, just a whiff of outside material can turn an entire batch to scrap. Numbers aren’t just about looking good—they’re about protecting people from harm and businesses from errors.

Getting the Look Right

With purity often comes a certain appearance. People expect pure granulated sugar to sparkle white or for salt to pour out perfectly crystalline. Any color shift, odd smell, clumping, or foreign specks send up red flags. In one of my earlier jobs, I learned fast how much customers rely on sight and touch: a slight yellow tint in chemical powders led to weeks of questions and product returns. Visual inspection never tells the whole story, but it remains the gut check everyone uses first.

Inspection and Testing

You can’t confirm purity just by looking. Reputable suppliers publish assay certificates, which give the results of thorough lab testing. Elements like atomic absorption spectroscopy or titration reveal the real breakdown—the numbers you find on the paperwork. Teams committed to quality invite spot checks from third parties and encourage side-by-side comparisons. Years ago, I saw how much difference transparency made: good labs reported failures openly and tracked impurities until they figured out the cause.

The Human Costs of Cutting Corners

Selling product with questionable purity sends a message. To the people building medicine, making electronics, or baking bread, it says that your bottom line trumps their trust. Recalls, wasted stock, and health risks come next. Years back, a contaminated batch of food sweetener caused allergic reactions across three states before the recall hit. Trust suffered, businesses collapsed, and customers faced real danger—all because impurity slipped in.

Practical Solutions

Being diligent means going right to the source. Work with producers that test every batch and write honest certificates. If something arrives off-color or wrong in feel, speak up and demand a replacement. For buyers, it pays to check reviews, visit facilities, and ask about quality steps—not just accept marketing claims. Regulators push for purity standards, but end users must stay alert and keep asking tough questions.

Purity and physical appearance matter for reasons that reach past numbers and pretty looks. Safety, reliability, and hard-earned trust start with getting the real thing every time.

Why Bulk Access Matters in Modern Industry

Scaling up from the lab to the factory floor changes everything. Small jars and sample bottles don’t cut it when you’re running reactors, mixing vats, or testing full lines. It’s simply not practical for research teams or production managers to hunt for grams and hope to deliver tons later. I know chemists who’ve seen promising projects stall on sourcing—availability often shapes the future of new tech as much as science ever does. Large-volume availability isn’t just a footnote. It matters for price, safety, quality, and staying on schedule.

Real Barriers to Bulk Purchasing

Securing steady streams of any chemical hinges on more than picking a name from a catalog. I’ve worked with procurement teams who find the journey from research-grade vials to industrial drums loaded with surprises. Supply chains break down at scale. Production plants for specialty compounds might run at narrow margins, unwilling to guarantee vast amounts. Competing buyers sometimes tie up global supply for months or years—an issue faced by makers of plastics, batteries, or pharmaceuticals just trying to keep up with promises to their clients.

Cost can swing wildly with order size. Prices for modest lab orders rarely mean much for full-truck or full-container loads. Transporting, storing, and handling some chemicals presents new risks at bulk scale. Regulators expect clear documentation and environmental plans in place before they sign off, adding more steps to a simple question about “availability.” I’ve watched deals unravel when paperwork lagged behind containers on the dock.

Quality and Consistency

Laboratory chemists love high-purity materials, but true bulk supply often runs closer to technical grade: plenty good for industry, sometimes not good enough for exacting needs. Tracing the quality from plant to delivery strengthens trust. Companies succeed where they can promise batch-to-batch consistency. Some vendors cut corners to fill big orders, risking contamination or out-of-spec issues—costly once you’re pouring thousands of liters at a time. We’ve all heard disaster stories of multi-ton shipments that forced costly cleanups or produced off-spec products, tarnishing brands overnight.

Concrete Solutions for Reliable Bulk Access

Direct relationships with producers pay off. Visiting sites, seeing real inventory, and meeting the teams in charge beats emailing faceless brokers. These connections reveal whether a supplier can deliver on both amount and timeline. It’s worth investing in audits and safety checks before signing annual contracts. Tools like ERP software and real-time supply tracking cut back on surprises and keep buyers better prepared.

Increasing transparency in the supply chain also helps. Open communication—planned outages, forecast spikes, sudden shortages—makes it easier for manufacturers down the line to adapt. Large buyers often create consortia to pool demand and wield more leverage for better prices and priority shipments. My own experience shows that a little planning here secures big savings and fewer headaches later.

Innovation and Long-Term Strategy

Sometimes the only way forward comes from rethinking what’s possible. R&D teams investigate alternative suppliers, consider process tweaks to use what’s actually on hand, or aim for flexible recipes that can handle minor variations. Reviewing the environmental impact and safety record of sourcing strategies gives a business better odds at lasting success, both in courtrooms and boardrooms.

Success lives at the intersection of chemistry, logistics, and honest business relationships. No matter what the compound, the lesson holds: those who put in the work upfront stand the best chance of seeing their plans through, no matter how much they need to order.